Nano porous silicon alloy material and preparation method thereof

A silicon alloy material, nanoporous technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as expensive, unsuitable for large-scale production, high temperature, etc., and achieve the effect of improving low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

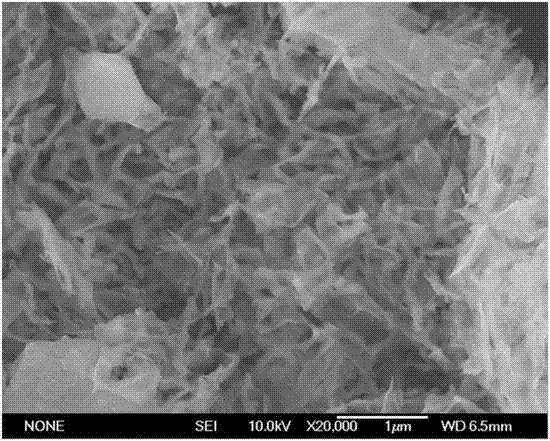

Image

Examples

Embodiment 1

[0023] (1) A Si / Fe / Al ternary alloy with a thickness of 500 microns, a width of 20 cm, a length of 100 cm, a composition of Si atomic percentage of 5%, Fe atomic percentage of 5%, and Al atomic percentage of 90% The tablets were placed in 0.5 mol / L sodium hydroxide solution.

[0024] (2) Free corrosion for 0.1 hour at 80°C.

[0025] (3) Collect the corroded alloy flakes and wash them repeatedly with ultrapure water until the sodium hydroxide solution is completely washed away. Then, the nanoporous ferrosilicon alloy material is obtained by drying at room temperature.

Embodiment 2

[0027] (1) A Si / Ag / Al alloy sheet with a thickness of 100 microns, a width of 1 cm, a length of 2 cm, a composition of Si atomic percentage of 5%, Ag atomic percentage of 5%, and Al atomic percentage of 90% was placed. In 2mol / L sulfuric acid solution.

[0028] (2) Free corrosion for 24 hours at room temperature of 30°C.

[0029] (3) Collect the corroded alloy pieces and wash them repeatedly with ultrapure water until the sulfuric acid solution is completely washed away. Then air-dried at 25 ℃ to obtain nanoporous silicon-silver alloy material.

Embodiment 3

[0031] (1) A Si / Cu / Al ternary alloy with a thickness of 500 microns, a width of 20 cm, a length of 100 cm, a composition of 6 atomic percent Si, 6 atomic percent Cu, and 88 atomic percent Al The tablets were placed in a 1 mol / L hydrochloric acid solution.

[0032] (2) Free corrosion for 0.1 hour at 80°C.

[0033] (3) Collect the corroded alloy pieces and wash them repeatedly with ultrapure water until the hydrochloric acid solution is completely washed away. Then, the nanoporous silicon-copper alloy material was obtained by air-drying at 40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com