Porous silicon-carbon composite material for lithium ion battery and preparation method of material

A carbon composite material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem that it is difficult to overcome the first efficiency at the same time, the agglomeration of nanomaterials is difficult to uniformly disperse, and chemical vapor deposition is difficult to encapsulate. Silicon-coated materials and other problems, to achieve excellent rate performance and cycle performance, low price, and the effect of overcoming expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

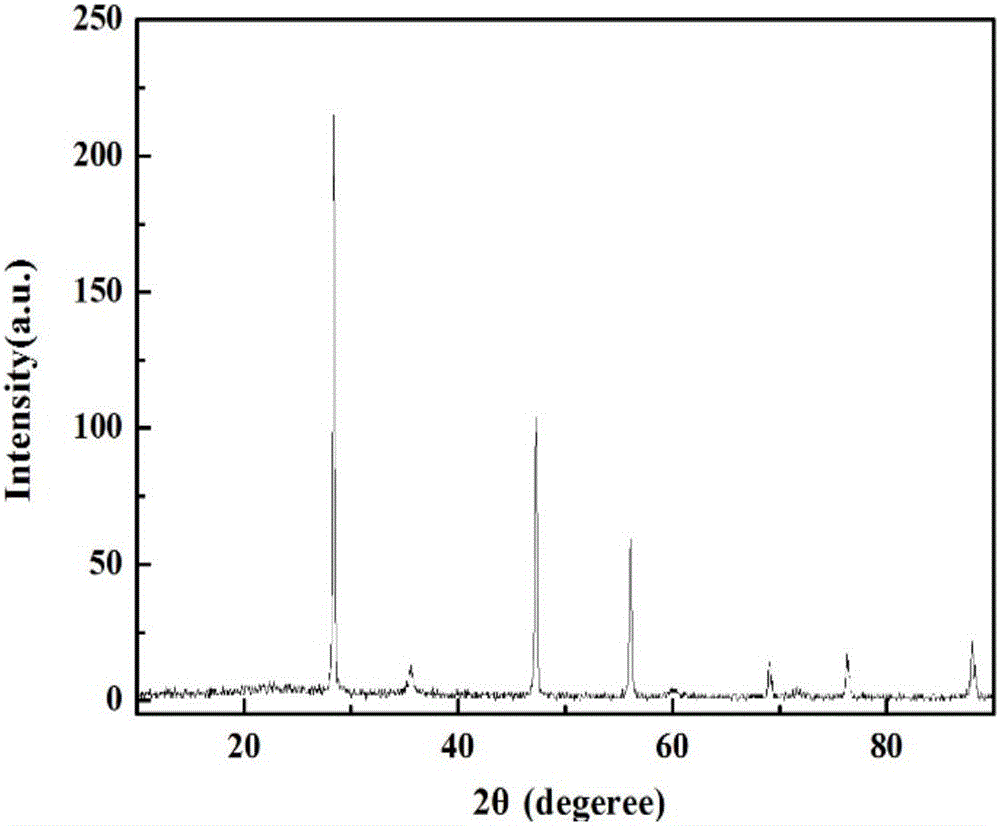

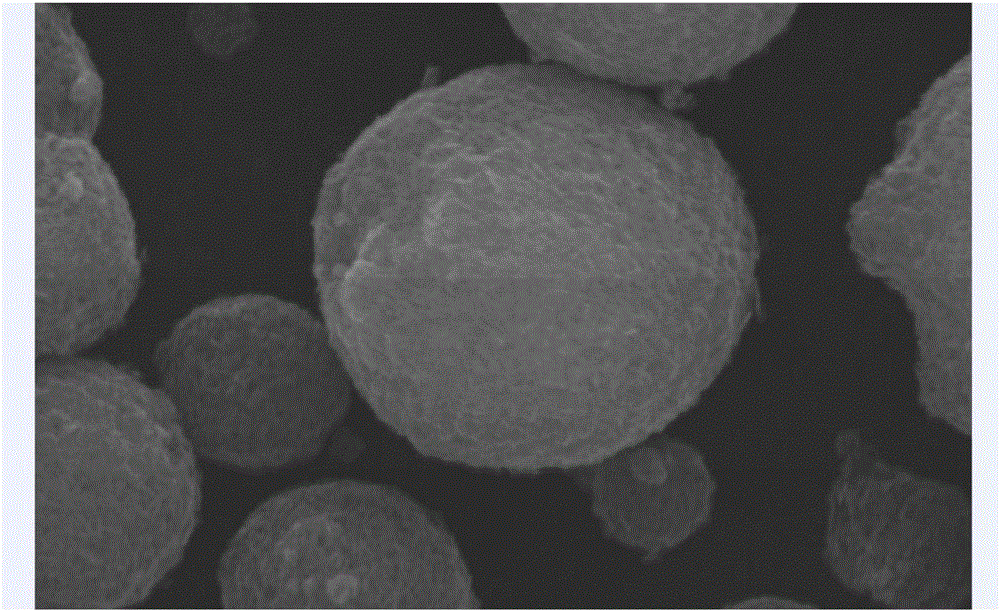

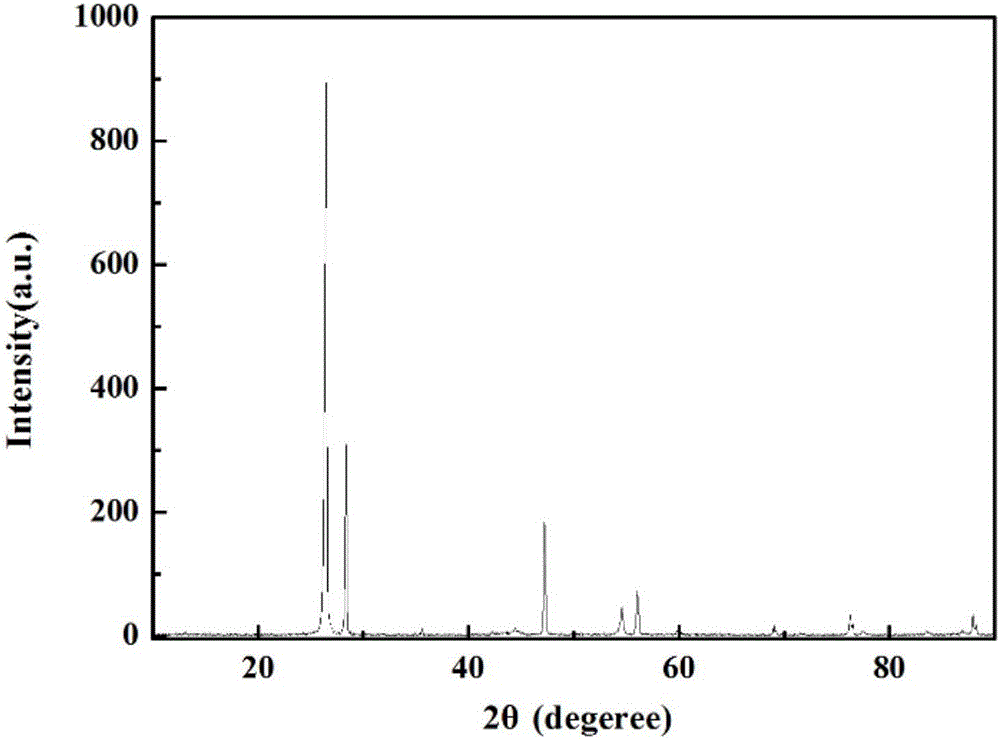

[0031] Put 10g of polysilicon with a purity of 99.999% as porous silicon, 25g of CMC, and 250g of deionized water as a ball milling agent and place it in a ball mill tank at a controlled speed of 400 rpm. After 40 hours of ball milling, microwave drying and granulation to obtain a precursor , the obtained precursor is subjected to high-temperature sintering treatment under the protection of nitrogen gas, the heating rate is controlled at 10°C / min, the sintering temperature is 1100°C, and the sintering time is 5h to obtain a carbon-coated porous silicon material. The carbon-coated porous silicon material XRD see attached figure 1 , SEM see attached figure 2 , weigh 5g of the carbon-coated porous silicon material after sintering, and 95g of mesocarbon microspheres, and mix them in a V-type machine for 4 hours to obtain a porous silicon-carbon composite material. The XRD test of the porous silicon-carbon composite material is shown in the attached image 3 .

[0032]Utilize th...

Embodiment 2

[0035] Put 10g of polysilicon with a purity of 99.999%, 10g of CMC, and 100g of deionized water in a ball mill tank. After ball milling at 400 rpm for 40 hours, microwave drying and granulation were performed to obtain a precursor. The obtained precursor was subjected to high temperature under nitrogen protection. Sintering treatment, the heating rate is 10°C / min, the sintering temperature is 1100°C, and the sintering time is 5h to obtain a porous silicon-carbon material, that is, a carbon-coated porous silicon material, the same below, and weigh 5g of the sintered material, that is, a carbon-coated porous silicon material , mesophase carbon microspheres 95g, mixed in a V-type machine for 4h to obtain porous silicon-carbon composites.

[0036] Its charging capacity is 425mAh / g, and its first-time efficiency is 93%. The assembly and testing of the button battery are the same as in Example 1.

Embodiment 3

[0038] Put 10g of monocrystalline silicon with a purity of 99.999%, 10g of CMC, and 100g of deionized water in a ball mill tank, and after ball milling at 400 rpm for 40 hours, microwave drying and granulation to obtain a precursor. Carry out high-temperature sintering treatment, the heating rate is 10°C / min, the sintering temperature is 1100°C, and the sintering time is 5h to obtain a porous silicon carbon material. Weigh 5g of the sintered material and 95g of mesophase carbon microspheres, and mix them in a V-type machine for 4h Finally, a porous silicon-carbon composite material is obtained.

[0039] Its charging capacity is 408mAh / g, and its first-time efficiency is 89% (the assembly and test of the button battery are the same as in Example 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com