Patents

Literature

39results about How to "Low chemical reactivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

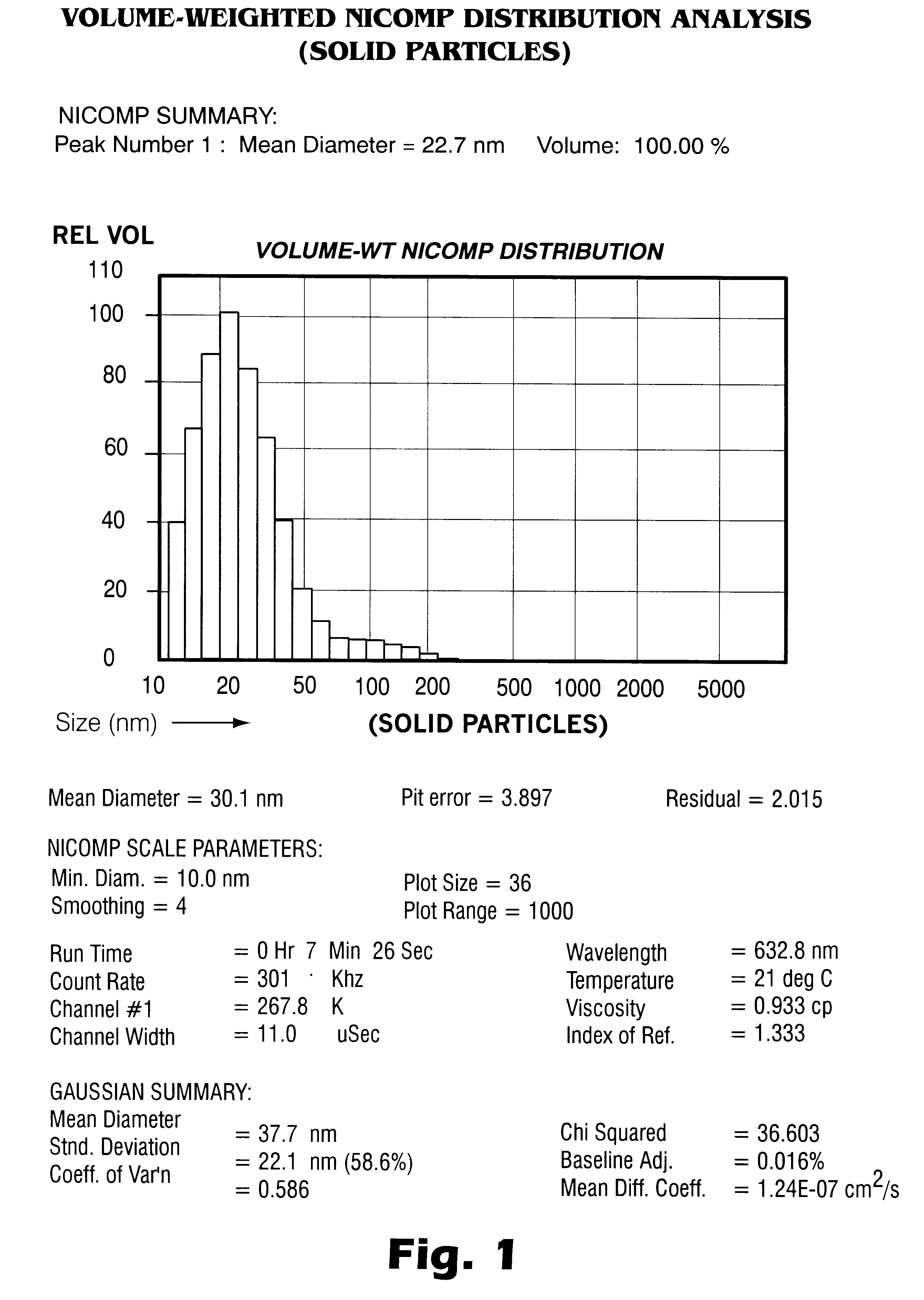

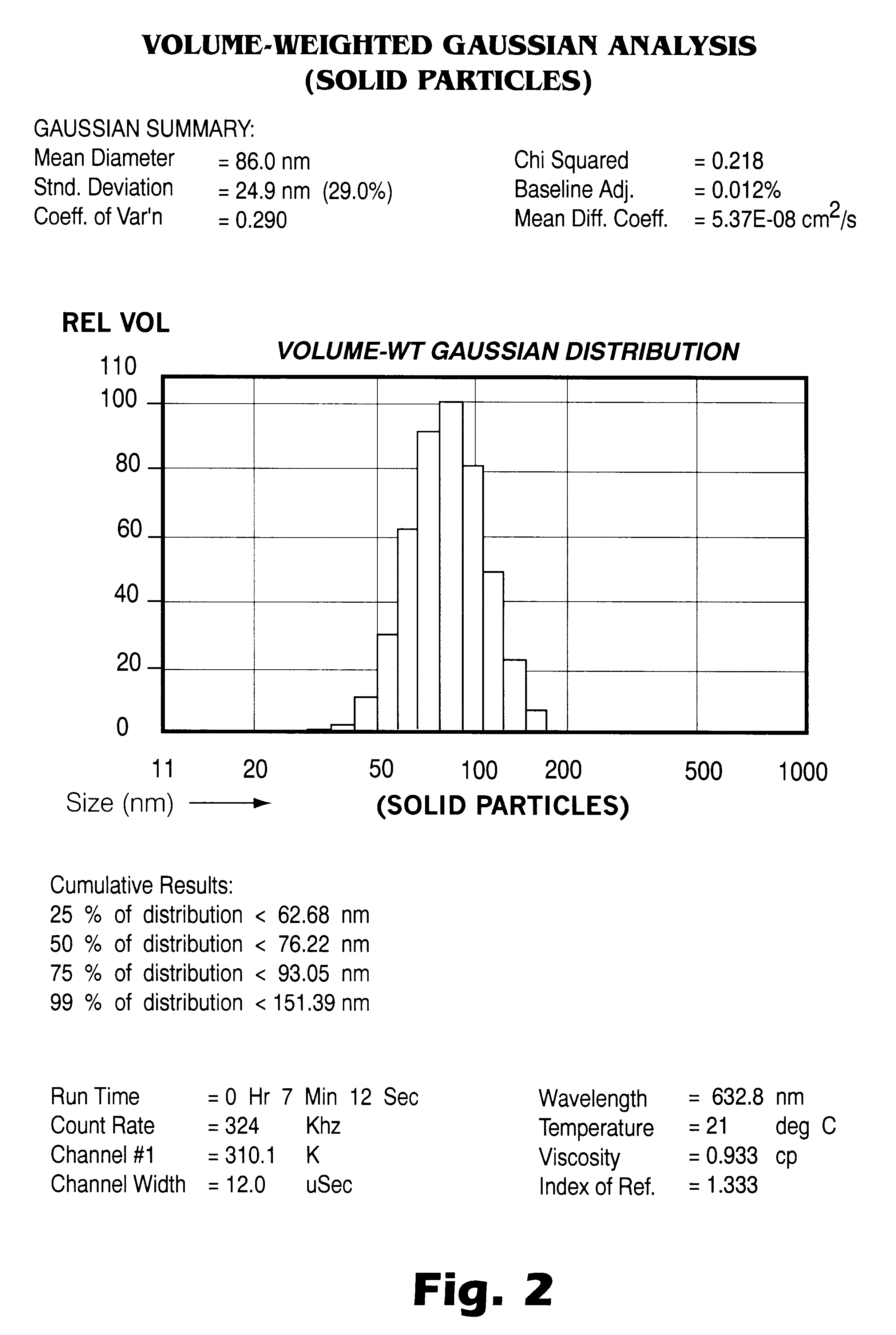

Processes to generate submicron particles of water-insoluble compounds

InactiveUS6177103B1Rapid of surface stabilizedRapid attainmentOrganic active ingredientsPowder deliveryWater insolubleChemical compound

Submicron particles of water-insoluble compounds, particularly drugs, are prepared by simultaneously stabilizing microparticulate suspensions of same with surface modifier molecules by rapid expansion into an aqueous medium from a compressed solution of the compound and surface modifiers in a liquefied gas and optionally homogenizing the aqueous suspension thus formed with a high pressure homogenizer.

Owner:JAGOTEC AG +1

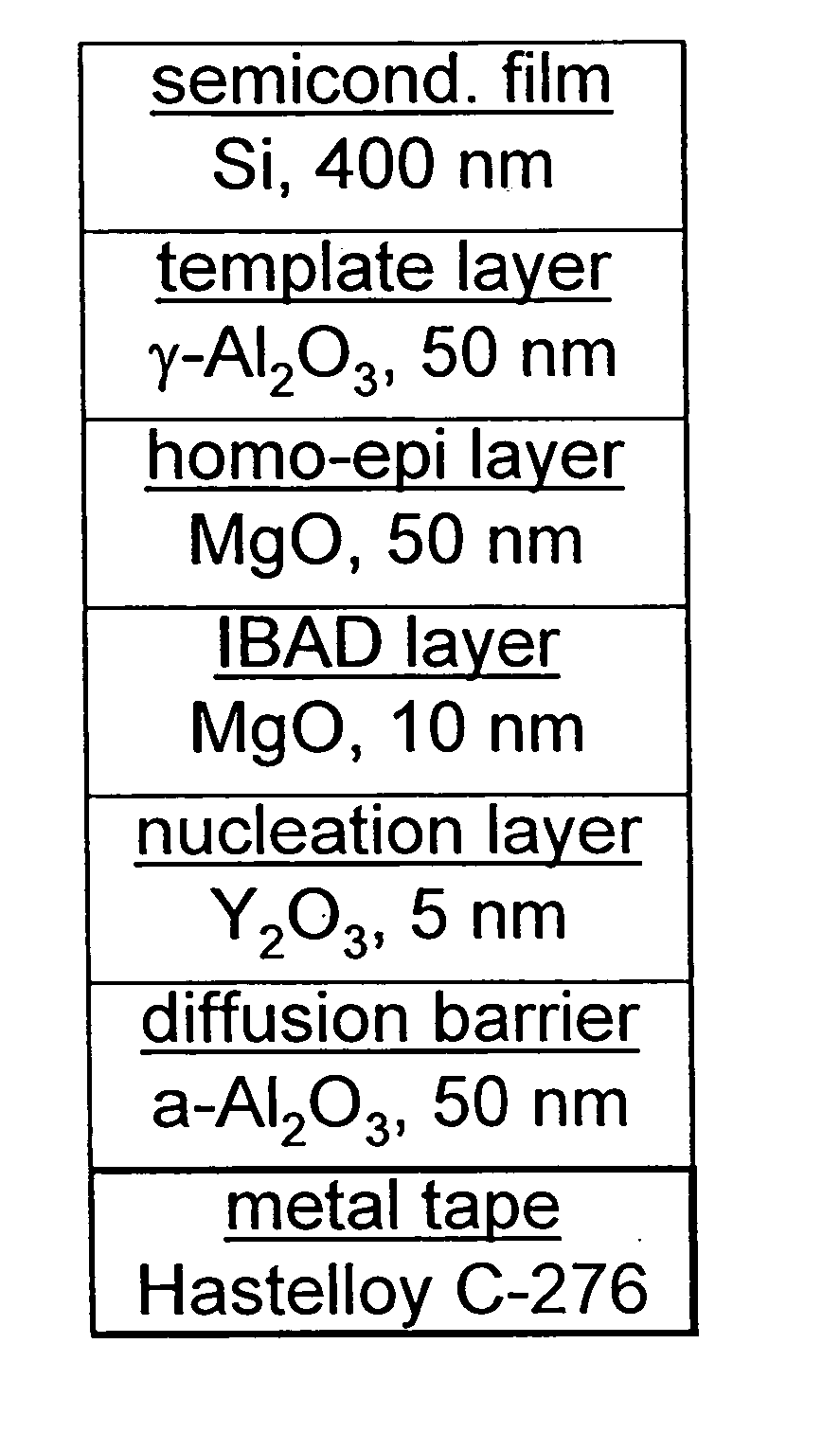

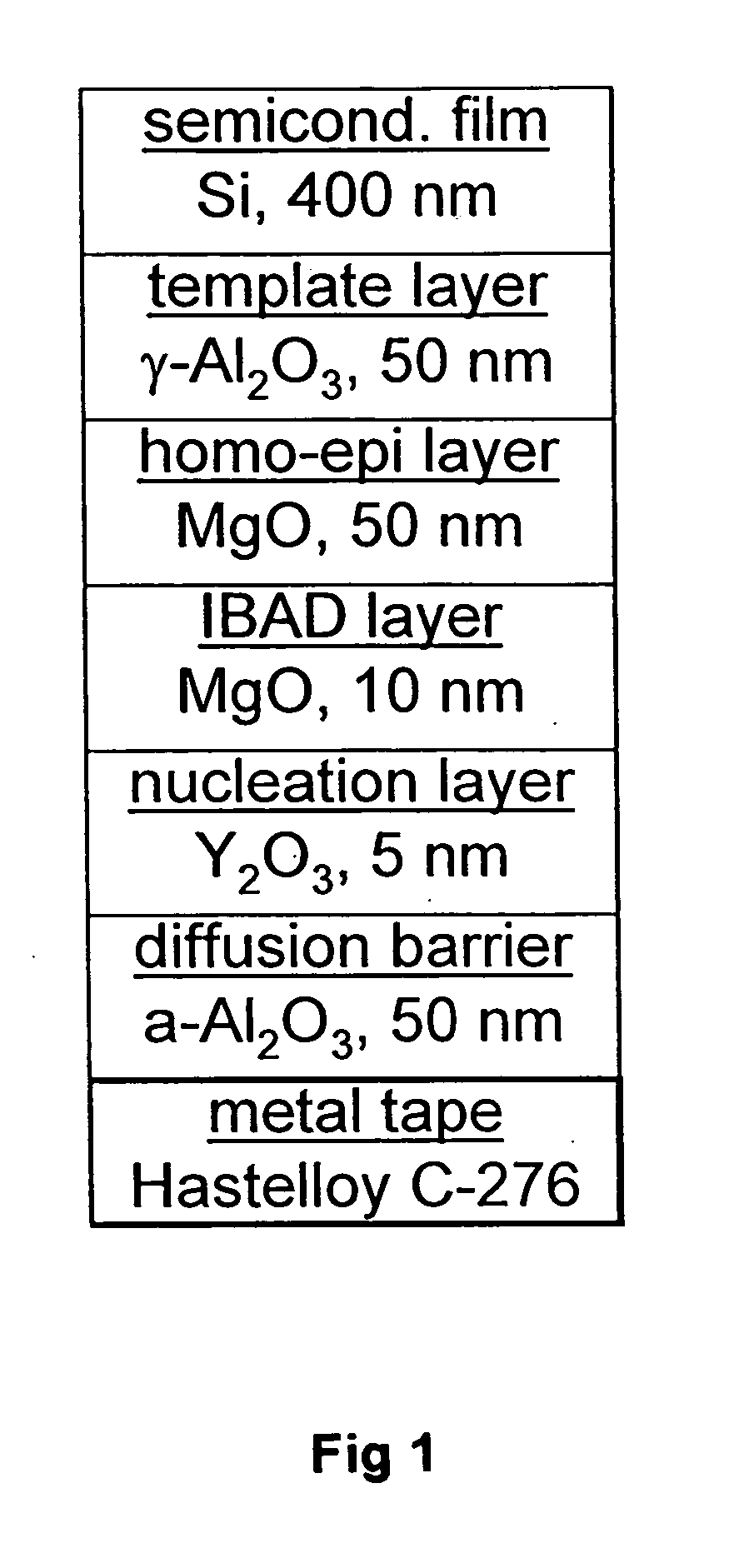

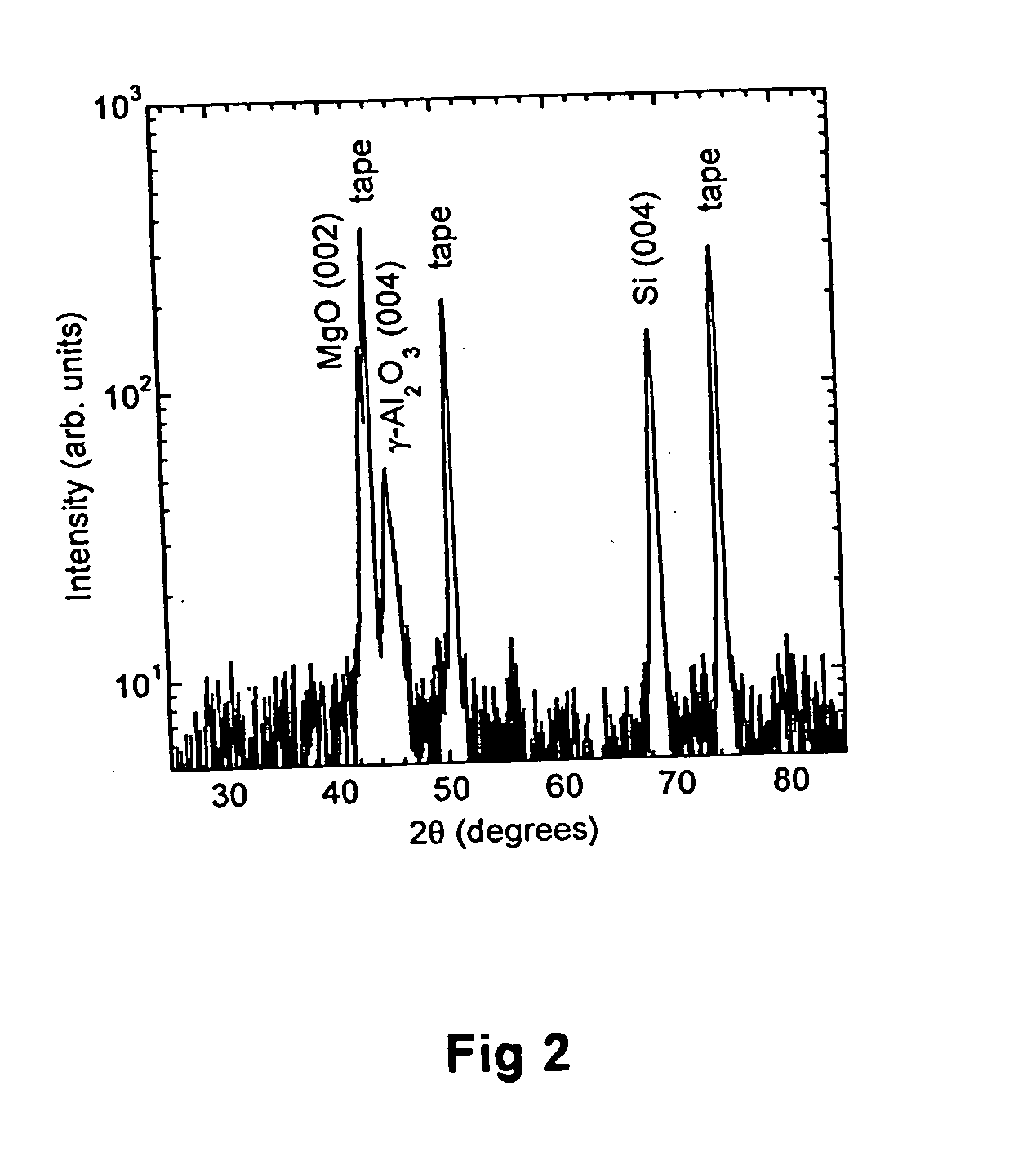

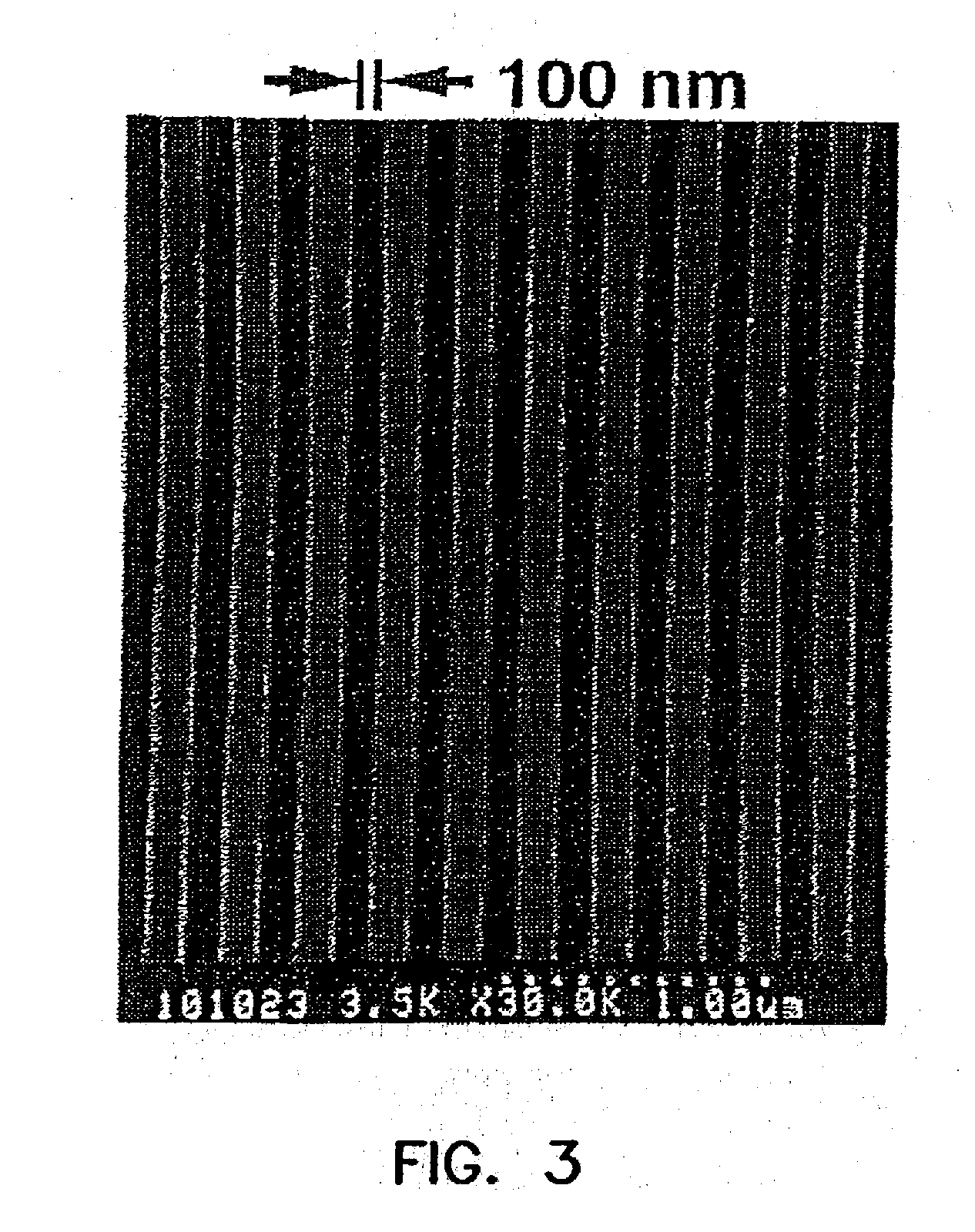

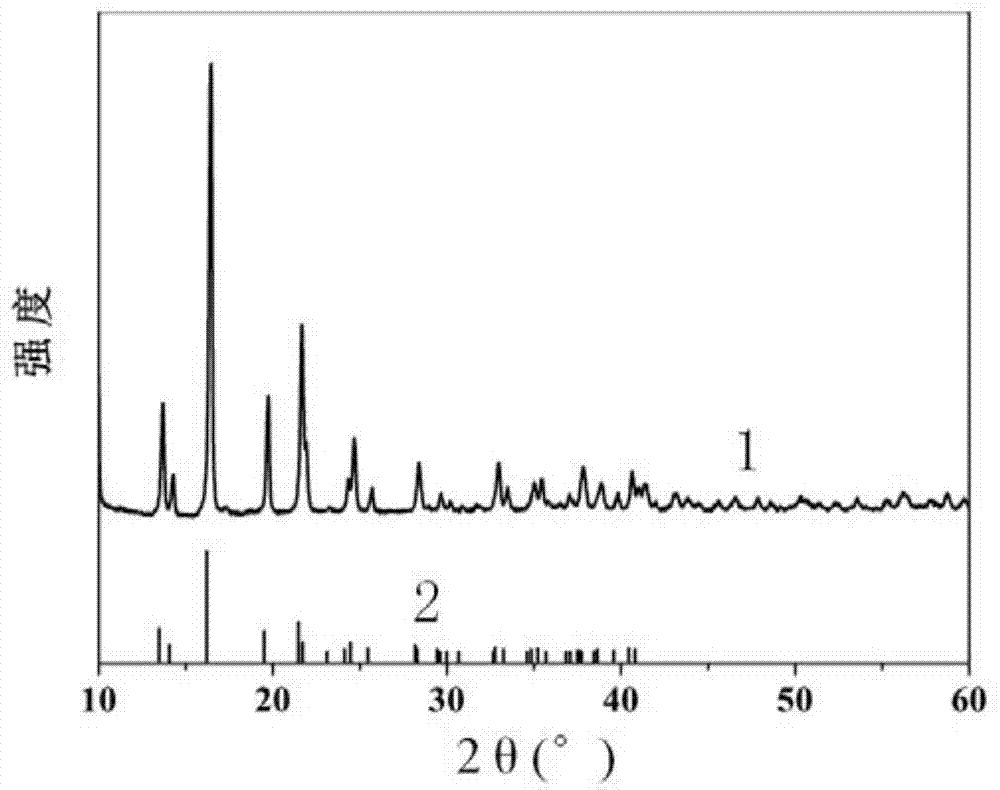

Near single-crystalline, high-carrier-mobility silicon thin film on a polycrystalline/amorphous substrate

InactiveUS20060115964A1Low chemical reactivityPolycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor materialsCharge carrier mobility

A template article including a base substrate including: (i) a base material selected from the group consisting of polycrystalline substrates and amorphous substrates, and (ii) at least one layer of a differing material upon the surface of the base material; and, a buffer material layer upon the base substrate, the buffer material layer characterized by: (a) low chemical reactivity with the base substrate, (b) stability at temperatures up to at least about 800° C. under low vacuum conditions, and (c) a lattice crystal structure adapted for subsequent deposition of a semiconductor material; is provided, together with a semiconductor article including a base substrate including: (i) a base material selected from the group consisting of polycrystalline substrates and amorphous substrates, and (ii) at least one layer of a differing material upon the surface of the base material; and, a buffer material layer upon the base substrate, the buffer material layer characterized by: (a) low chemical reactivity with the base substrate, (b) stability at temperatures up to at least about 800° C. under low vacuum conditions, and (c) a lattice crystal structure adapted for subsequent deposition of a semiconductor material, and, a top-layer of semiconductor material upon the buffer material layer.

Owner:LOS ALAMOS NATIONAL SECURITY

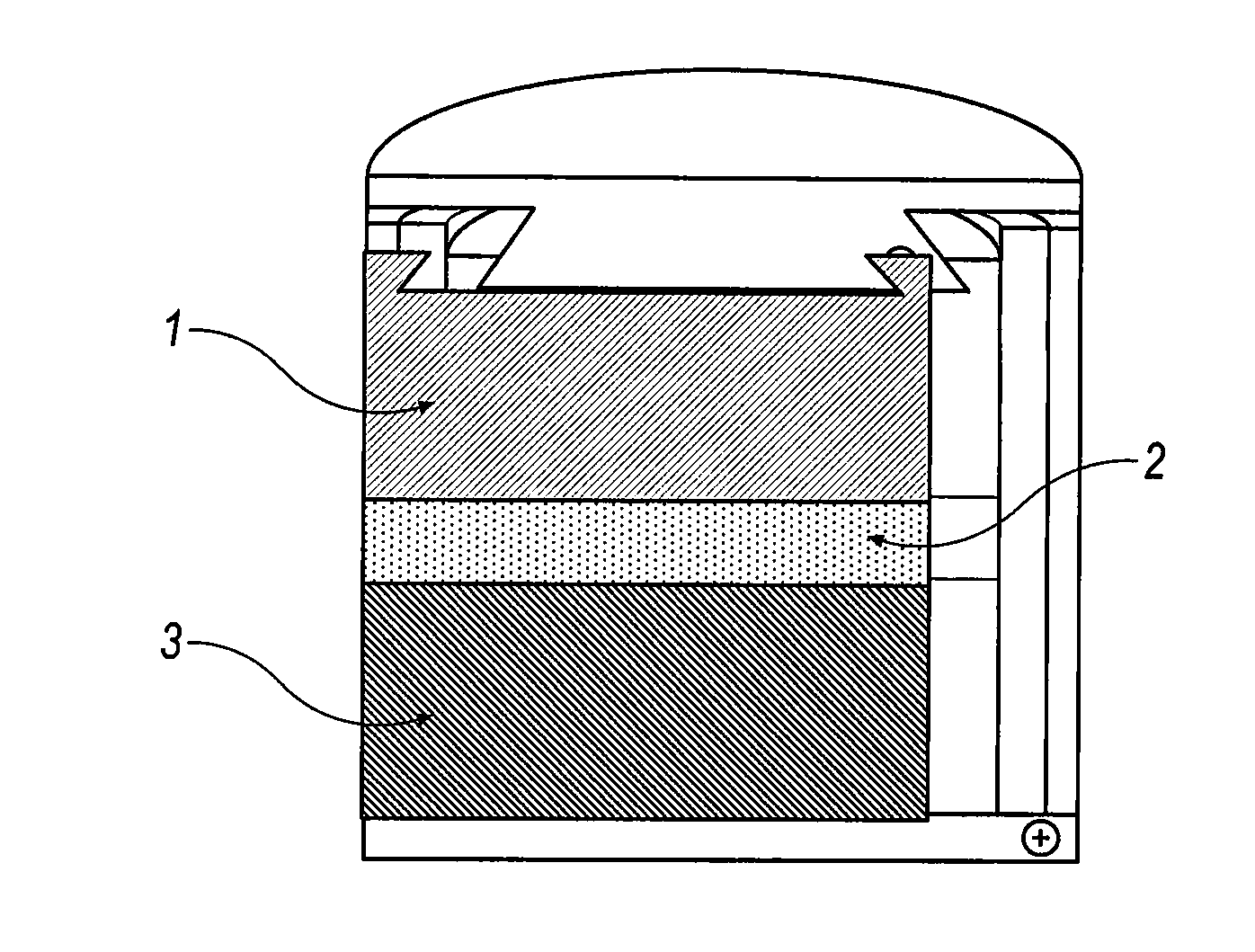

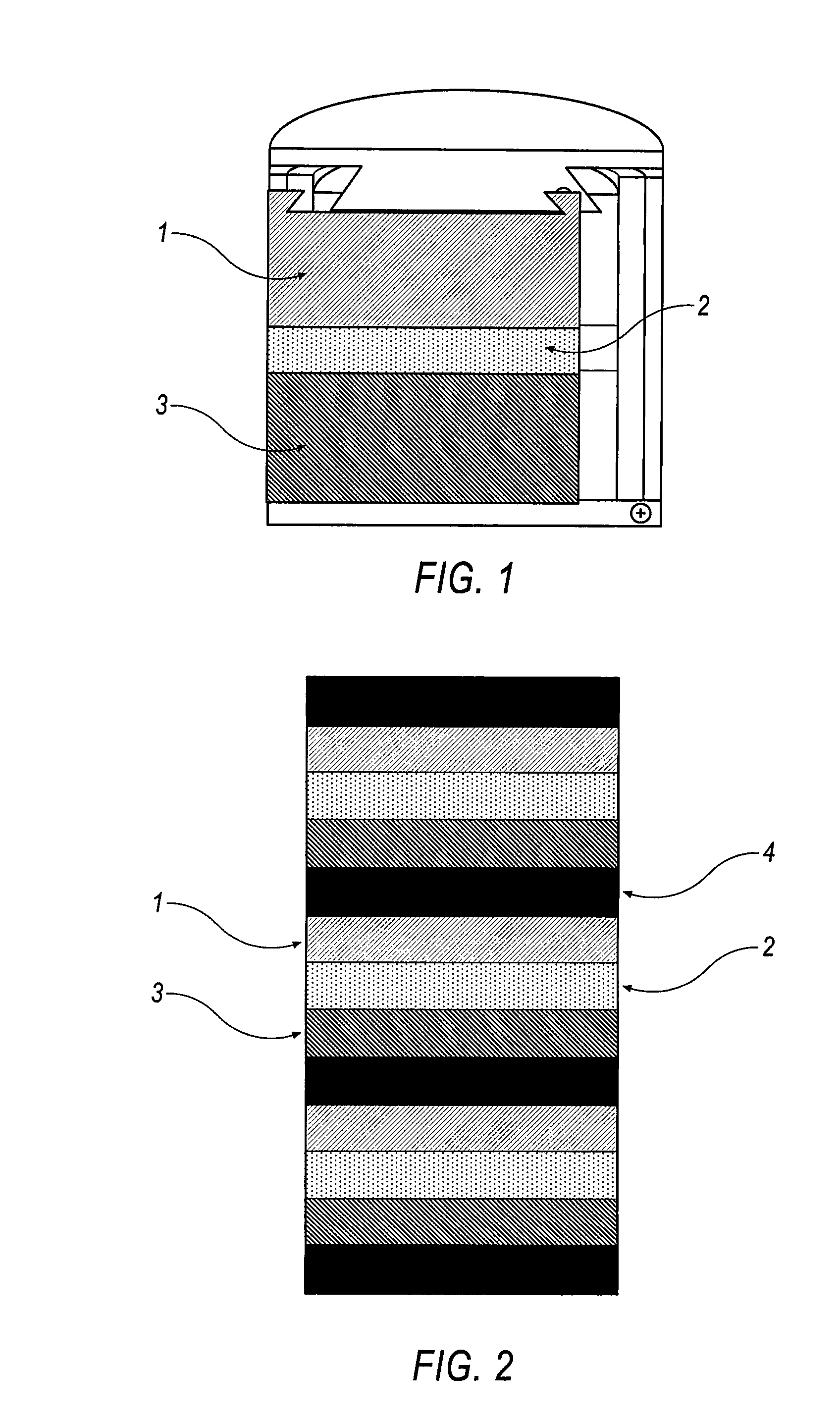

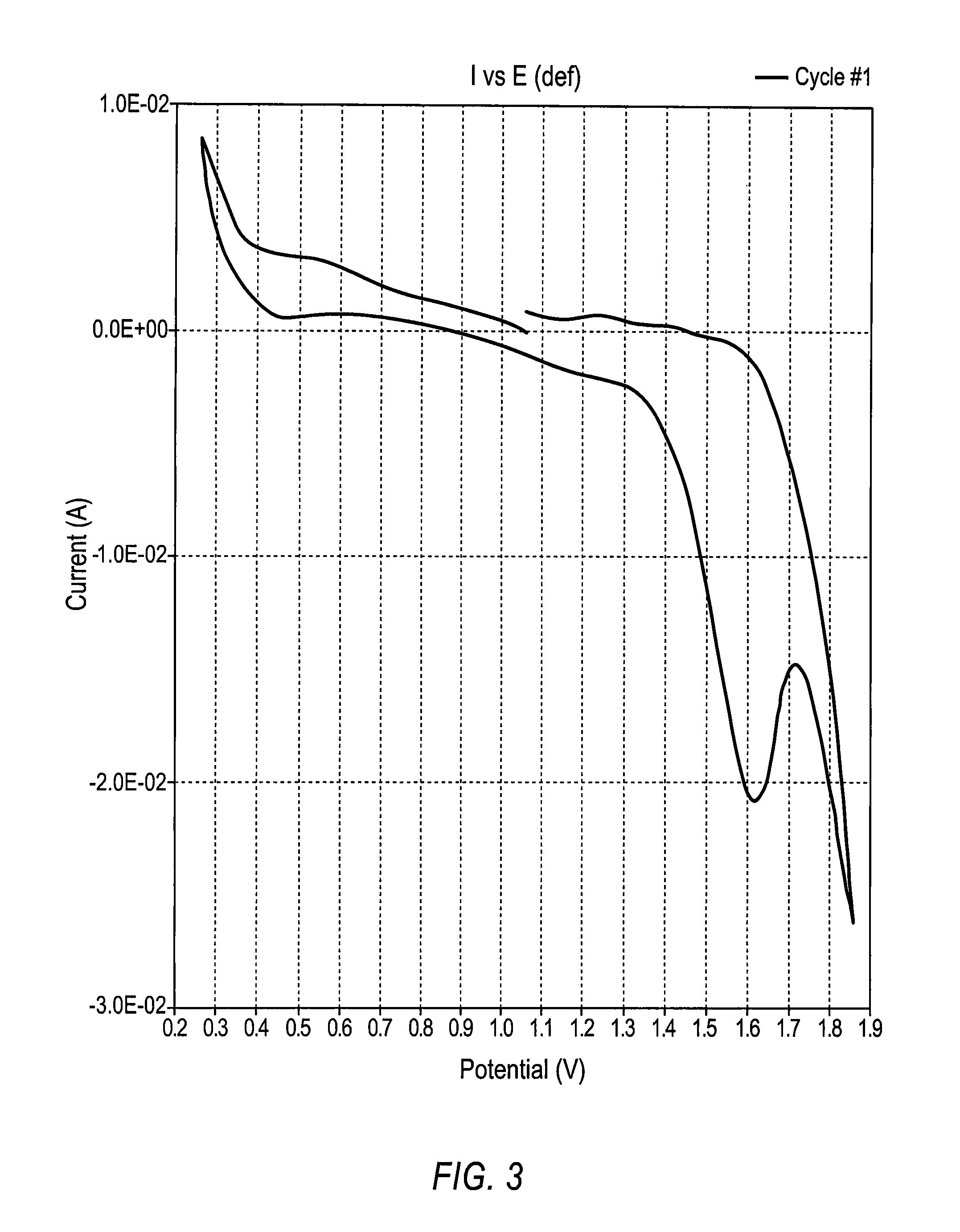

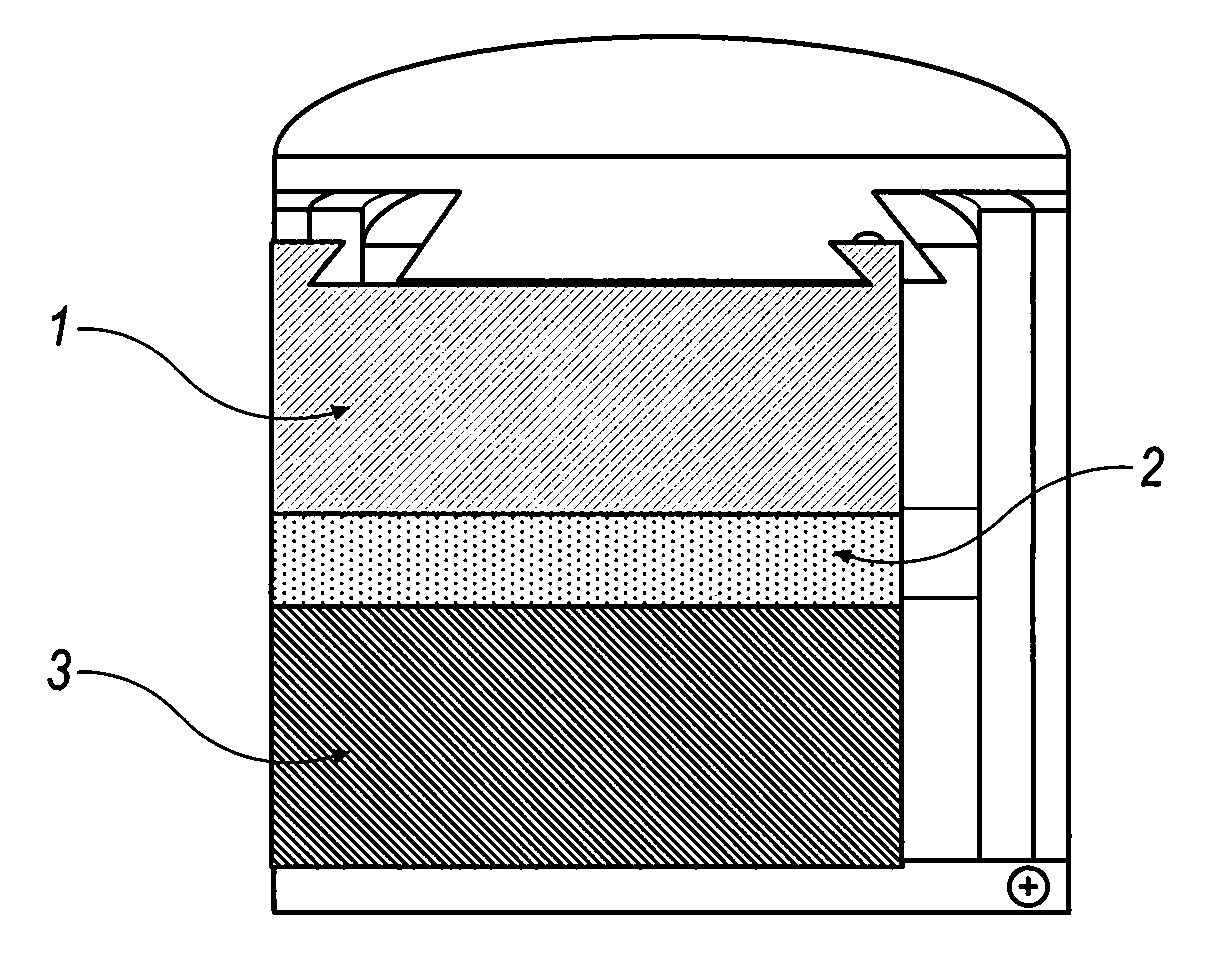

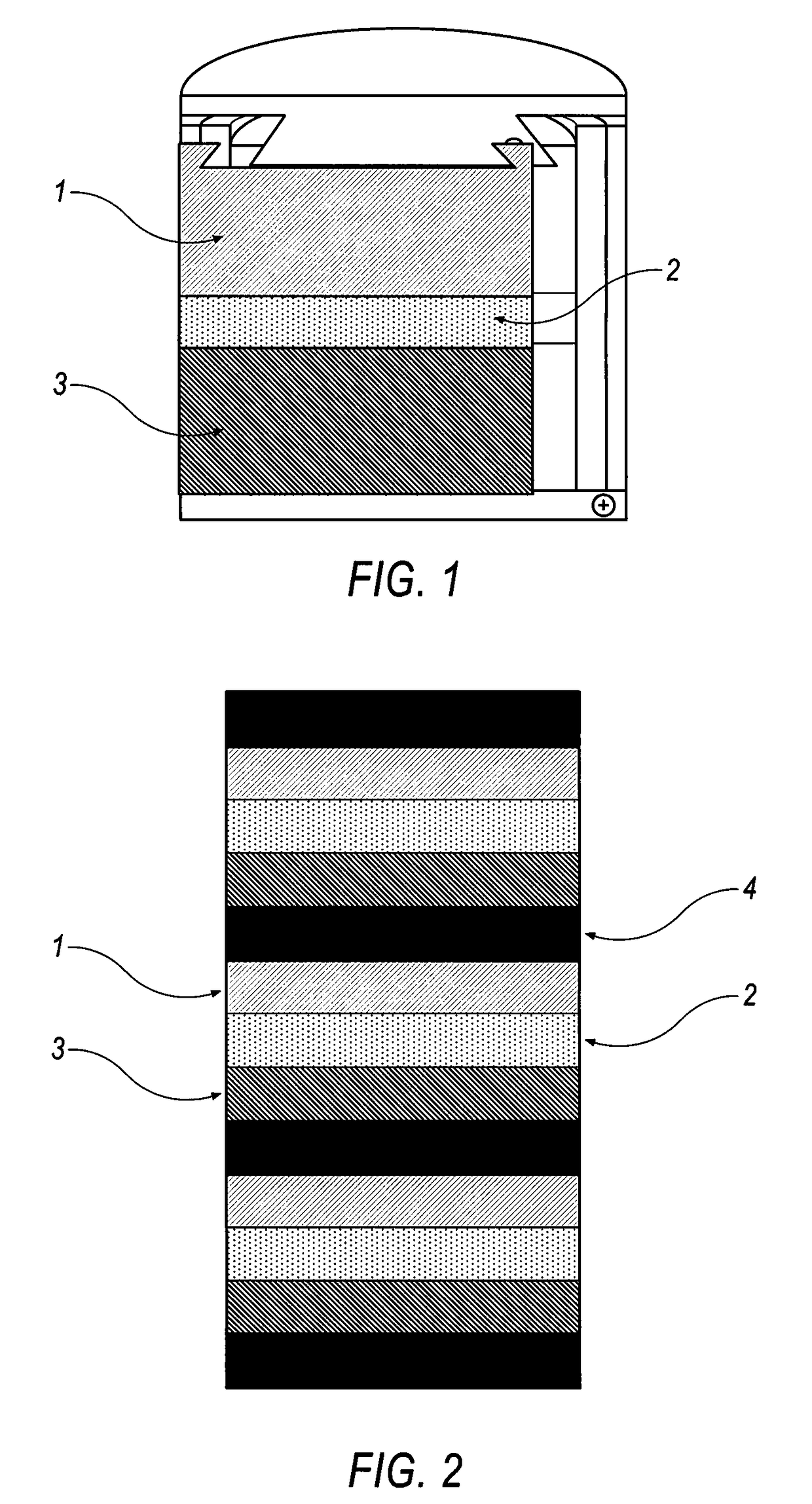

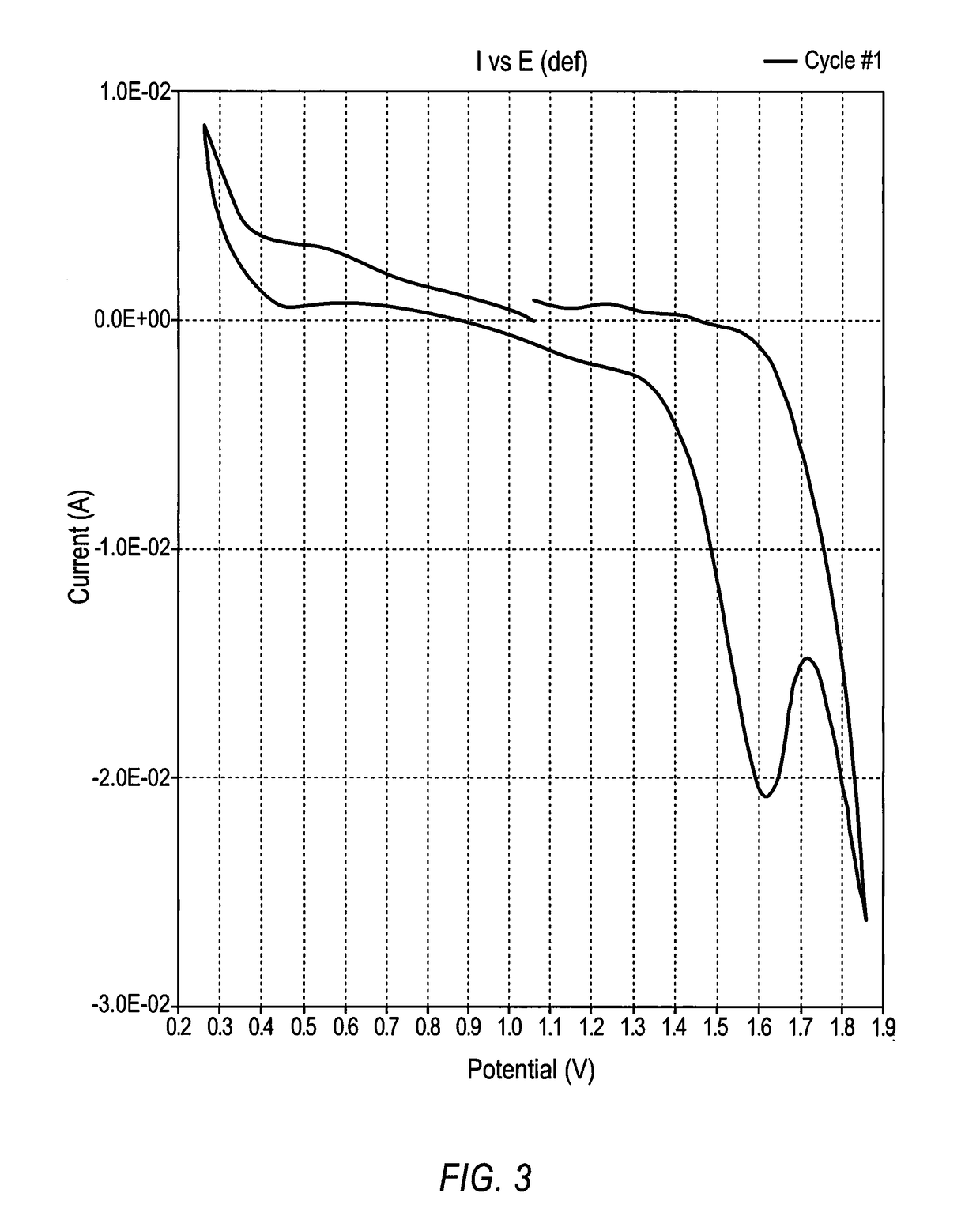

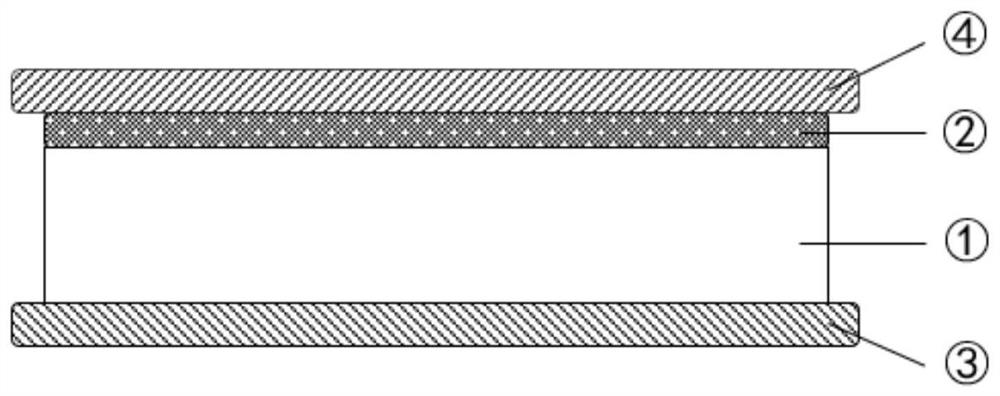

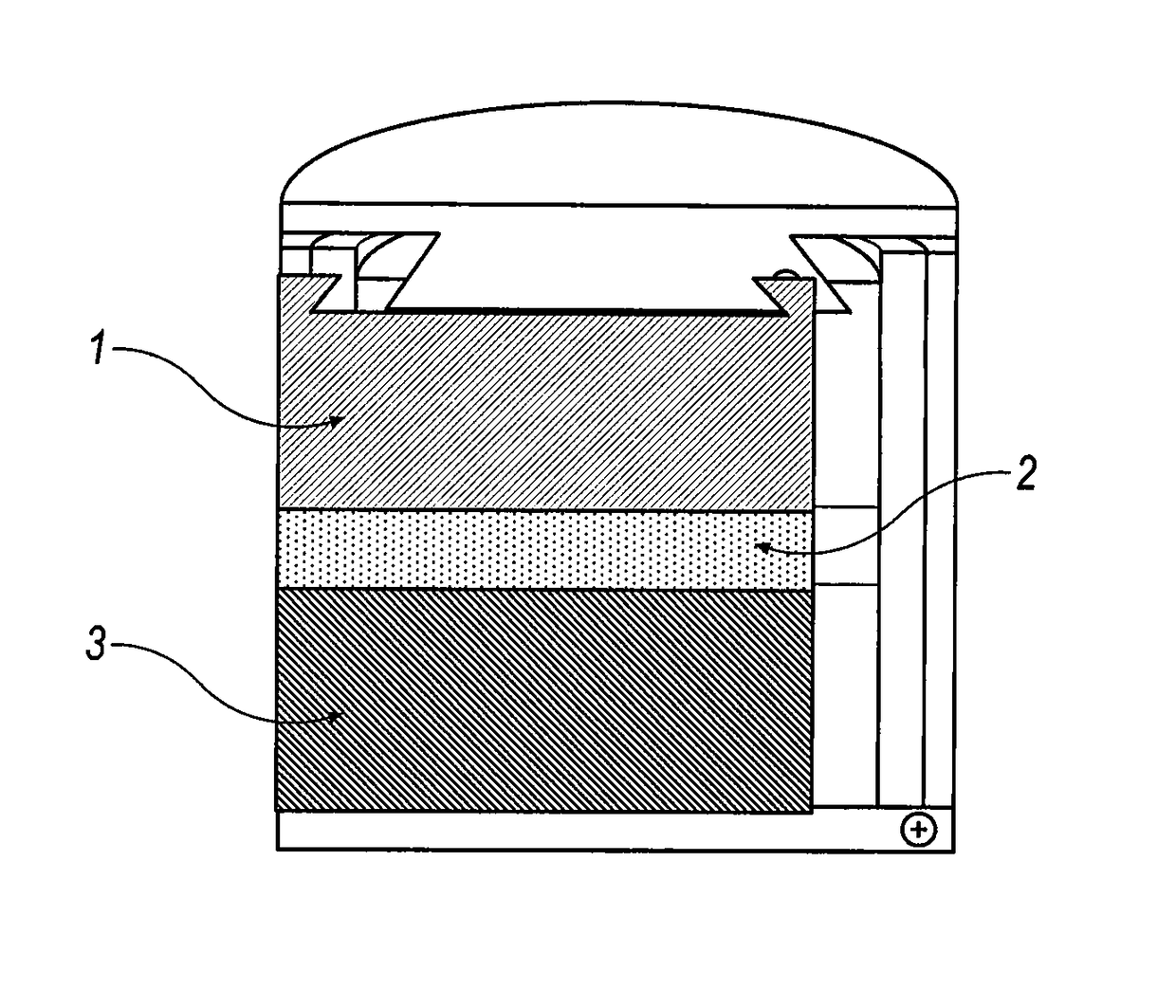

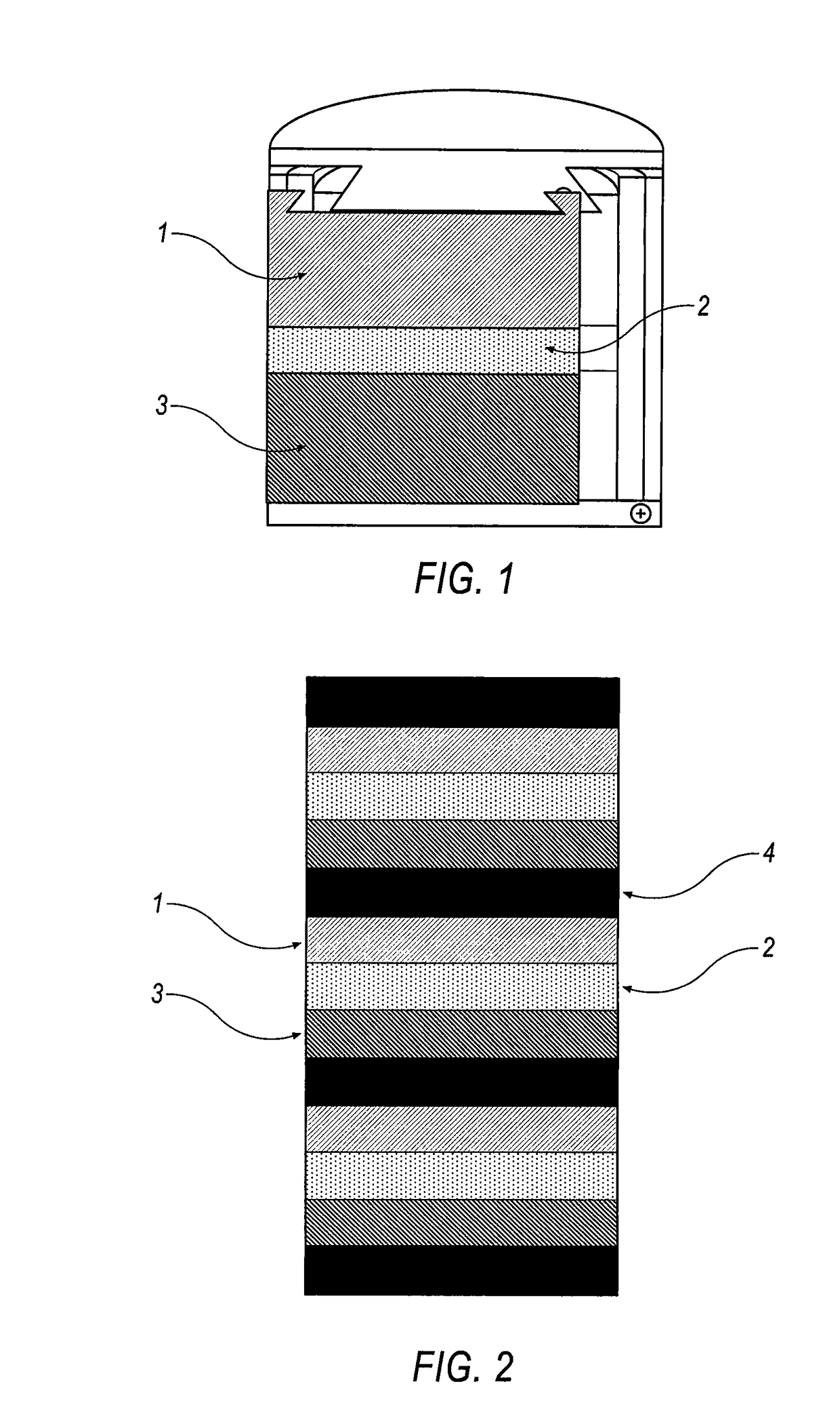

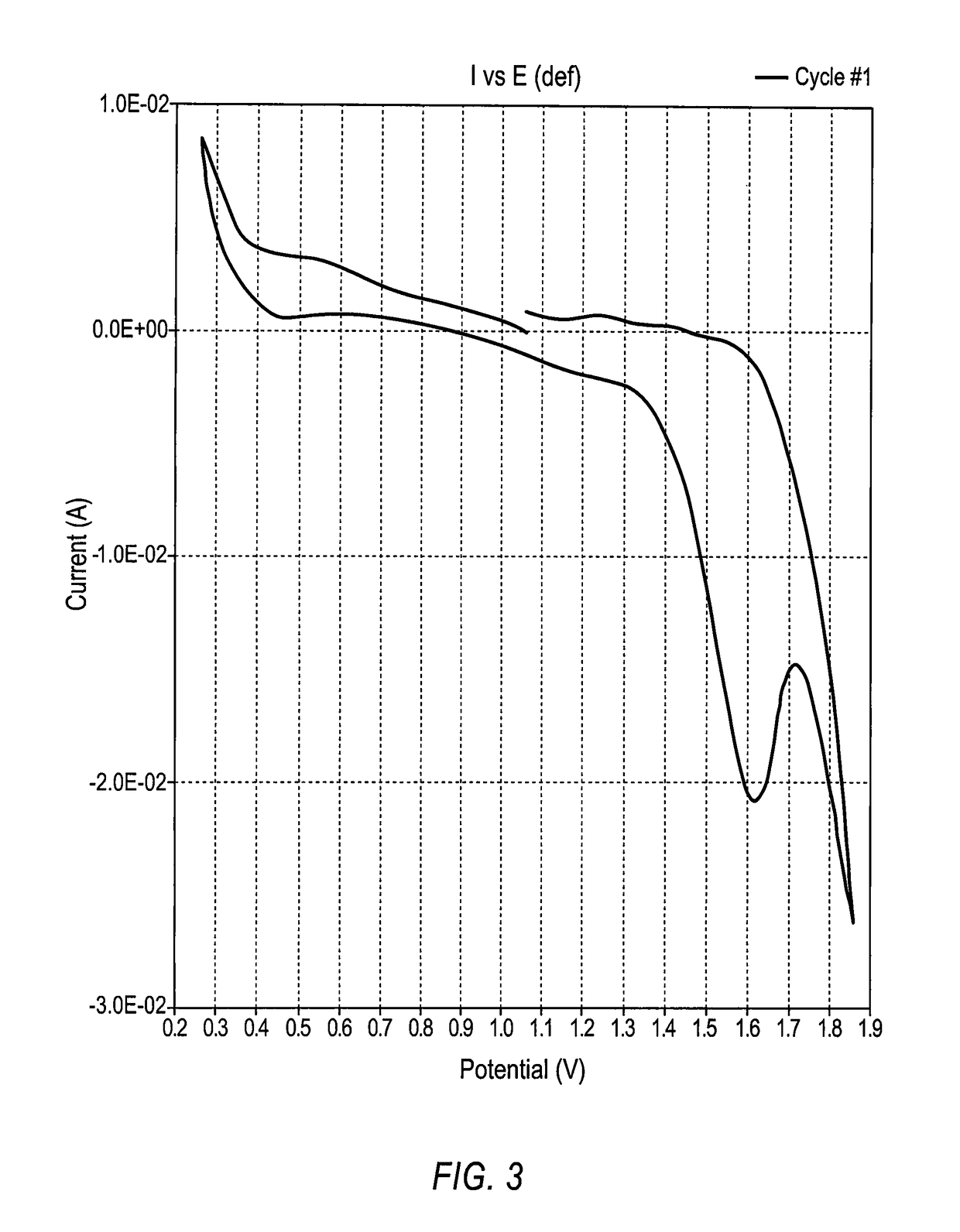

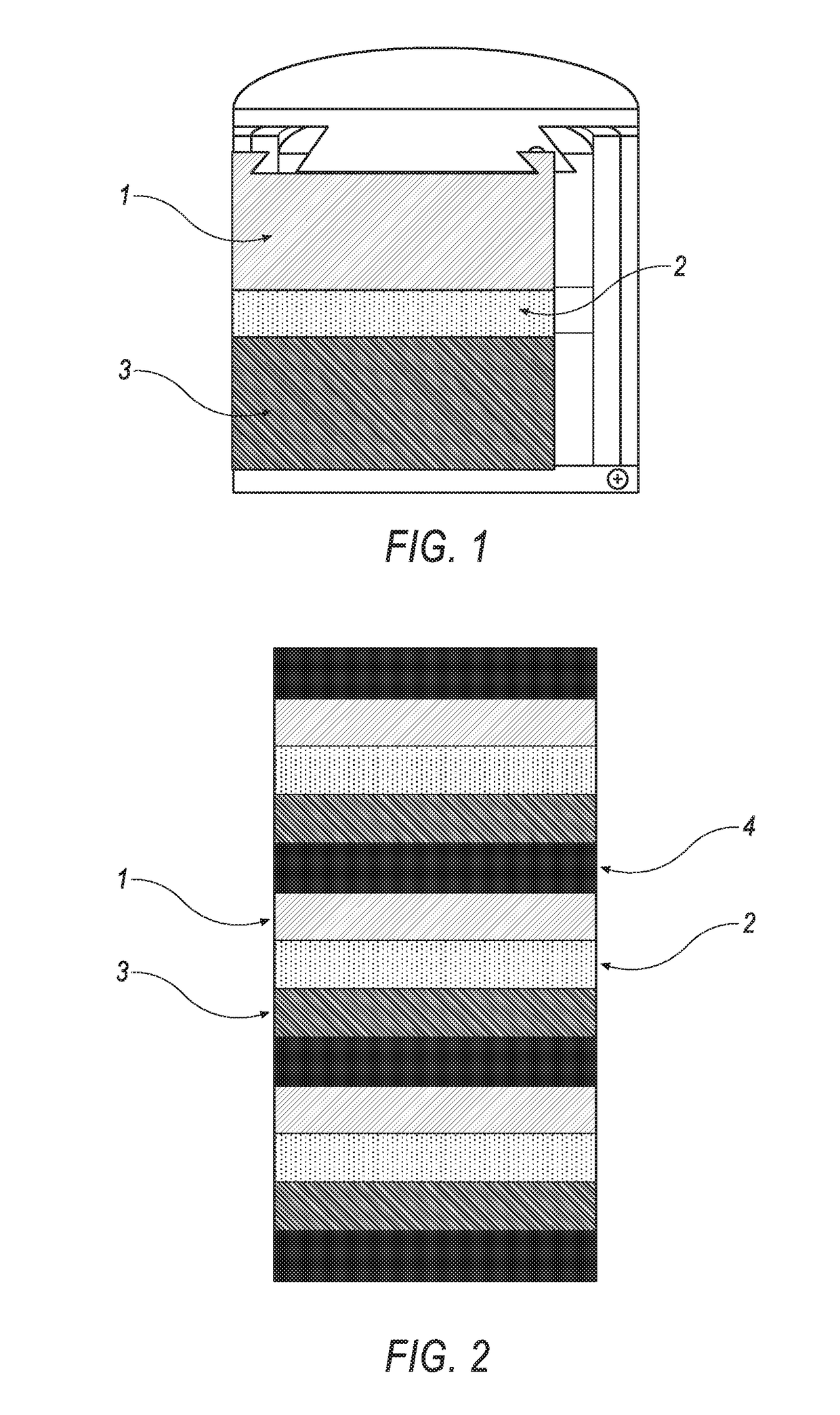

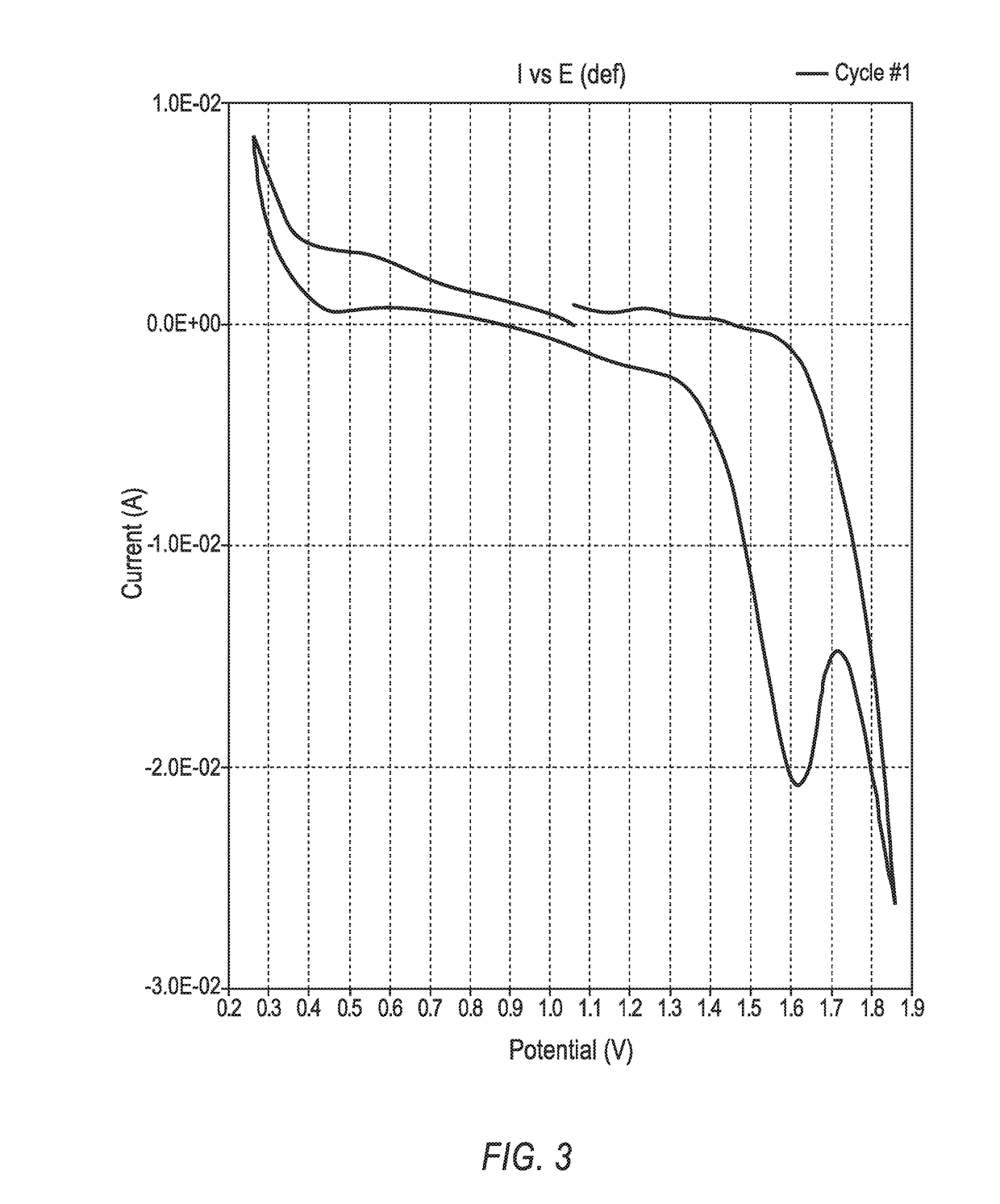

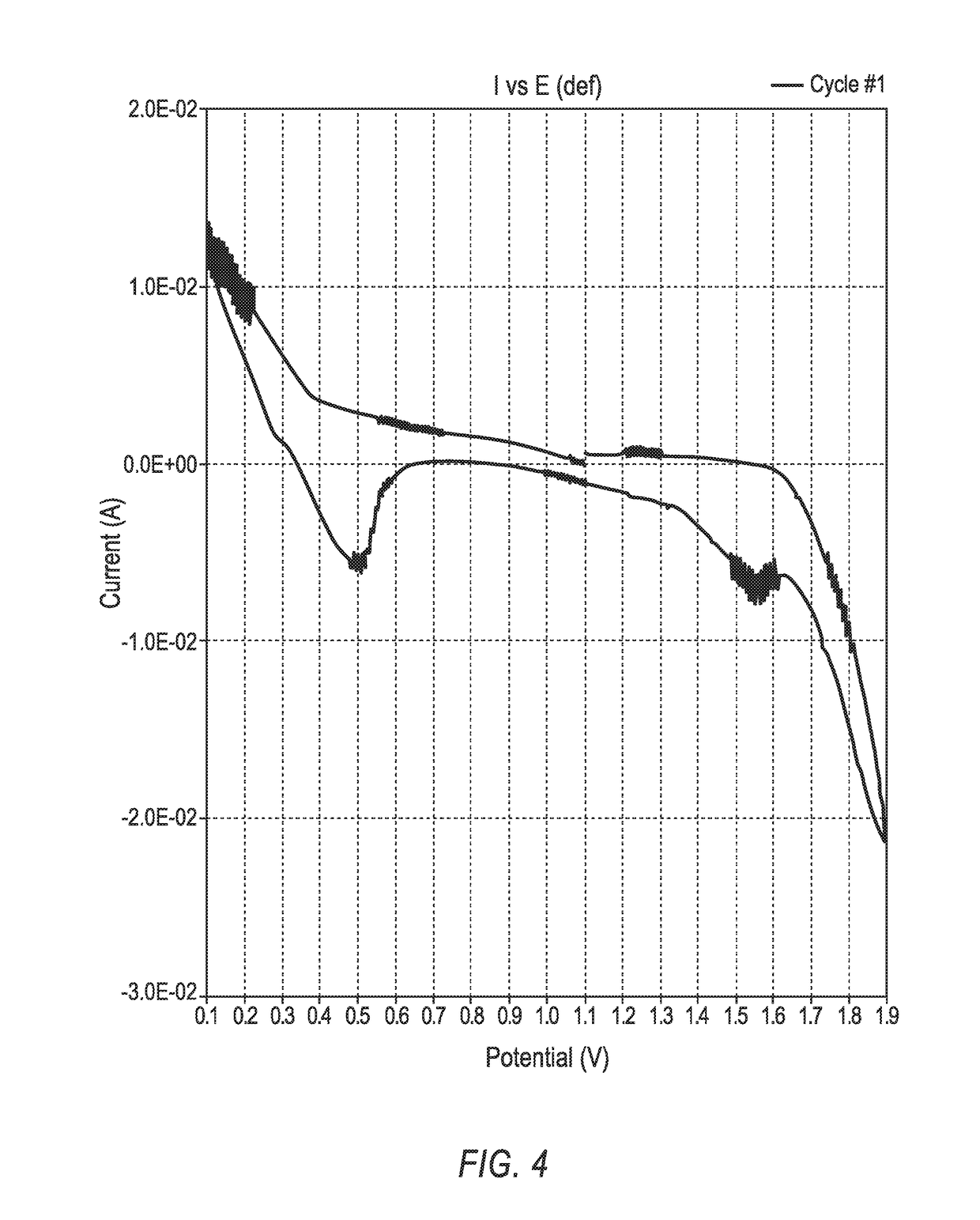

Molten metal rechargeable electrochemical cell

ActiveUS20150010792A1Low costImprove usabilityCell electrodesSecondary cellsElectrical batteryElectrochemical cell

The present invention provides rechargeable electrochemical cells comprising a molten anode, a cathode, and a non-aqueous electrolyte salt, wherein the electrolyte salt is situated between the molten anode and the cathode during the operation of the electrochemical cell, and the molten anode comprises an aluminum material; also provided are batteries comprising a plurality of such rechargeable electrochemical cells and processes for manufacturing such rechargeable electrochemical cells.

Owner:EOS ENERGY TECH HLDG LLC

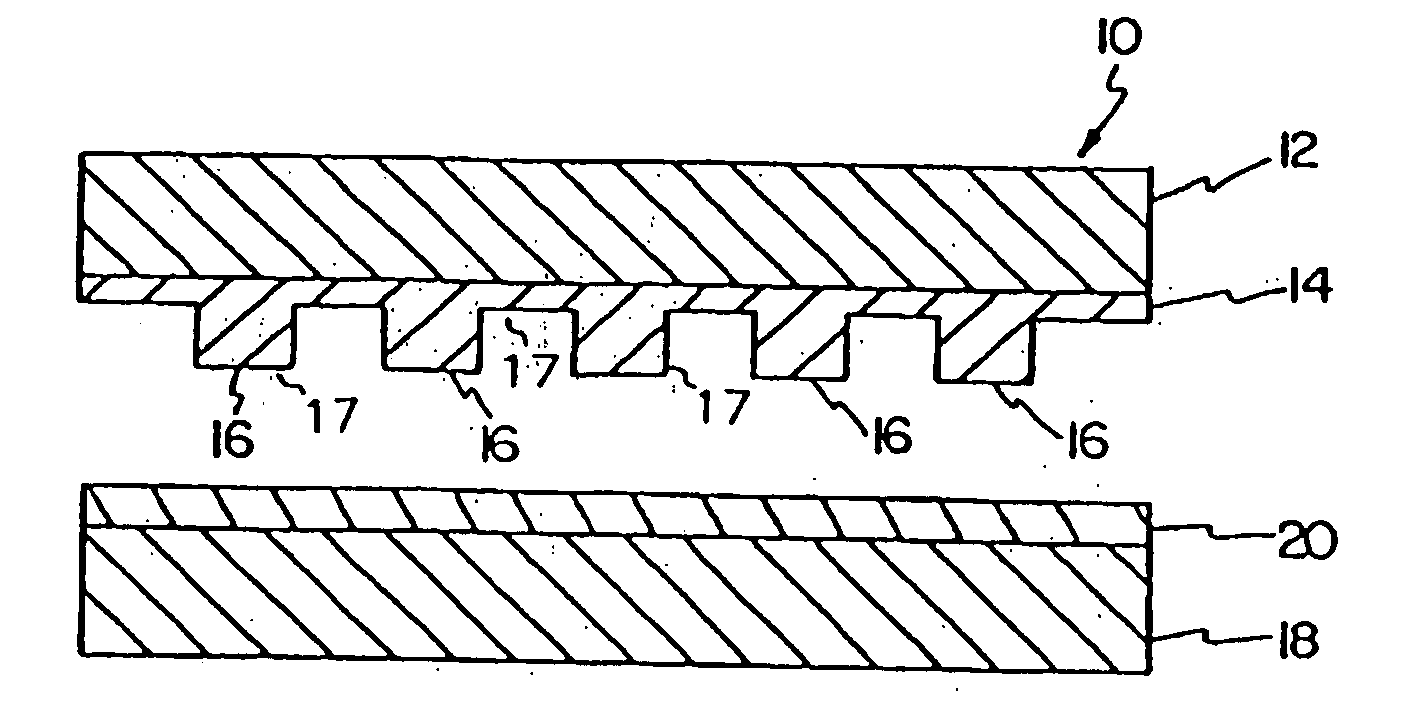

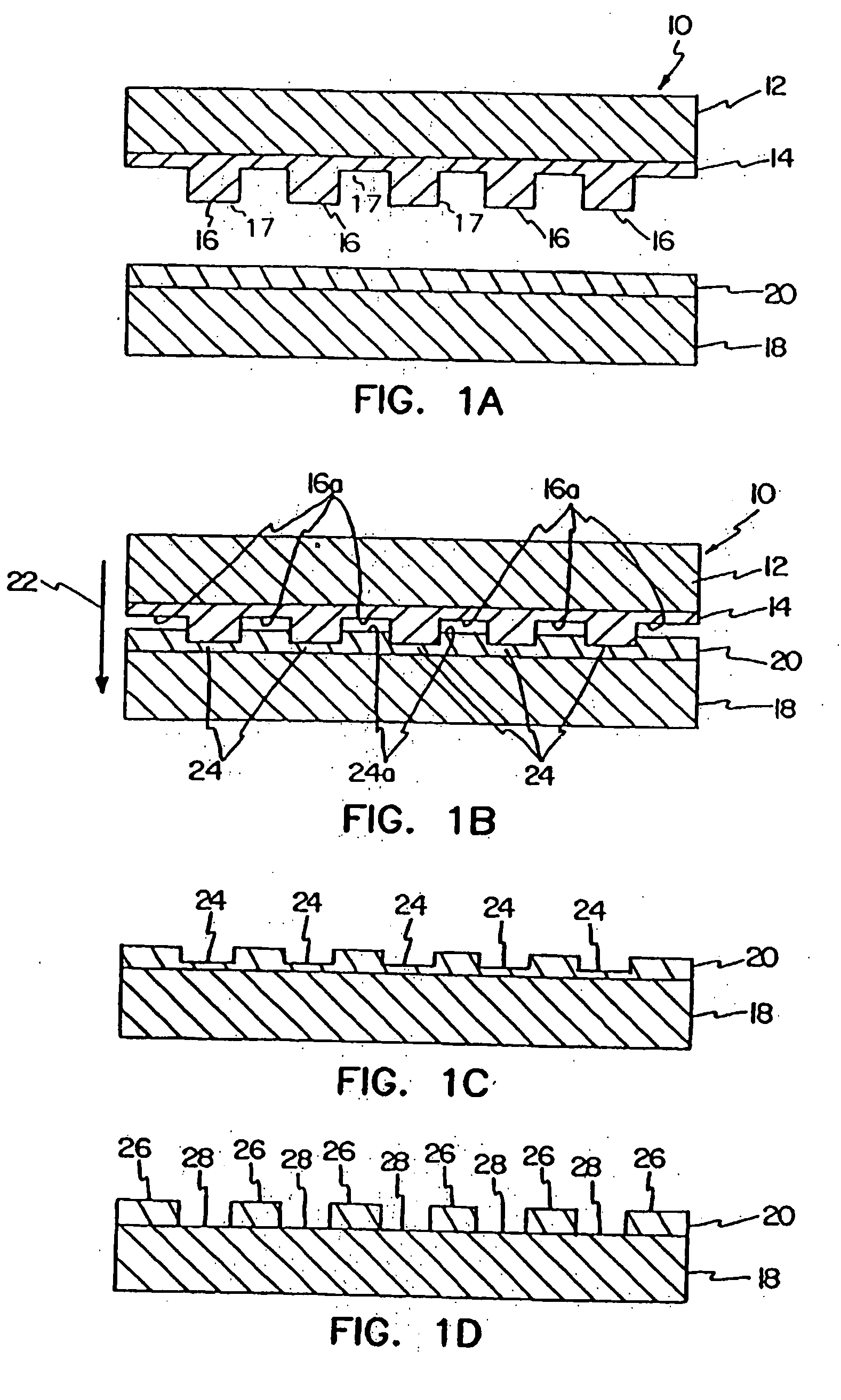

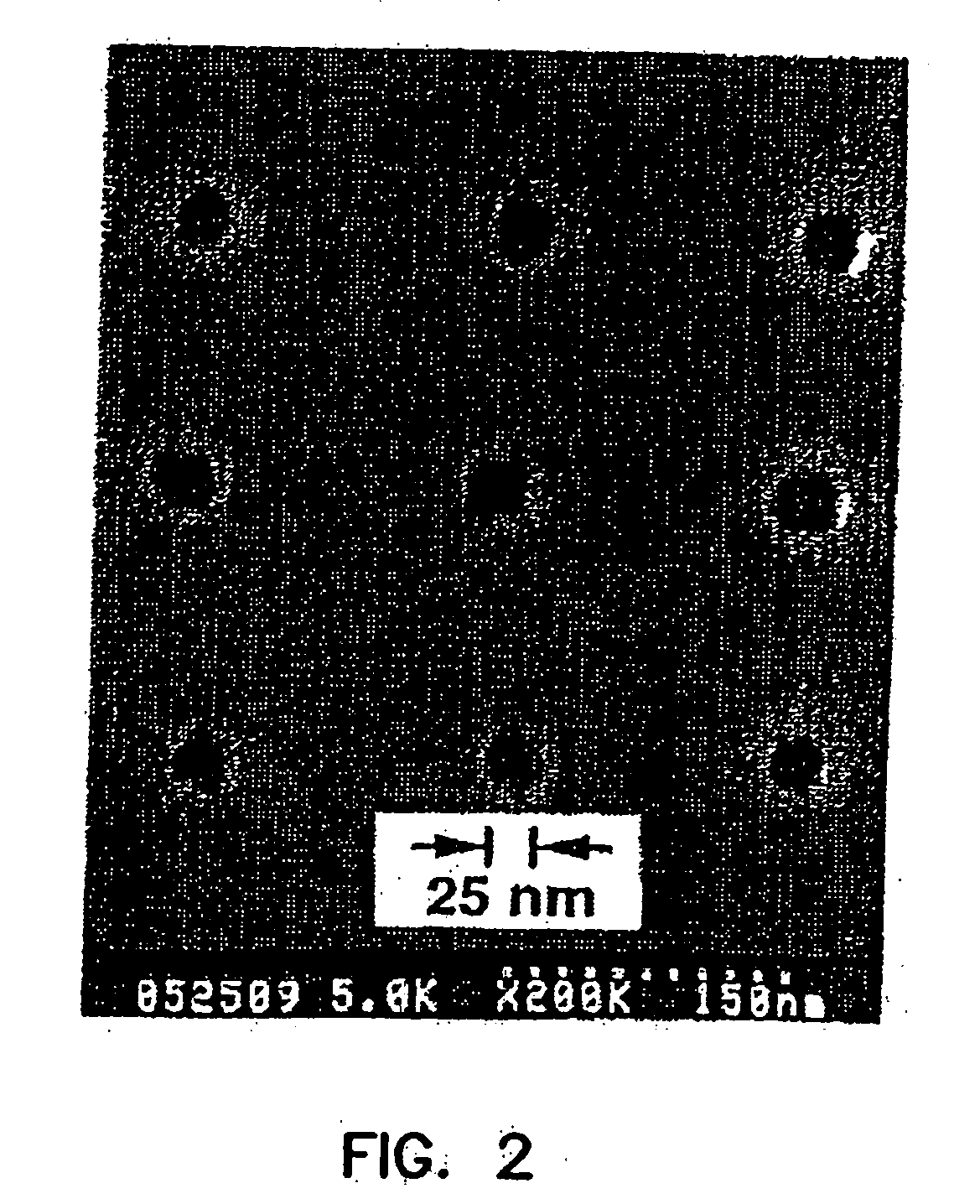

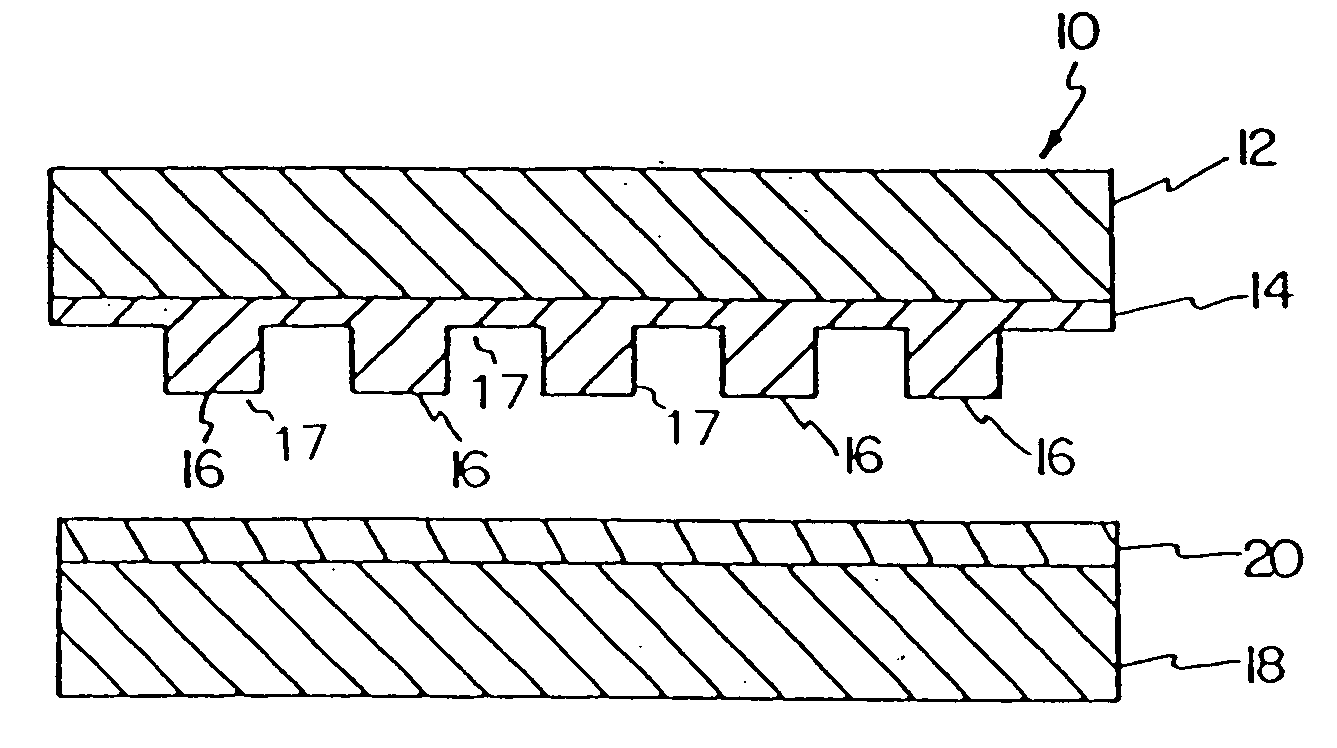

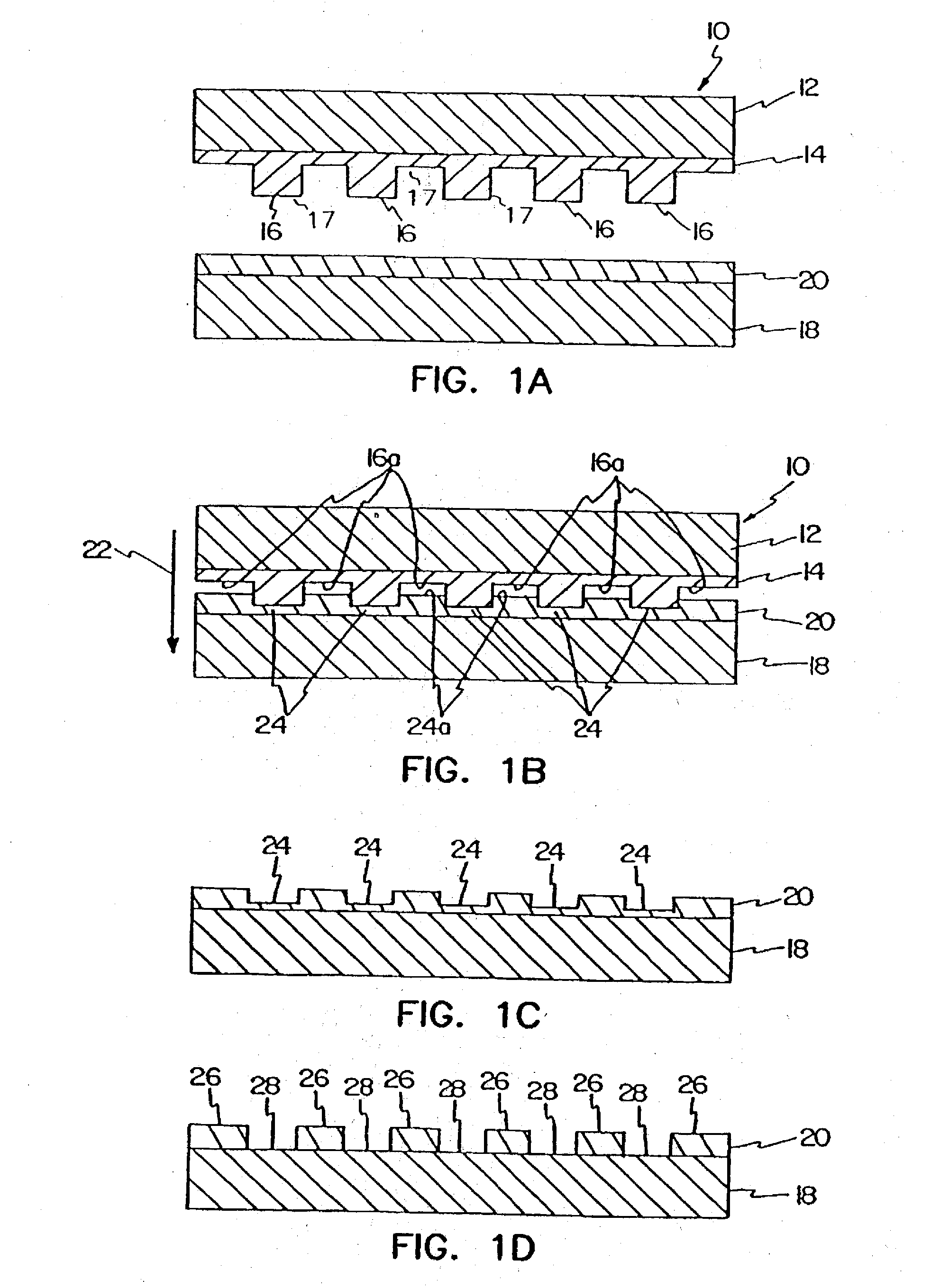

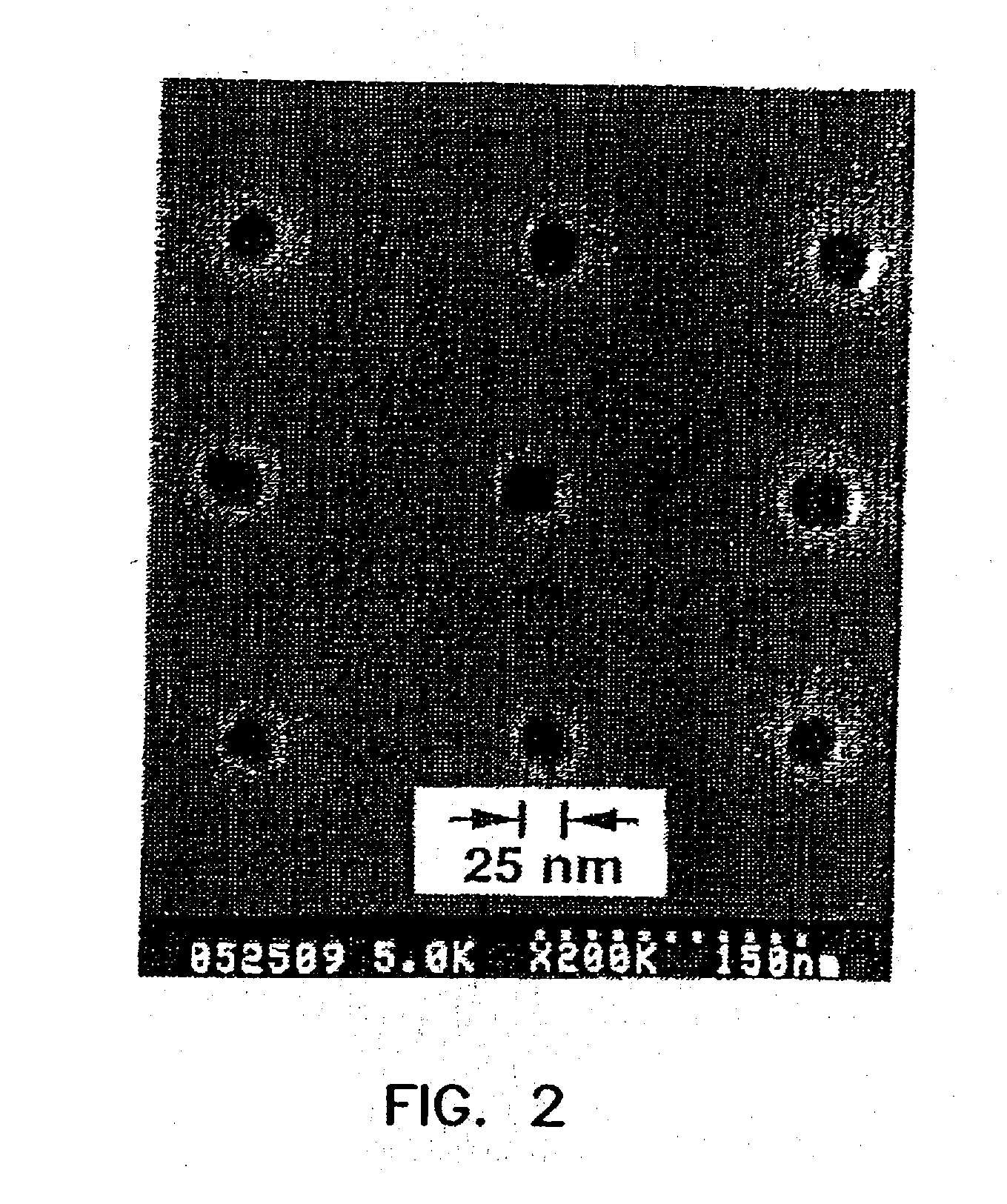

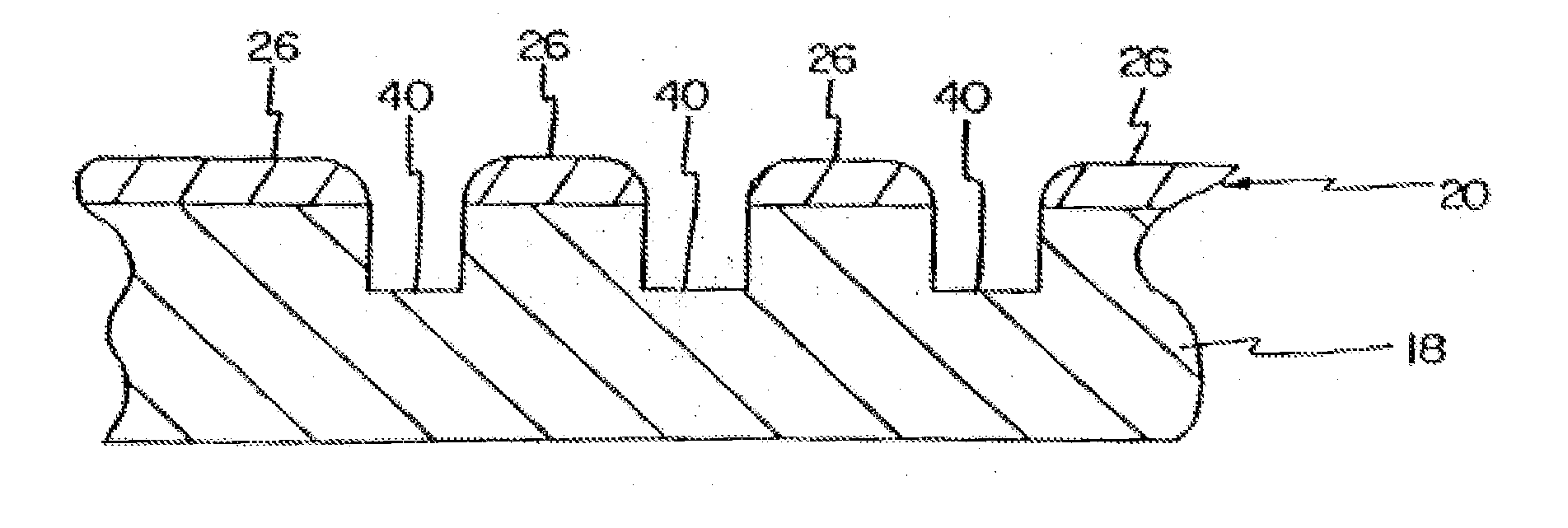

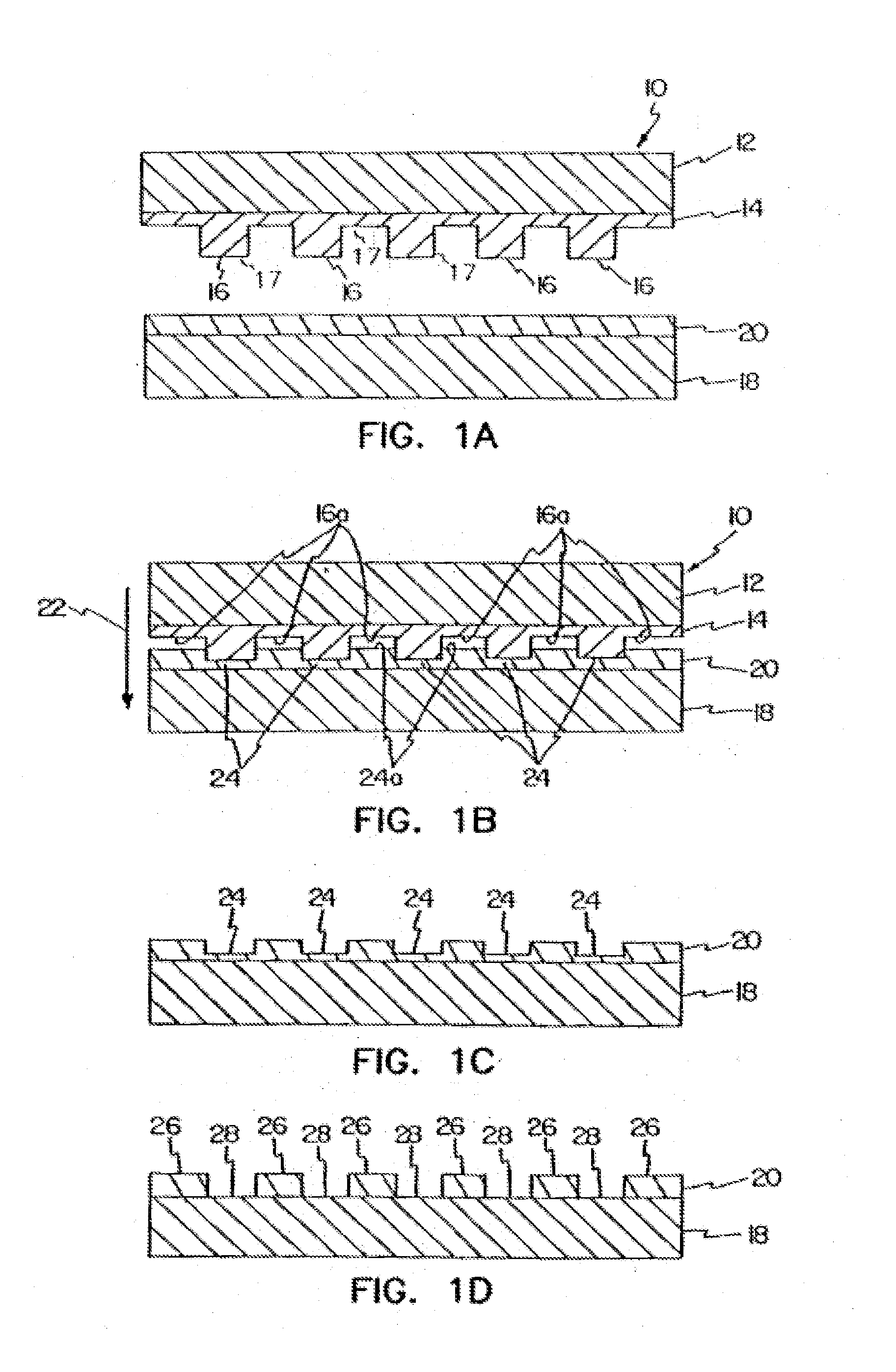

Release surfaces, particularly for use in nanoimprint lithography

InactiveUS20080217813A1Efficient processingLow chemical reactivityNanoinformaticsPhotomechanical apparatusHydrogenHalogen

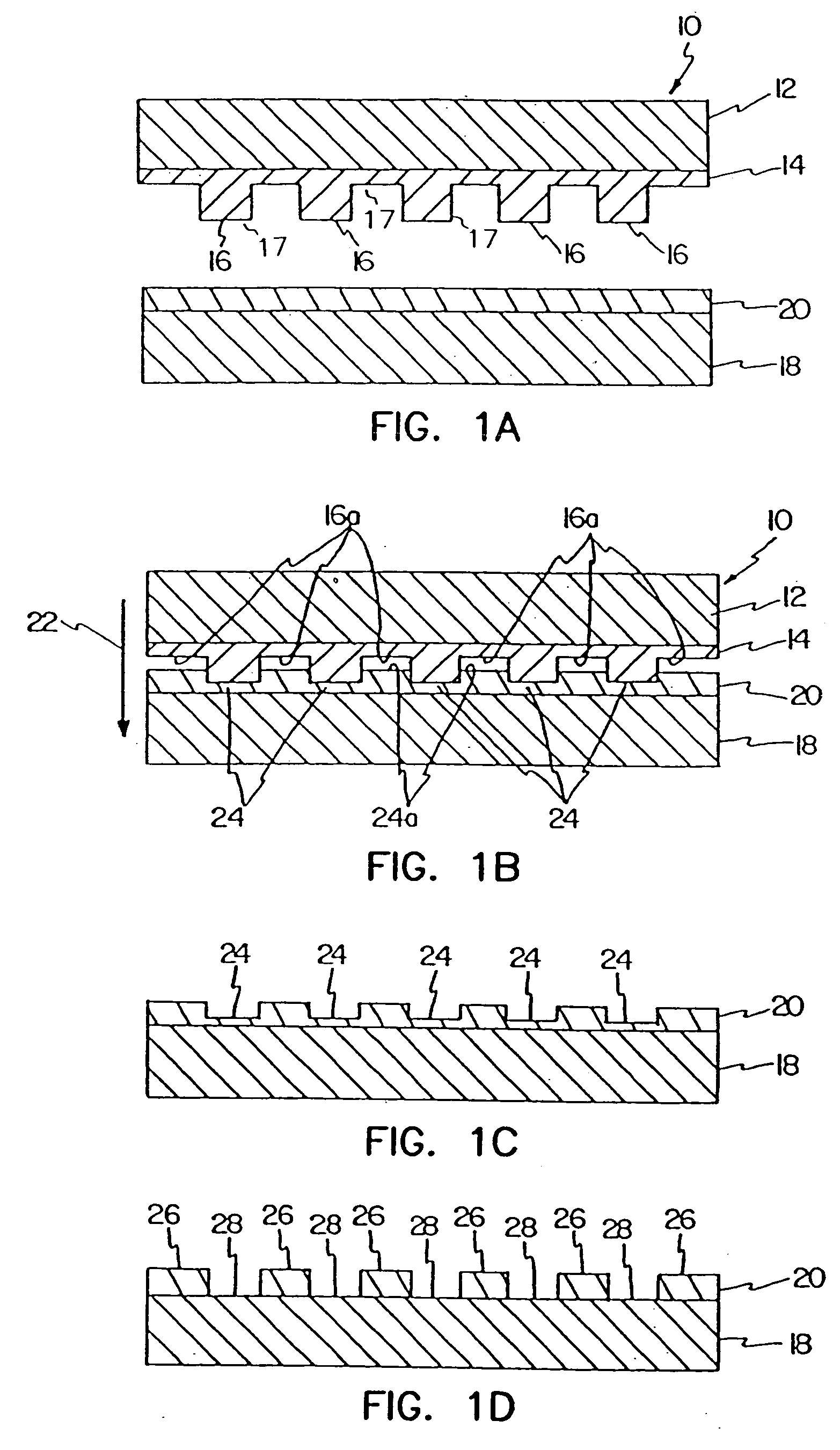

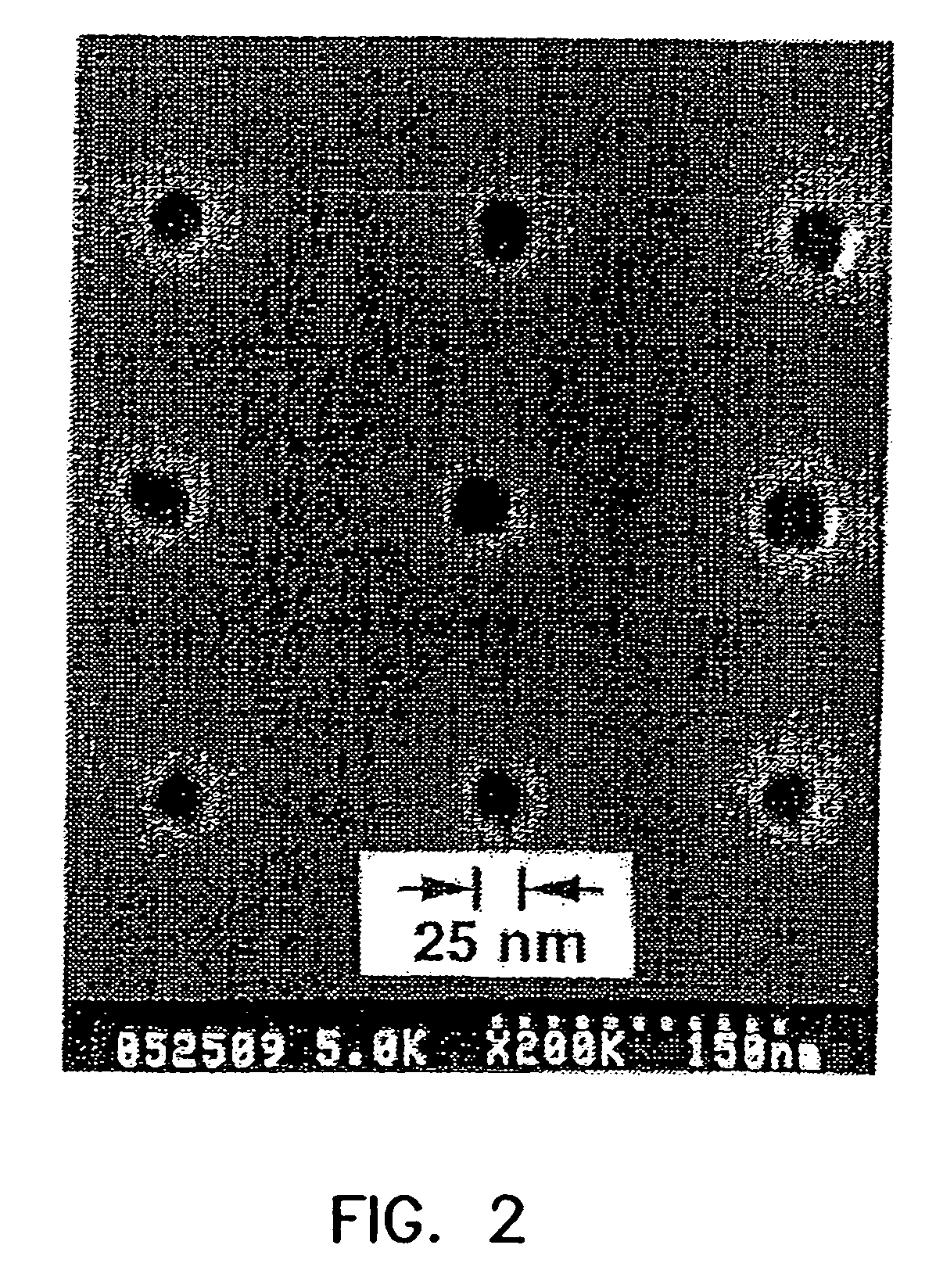

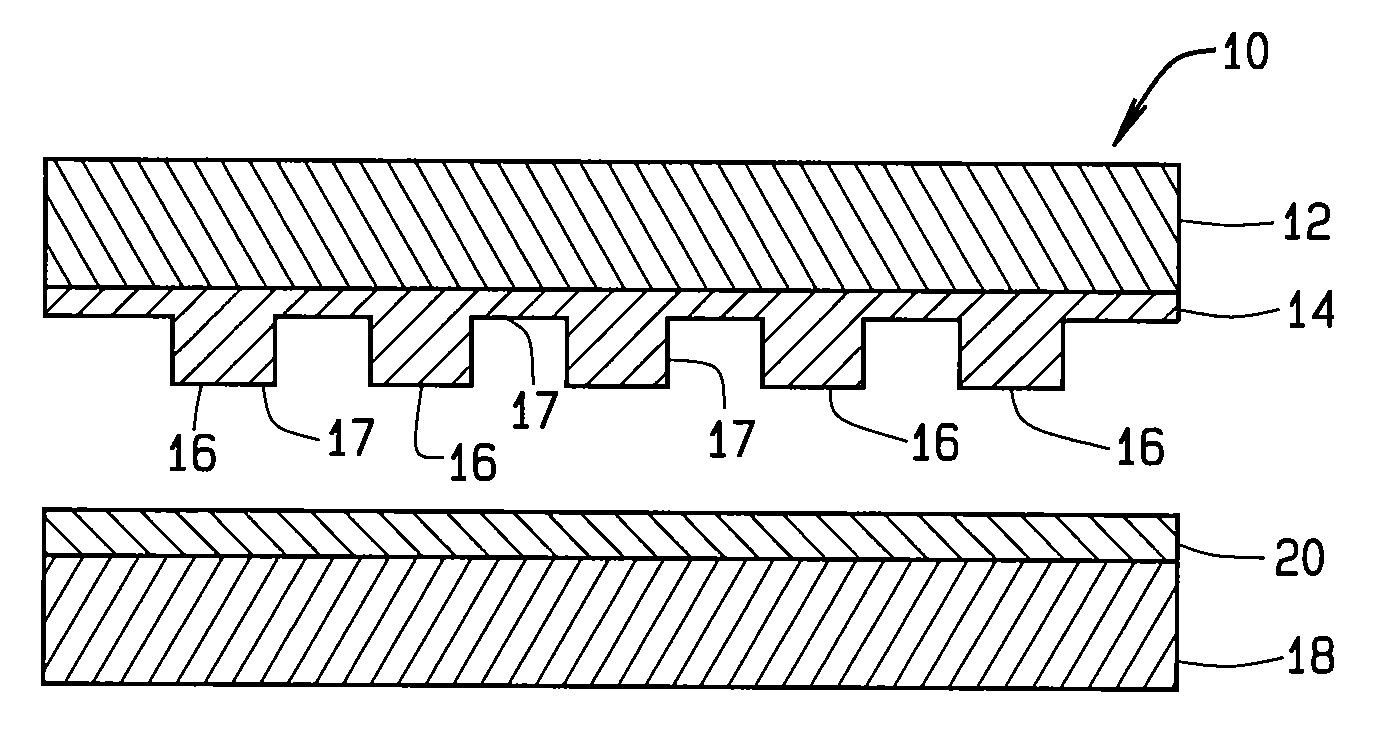

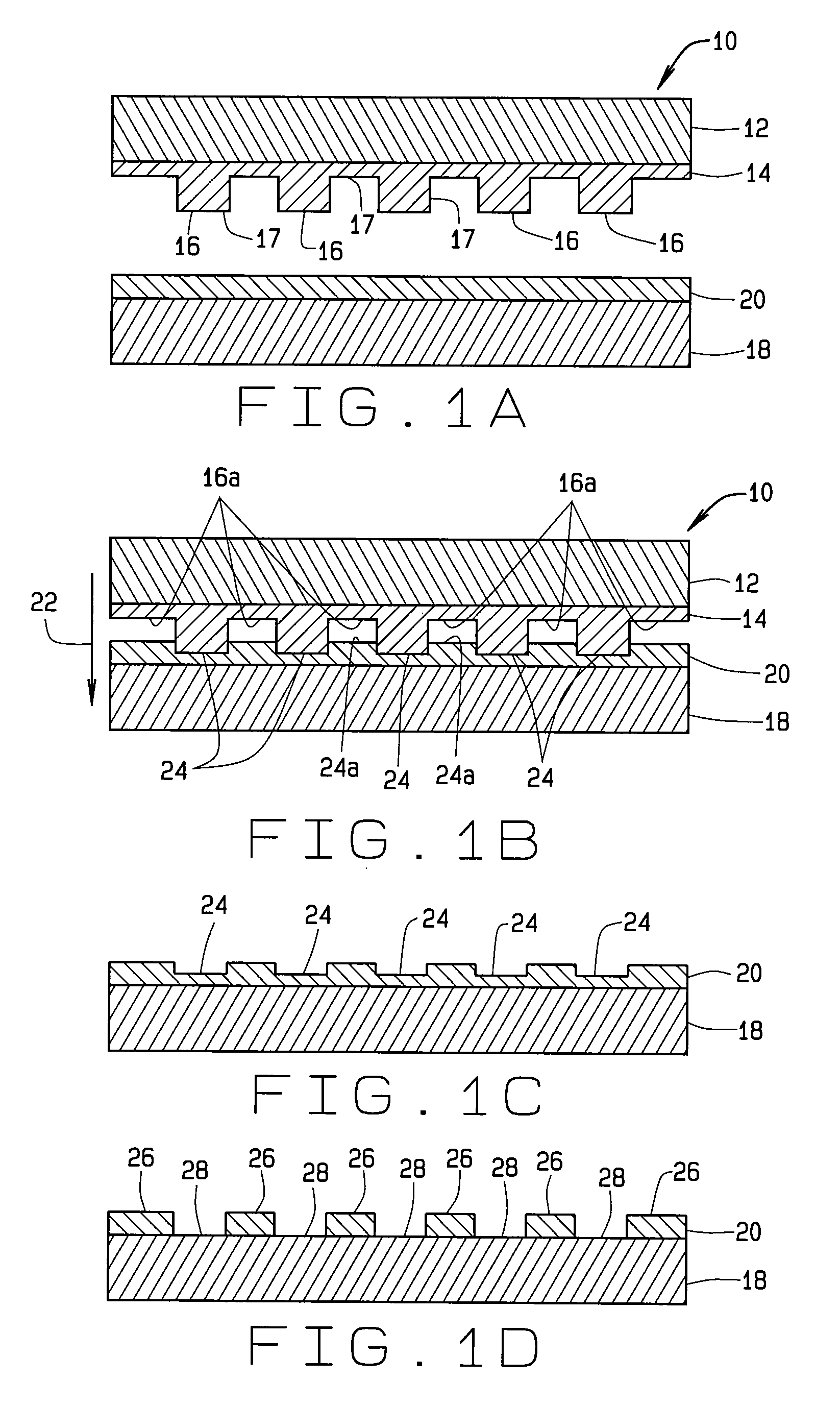

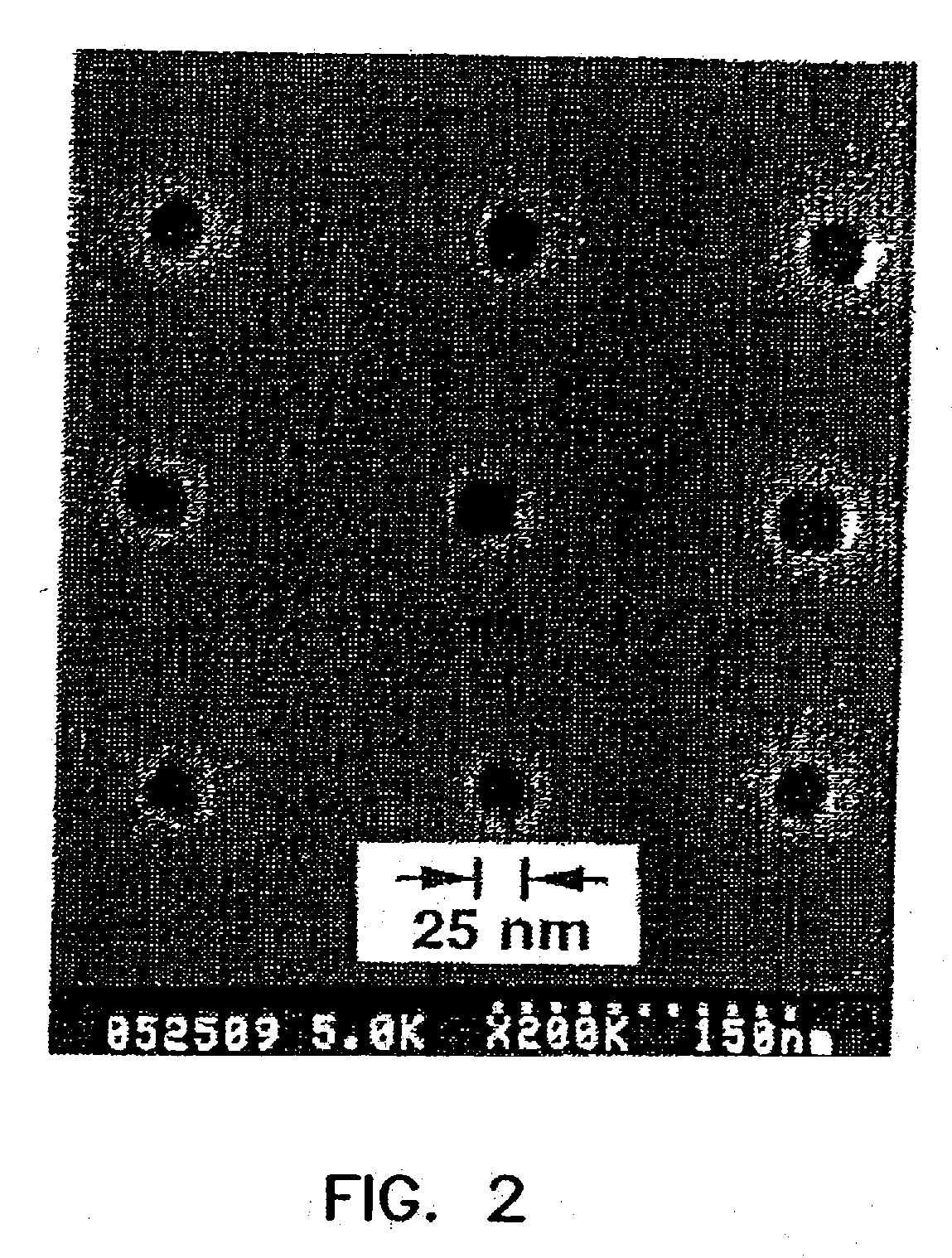

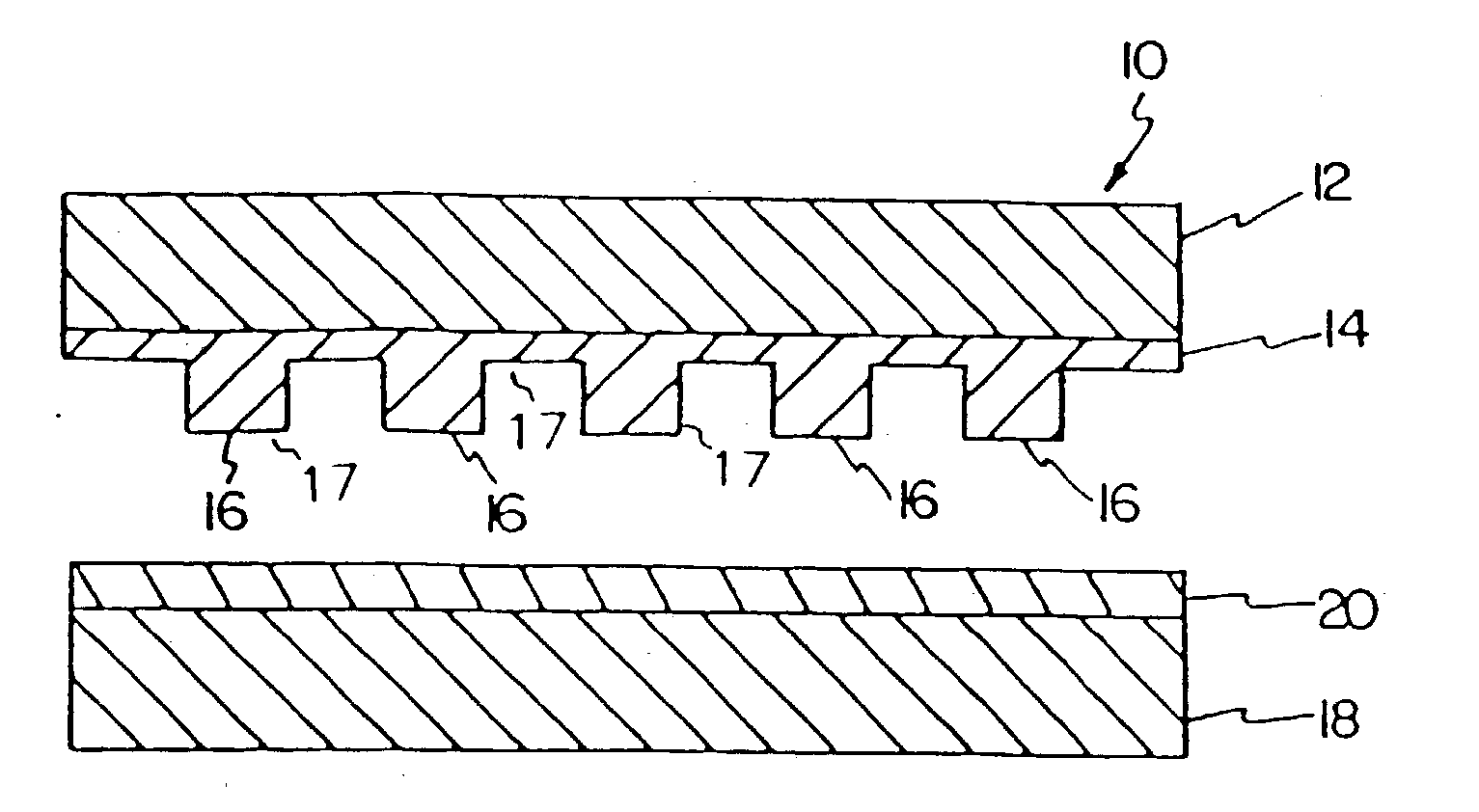

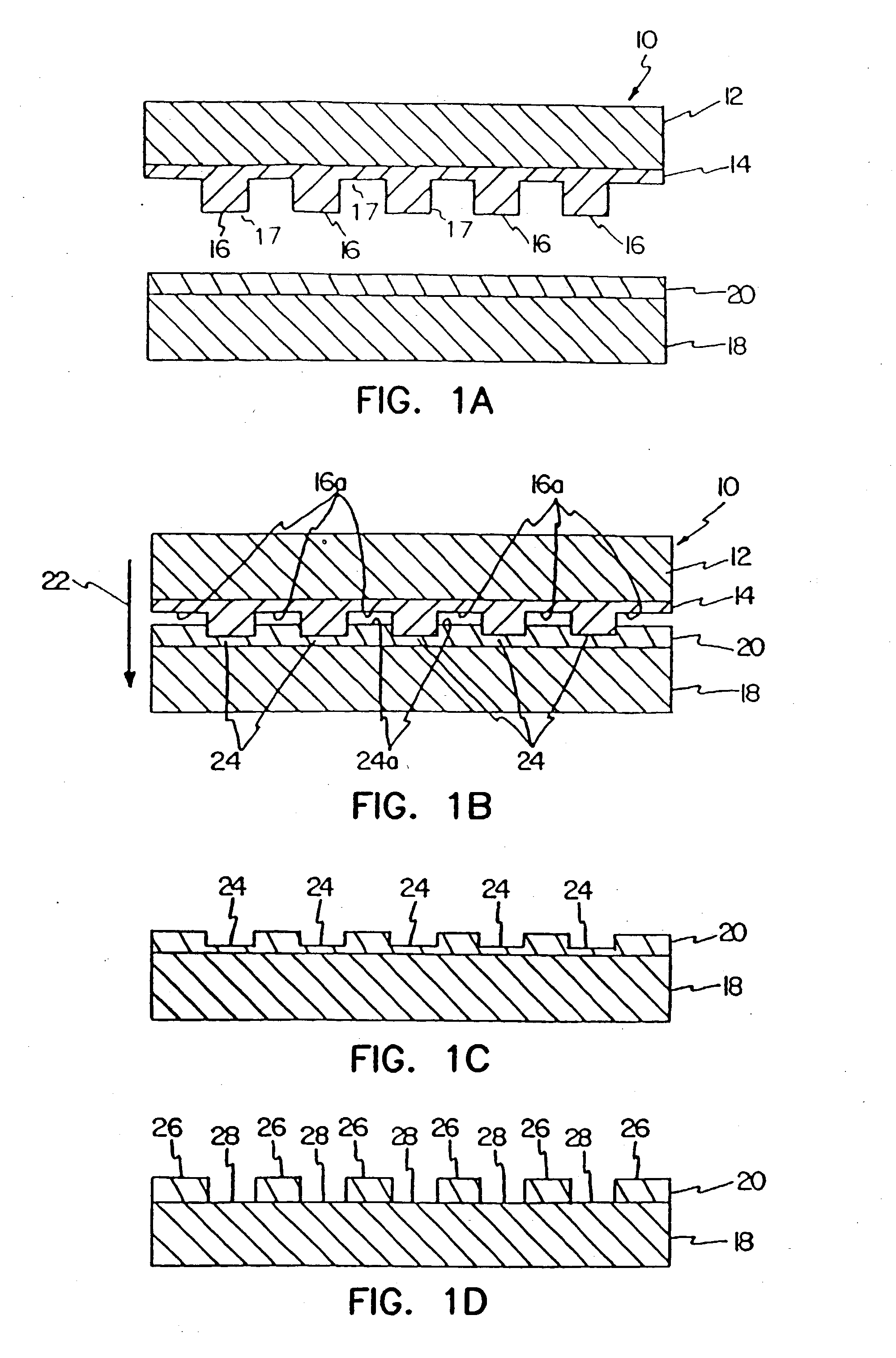

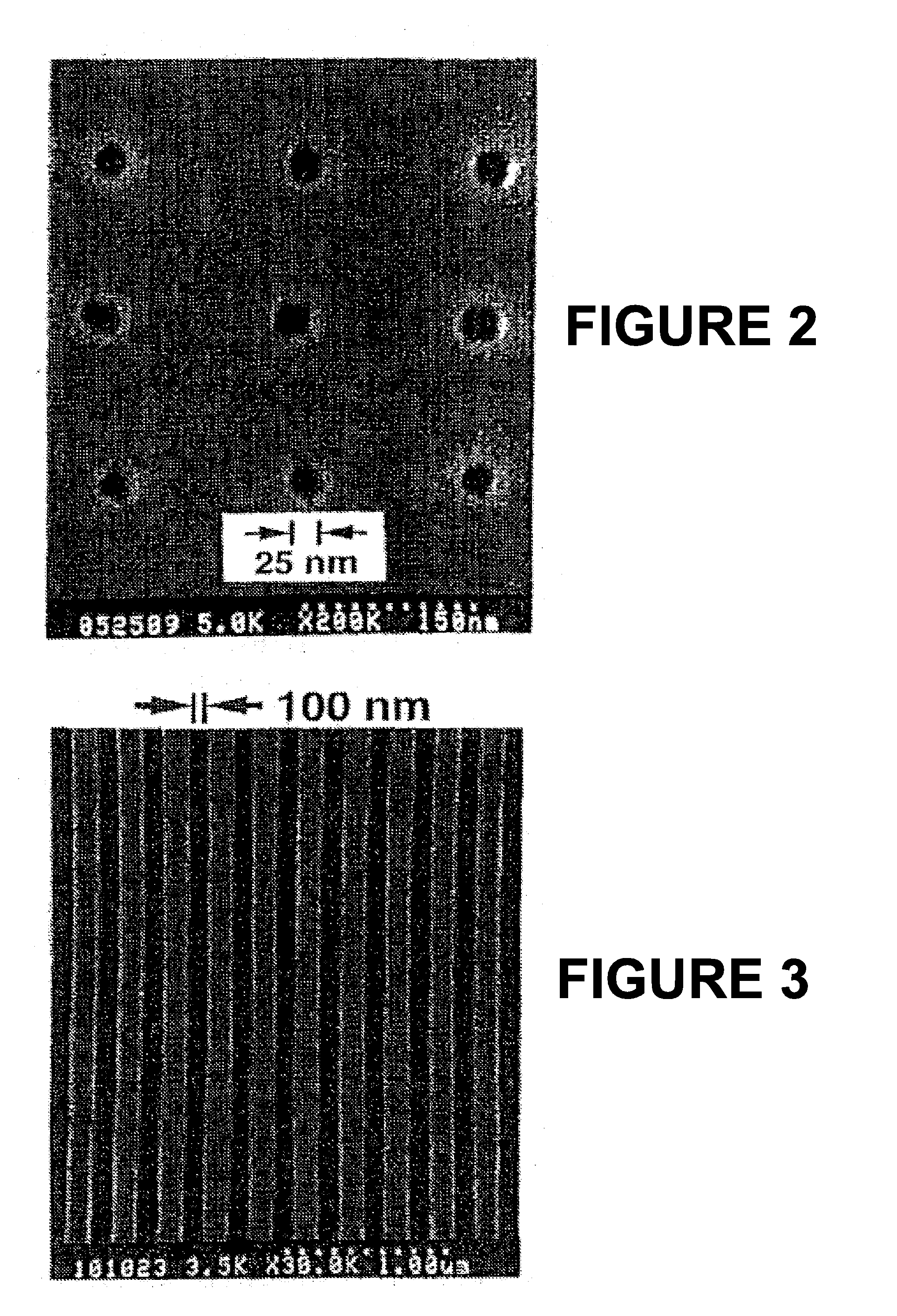

The addition of thin coatings (less than and approaching monomolecular coatings) of persistent release materials comprising preferred compounds of the formula:RELEASE-M(X)n-1—RELEASE-M(X)n-m-1Qm,OrRELEASE-M(OR)n-1—, whereinRELEASE is a molecular chain of from 4 to 20 atoms in length, preferably from 6 to 16 atoms in length, which molecule has either polar or non-polar properties;M is a metal atom, semiconductor atom, or semimetal atom;X is a halogen or cyano, especially Cl, F, or Br;Q is hydrogen or alkyl group;M is the number Q representsR is hydrogen, alkyl or phenyl, preferably hydrogen or alkyl of 1 to 4 carbon atoms; andN is the valence −1 of M,and n-m-1 is at least 1provides good release properties. The coated substrates are particularly good for a lithographic method and apparatus for creating ultra-fine (sub-25 nm) patters in a thin film coated on a substrate is provided, in which a mold having at least one protruding feature is pressed into a thin film carried on a substrate. The protruding feature in the mold creates a recess of the thin film. The mold is removed from the film. The thin film then is processed such that the thin film in the recess is removed exposing the underlying substrate. Thus, the patterns in the mold is replaced in the thin film, completing the lithography. The patterns in the thin film will be, in subsequent process, reproduced in the substrate or in another material which is added onto the substrate.

Owner:CHOU

Lithographic method for molding a pattern

InactiveUS20050146079A1Low chemical reactivityHigh resolutionDecorative surface effectsNanoinformaticsHydrogenUltra fine

The addition of thin coatings (less than and approaching monomolecular coatings) of persistent release materials comprising preferred compounds of the formula: RELEASE-M(X)n-1—RELEASE-M(X)n-m-1Qm, or RELEASE-M(OR)n-1—, wherein RELEASE is a molecular chain of from 4 to 20 atoms in length, preferably from 6 to 16 atoms in length, which molecule has either polar or non-polar properties; M is a metal atom, semiconductor atom, or semimetal atom; X is halogen or cyano, especially Cl, F, or Br; Q is hydrogen or alkyl group; m is the number of Q groups; R is hydrogen, alkyl or phenyl, preferably hydrogen or alkyl of 1 to 4 carbon atoms; and; n is the valence −1 of M, and n−m−1 is at least 1 provides good release properties. The coated substrates are particularly good for a lithographic method and apparatus for creating ultra-fine (sub-25 nm) patterns in a thin film coated on a substrate is provided, in which a mold having at least one protruding feature is pressed into a thin film carried on a substrate. The protruding feature in the mold creates a recess of the thin film. The mold is removed from the film. The thin film then is processed such that the thin film in the recess is removed exposing the underlying substrate. Thus, the patterns in the mold is replaced in the thin film, completing the lithography. The patterns in the thin film will be, in subsequent processes, reproduced in the substrate or in another material which is added onto the substrate.

Owner:CHOU

Release surfaces, particularly for use in nanoimprint lithography

InactiveUS20080143019A1Low chemical reactivityHigh resolutionNanoinformaticsPhotomechanical apparatusHydrogenHalogen

The addition of thin coatings (less than and approaching monomolecular coatings) of persistent release materials comprising preferred compounds of the formula:RELEASE-M(X)n−1-RELEASE-M(X)n−m−1 Qm,OrRELEASE-M(OR)n−1-,whereinRELEASE is a molecular chain of from 4 to 20 atoms in length, preferably from 6 to 16 atoms in length, which molecule has either polar or non-polar properties;M is a metal atom, semiconductor atom, or semimetal atom;X is a halogen or cyano, especially Cl, F, or Br;Q is hydrogen or alkyl group;M is the number Q representsR is hydrogen, alkyl or phenyl, preferably hydrogen or alkyl of 1 to 4 carbon atoms; andN is the valence −1 of M,and n−m−1 is at least 1provides good release properties. The coated substrates are particularly good for a lithographic method and apparatus for creating ultra-fine (sub-25 nm) patters in a thin film coated on a substrate is provided, in which a mold having at least one protruding feature is pressed into a thin film carried on a substrate. The protruding feature in the mold creates a recess of the thin film. The mold is removed from the film. The thin film then is processed such that the thin film in the recess is removed exposing the underlying substrate. Thus, the patterns in the mold is replaced in the thin film, completing the lithography. The patterns in the thin film will be, in subsequent process, reproduced in the substrate or in another material which is added onto the substrate.

Owner:RGT UNIV OF MINNESOTA

Lithographic apparatus for molding ultrafine features

InactiveUS20060127522A1Low chemical reactivityHigh resolutionConfectioneryNanoinformaticsEngineeringLithography

An apparatus for performing imprint lithography especially useful in creating patterns with ultrafine features on a substrate. The apparatus comprises a substrate having moldable surface carried on a first block, a mold having a molding surface carried on a second block, positioners for moving the first and second blocks relative to each other, a sensor of the relative positions of the blocks and a controller for controlling the relative positions of the blocks.

Owner:RGT UNIV OF MINNESOTA

Molten metal rechargeable electrochemical cell

InactiveUS20170149095A1Low costHigh commercial availabilityCell electrodesSecondary cellsElectrical batteryElectrochemical cell

The present invention provides rechargeable electrochemical cells comprising a molten anode, a cathode, and a non-aqueous electrolyte salt, wherein the electrolyte salt is situated between the molten anode and the cathode during the operation of the electrochemical cell, and the molten anode comprises an aluminum material; also provided are batteries comprising a plurality of such rechargeable electrochemical cells and processes for manufacturing such rechargeable electrochemical cells.

Owner:EOS ENERGY STORAGE

Surface-treated pigments

ActiveUS20060042510A1Improve chemical qualityImprove physical qualityInorganic pigment treatmentPolyolInorganic pigments

Inorganic pigments, having deposited on the pigment surface at least one alkenyl- or alkyl-substituted succinic anhydride and at least one organic polyol, possess improved processibility and dispersibility in thermoplastic materials, and impart improved properties to thermoplastic compositions containing said surface-treated pigments.

Owner:TRONOX LLC

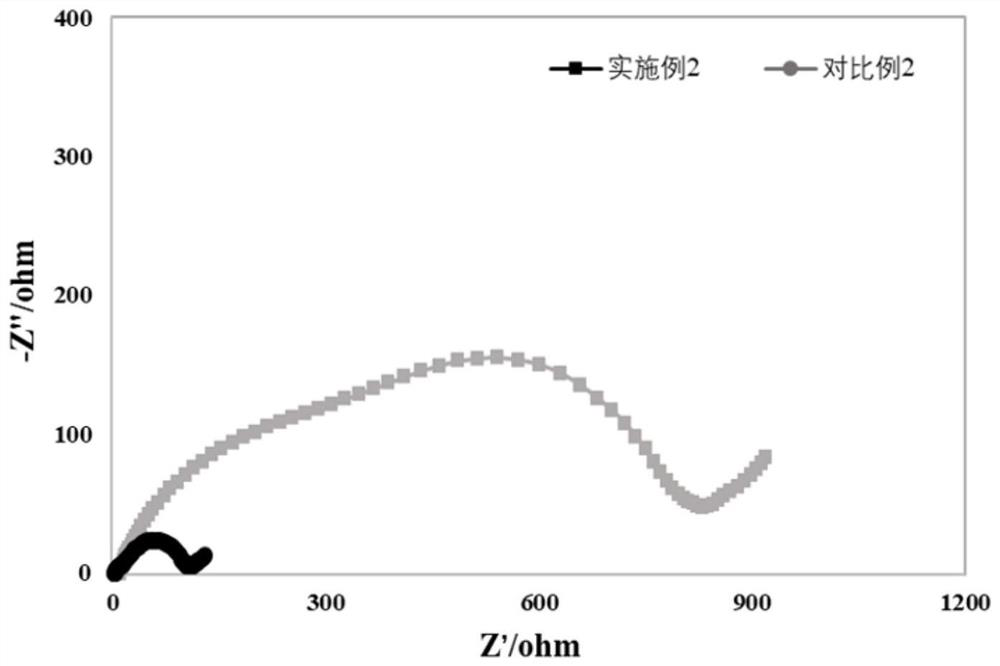

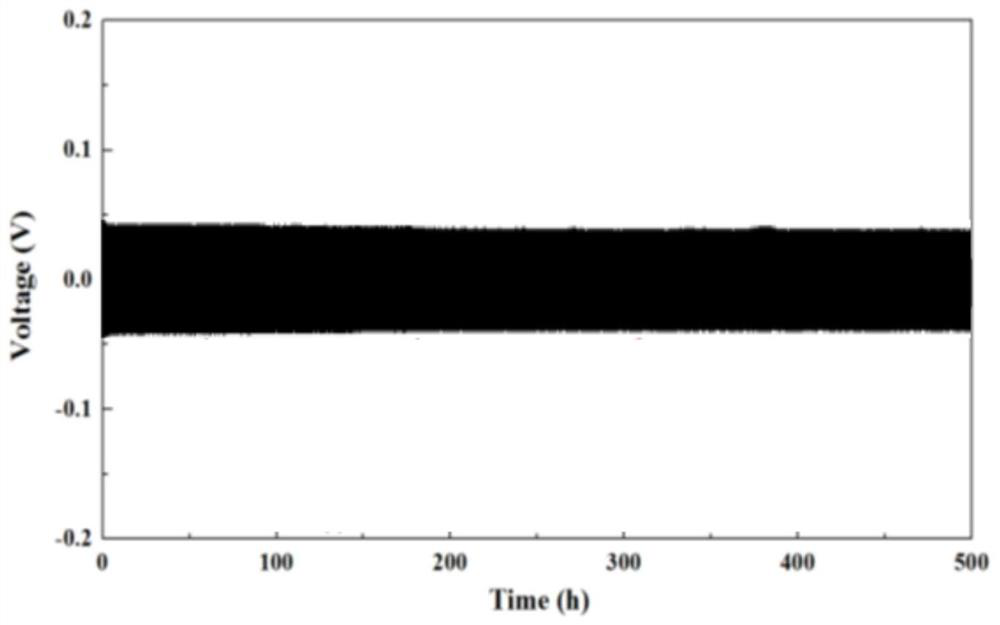

Interface layer and lithium ion battery comprising same

PendingCN113451580AImprove interface contact performanceImprove interfacial wettabilityCell electrodesSecondary cellsMetallic lithiumSolid state electrolyte

The invention relates to the technical field of lithium ion batteries, in particular to an interface layer and a lithium ion battery comprising the interface layer. Lithium halide generated by the in-situ reaction at the interface of a solid electrolyte and a metal lithium negative electrode can optimize the interface contact property and the interface wettability and provide a rapid ion diffusion path. The metal particles generated by the in-situ reaction at the interface of the solid electrolyte and the metal lithium negative electrode can guide the uniform distribution of an electric field, regulate and control the uniform deposition of the metal lithium in the circulation process, and inhibit the formation and growth of lithium dendrites. The lithium ion battery provided by the invention can effectively stabilize the interface between the electrode and the electrolyte, reduces the chemical reaction activity of the metal lithium negative electrode, avoids the side reaction at the interface, and shows higher cycling stability and coulombic efficiency in continuous charge-discharge cycles.

Owner:ZHUHAI COSMX BATTERY CO LTD

Release surfaces, particularly for use in nanoimprint lithography

InactiveUS20080164637A1Low chemical reactivityHigh resolutionNanoinformaticsPhotomechanical apparatusUltra fineNanoimprint lithography

The present invention relates to release surfaces, particularly release surfaces with fine features to be replicated, and to lithography which may be used to produce integrated circuits and microdevices. More specifically, the present invention relates to a process of using an improved mold or microreplication surface that creates patterns with ultra fine features in a thin film carried on a surface of a substrate.

Owner:CHOU

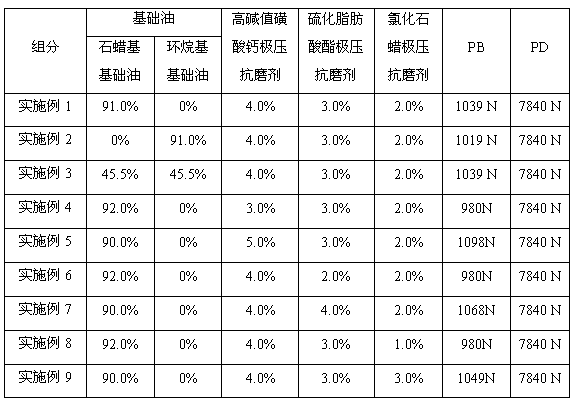

Oil-soluble gravity cutting oil

InactiveCN102703174ALow chemical reactivityAchieve lubricationAdditivesLow loadChlorinated paraffins

The invention discloses oil-soluble gravity cutting oil. The oil-soluble gravity cutting oil comprises the following components in percentage by weight: 88.0-94.0 percent of base oil, 3.0-5.0 percent of high-alkaline calcium sulfonate extreme pressure anti-wear additive, 2.0-4.0 percent of vulcanized fatty acid ester extreme pressure anti-wear additive and 1.0-3.0 percent of chlorcosane extreme pressure anti-wear additive. According to the oil-soluble gravity cutting oil disclosed by the invention, the high-alkaline calcium sulfonate extreme pressure anti-wear additive, the vulcanized fatty acid ester extreme pressure anti-wear additive and the chlorcosane extreme pressure anti-wear additive are added; and a compound formula of three additives can realize the lubrication from low temperature to high temperature and from low load to high load born by gravity cutting. Therefore, the oil-soluble gravity cutting oil disclosed by the invention can meet the harsh requirement of gravity cutting processing.

Owner:重庆德蒙特科技发展有限公司

Release surfaces, particularly for use in nanoimprint lithography

InactiveUS20100233309A1Low chemical reactivityHigh resolutionNanoinformaticsConfectioneryUltra fineNanoimprint lithography

The present invention relates to release surfaces, particularly release surfaces with fine features to be replicated, and to lithography which may be used to produce integrated circuits and microdevices. More specifically, the present invention relates to a process of using an improved mold or microreplication surface that creates patterns with ultra fine features in a thin film carried on a surface of a substrate.

Owner:CHOU

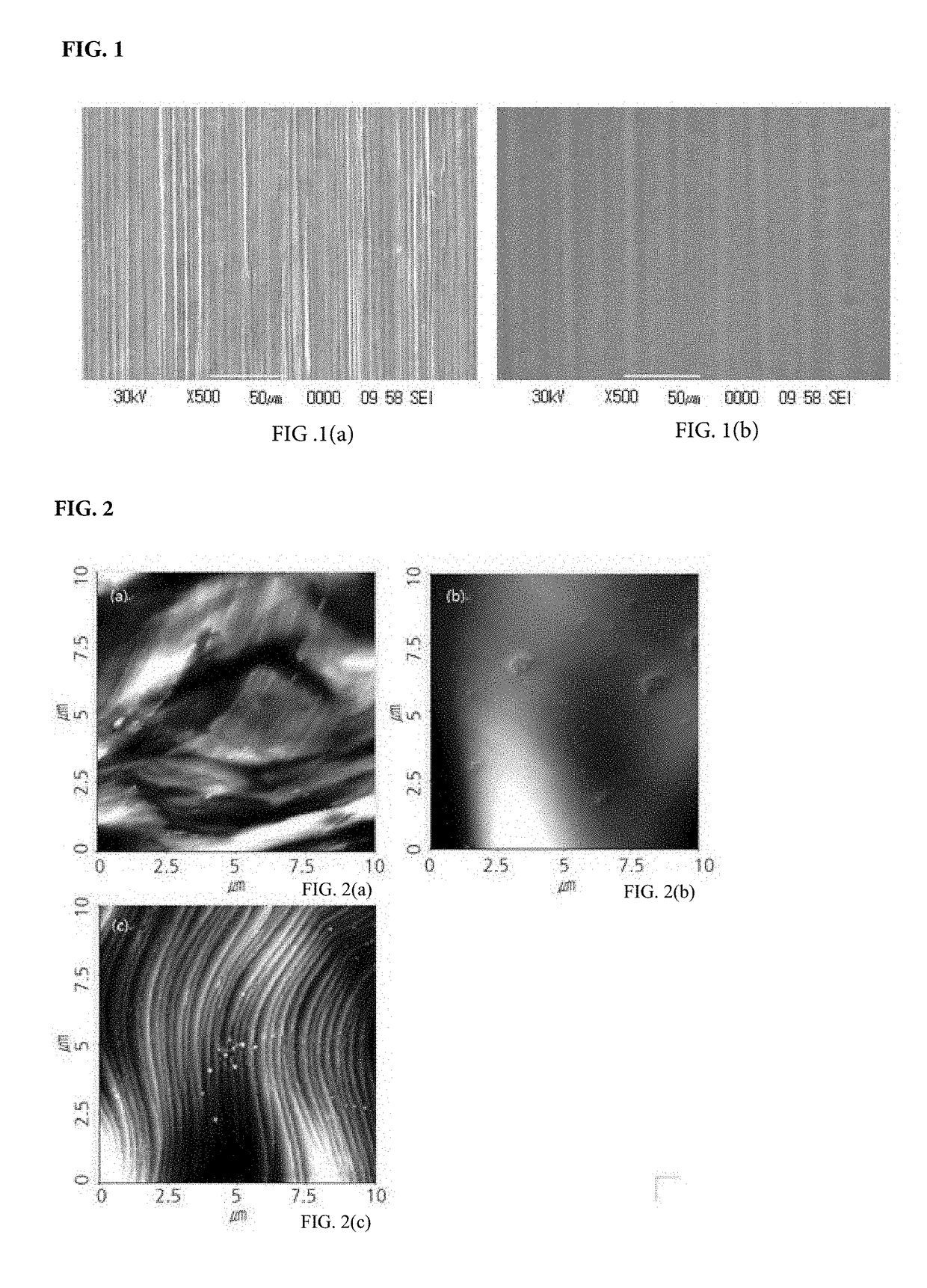

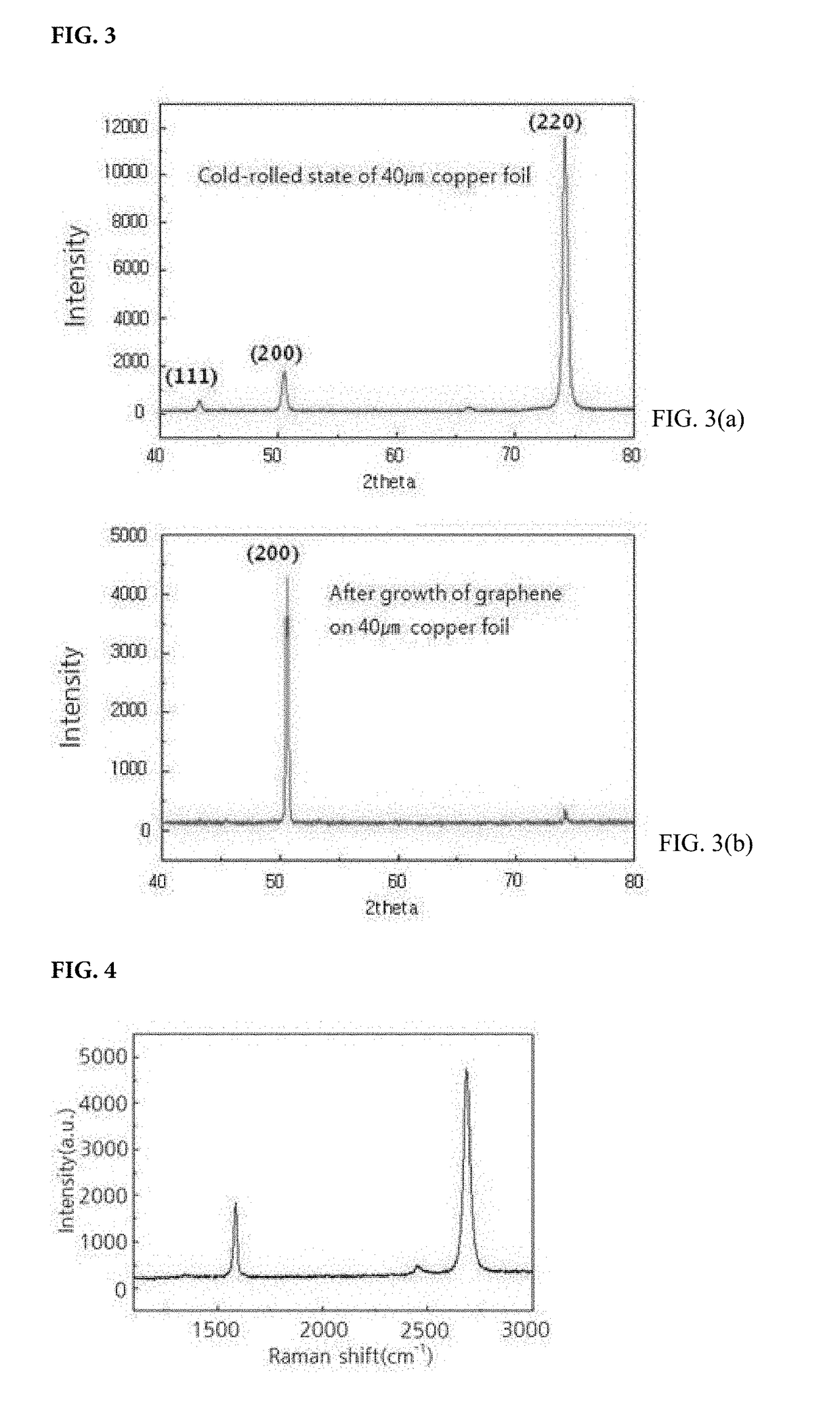

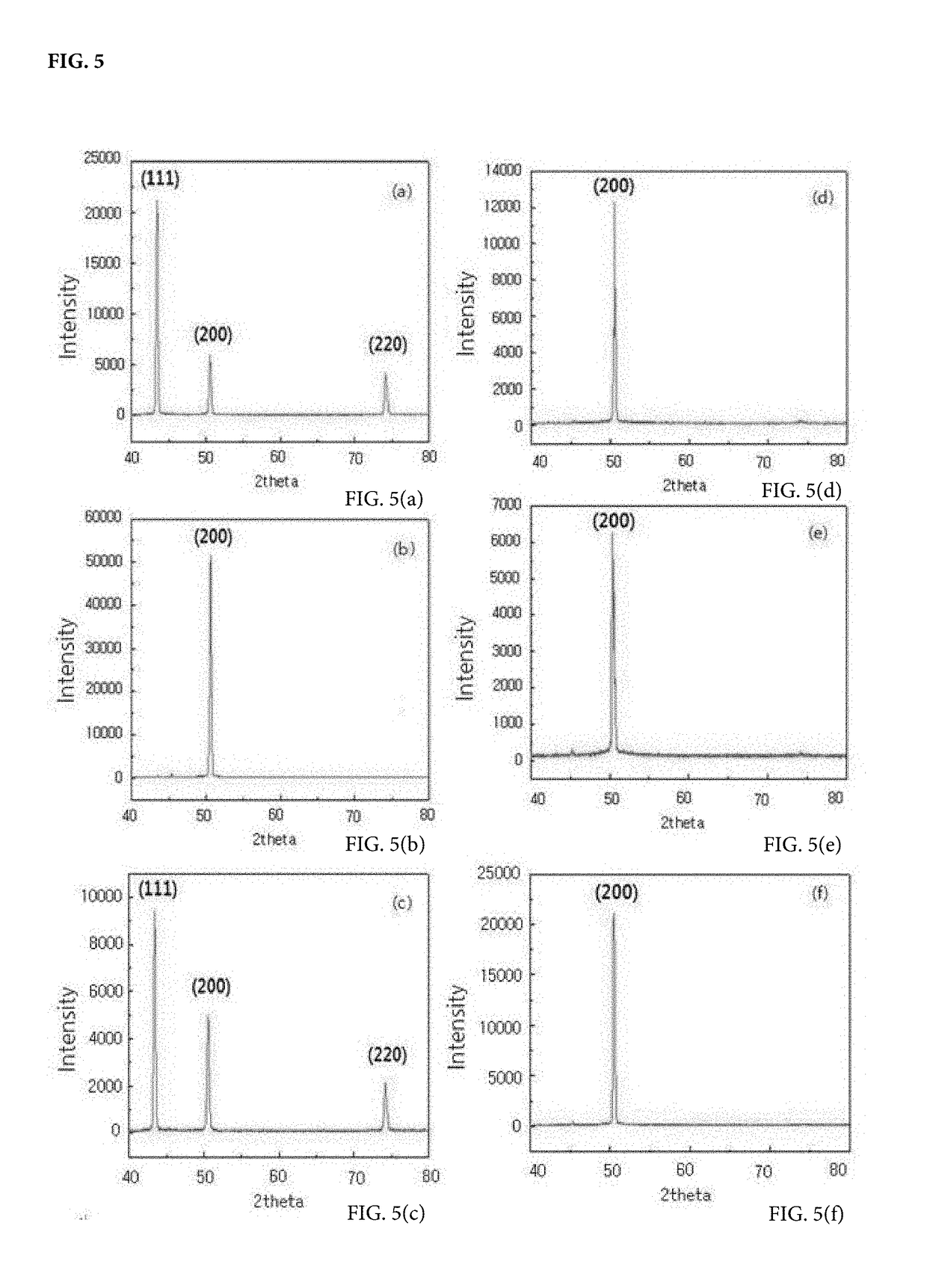

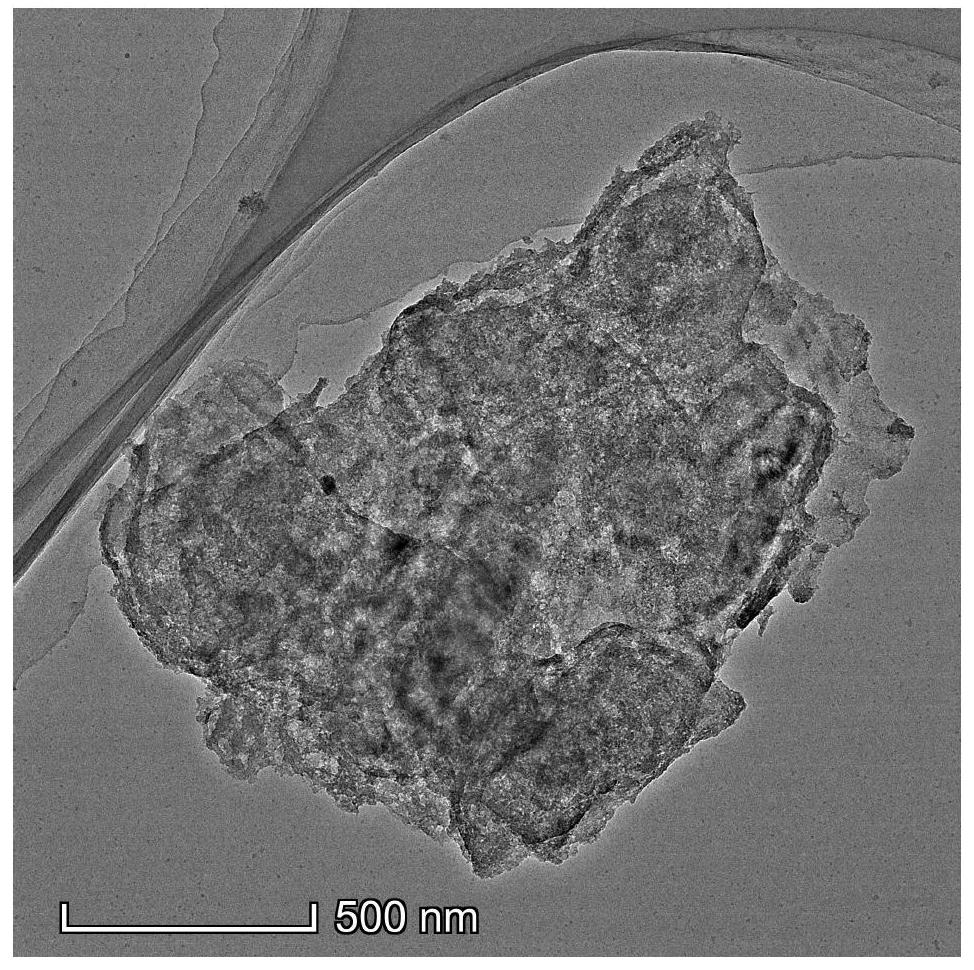

Method of manufacturing graphene using metal catalyst

The present invention relates to a method for producing graphene on a face-centered cubic metal catalyst having a plane oriented in one direction, and more particularly to a method of producing graphene on a metal catalyst having the (100) or (111) crystal structure and a method of producing graphene using a catalyst metal foil having a single orientation, obtained by electroplating a metal catalyst by a pulse wave current and annealing the metal catalyst. The invention also relates to a method of producing graphene using a metal catalyst, and more particularly to a method of producing graphene, comprising the steps of: alloying a metal catalyst with an alloying element; forming step structures on the metal catalyst substrate in an atmosphere of a gas having a molecular weight of carbon; and supplying hydrocarbon and hydrogen gases to the substrate. On unidirectionally oriented metal catalyst prepared according to the present invention, graphene can be grown uniformly and epitaxially. Moreover, a method for producing graphene according to the present invention can form monolayer graphene by epitaxially growing graphene while increasing the growth rate of graphene.

Owner:SRC INC

Sn-Zn-Cr alloy lead-free solder preparation method

Disclosed is a Sn-Zn-Cr alloy lead-free solder preparation method which comprises, (1) preparation of Sn-Cr intermediate alloy, which consists of mixing Cr 0.005-1.5%, Zn 3-12%, and balancing Sn, elevating temperature to above the fusion point of the metal Cr, melting and thermally insulating, fully stirring, charging the residue Sn raw material into the furnace, waiting for dissolution, cooling down, thermally insulating, continuing stirring simultaneously, (2) smelting of Sn-Zn-Cr alloy, which consists of charging the Zn raw material into melting Sn-Cr intermediate alloy, waiting for complete dissolution, fully stirring, thermally insulating, cooling down, thermally insulating while agitating continuously, finally cooling down to room temperature or casting as requirement.

Owner:SHANGHAI JIAO TONG UNIV

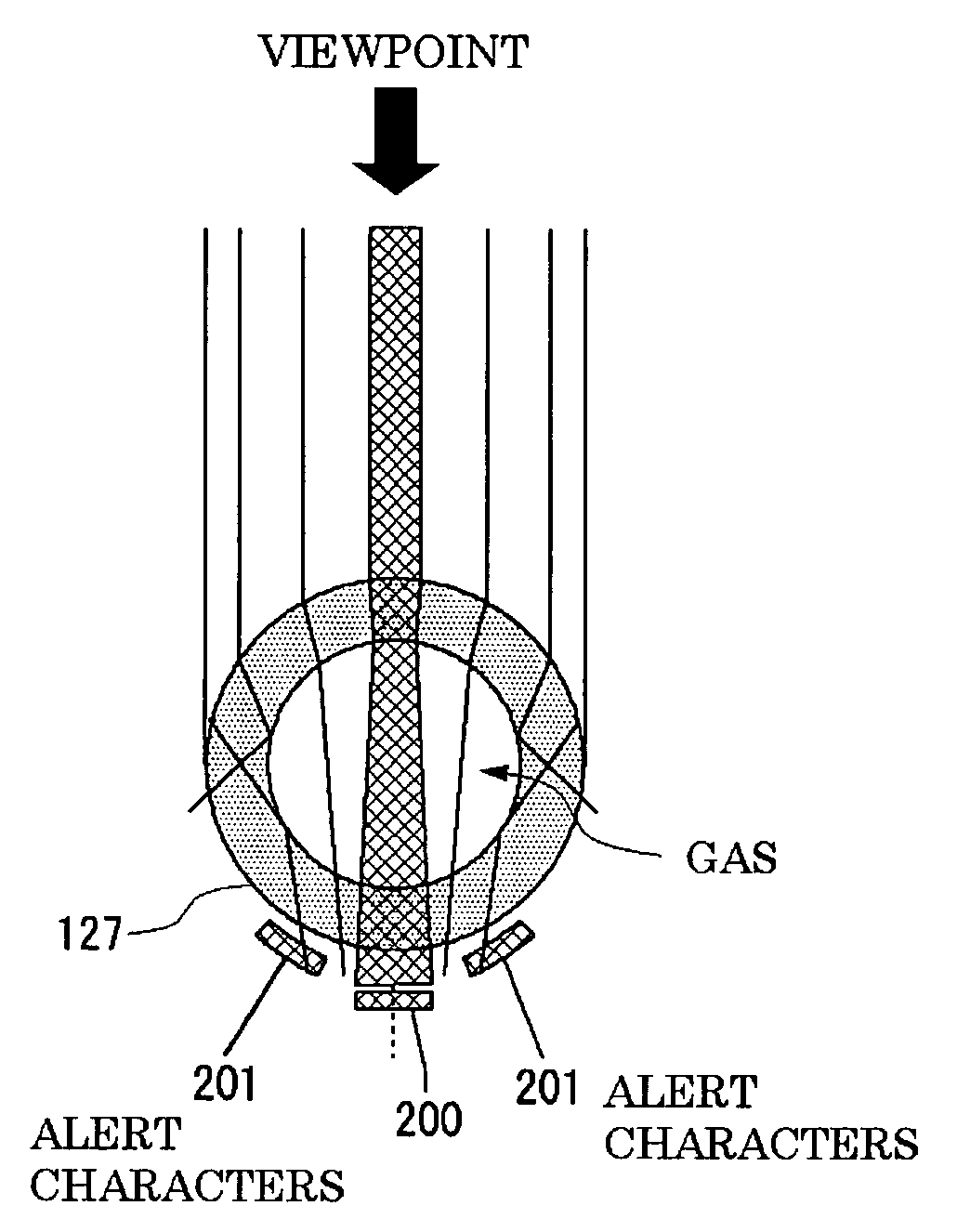

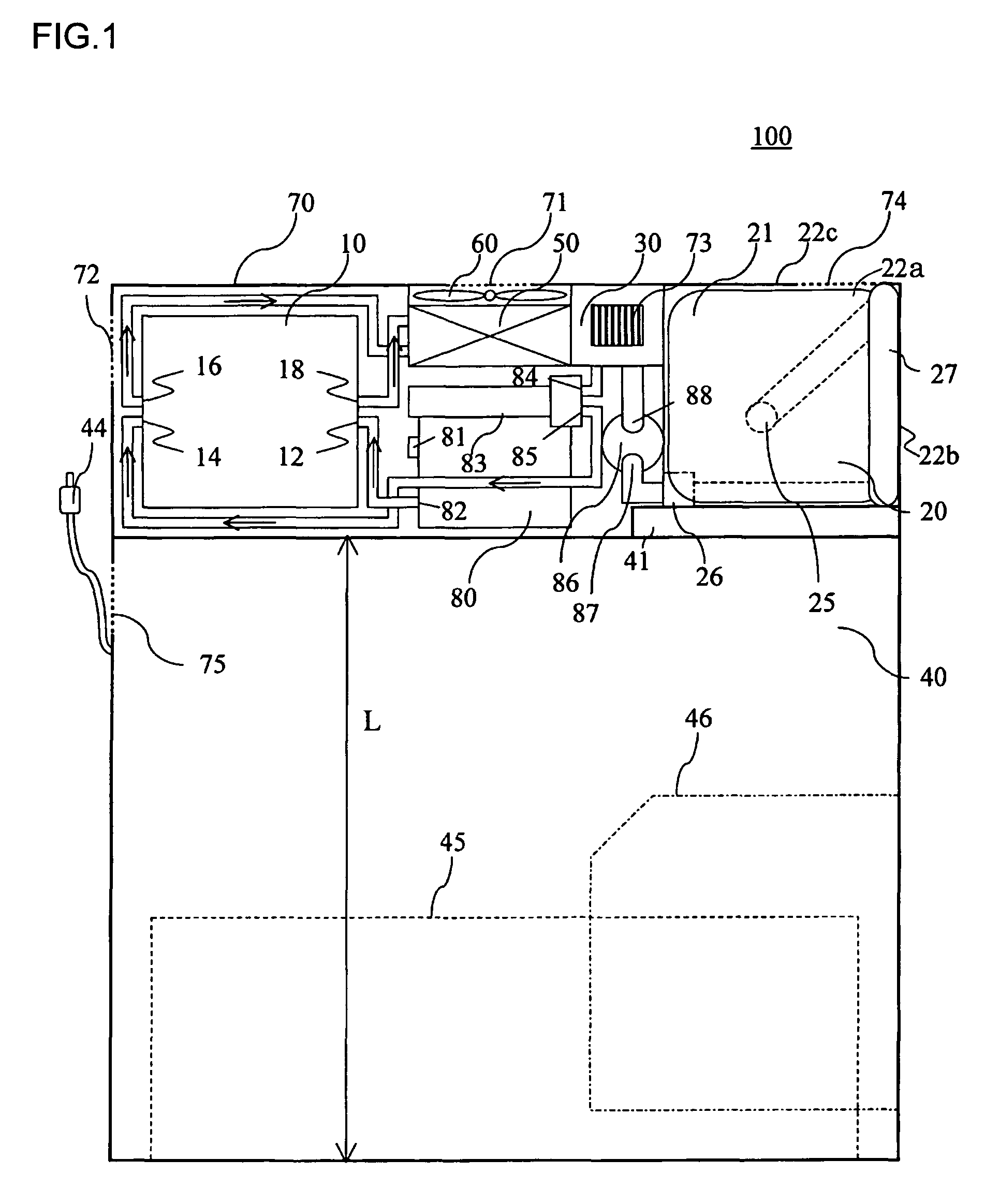

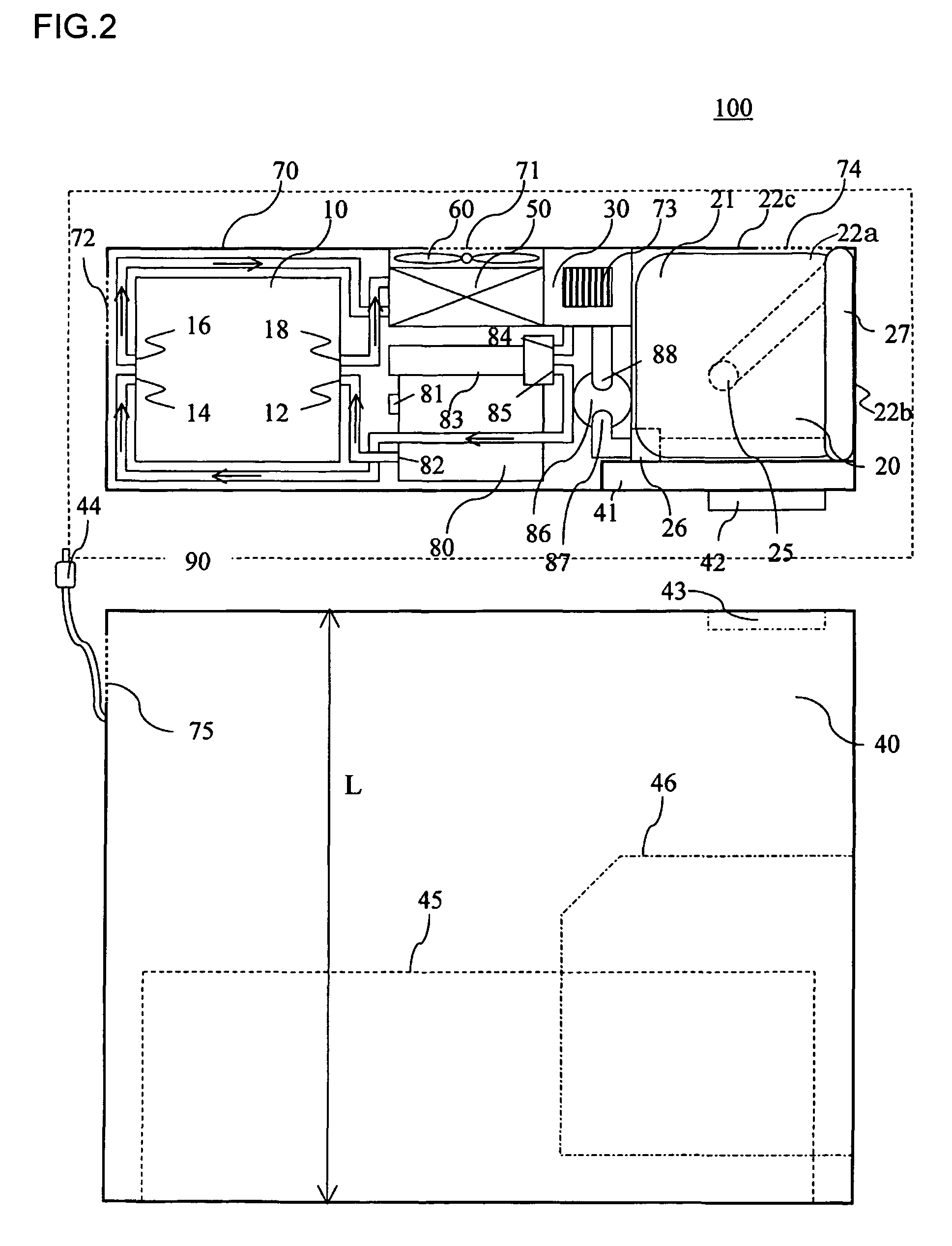

Liquid tank and fuel cell system with fuel monitoring

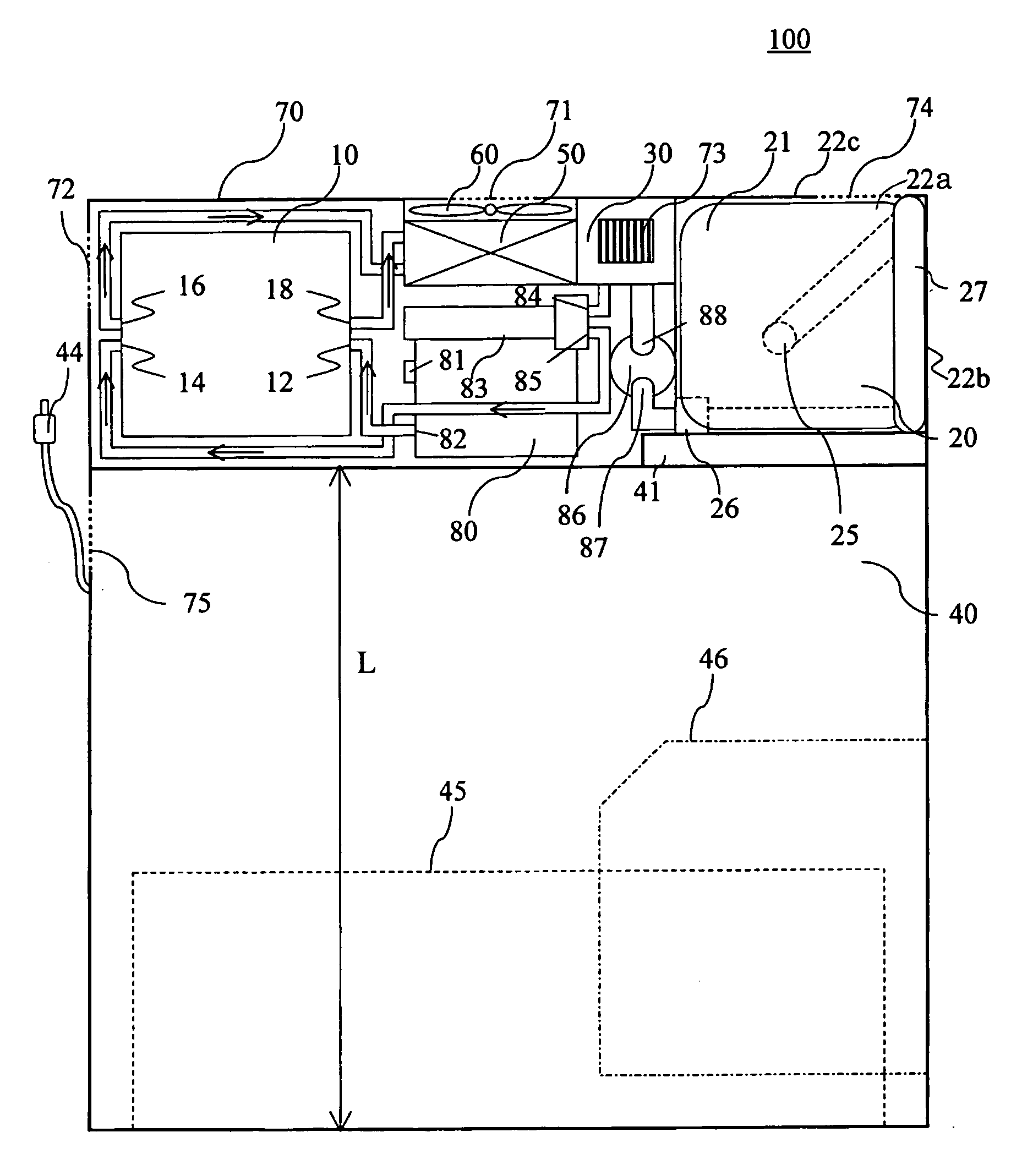

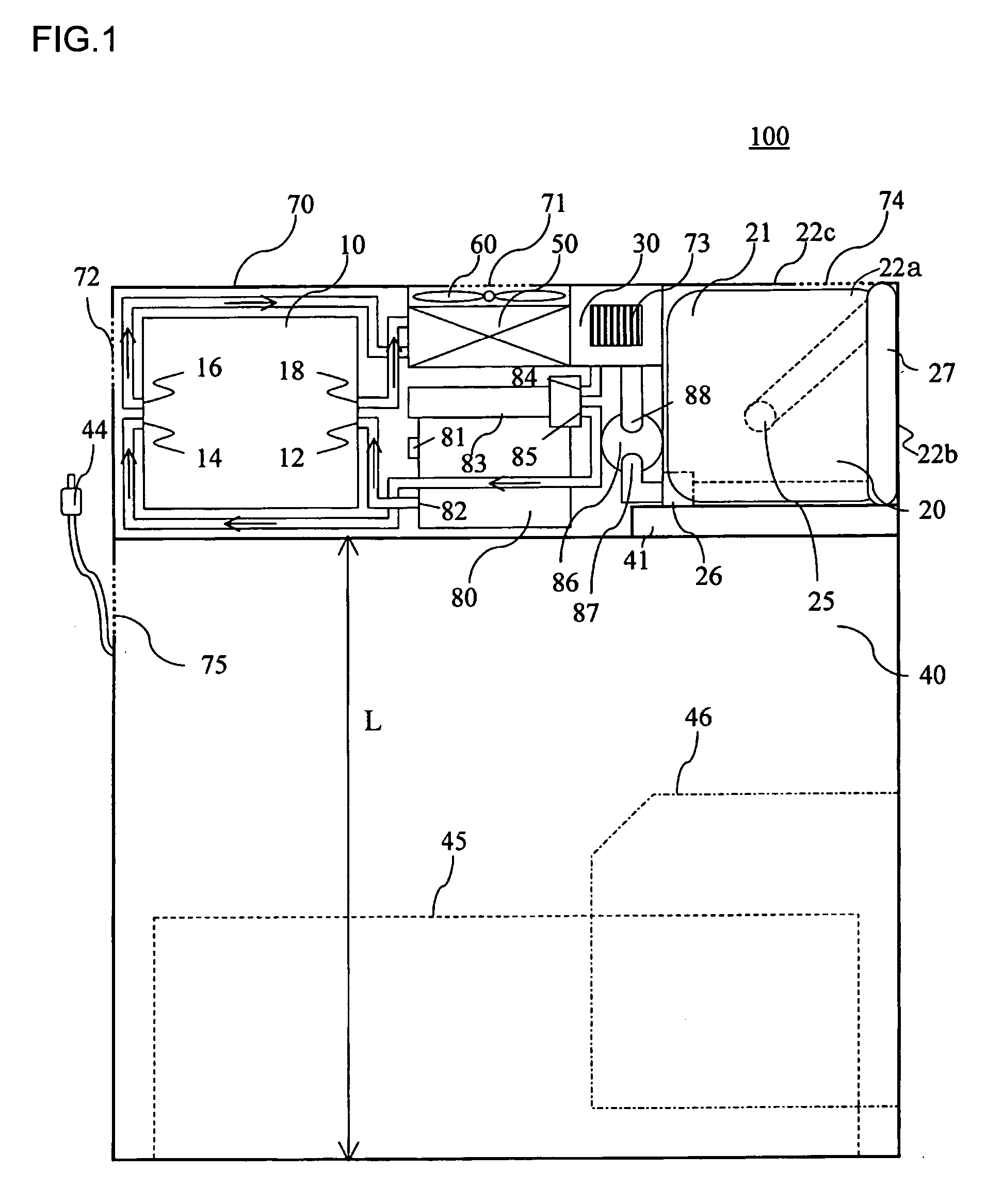

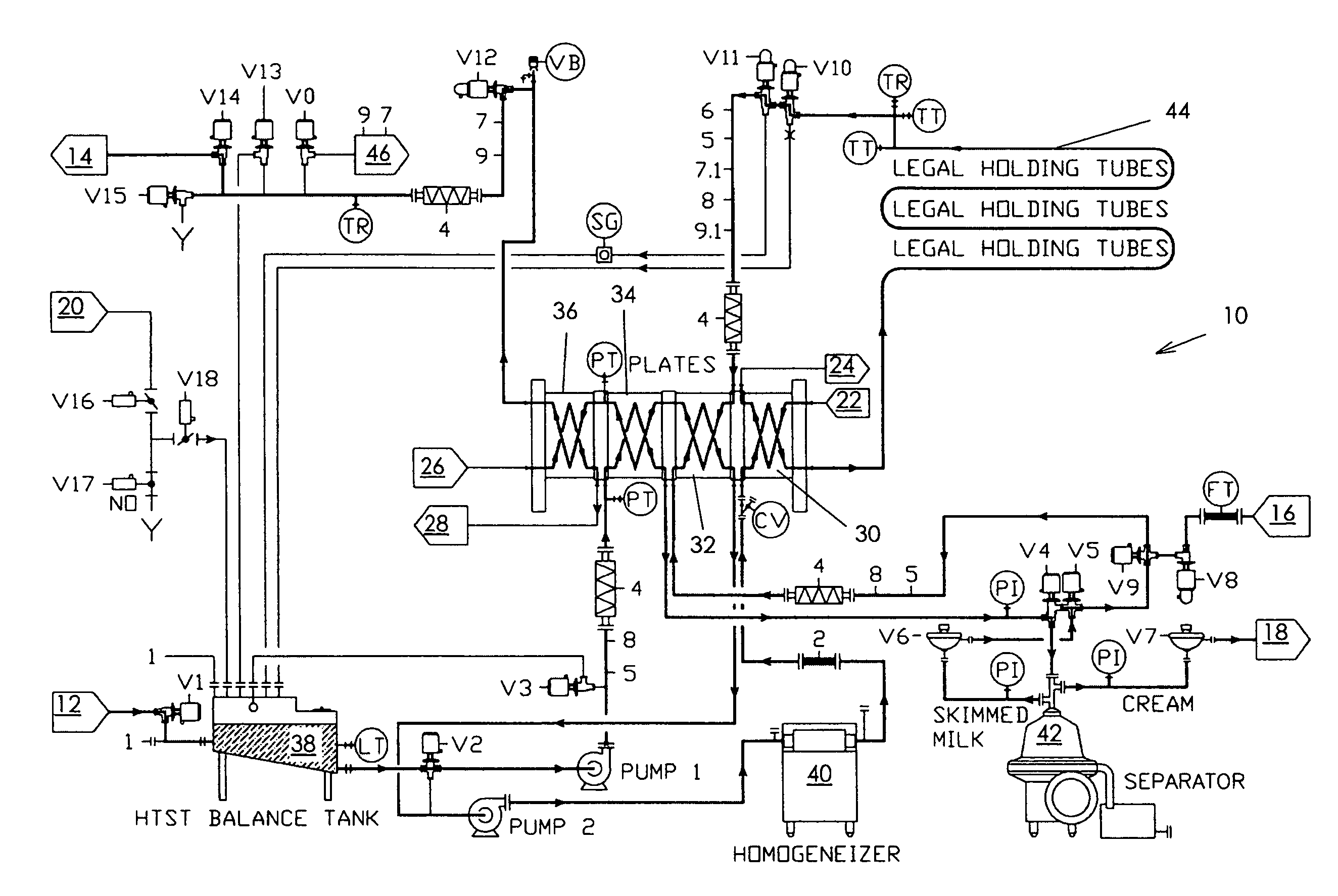

InactiveUS20060228595A1Easy to monitorEasy to knowReactant parameters controlSecondary cellsFuel cellsEngineering

A liquid tank includes: a first container; a second container provided in the first container to contain liquid and gas; a joint which is provided in the first container and discharges the liquid outside the first container; an outlet pipe which connects the joint to the second container; and a remaining indicator window provided to make the interior of the outlet pipe viewable.

Owner:SANYO ELECTRIC CO LTD

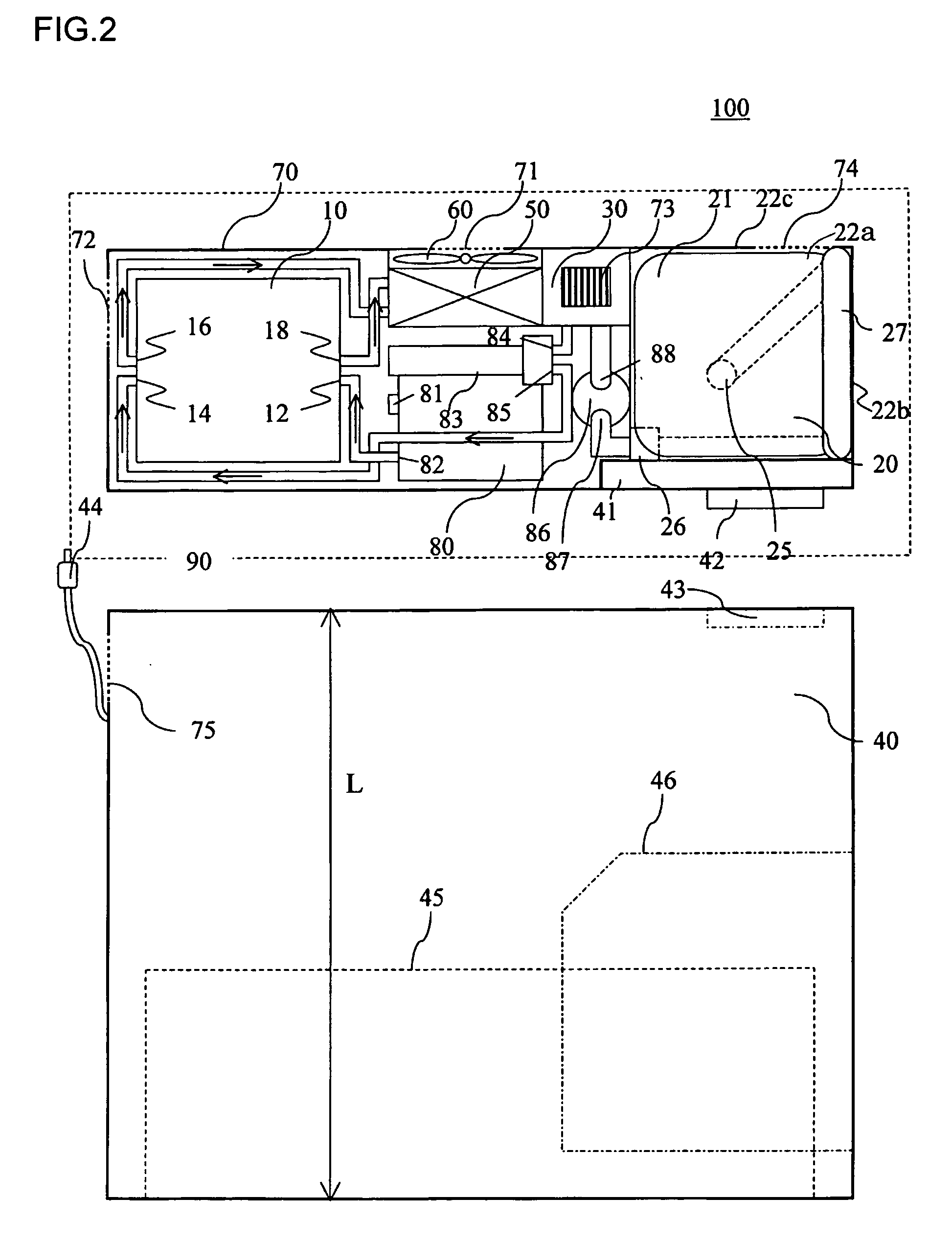

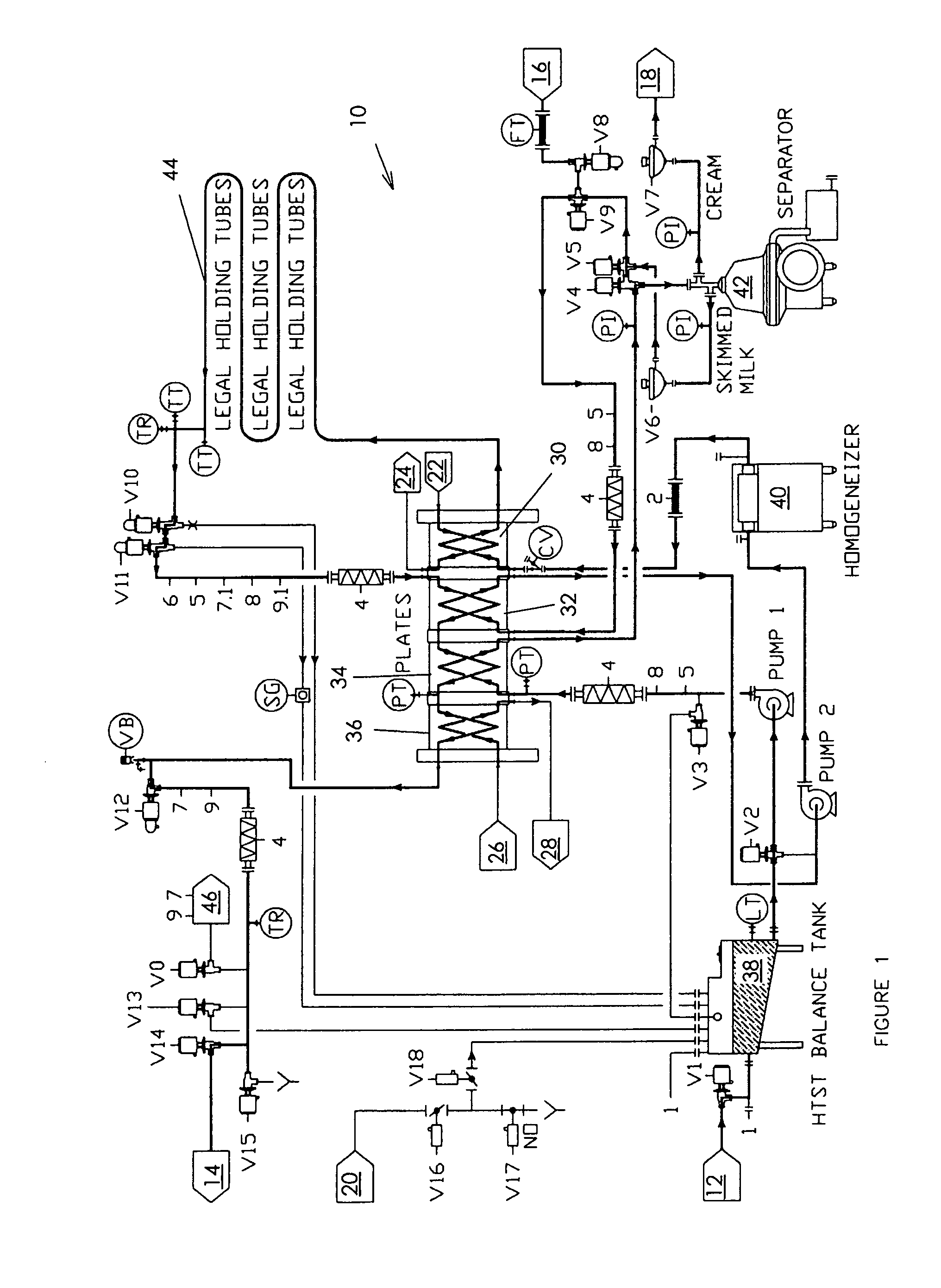

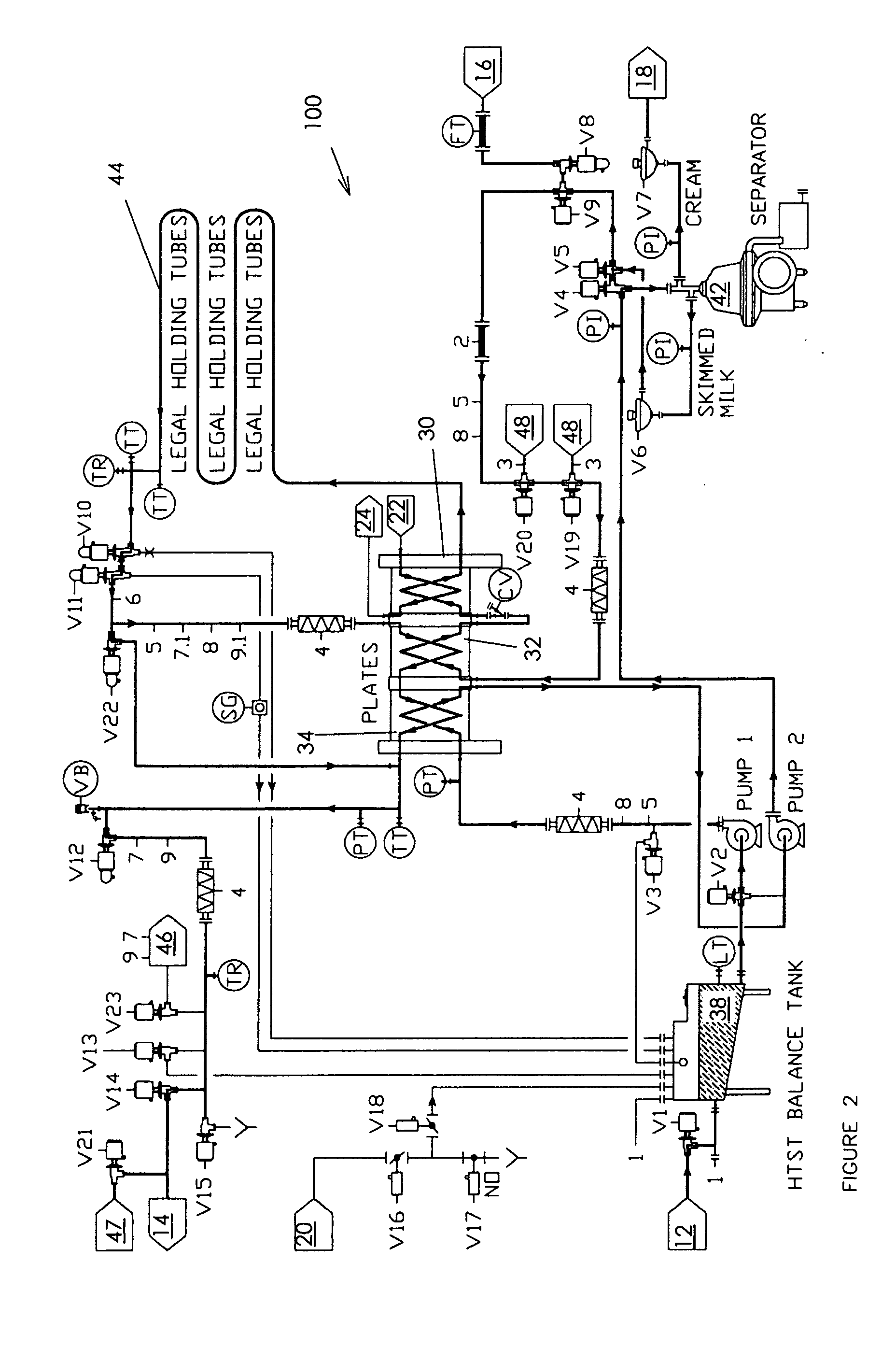

Method for controlling microbiological contamination in a heat exchanger while processing a food product.

ActiveUS20160192669A1Low chemical reactivityMany pointsMilk preservationFood preservationChemical reactionEngineering

A method for controlling microbiological contamination in a heat exchanger while using the heat exchanger to process a food product. The method includes: while processing the food product in the heat exchanger, adding a microbiological control agent to the food product at a first location; and neutralizing at least partially the microbiological control agent by adding a neutralizing agent to the food product at a second location, the second location being downstream from the first location, at least part of the heat exchanger being between the first and second locations, the neutralizing agent being operative for reducing a chemical reactivity of the microbiological control agent in the food product. The microbiological control agent controls the microbiological contamination in the heat exchanger while the food product is processed. In some embodiments, the food product is a milk product.

Owner:LAUZON NORMAND

Non-Ferrous Metal Cover Gases

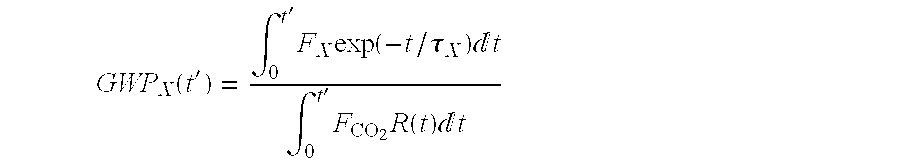

InactiveUS20080003127A1Low chemical reactivityPrevent and at least substantially inhibit oxidationOrganic chemistryGas emission reductionGas compositionNonferrous metal

Disclosed are cover gas compositions comprising fluoroolefins for impeding the oxidation of molten nonferrous metals and alloys, such as magnesium.

Owner:HONEYWELL INT INC

Secondary battery

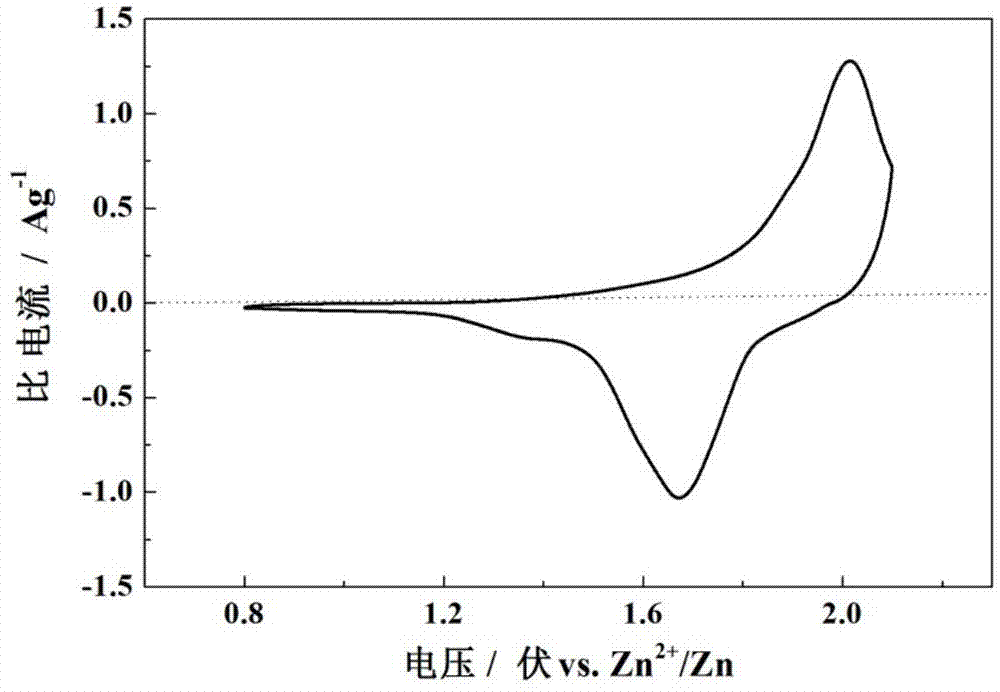

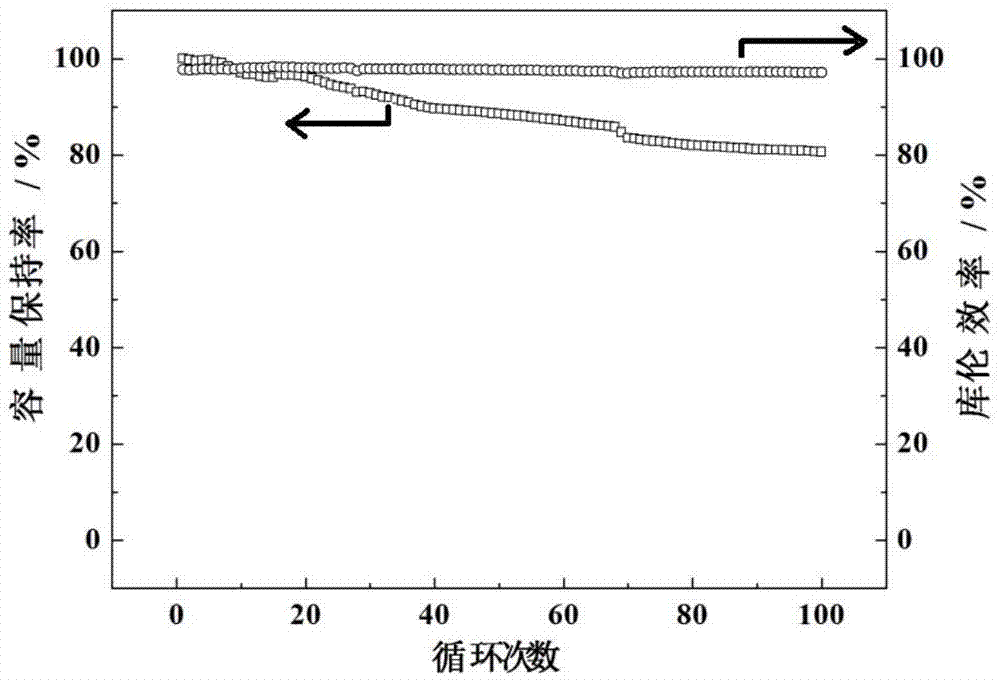

ActiveCN103972582AImprove Coulombic efficiencyNot prone to explosionCell electrodesSecondary cellsSpace groupIron cyanide

The invention provides a secondary battery. The secondary battery comprises a positive electrode, a negative electrode, and an isolating membrane and electrolyte which are arranged between the positive electrode and the negative electrode; the positive electrode comprises a divalent metal ion iron cyanide complex; the secondary battery adopts the divalent metal ion iron cyanide complex as an positive electrode active material; the divalent metal ion iron cyanide complex is of a rhombohedral structure, belongs to the R-3c space group, and uses (Fe(CN)6) as a structural unit so that a three-dimensional frame network with a special pore passage structure is formed. positive ions can be rapidly embedded into and released from pore passages in a three-dimensional frame, and the three-dimensional frame is stable during embedding and releasing of the positive ions; the secondary battery adopting the divalent metal ion iron cyanide complex as the positive electrode active material has the high coulombic efficiency and the long cycle life; the divalent metal ion iron cyanide complex has the low reaction activity and the prepared battery is difficult to explode.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for producing high dielectric strength microvalves

ActiveUS7022381B2Improve abilitiesHigh dielectric strengthValve arrangementsRadiation applicationsElectricity1-Propanol

A microvalve having a cast-in-place and lithographically shaped mobile, polymer monolith for fluid flow control in microfluidic devices and method of manufacture. The microvalve contains a porous fluorinated polymer monolithic element whose pores are filled with an electrically insulating, high dielectric strength fluid, typically a perfluorinated liquid. This combination provides a microvalve that combines high dielectric strength with extremely low electrical conductivity. These microvalves have been shown to have resistivities of at least 100 GΩ and are compatible with solvents such as water at a pH between 2.7 and 9.0, 1-1 propanol, acetonitrile, and acetone.

Owner:SANDIA NAT LAB

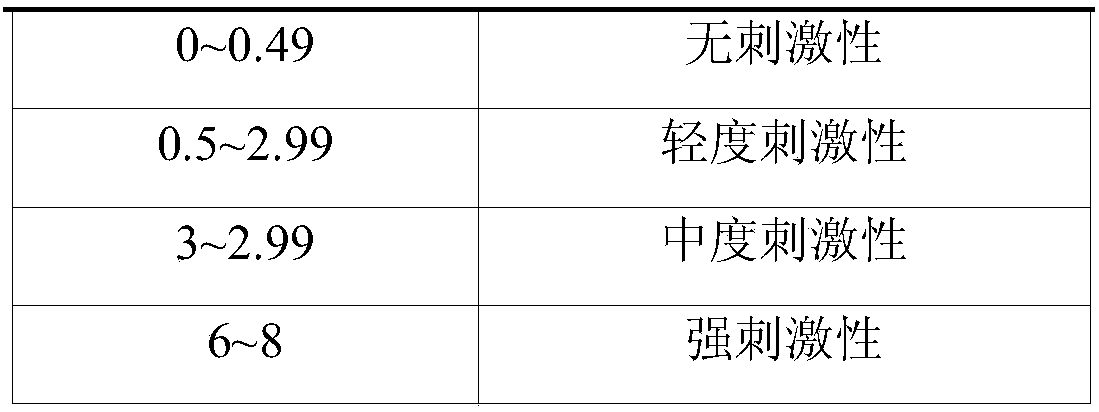

Nano-diamond modified liquid band aid and preparation method thereof

InactiveCN107595819AGood biocompatibilityLow toxicityCarbon active ingredientsPharmaceutical non-active ingredientsIrritationEthyl acetate

A nano-diamond modified liquid band aid is prepared from raw materials in parts by weight as follows: 15-20 parts of a film forming material, 10-20 parts of ethyl acetate, 40-50 parts of ethanol, 3-5parts of propylene glycol, 2-6 parts of polydimethylsiloxane, 4-7 parts of medical vaseline, 4-8 parts of a cattail spike extract and 2-4 parts of modified nano-diamond, wherein the film forming material, ethyl acetate, ethanol, propylene glycol, polydimethylsiloxane and the medical vaseline are taken as basic raw materials, the cattail spike extract and the modified nano-diamond are taken as active ingredients, and the sum of parts of the basic raw materials and the cattail spike extract by weight is 100. The invention further discloses a preparation method of the nano-diamond modified liquidband aid. Compared with conventional band aids, the liquid band aid is convenient to use, has good antibacterial and anti-inflammatory functions and has no irritation or toxicity to skin, external wounds in any shape and in any position can be more conveniently treated, and the liquid band aid can rapidly form a film and has the efficacy of stopping bleeding, diminishing inflammation, relieving pain and promoting blood circulation to remove blood stasis.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Method for processing printed circuit board by applying calixarene

ActiveCN106714464AImprove conductivityImprove adhesionConductive pattern formationCooking & bakingSilver paste

The invention discloses a method for processing a printed circuit board by applying calixarene. The method comprises the following steps that a) calixarene and an organic solvent are added to a container equipped with a stirring device under the normal temperature and the normal pressure and continuously stirred so as to obtain a calixarene solution; b) liquid silver paste and the calixarene soluation are added to a container equipped with a dispersing device under the normal temperature and the normal pressure and continuously dispersed and then discharged so as to obtain primary printing liquid; c) drilling and cleaning and other processing are performed on a substrate according to the line requirements and the substrate is arranged on a screen printing machine; d) printing liquid is added to the screen printing machine, and the primary printing liquid is coated on the substrate; and e) the substrate is arranged in a baking oven to be baked and then naturally cooled to the normal temperature and then the printed circuit board manufactured by applying calixarene can be obtained. The method for processing the printed circuit board by applying calixarene is high in environmental protection performance and can enhance the adhesive force of silver particles on the substrate so as to effectively reduce the processing cost of the printed circuit board.

Owner:GUANGDONG CHENGDE ELECTRONICS TECH CO LTD +1

Molten metal rechargeable electrochemical cell

ActiveUS10128543B2Low costImprove usabilityElectrode carriers/collectorsSecondary cellsElectrochemical cellMolten metal

The present invention provides rechargeable electrochemical cells comprising a molten anode, a cathode, and a non-aqueous electrolyte salt, wherein the electrolyte salt is situated between the molten anode and the cathode during the operation of the electrochemical cell, and the molten anode comprises an aluminum material; also provided are batteries comprising a plurality of such rechargeable electrochemical cells and processes for manufacturing such rechargeable electrochemical cells.

Owner:EOS ENERGY TECH HLDG LLC

Liquid tank and fuel cell system with fuel monitoring

InactiveUS7892697B2Easy to monitorEasy to knowReactant parameters controlSecondary cellsFuel cellsLiquid tank

A fuel cell system includes a fuel cell provided with an anode and a cathode, a first container for storing a liquid fuel to be supplied to the anode, a second container provided in the first container to contain liquid and gas, a joint which is provided in the first container and discharges the liquid fuel outside the first container, an outlet pipe connecting the joint to the second container, and a remaining indicator window provided to make the interior of the outlet pipe is viewable. Further, an alert color is applied to an area that becomes viewable when the gas is flowing through the outlet pipe, the color being applied on the area opposite to the remaining indicator window across the outlet pipe.

Owner:SANYO ELECTRIC CO LTD

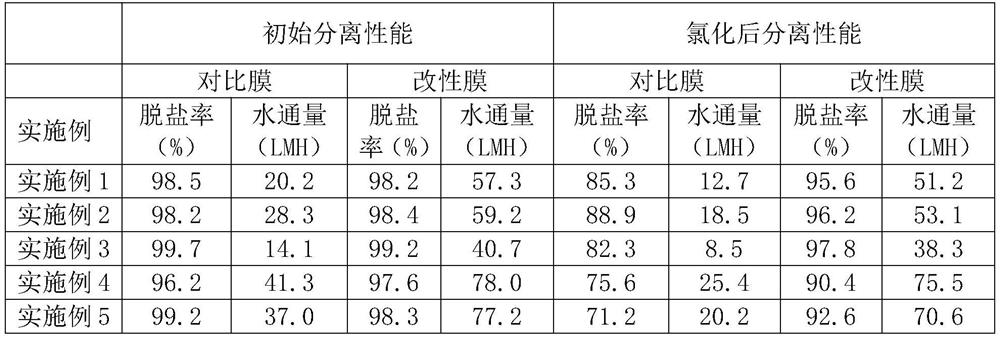

Polyamide composite membrane chlorine-resistant high-flux modification method based on ketone free radicals

InactiveCN114307684AReduce chemical reactivityImprove chlorine resistanceSemi-permeable membranesGeneral water supply conservationPolyamideKetone

The invention belongs to the technical field of organic membrane materials, and particularly relates to a polyamide composite membrane chlorine-resistant high-flux modification method based on ketone free radicals. According to the polyamide composite membrane, a polyamide active layer is modified in a free radical grafting mode, free radicals are generated by mixing a substrate and an oxidizing agent, the free radicals are ketone free radicals, the substrate is small molecule ketone with the carbon number smaller than or equal to 5, and the oxidizing agent is persulfate. According to the method, ketone free radicals are introduced to amido bonds of polyamide for the first time, due to the fact that the ketone free radicals can effectively occupy reaction active sites of chlorine and polyamide and improve the hydrophilicity of polyamide, the chlorine resistance and permeability of the membrane are improved, and in addition, the modification method is simple and easy to implement, production is easy to expand, and the method has great market prospects.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

A kind of vanadium disulfide and black phosphorus composite electrode material and preparation method thereof

ActiveCN111584847BLarge specific surface areaIncrease the active siteMaterial nanotechnologyNegative electrodesElectrolytic agentVanadium disulfide

The invention belongs to the technical field of electrode material preparation, and in particular relates to a composite electrode material of vanadium disulfide and black phosphorus and a preparation method thereof. Firstly, the black phosphorus is stripped; secondly, the vanadium disulfide is stripped; finally, the vanadium disulfide and the black phosphorus are compounded to obtain a composite electrode material of vanadium disulfide and black phosphorus. The material has the characteristics of high specific surface area, high active sites, and high specific capacity. The pores between the nanosheets can buffer the volume change of the active material during charging and discharging, and can increase the contact area with the electrolyte, reducing the The ion transport path is opened, which is conducive to the rapid transfer of electrons / ions, thereby improving the cycle stability and rate performance of the electrode material.

Owner:QINGDAO UNIV OF SCI & TECH

Freezing process in process of making yellow wine

The invention discloses a freezing process in process of making yellow wine. The whole temperature reduction program is divided into three sections, the temperature is gradually reduced to 5-7 DEG C below zero, the quality of the whole batch of yellow wine can be effectively kept consistent, the temperature of the yellow wine is kept for 160-175 hours, insoluble substances which affect the mouthfeel and quality of the yellow wine can be effectively precipitated, and the quality of the yellow wine is improved.

Owner:FUJIAN HUIZELONG WINE

A method of applying calixarene to process printed circuit boards

ActiveCN106714464BImprove conductivityImprove adhesionConductive pattern formationScreen printingCooking & baking

The invention discloses a method for processing a printed circuit board by applying calixarene. The method comprises the following steps that a) calixarene and an organic solvent are added to a container equipped with a stirring device under the normal temperature and the normal pressure and continuously stirred so as to obtain a calixarene solution; b) liquid silver paste and the calixarene soluation are added to a container equipped with a dispersing device under the normal temperature and the normal pressure and continuously dispersed and then discharged so as to obtain primary printing liquid; c) drilling and cleaning and other processing are performed on a substrate according to the line requirements and the substrate is arranged on a screen printing machine; d) printing liquid is added to the screen printing machine, and the primary printing liquid is coated on the substrate; and e) the substrate is arranged in a baking oven to be baked and then naturally cooled to the normal temperature and then the printed circuit board manufactured by applying calixarene can be obtained. The method for processing the printed circuit board by applying calixarene is high in environmental protection performance and can enhance the adhesive force of silver particles on the substrate so as to effectively reduce the processing cost of the printed circuit board.

Owner:GUANGDONG CHENGDE ELECTRONICS TECH CO LTD +1

A kind of method utilizing calixarene to process printed circuit board

ActiveCN106686900BImprove conductivityImprove adhesionLithography/patterningConductive pattern formationLiquid layerCooking & baking

The invention discloses a method for processing a printed circuit board by using calixarene. The method comprises the following steps of (a) adding the calixarene and an organic solvent to a container with a stirring device at a room temperature and atmospheric pressure and lastingly stirring to obtain a printing liquid; (b) carrying out treatment of drilling, cleaning and the like on a substrate and putting the substrate on one screen printing machine; (c) adding the printing liquid to the screen printing machine and rubbing the substrate with the printing liquid; (d) putting the substrate in the environments of the room temperature and the atmospheric pressure, naturally airing for later use and forming a printing liquid layer by the printing liquid on the substrate; (e) putting the substrate on a screen printing table of another screen printing machine, adding liquid silver paste to the screen printing machine and rubbing the printing liquid layer with the silver paste; and (f) putting the substrate obtained in the step (e) into an oven for baking, and naturally cooling to obtain the printed circuit board. The method for processing the printed circuit board by using the calixarene is high in environmental protection property, the adhesive force of silver particles on the substrate can be improved and the impedance of a conducting circuit can be reduced.

Owner:GUANGDONG CHENGDE ELECTRONICS TECH CO LTD +1

Molten metal rechargeable electrochemical cell

InactiveUS20190044191A1Low costImprove usabilityElectrode carriers/collectorsSecondary cellsElectrochemical cellMolten metal

The present invention provides rechargeable electrochemical cells comprising a molten anode, a cathode, and a non-aqueous electrolyte salt, wherein the electrolyte salt is situated between the molten anode and the cathode during the operation of the electrochemical cell, and the molten anode comprises an aluminum material; also provided are batteries comprising a plurality of such rechargeable electrochemical cells and processes for manufacturing such rechargeable electrochemical cells.

Owner:EOS ENERGY TECH HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com