A method for assemble a blocking cell to improve that interface contact of the blocking cell

An assembly method and battery assembly technology, which are used in non-aqueous electrolyte batteries, electrolyte battery manufacturing, climate sustainability, etc., can solve problems such as poor interfacial contact of blocked batteries, polymer decomposition, and inaccurate calculation of electrical conductivity, and achieve improved performance. Interface contact, good fit, the effect of avoiding interface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A blocking battery assembly method for improving the interface contact of the blocking battery, comprising the following steps:

[0025] (1) Cut the PPC-based (polypropylene carbonate) polymer electrolyte membrane supported by a cellulose membrane with a total thickness of 200 μm into a disc with a diameter of 19 mm, and drop-coat it on the positive side of the polymer electrolyte membrane with DMF. Make both sides wet (the coating amount is 0.02mL / cm 2 );

[0026] (2) Two stainless steel sheets with a thickness of 0.8 mm and a diameter of 16 mm are attached to the two surfaces of the polymer electrolyte membrane (disc) to form a blocked battery precursor;

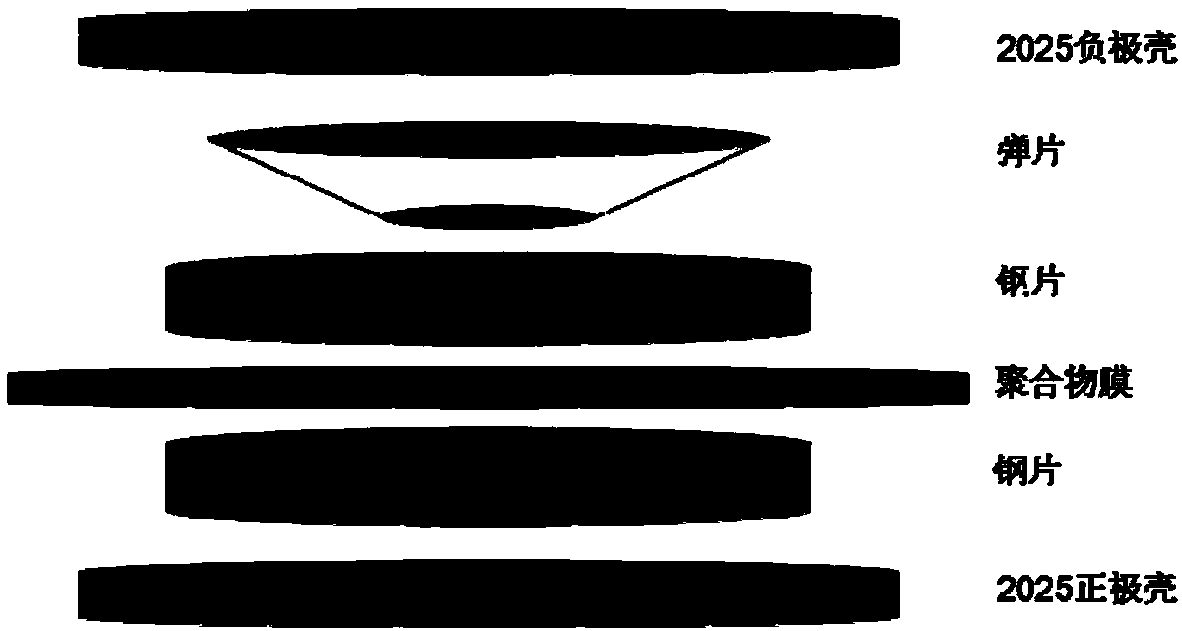

[0027] (3) Air-dry the blocked battery precursor at 60°C for 24 hours, then move it into a vacuum box and dry it at 120°C for 24 hours, and finally package it with shrapnel and 2025 battery case (the installation diagram is shown in figure 1 shown), to obtain the final blocked cell.

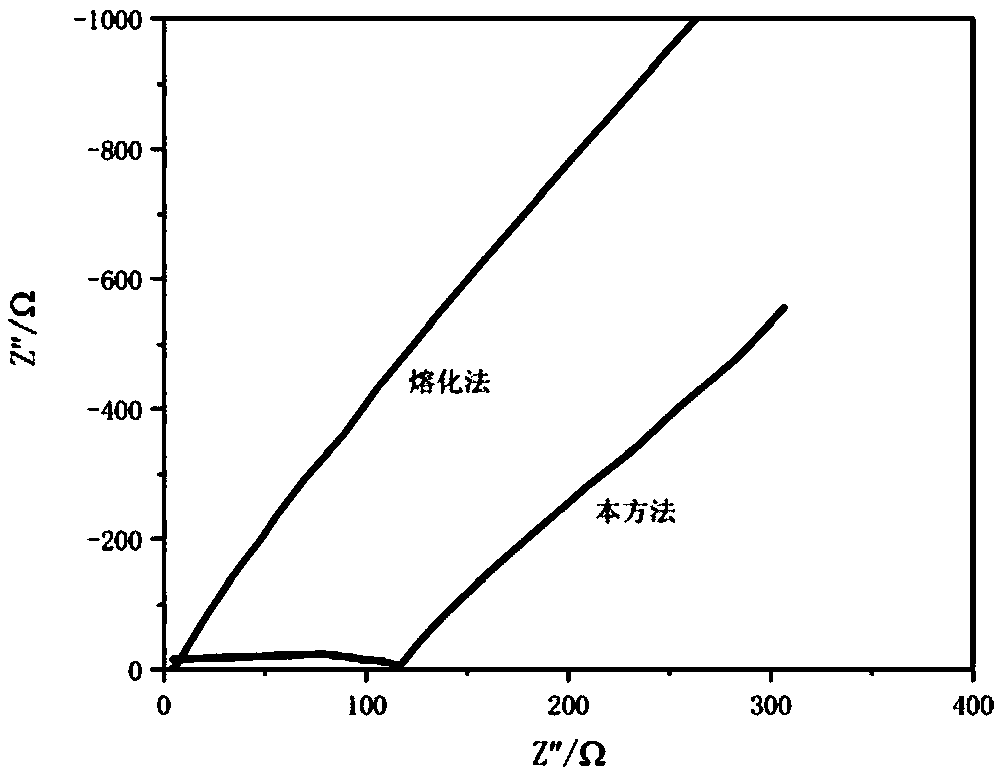

[0028] In the glove box, a b...

Embodiment 2

[0032] A blocking battery assembly method for improving the interface contact of the blocking battery, comprising the following steps:

[0033] (1) Cut the PEC (polypropylene carbonate)-based polymer electrolyte membrane with a total thickness of 80um into discs with a diameter of 18mm, and drip-coat the front and back sides of the polymer electrolyte membrane with tetrahydrofuran to make both surfaces wet (coating amount is 0.01mL / cm 2 );

[0034] (2) Two gold sheets with a thickness of 0.5 mm and a diameter of 12 mm are attached to the surface of the polymer electrolyte membrane (disc) to form a blocked battery precursor;

[0035] (3) Dry the blocked battery precursor at 60°C for 30 hours, then move it into a vacuum box and dry it at 120°C for 24 hours, and finally package it with a 2032 battery case to obtain the final blocked battery.

Embodiment 3

[0039] A blocking battery assembly method for improving the interface contact of the blocking battery, comprising the following steps:

[0040] (1) Cut the PVC-based (poly(vinylene carbonate)) polymer electrolyte membrane supported by glass fibers with a total thickness of 120 μm into discs with a diameter of 14 mm, and coat the polymer electrolyte membrane with dimethyl sulfoxide The front and back sides of the front and back, so that both surfaces are wet (the coating amount is 0.04mL / cm 2 );

[0041] (2) Two stainless steel sheets with a thickness of 1.5 mm and a diameter of 12 mm are attached to the surface of the polymer electrolyte membrane (disc) to form a blocked battery precursor;

[0042] (3) Air-dry the blocked battery precursor at 40°C for 48 hours, then move it into a vacuum box and dry at 90°C for 24 hours, and finally package it with a 2025 battery case to obtain the final blocked battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com