Novel porous silicon and a preparation method thereof

A new type of porous silicon technology, applied in the field of new porous silicon and its preparation, can solve the problems of limitation, thin hole wall, uneven surface, etc., and achieve the effect of wide resistance range of silicon wafer, stable production conditions and basic production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

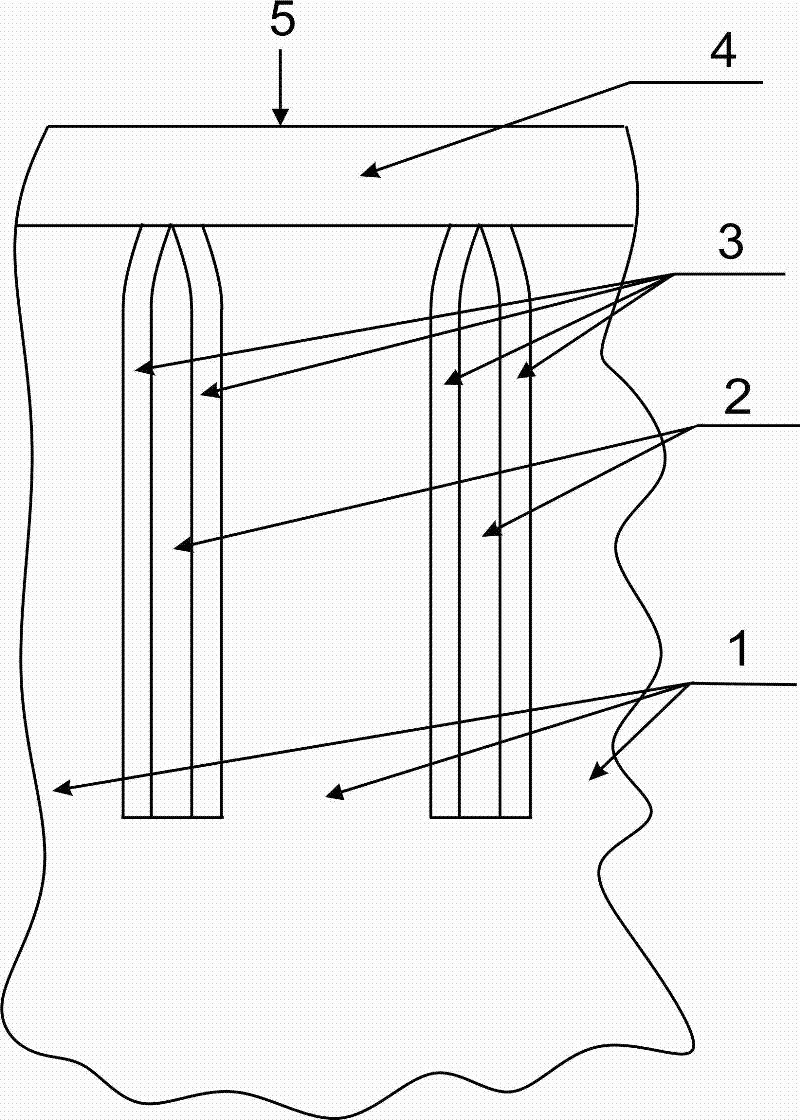

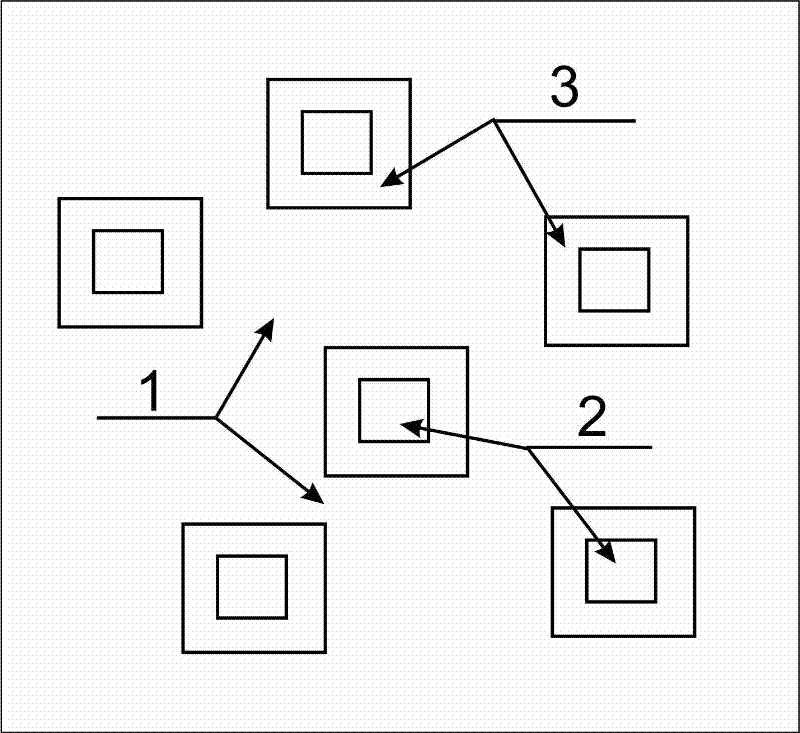

[0026] The preparation method of the novel porous silicon of the present embodiment comprises the following steps:

[0027] Step 1. Clean the substrate, ultrasonically clean the silicon wafer with acetone, ethanol, and deionized water for 10 minutes respectively, take it out and blow dry;

[0028] Step 2. Install the substrate, install the silicon wafer into the electrochemical corrosion tank, the corrosion tank is open, the polished surface, that is, the corrosion surface 5 of the silicon wafer faces in the groove, and keeps light from entering, the back faces outward, and the graphite sheet or metal slice and lead out the electrode wiring;

[0029] Step 3, prepare the solution, mix the concentrated HF acid and the organic solvent in a volume ratio of 1:1 to 1:1.5, and the organic solvent is one of ethanol, propanol, isopropanol, and methanol;

[0030] Step 4. Connect to the power supply, pour the prepared mixed solution into the corrosion tank, the polished surface of the s...

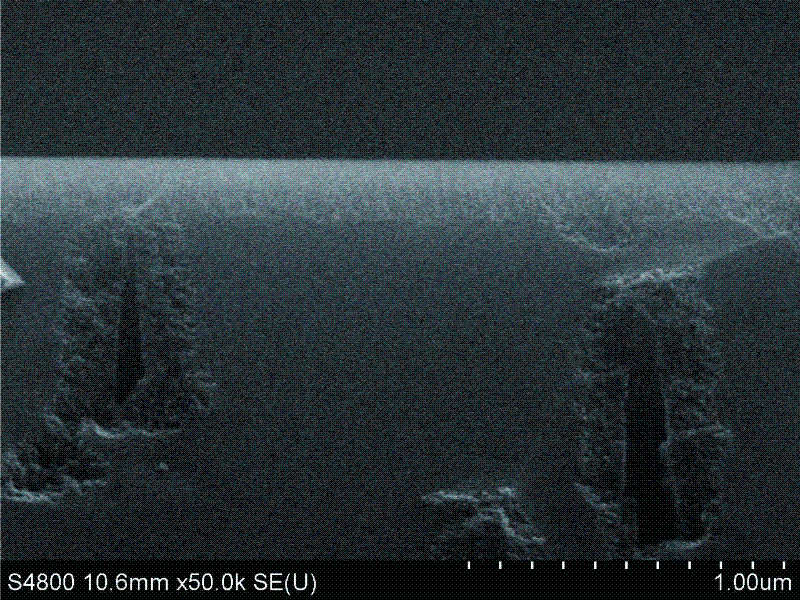

Embodiment 1

[0033] The resistance of the silicon chip is 1 to 10 Ωcm.

[0034] The preparation method is as follows:

[0035] Step 1. Clean the substrate, ultrasonically clean the silicon wafer with acetone, ethanol, and deionized water for 10 minutes respectively, take it out and blow dry;

[0036] Step 2. Install the substrate, install the silicon wafer into the electrochemical corrosion tank, the corrosion tank is open, the polished side faces the tank, and keeps the light entering, the back side faces outward, pad the graphite sheet and lead out the electrode wiring;

[0037] Step 3, prepare solution, mix 48% HF acid and ethanol by volume ratio of 1:1;

[0038] Step 4. Connect the power supply, pour the prepared mixed solution into the corrosion tank, the polished surface of the silicon wafer is in contact with the solution, insert a carbon rod into the solution as an electrode and connect it to the anode, and the electrode on the back of the silicon wafer is connected to the cathode...

Embodiment 2

[0042] The resistance of the silicon chip is 20 to 25 Ωcm.

[0043] The preparation method is as follows:

[0044] Step 1. Clean the substrate, ultrasonically clean the silicon wafer with acetone, ethanol, and deionized water for 10 minutes respectively, take it out and blow dry;

[0045] Step 2. Install the substrate, install the silicon wafer into the electrochemical corrosion tank, the corrosion tank is open, the polished side faces the tank, and keeps the light entering, the back side faces outward, pad the graphite sheet and lead out the electrode wiring;

[0046] Step 3, prepare solution, mix 48% HF acid and ethanol by volume ratio of 1:1.2;

[0047] Step 4. Connect the power supply, pour the prepared mixed solution into the corrosion tank, the polished surface of the silicon wafer is in contact with the solution, insert a carbon rod into the solution as an electrode and connect it to the anode, and the electrode on the back of the silicon wafer is connected to the cathod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com