Method for preparing metal Ni, Cu, coated LiFePo4 powder

A powder and coating technology, applied in the field of material science, can solve the problems of low electronic conductivity, low manufacturing cost, low synthesis temperature, etc., and achieve the effect of high material yield, low production cost and low firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

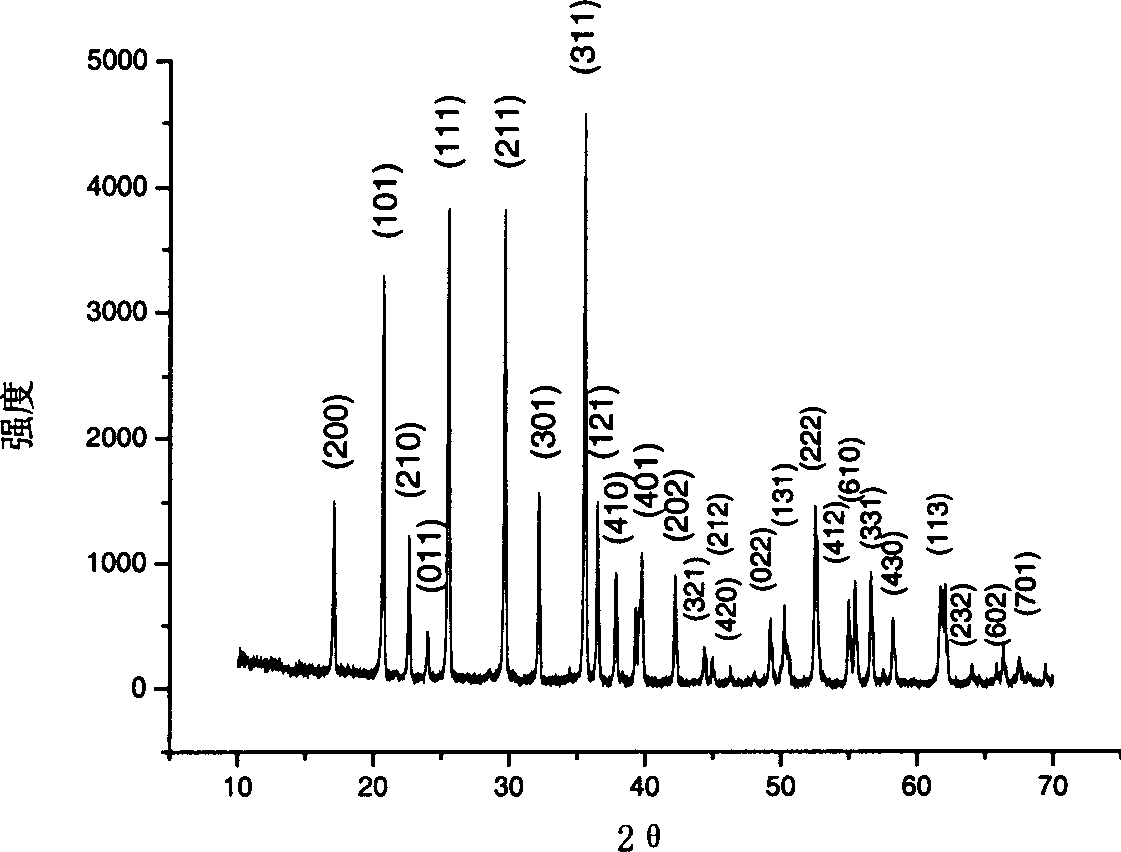

[0027] Weigh ferrous oxalate 2 hydrate, lithium carbonate and ammonium dihydrogen phosphate according to the molar ratio. Using absolute ethanol as the grinding medium, it was ball-milled on a planetary mill for 4 hours and then dried at a lower temperature. Grind the dried mixture powder into a porcelain boat, put it into an atmosphere furnace, and keep it at 400°C for 2 hours under the protection of an inert atmosphere or a reducing atmosphere, and then keep it at 550°C for 24 hours to synthesize LiFePO 4 Powder A1, figure 1 It is the XRD pattern of A1.

[0028] Prepare the electroless plating solution containing Cu and Ni ions: prepare the plating solution containing Ni ions according to the following ratio: nickel sulfate hexahydrate 45 g / L, sodium hypophosphite 30 g / L, sodium citrate 60 g / L, acetic acid Ammonium 45 g / L. Adjust the pH value of the mixed liquid to 8 with ammonia water to obtain the plating solution B containing Ni. According to 21 g / L of copper sulfate ...

Embodiment 2

[0031] Weigh ferrous oxalate 2 hydrate, lithium carbonate and ammonium dihydrogen phosphate according to the molar ratio. Using absolute ethanol as the grinding medium, it was ball-milled on a planetary mill for 6 hours and then dried at a lower temperature. Grind the dried mixture powder into a porcelain boat, put it into an atmosphere furnace, and keep it at 400°C for 2 hours under the protection of an inert atmosphere or a reducing atmosphere, and then keep it at 850°C for 8 hours to synthesize LiFePO 4 Powder A2.

[0032] The method for preparing the electroless plating solution containing Cu and Ni ions is the same as embodiment 1.

[0033] Measure SnCl 2 Put 30 ml of aqueous solution into a beaker, add 24 grams of prefabricated powder A, stir vigorously for 2 minutes, separate the solid and liquid by suction filtration, and wash twice. The filter cake was placed in a solution of 20 ml of palladium chloride, the solid and liquid were separated after vigorous stirring f...

Embodiment 3

[0035] Weigh ferrous oxalate 2 hydrate, lithium carbonate and ammonium dihydrogen phosphate according to the molar ratio. Using absolute ethanol as the grinding medium, it was ball-milled on a planetary mill for 6 hours and then dried at a lower temperature. Grind the dried mixture powder into a porcelain boat, put it into an atmosphere furnace, and keep it at 400°C for 6 hours under the protection of an inert atmosphere or a reducing atmosphere, and then keep it at 650°C for 10 hours to synthesize LiFePO 4 Powder A3.

[0036] The method for preparing the electroless plating solution containing Cu and Ni ions is the same as embodiment 1.

[0037] Measure SnCl 2 Put 20 ml of aqueous solution into a beaker, add 34 grams of prefabricated powder A, stir vigorously for 2 minutes, separate the solid and liquid by suction filtration, and wash twice. The filter cake was placed in a solution of 25 ml of palladium chloride, the solid and liquid were separated after vigorous stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com