Metal catalytic texturing method for decreasing reflectance of polycrystalline silicon wafer cut with diamond wire

A diamond wire cutting, polycrystalline silicon wafer technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problems of reducing reflectivity, corroding texture structure, high concentration, and achieving increased reactivity and low reflection. The effect of high efficiency and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A metal-catalyzed texturing method for reducing the reflectivity of diamond-wire-cut polycrystalline silicon wafers, comprising the steps of:

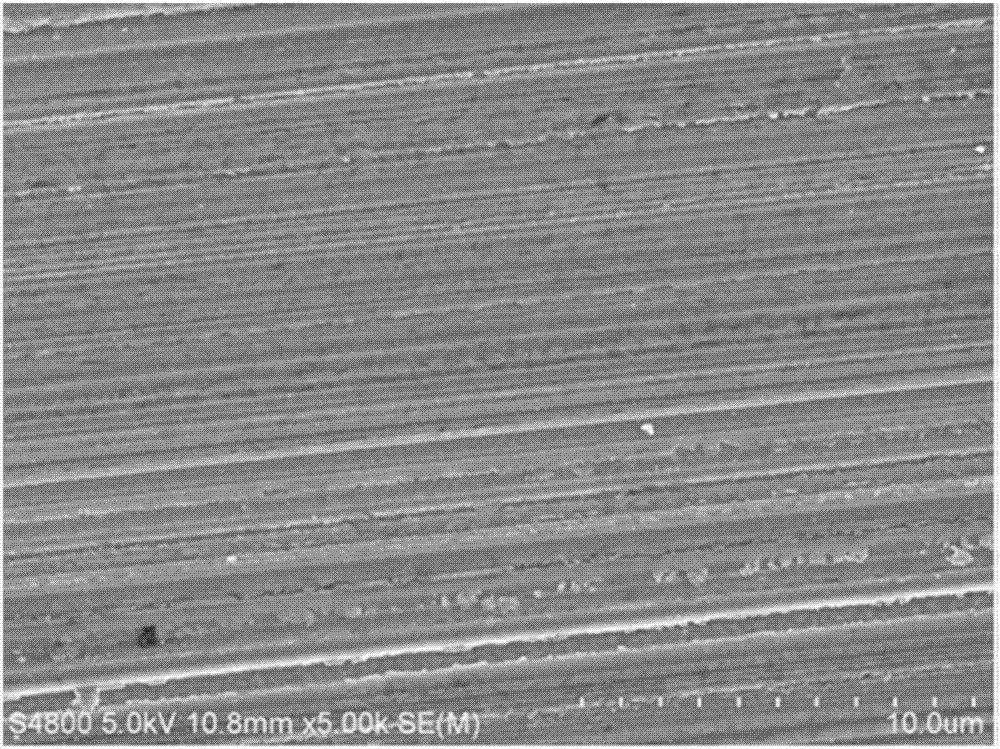

[0032] The first step is to immerse the diamond wire-cut polysilicon wafer in NaOH solution for treatment, remove the mechanical damage layer on the surface of the silicon wafer, take out the silicon wafer and immerse it in an aqueous solution for cleaning, wherein the concentration of NaOH solution is 6%, and the treatment temperature is 55°C , the alkali treatment time is 4min.

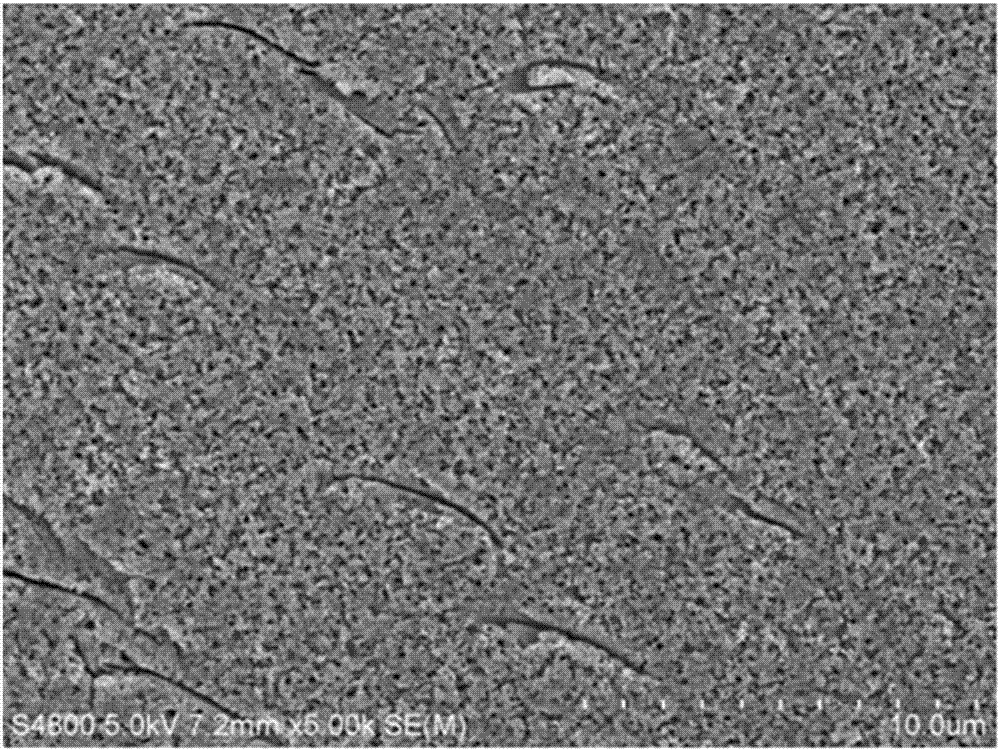

[0033] In the second step, the polysilicon wafer with the mechanically damaged layer removed is placed in a mixed solution of hydrofluoric acid, hydrogen peroxide, metal salts, additives and deionized water for black silicon treatment, that is, metal catalysis, chemical etching, and silver plating are used to dig holes. After integrated processing. The mass fraction of described hydrofluoric acid is 28%, and the mass fraction of hydrogen peroxide is ...

Embodiment 2

[0038] A metal-catalyzed texturing method for reducing the reflectivity of diamond-wire-cut polycrystalline silicon wafers, comprising the steps of:

[0039] The first step is to immerse the diamond wire-cut polysilicon wafer in NaOH solution for treatment, remove the mechanical damage layer on the surface of the silicon wafer, take out the silicon wafer and immerse it in an aqueous solution for cleaning, wherein the concentration of NaOH solution is 8%, and the treatment temperature is 60°C , the alkali treatment time is 3min.

[0040] In the second step, the polysilicon wafer with the mechanically damaged layer removed is placed in a mixed solution of hydrofluoric acid, hydrogen peroxide, metal salt, additives and deionized water for black silicon pretreatment, and metal catalysis and chemical etching are used to dig holes through silver plating After integrated processing. The mass fraction of described hydrofluoric acid is 30%, and the mass fraction of hydrogen peroxide i...

Embodiment 3

[0045] The polysilicon suede sheet of embodiment 1, embodiment 2 and comparative example 1 gained is carried out as follows respectively:

[0046] (1) Put the silicon wafer into the tubular diffusion furnace for diffusion treatment;

[0047] (2) Carry out edge etching and dephosphorous silicon glass treatment to the diffused silicon wafer;

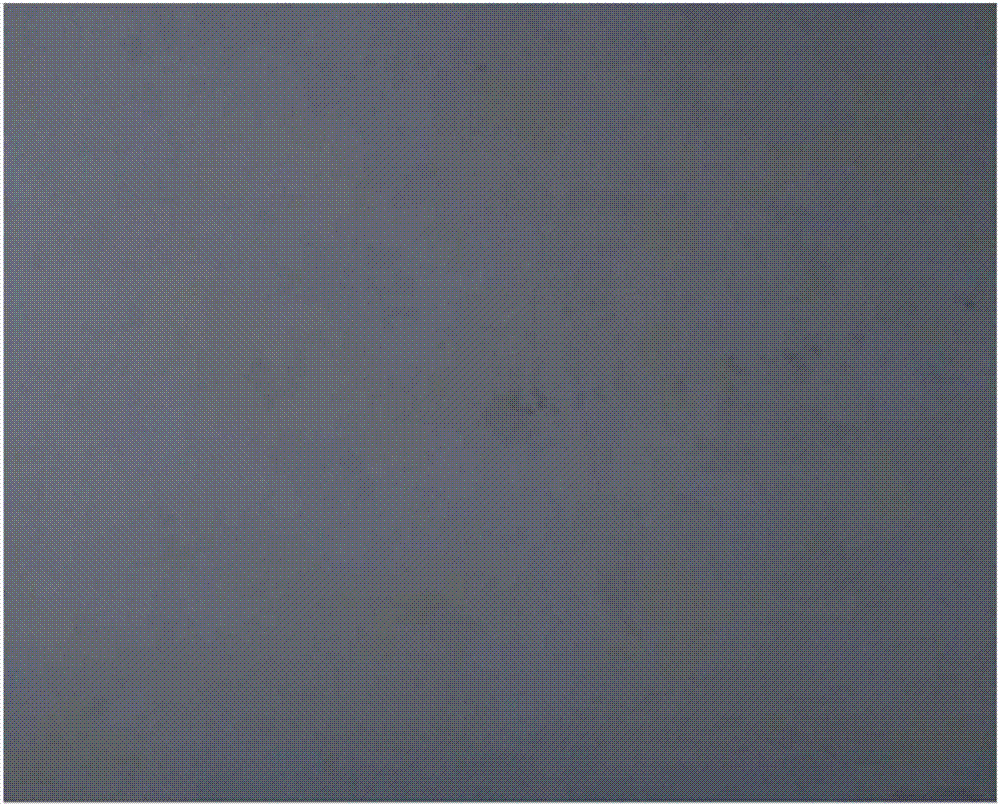

[0048] (3) Deposit silicon nitride anti-reflection film 83nm with the method of tubular PECVD on the front after step (2) treatment;

[0049] (4) Print the back electrode and the aluminum back field on the back, and print the grid line on the front surface of the silicon wafer;

[0050] (5) Sintering to test the electrical properties of the battery sheet.

[0051] The reflectance and electrical properties of the above three different battery sheets were tested, and the obtained results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com