Nickel-based catalyst for hydrogen production by ethanol steam reforming and preparation method thereof

A technology for steam reforming and nickel-based catalysts, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Dispersion and uniform dispersion of catalysts, catalyst coke deposits, poor stability and other problems, to achieve good catalytic activity, improved mechanical strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The nitrate (the molar ratio of nickel nitrate and cerium nitrate is 4:1), tetraethyl orthosilicate, ethylene glycol, and phosphoric acid in a molar ratio of 0.25:1:3:0.10 are formulated into a metal-containing silicon gel in a two-step method. That is: first, nitrate (nickel nitrate and cerium nitrate) and ethylene glycol solvent are used as raw materials, and the reaction is carried out at 90°C for 9 hours under mechanical stirring to synthesize metal-containing ethylene glycol; then the metal-containing ethylene glycol and silicon alkoxide are mechanically Stir and react at 90°C for 9 hours to form a metal-containing silica sol in situ; age at 60°C for 3 days, put it in an autoclave, and pre-fill with N 2 to 3.0MPa., heat up to 260°C at a heating rate of 60°C / h, keep the temperature constant for 1 hour, release the pressure slowly at a rate of 3MPa / h, and use N 2 Rinse the autoclave for 30 minutes, turn off the power, and allow it to cool down naturally to obtain a n...

Embodiment 2

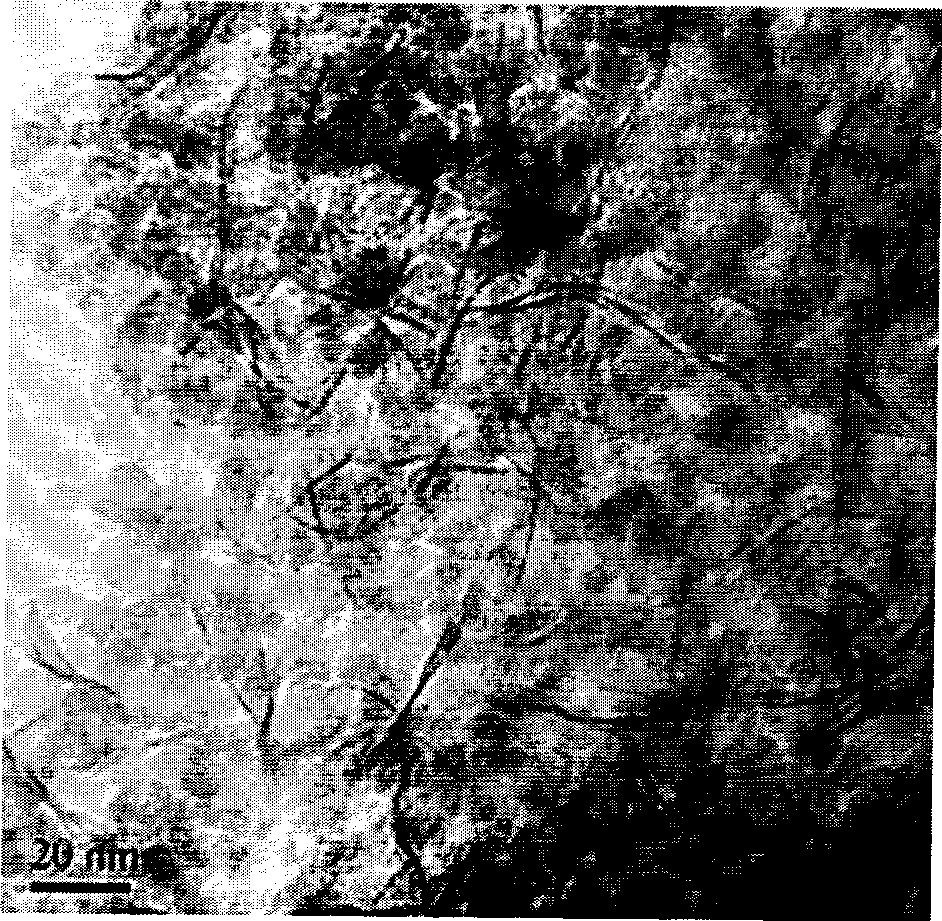

[0035] Nitrate (the molar ratio of nickel nitrate and magnesium nitrate is 4:1), tetraethyl orthosilicate, ethylene glycol, and phosphoric acid in a molar ratio of 0.25:1:3:0.10 are formulated into a metal-containing silicon gel in a two-step method. First, use nitrate (nickel nitrate and magnesium nitrate) and ethylene glycol solvent as raw materials, and react with mechanical stirring at 90°C for 9h to synthesize metal-containing ethylene glycol; then metal-containing ethylene glycol and silicon alkoxide are mixed under mechanical stirring and React at 90°C for 9 hours to form metal-containing silica sol in situ; age at 60°C for 3 days, and perform supercritical drying treatment on the obtained metal-containing silicon wet gel according to Example 1 to obtain hydrogen production by steam reforming of ethanol Nickel-based catalyst, the nickel metal active component is in the form of one-dimensional nanowires with a diameter of 1-5nm and a length of 10-50nm, and the additive co...

Embodiment 3

[0038] Nitrate (the molar ratio of nickel nitrate and calcium nitrate is 4:1), ethyl orthosilicate, ethylene glycol, and phosphoric acid in a molar ratio of 0.25:1:3:0.10 are formulated into metal-containing silicon gel in a two-step method. That is: firstly use nitrate (nickel nitrate and calcium nitrate) and ethylene glycol solvent as raw materials, react with mechanical stirring at 90°C for 9 hours to synthesize metal-containing ethylene glycol; then metal-containing ethylene glycol and silicon alkoxide are mechanically Stir and react at 90°C for 9 hours to form a metal-containing silica sol in situ; age at 60°C for 3 days, and perform supercritical drying treatment on the obtained metal-containing silicon wet gel according to Example 1 to obtain ethanol steam reforming Nickel-based catalyst for hydrogen production, the nickel metal active component is in the form of one-dimensional nanowires, with a diameter of 1-5nm and a length of 10-50nm, and the additive component CaO i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com