Method for preparing nano porous silicon by utilizing doped silicon particles

A nanoporous, silicon-doped technology, applied in nanotechnology, chemical instruments and methods, silicon compounds, etc., can solve the problems of restricting the application of porous silicon materials, the size of the base silicon material and the limited range of doping concentrations, etc. It has the effect of application value, good industrial value and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

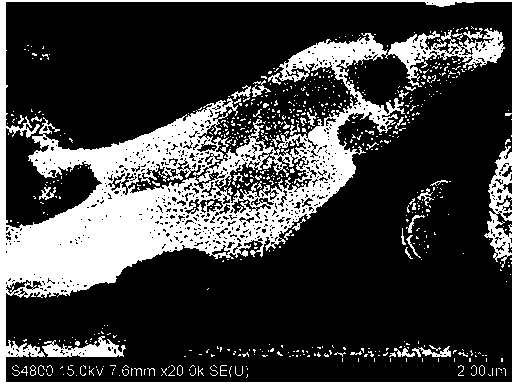

Image

Examples

Embodiment 1

[0029]This embodiment provides a method for preparing nanoporous silicon using doped silicon particles. When using doped silicon particles as a raw material, chemical etching is used to prepare nanoporous silicon. The specific steps are as follows:

[0030] 1) The phosphorus doping concentration is selected to be 5.53×10 19 atoms / cm 3 (Conductivity 0.001~0.002Ω·cm) N-type single crystal silicon master alloy is used as raw material, processed by pulse discharge method, processing parameters are: open circuit voltage 150V; peak current 10A; pulse width 50μs; duty ratio 1:2, The working fluid is deionized water, and the electrodes are copper electrodes. Process and collect doped silicon particles, the particle size range of silicon particles is 1-10 μm, the size is concentrated at 5 μm, the concentration is greater than 90%, and the particles are block and spherical particles.

[0031] 2) Take 10g of silicon particles as the base material;

[0032] 3) Cleaning the surface of t...

Embodiment 2

[0041] This embodiment provides a method for preparing nanoporous silicon using doped silicon particles. When using doped silicon particles as a raw material, chemical etching is used to prepare nanoporous silicon. The specific steps are as follows:

[0042] 1) The boron doping concentration is selected to be 5×10 18 atoms / cm 3 (Conductivity 0.01~0.02Ω·cm) P-type polysilicon ingot is used as raw material, processed by pulse discharge method, the processing parameters are: open circuit voltage 100V; peak current 5A; pulse width 20μs; duty ratio 1:5, working fluid is Deionized water, the electrode is a copper electrode. Process and collect doped silicon particles, the particle size range of silicon particles is 1-5 μm, the size is concentrated at 2 μm, the concentration is greater than 90%, and the particles are spherical particles.

[0043] 2) Take 10g of silicon particles as the base material;

[0044] 3) Cleaning the surface of the silicon particles with a chemical solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com