Interface layer and lithium ion battery comprising same

A lithium-ion battery, interface layer technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as lithium dendrite growth, avoid side reactions at the interface, high cycle stability and Coulomb efficiency, and inhibit the formation of and growth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

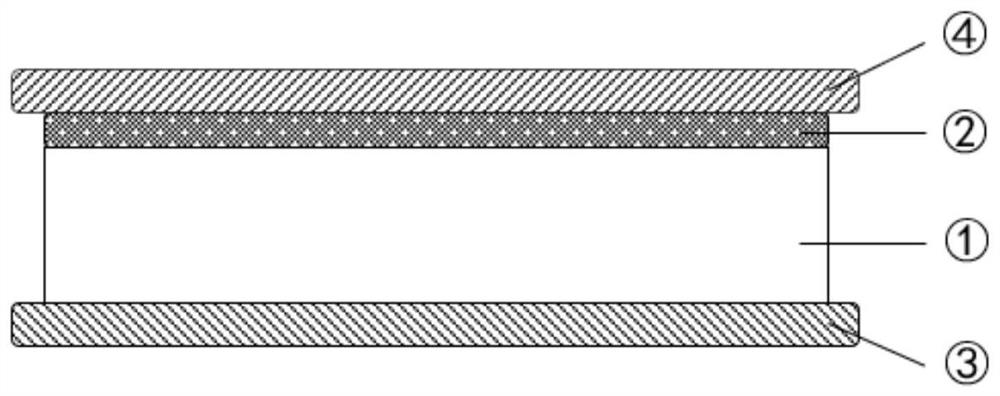

[0041] As mentioned above, the present invention provides a kind of interface layer, here also provides the preparation method of above-mentioned interface layer, described method comprises the following steps:

[0042] 1) dissolving the metal halide in a solvent to form a precursor solution;

[0043] 2) Coating the precursor solution on one side of the solid electrolyte and drying in vacuum;

[0044] 3) attaching the metal lithium negative electrode to one side surface of the solid electrolyte coated with the precursor solution, reacting, and preparing the interface layer.

[0045] According to an embodiment of the present invention, in step 1), the solvent is selected from deionized water, methanol, ethanol, ether, acetone, ammonia water, hydrofluoric acid, tetrahydrofuran, dimethyl sulfoxide, chloroform, benzene, toluene and di at least one of toluene.

[0046] According to an embodiment of the present invention, in step 1), the definition of the metal halide is as above....

Embodiment 1

[0126] S1: put Li 6.6 La 3 Zr 1.6 Ta 0.4 o 12 The solid electrolyte powder is fully dried to remove the influence of trace moisture;

[0127] S2: put Li 6.6 La 3 Zr 1.6 Ta 0.4 o 12 The solid electrolyte powder is cold-pressed into thin sheets at 5 MPa, then sintered at 1000°C for 5 hours, and cooled to room temperature with the furnace;

[0128] S3: copper chloride CuCl 2 Dissolved in acetone to prepare a precursor solution with a ratio of 20wt%, and fully stirred at a speed of 500rpm for 10h to a homogeneous solution;

[0129] S4: Then the CuCl in S3 2 The precursor solution was evenly scraped on the Li 6.6 La 3 Zr 1.6 Ta 0.4 o 12 The upper surface of the solid electrolyte sheet is fully vacuum-dried at 30°C for 12 hours to form a thin film layer;

[0130] S5: Heat metal lithium to 190°C to make it into a molten state, and then evenly coat the Li treated in S4 6.6 La 3 Zr 1.6 Ta 0.4 o 12 On the upper surface of the solid electrolyte sheet, the interface ...

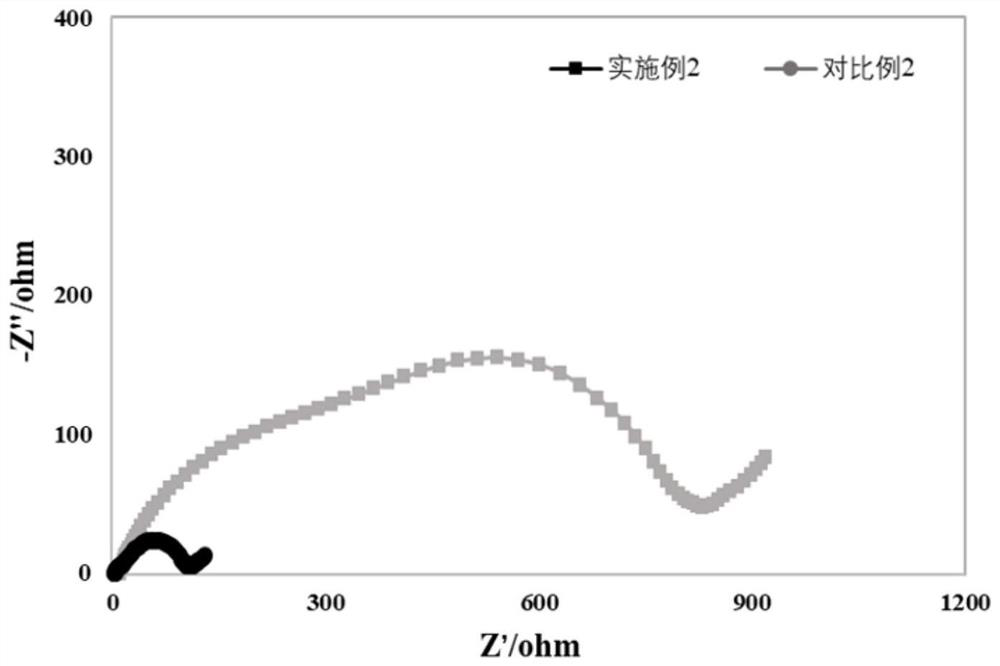

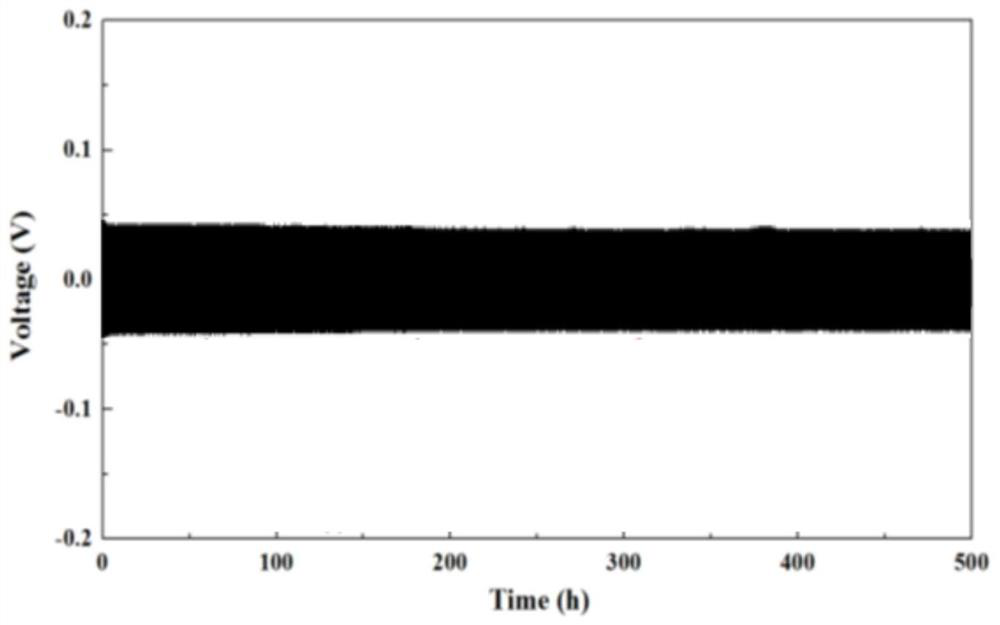

Embodiment 2

[0138] S1: put Li 1.5 Al 0.5 Ti 1.5 (PO 4 ) 3 The solid electrolyte powder is fully dried to remove the influence of trace moisture;

[0139] S2: put Li 1.5 Al 0.5 Ti1.5 (PO 4 ) 3 The solid electrolyte powder is cold-pressed into thin sheets at 4MPa, then sintered at 850°C for 8h, and cooled to room temperature with the furnace;

[0140] S3: nickel bromide NiBr 2 Dissolved in methanol to prepare a precursor solution with a ratio of 8wt%, and fully stirred at a speed of 700rpm for 6h to a homogeneous solution;

[0141] S4: Then the NiBr in S3 2 The precursor solution was evenly spin-coated on the Li 1.5 al 0.5 Ti 1.5 (PO 4 ) 3 The upper surface of the solid electrolyte sheet is spin-coated at a rotational speed of 1000rpm. After the spin-coating is completed, it is fully vacuum-dried at 50°C for 10h to form a thin film layer;

[0142] S5: Heat metallic lithium to 200°C to make it into a molten state, and then evenly coat the Li treated in S4 1.5 al 0.5 Ti 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com