Preparation method of lithium ion battery nanoporous silicon negative electrode material

A lithium-ion battery, nanoporous technology, applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of commercial scale application of difficult silicon-based negative electrode materials, complex processing technology, low output, etc., to achieve resource utilization Utilization, improvement of coulombic efficiency, and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

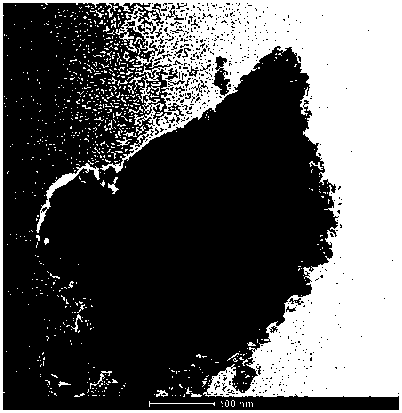

[0033] Embodiment 1: A kind of preparation method of nanoporous silicon negative electrode material of lithium ion battery, concrete steps are as follows:

[0034] (1) In a protective gas (nitrogen) atmosphere, pulverize the high-purity silicon material to obtain micro-nano silicon powder with a particle size of less than 30 μm, wash it with deionized water for 3 times at room temperature, and wash it for 20 minutes each time, then dry it ;

[0035] (2) Add silicon powder in step (1) to the metal salt / HF / alcohol mixed solution system A, wherein the metal salt / HF / alcohol mixed solution system A contains a reducing agent to enhance the crushing effect. Under the condition of ℃, the one-step metal nanoparticle assisted etching method is used for crushing pretreatment for 120 minutes, and the metal nanoparticles on the surface of the silicon powder are removed by washing with detergent for 30 minutes. The metal salt in the quasi-mixed solution system A is Cu(NO 3 ) 2 , the alco...

Embodiment 2

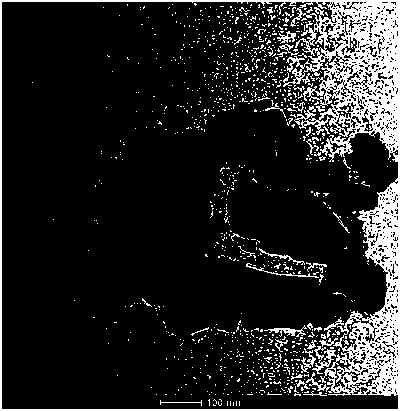

[0040] Embodiment 2: a kind of preparation method of nanoporous silicon negative electrode material of lithium ion battery, concrete steps are as follows:

[0041] (1) In a protective gas (nitrogen) atmosphere, crush and finely grind the screened waste silicon slag from the photovoltaic industry to obtain micro-nano silicon powder with a particle size of less than 30 μm. 20min, drying;

[0042] (2) Add silicon powder in step (1) to the metal salt / HF / alcohol mixed solution system A, wherein the metal salt / HF / alcohol mixed solution system A contains a reducing agent to enhance the crushing effect. Under the condition of ℃, the one-step metal nanoparticle assisted etching method is used for crushing pretreatment for 60 minutes, and the metal nanoparticles on the surface of the silicon powder are removed by washing with detergent for 100 minutes, solid-liquid separation, and drying to obtain nano-scale silicon powder. The metal salt in the quasi-mixed solution system A is Cu(NO ...

Embodiment 3

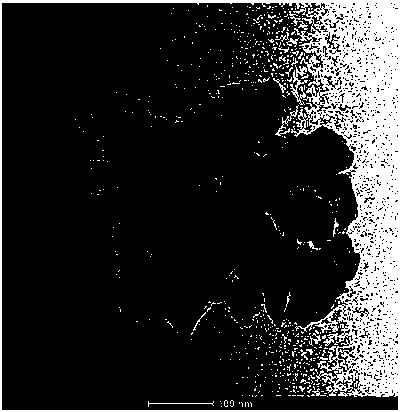

[0046] Embodiment 3: A kind of preparation method of nanoporous silicon negative electrode material of lithium ion battery, concrete steps are as follows:

[0047] (1) In a protective gas (nitrogen) atmosphere, crush and finely grind the screened waste silicon slag from the photovoltaic industry to obtain micro-nano silicon powder with a particle size of less than 30 μm. 20min, drying;

[0048] (2) Add the silicon powder in step (1) to the metal salt / HF / alcohol mixed solution system A, wherein the metal salt / HF / alcohol mixed solution system A contains a reducing agent to enhance the crushing effect. Under the condition of ℃, a one-step metal nanoparticle assisted etching method was used for crushing pretreatment for 90 minutes, and detergent was used for 30 minutes to remove metal nanoparticles on the surface of silicon powder, solid-liquid separation, and drying to obtain nano-scale silicon powder; where metal salt / HF / alcohol The metal salt in the quasi-mixed solution system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com