Patents

Literature

66results about How to "Not prone to explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorosurfactant free of perfluorooctanoic acid as well as preparation method and process system of fluorosurfactant

ActiveCN105170018ASolve pollutionPromote decompositionPreparation from carboxylic acid halideTransportation and packagingProcess systemsPeroxide value

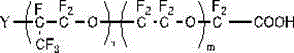

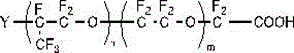

The invention discloses a fluorosurfactant free of perfluorooctanoic acid as well as a preparation method and a process system of the fluorosurfactant. The fluorosurfactant is a repeated structure unit which comprises at least one oxoperfluoropropenyl and one or a combination of more of perfluoromethoxyl, a Y group and oxoperfluorovinyl and is provided with a carboxyl group or carboxylate at one end. The fluorosurfactant is a fluoropolymer with the C-O-C ether bond structure as the main structural body; in view of indexes, the fluorosurfactant does not contain perfluorooctanoic acid with a 8-C straight-chain structure or salt of the perfluorooctanoic acid, is easily decomposed in nature and is proved to be harmless to human bodies, the peroxide value is 0.001%-0.1%, the surface tension is 10-30 mN / m, and the fluorosurfactant has an amphiphilic structure of a surfactant.

Owner:成都晨光博达新材料股份有限公司

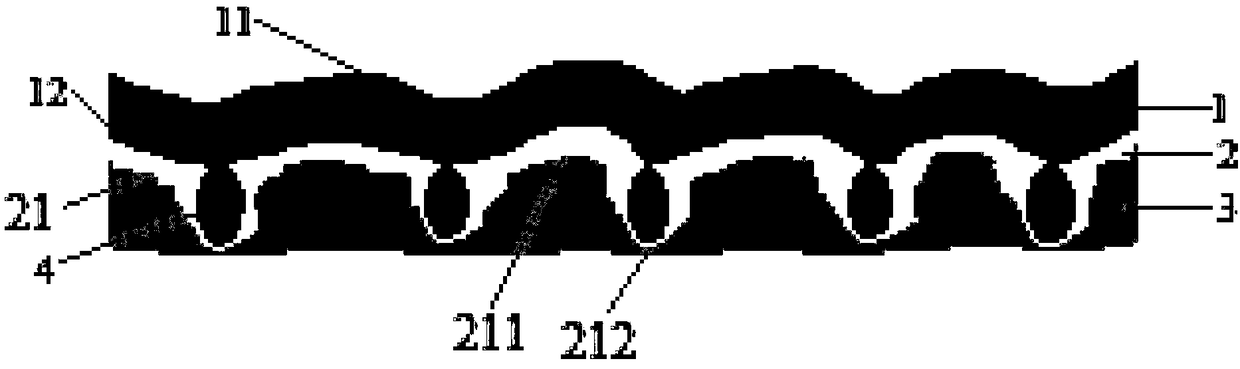

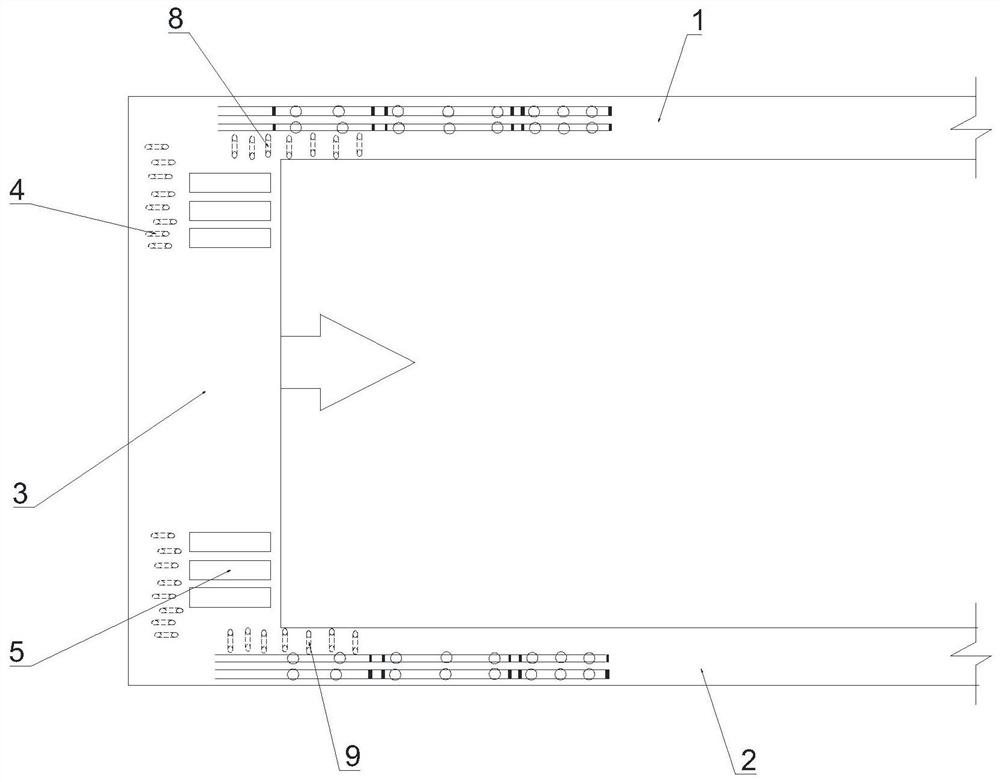

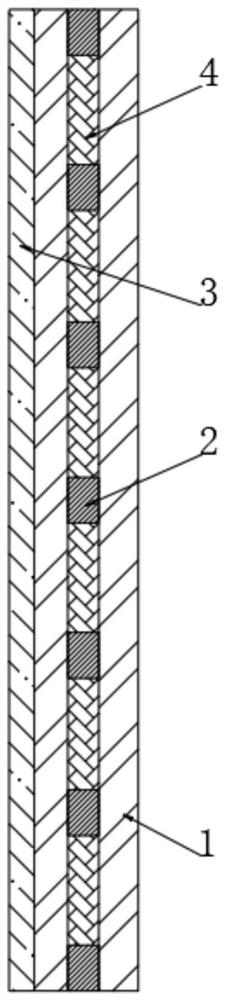

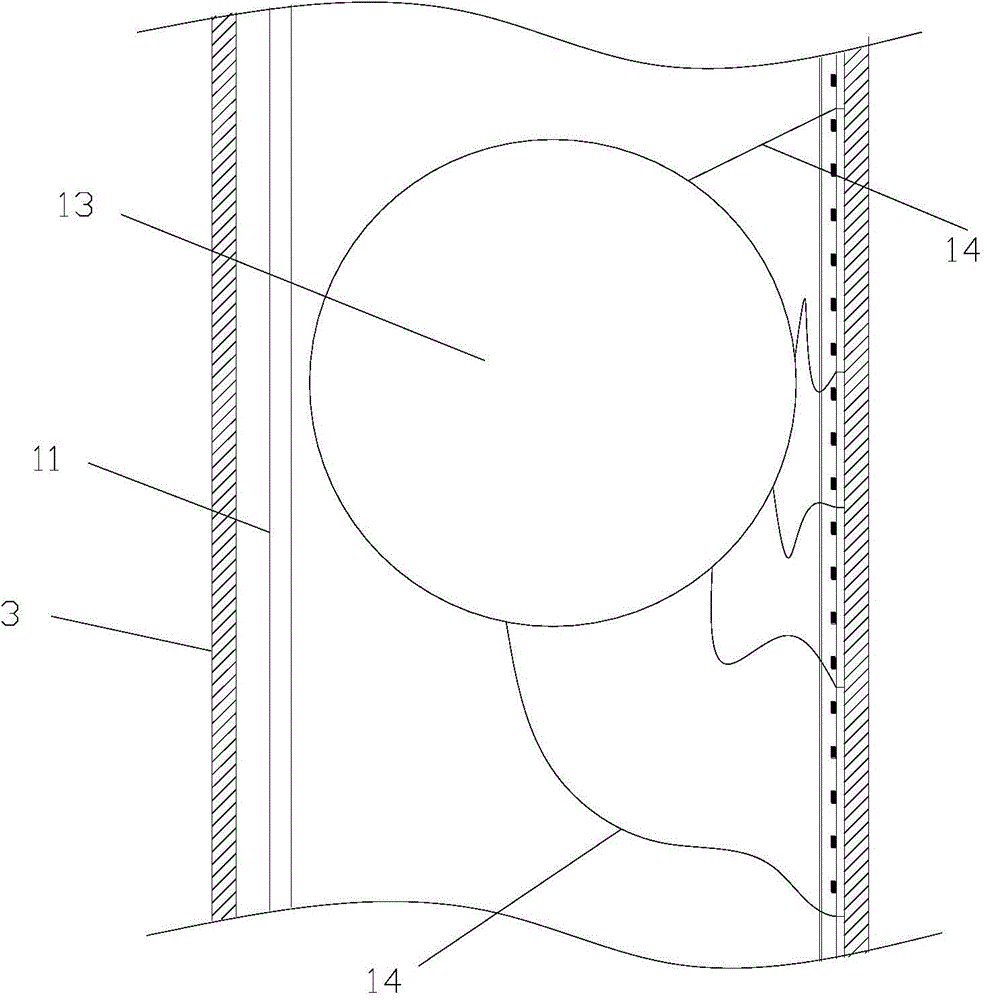

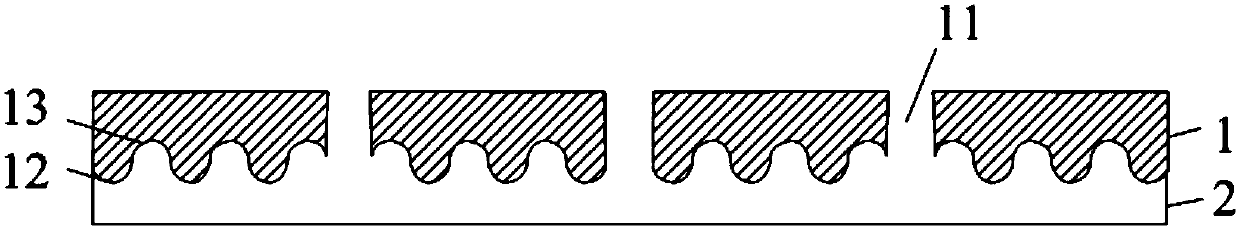

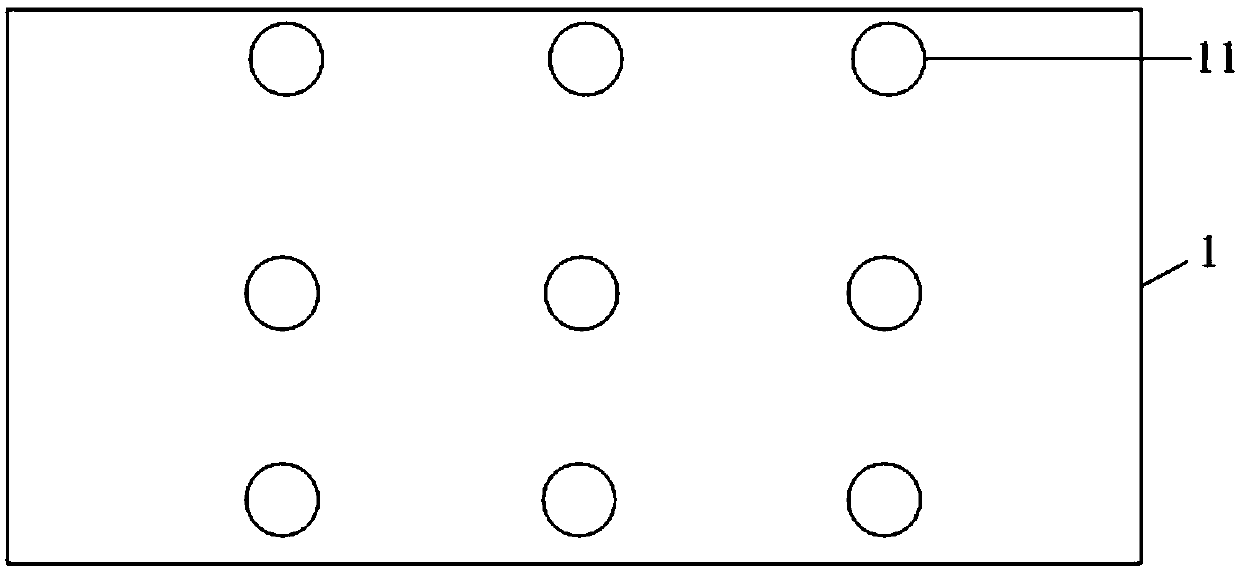

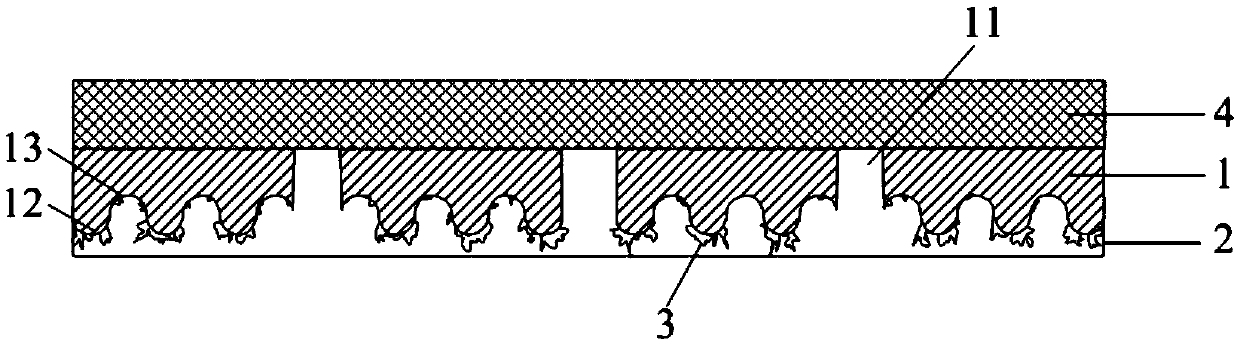

Electromagnetic shielding film, circuit board and electromagnetic shielding film preparation method

ActiveCN108323143ASolve the phenomenon of high temperature explosionHigh peel strengthMagnetic/electric field screeningLayered productsElectromagnetic shieldingEngineering

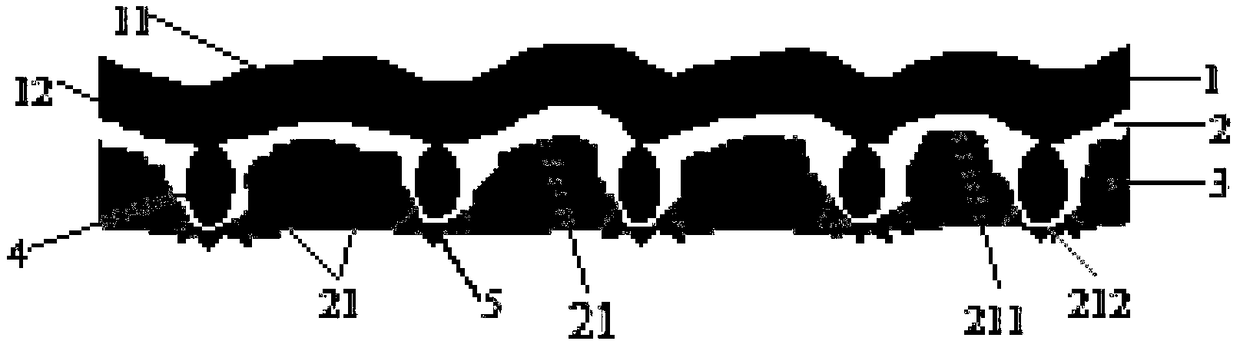

The embodiment of the invention provides an electromagnetic shielding film, a circuit board and an electromagnetic shielding film preparation method; the electromagnetic shielding film comprises a first shield layer, a second shield layer, a glue film and a plurality of convex particles; the first shield layer comprises a first surface and a second surface arranged in opposite; the second surfaceis a fluctuating non-flat surface; the plurality of convex particles are attached to the second surface of the first shield layer; the second shield layer is configured on the second surface of the first shield layer, and covers the plurality of convex particles, thus forming convex portions, matched with the convex particles, on the outer surface of the second shield layer, and forming concave portions on other positions, wherein the fluctuation level on the outer surface of the second shield layer is greater than that of the second surface; the glue film is configured on the outer surface ofthe second shield layer.

Owner:GUANGZHOU FANGBANG ELECTRONICS

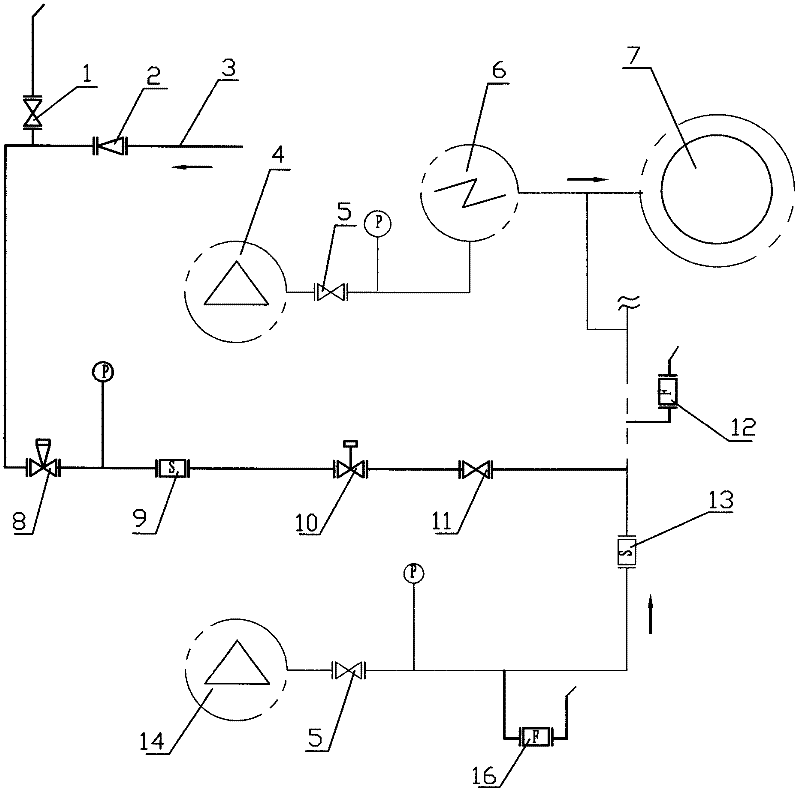

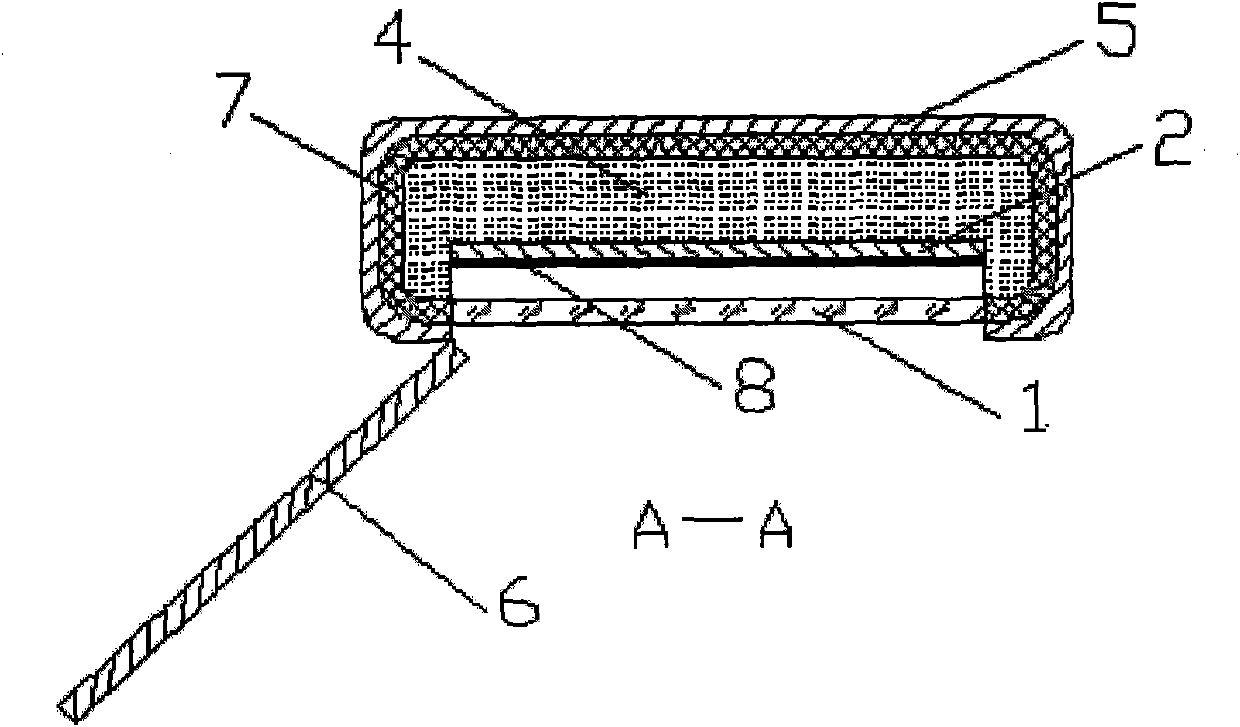

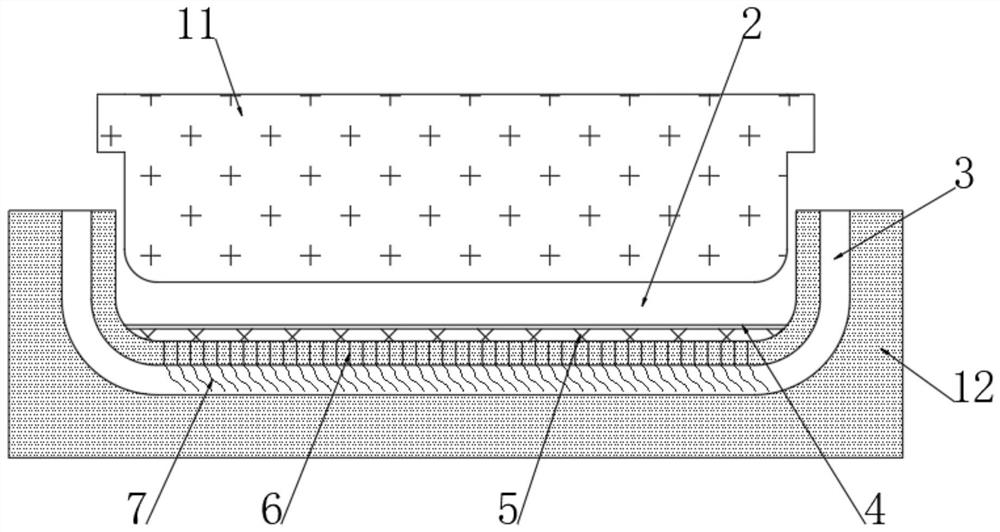

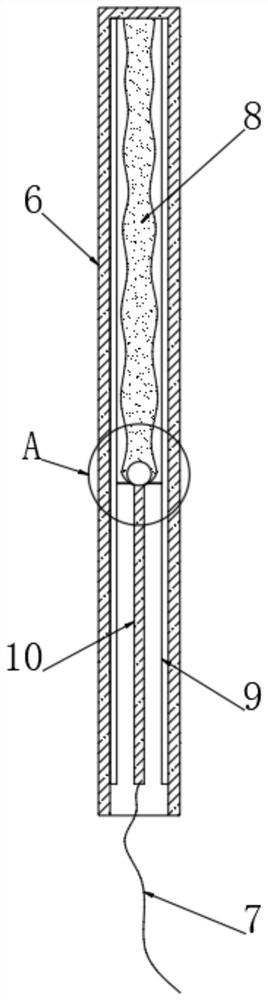

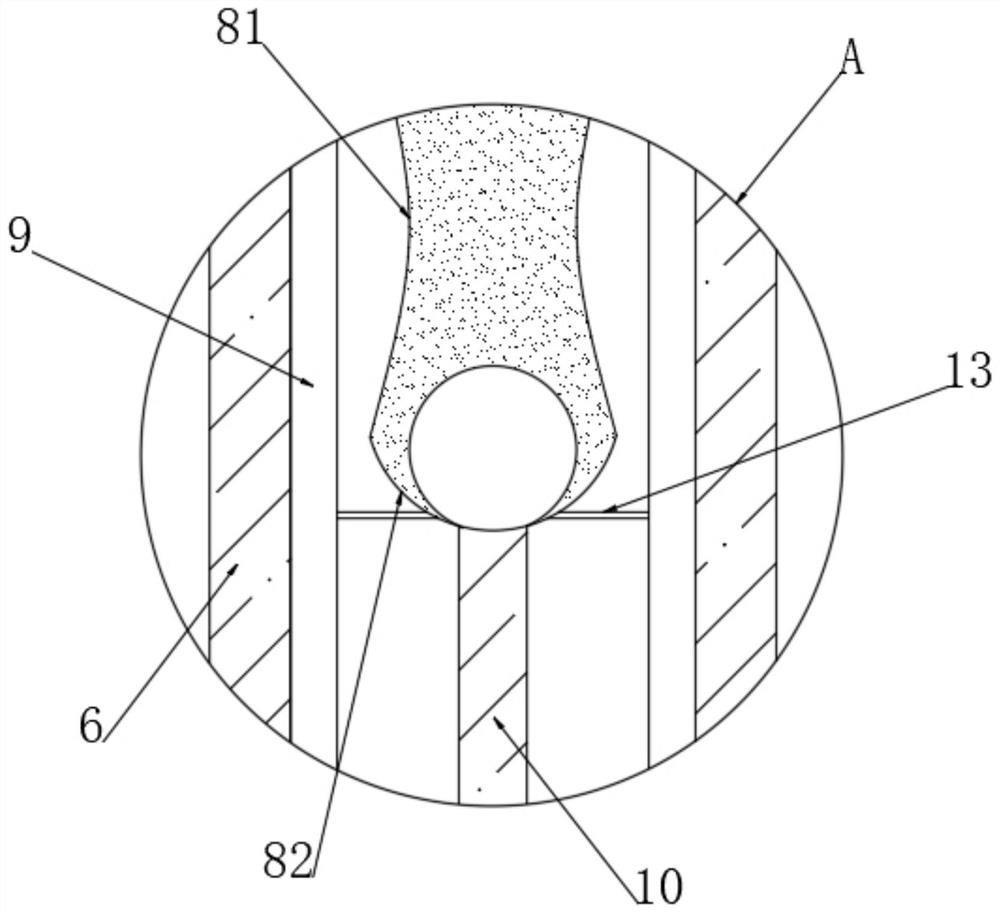

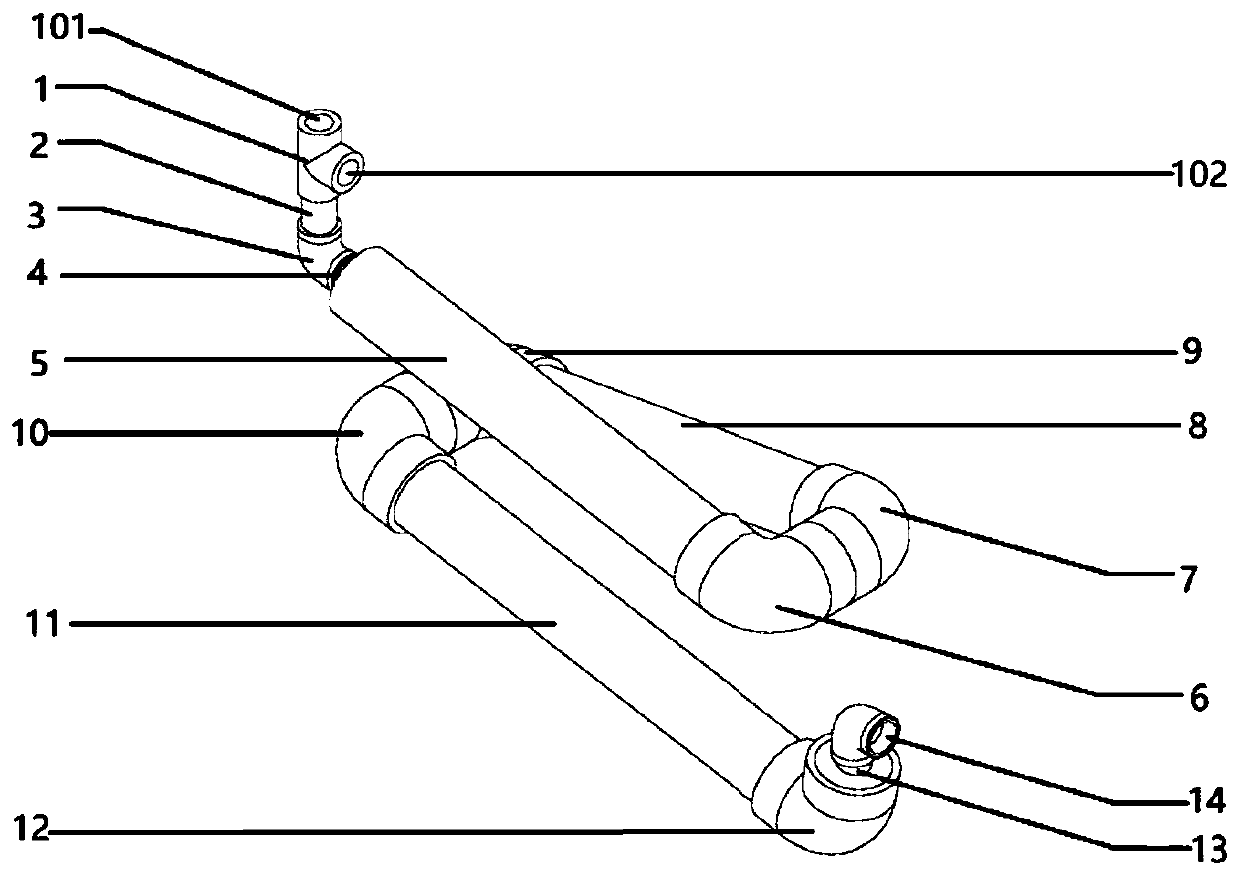

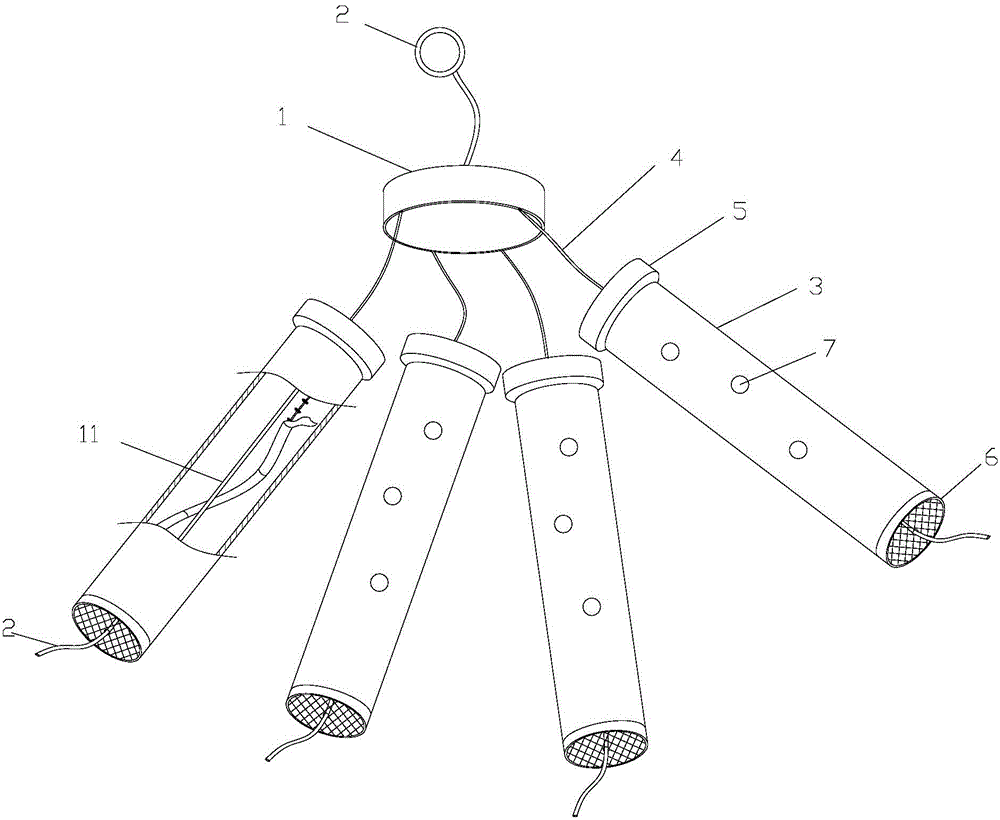

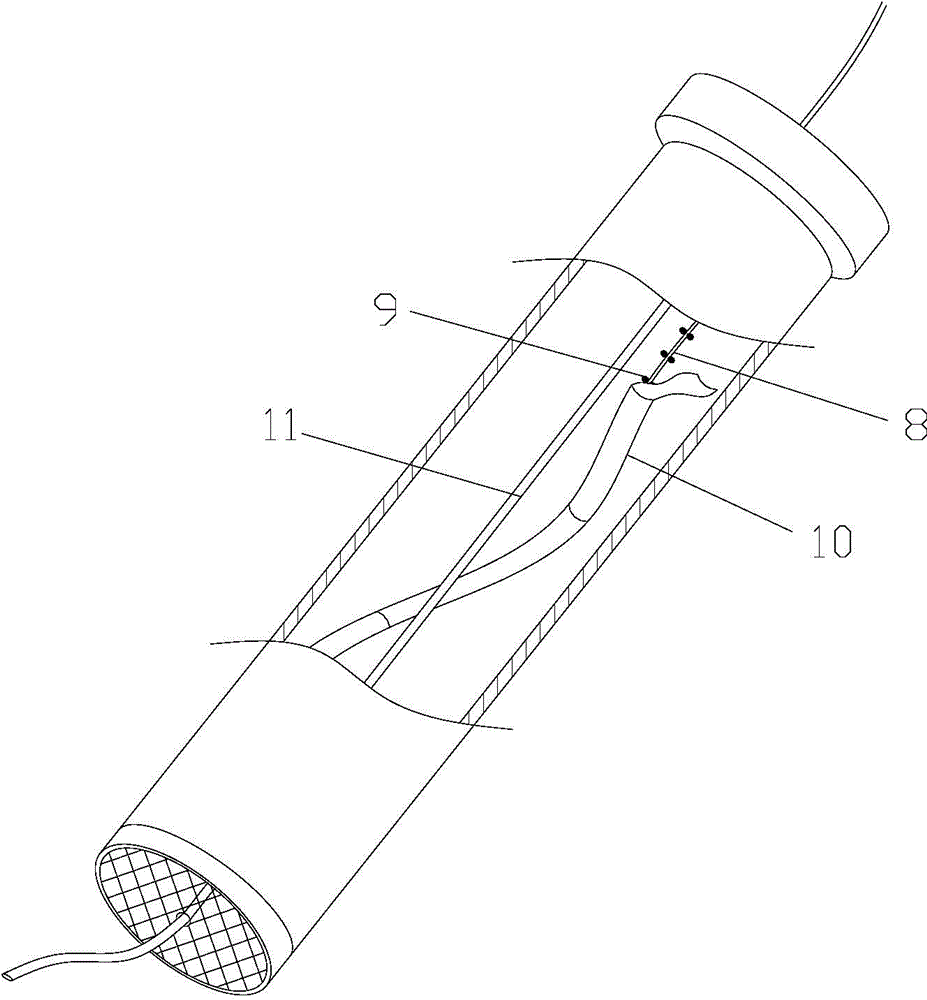

Cryoablation apparatus and cryoablation method

ActiveCN109009406ALow temperature requirementNot prone to explosionCatheterSurgical instruments for coolingTemperature controlProcess engineering

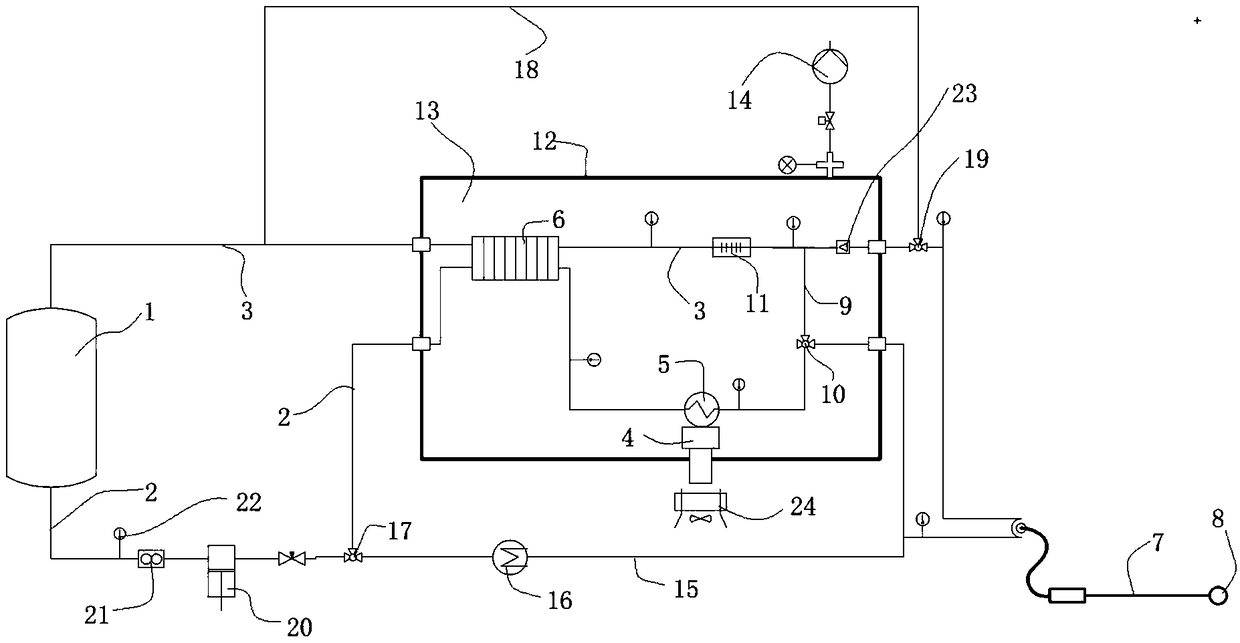

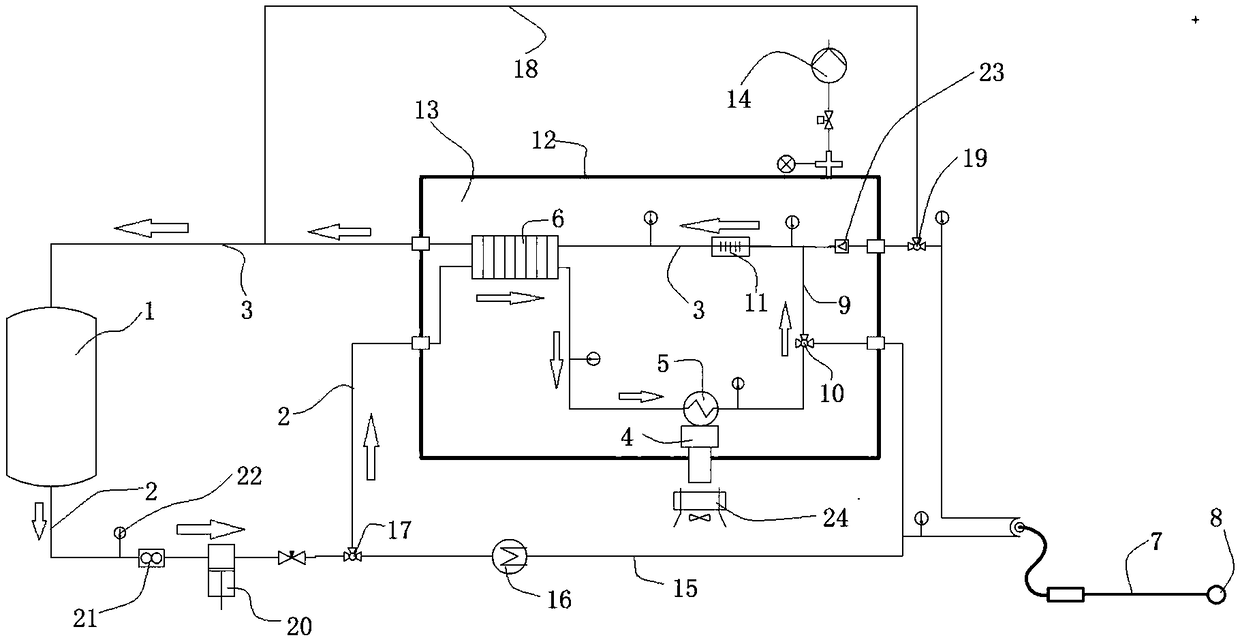

The invention discloses a cryoablation apparatus and a cryoablation method, belonging to the technical field of cryoablation. The cryoablation apparatus includes a refrigeration capsule, a conduit, amedium storage tank, a medium supply pipeline, a medium recycling pipeline and a refrigeration assembly. The cryoablation method includes four steps: pre-refrigeration, ablation, recycling and rewarming. The cryoablation apparatus and the cryoablation method have the advantages of being low in the danger coefficient, being simple in operation, being convenient to use, being high in the cooling capacity utilization efficiency, and being accurate in temperature control at the same time.

Owner:PIEDMONT MEDSYST ZHUHAI CO LTD

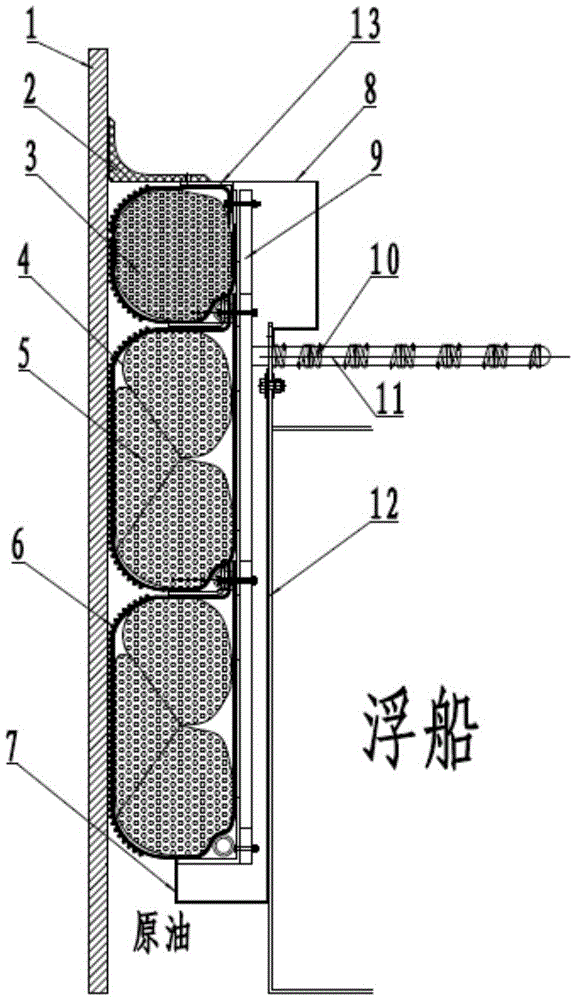

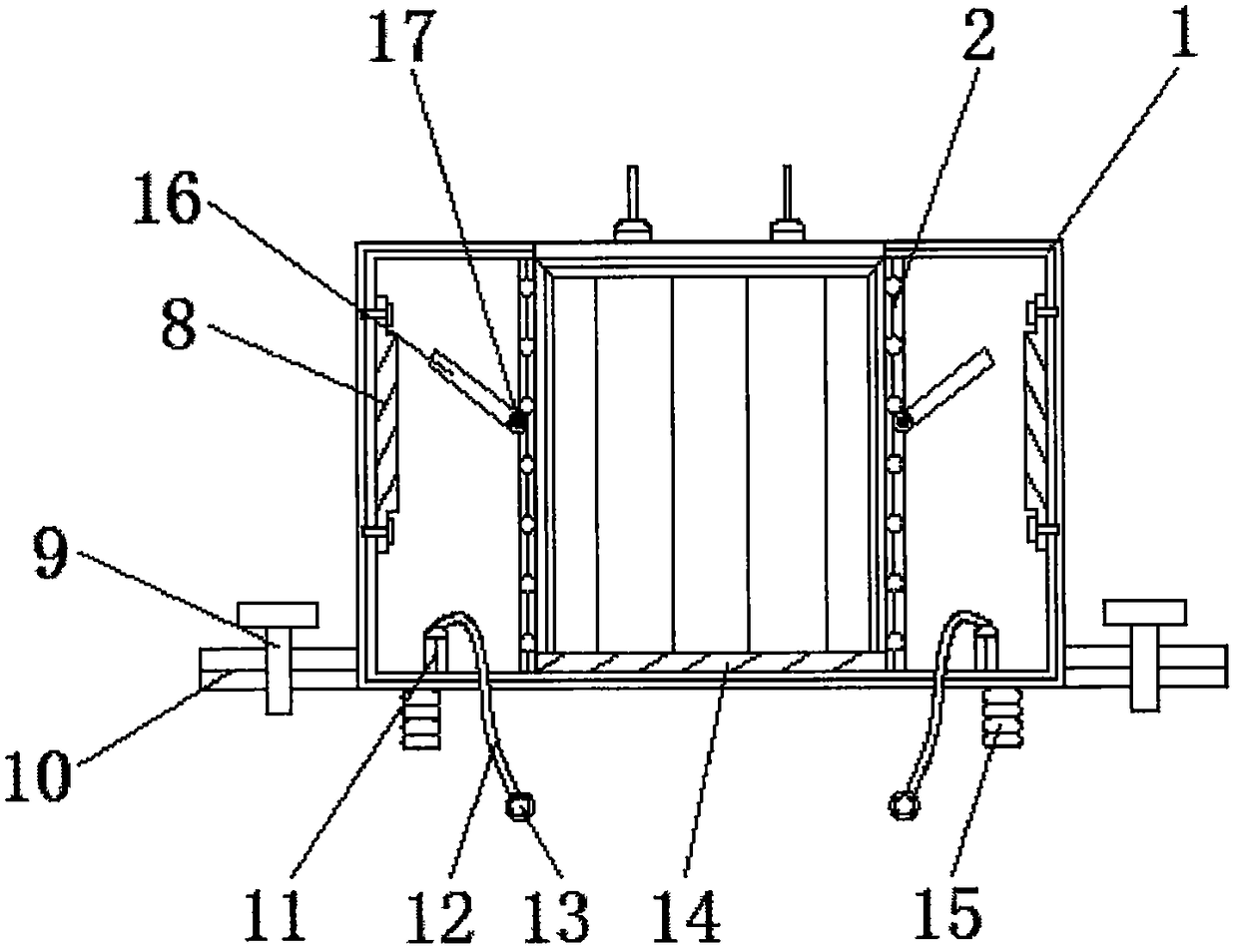

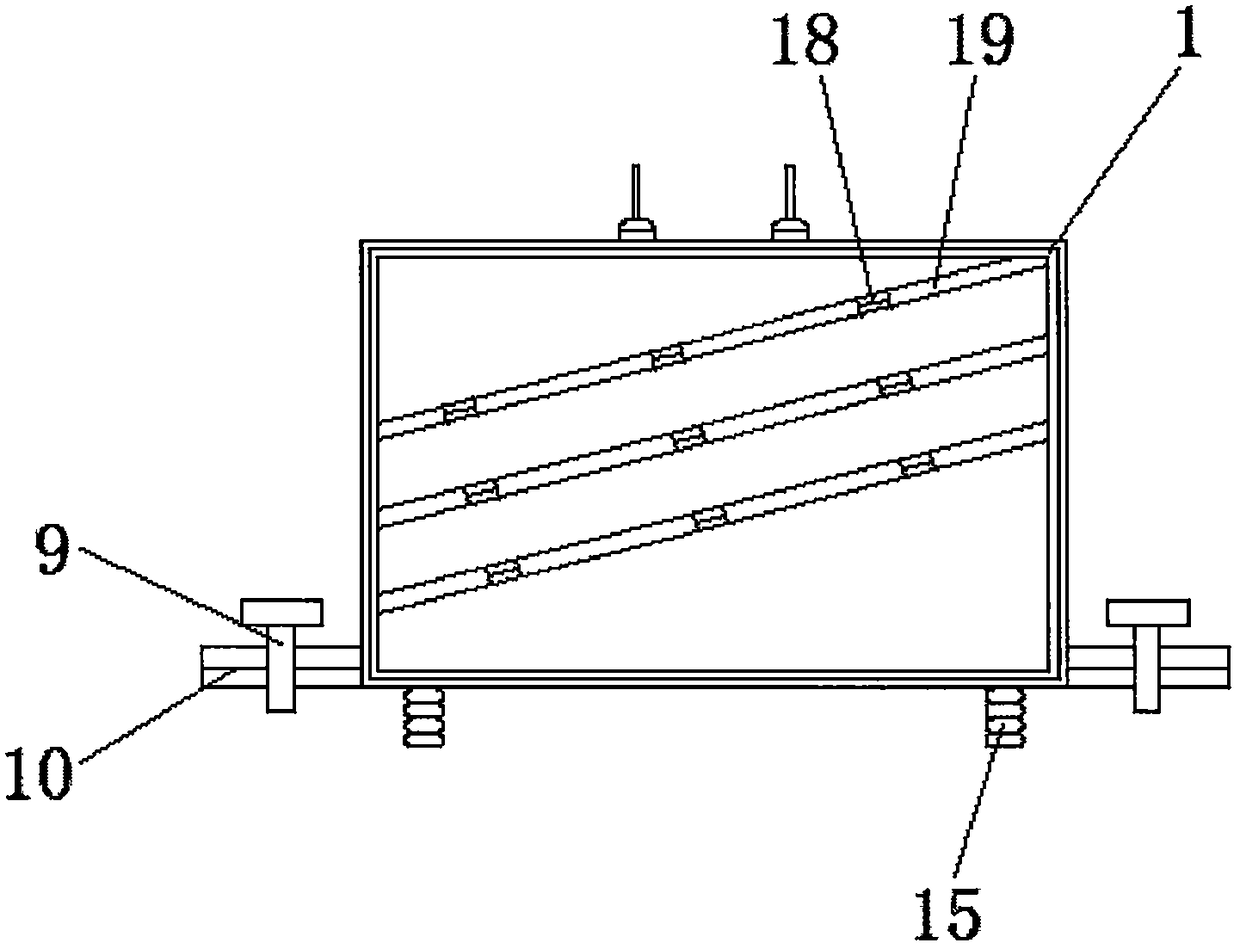

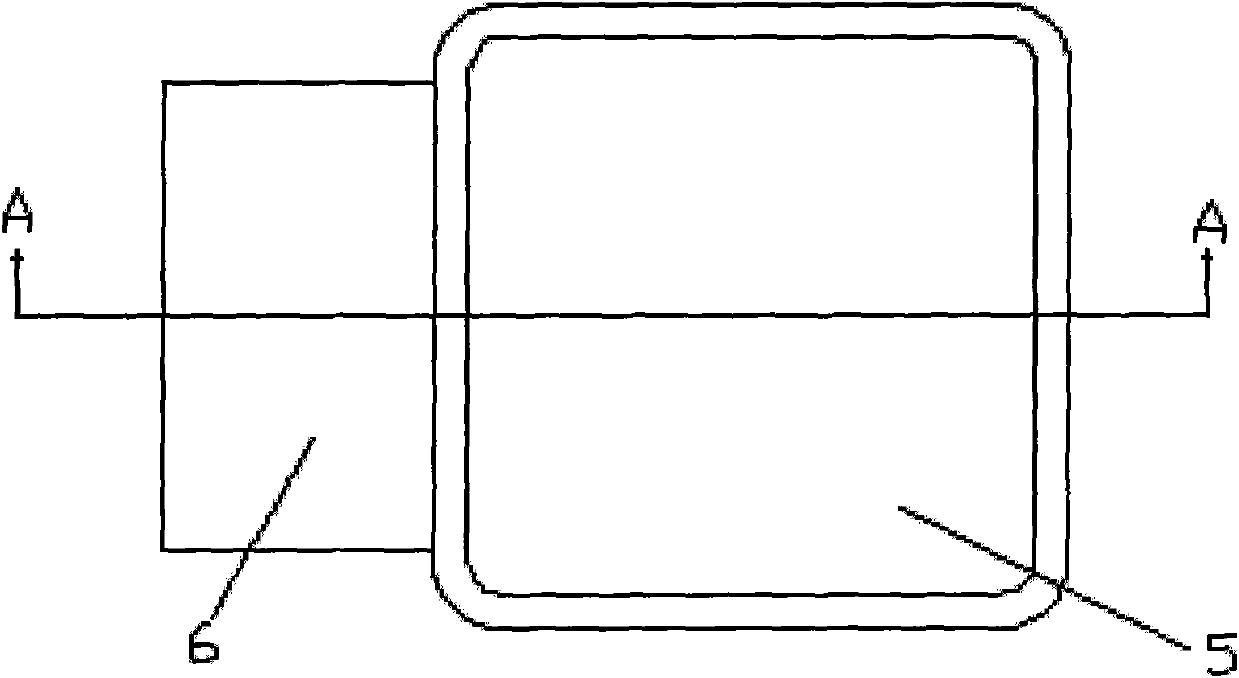

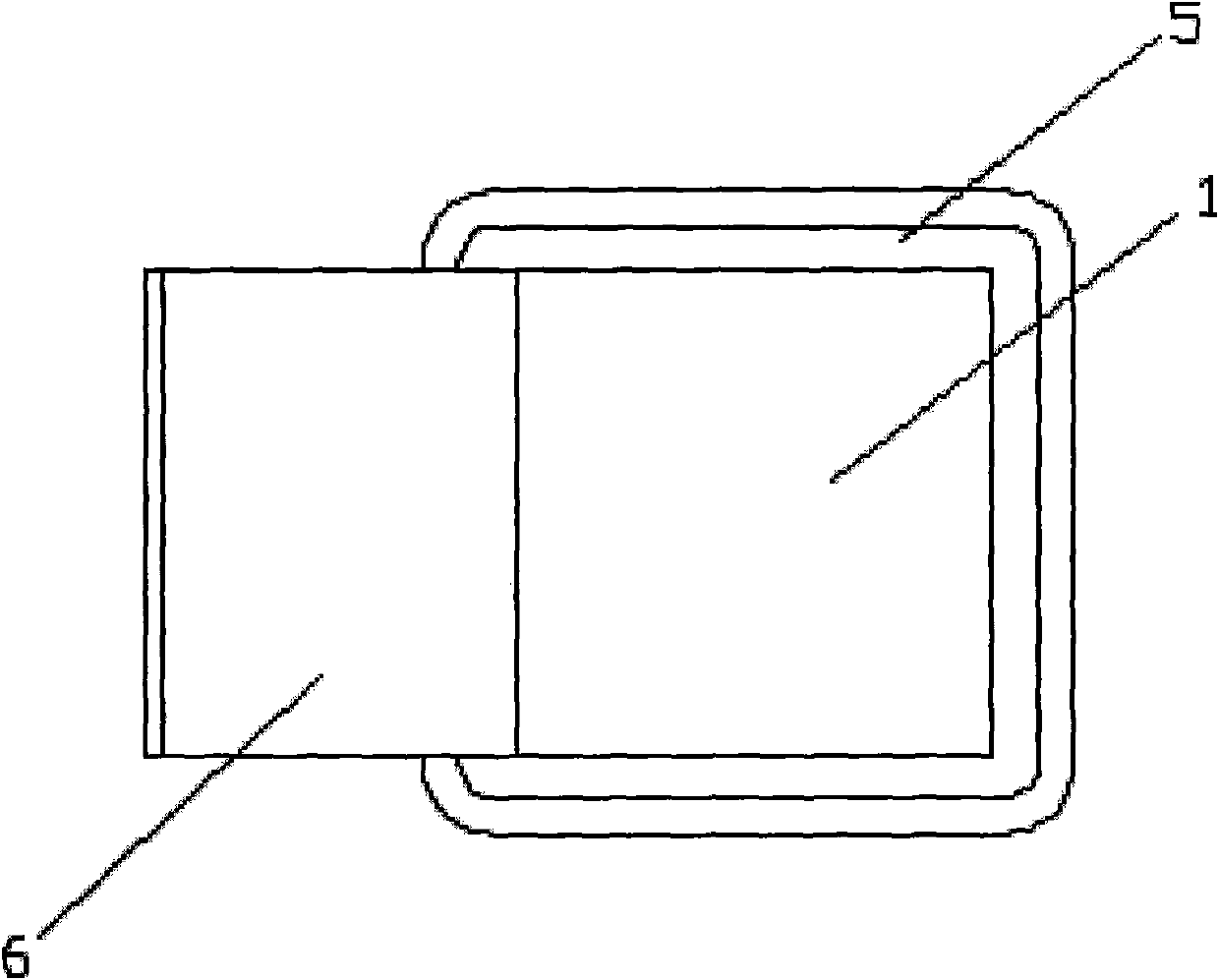

Spring compensation type soft seal device for external floating-roof oil tank

The invention discloses a spring compensation type soft seal device for an external floating-roof oil tank. The spring compensation type soft seal device comprises multiple sealing assemblies arranged around a floating roof; the floating roof is provided with a spring compensation mechanism connected with each sealing assembly; the spring compensation mechanism comprises a pressurization connection rod and a reset spring; one end of the pressurization connection rod is connected with the sealing assemblies; the other end of the pressurization connection rod is connected with the rest spring; the pressurization connection rod oppresses the sealing assemblies towards the outer side of the floating roof all the time through elastic force of the reset spring; each sealing assembly comprises a movable pressurization board with one side connected with the spring compensation mechanism; open-hole sponges and closed-hole sponges which are tightly attached to the tank wall are arranged on the other sides of the movable pressurization boards; the closed-hole sponges are located above the open-hole sponges. Through the spring compensation mechanism, the sealing assemblies abut against the inner wall of the oil tank all the time, and even if the volume of crude oil in the oil tank changes and the floating roof ascends or descends along with the liquid level, the sealing assemblies can still keep the good sealing effect.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +2

Stirring device for livestock manure full-mixing type fermentation tank

InactiveCN102180708AHigh torqueStir wellClimate change adaptationExcrement fertilisersHydraulic motorLivestock manure

The invention relates to a stirring device of a livestock manure full-mixing type fermentation tank. The stirring device comprises a fermentation tank, a stirrer and a hydraulic motor component, wherein the fermentation tank is used for accommodating a livestock manure mixed medium; the stirrer is positioned in the fermentation tank; and the hydraulic motor component serving as a power source directly drives the stirrer to rotate. The stirring device has a compact structure, is convenient to install and operate, safe, reliable and high in corrosion resistance, and hardly triggers safety accidents such as a fire hazard, explosion, methane leakage and the like.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

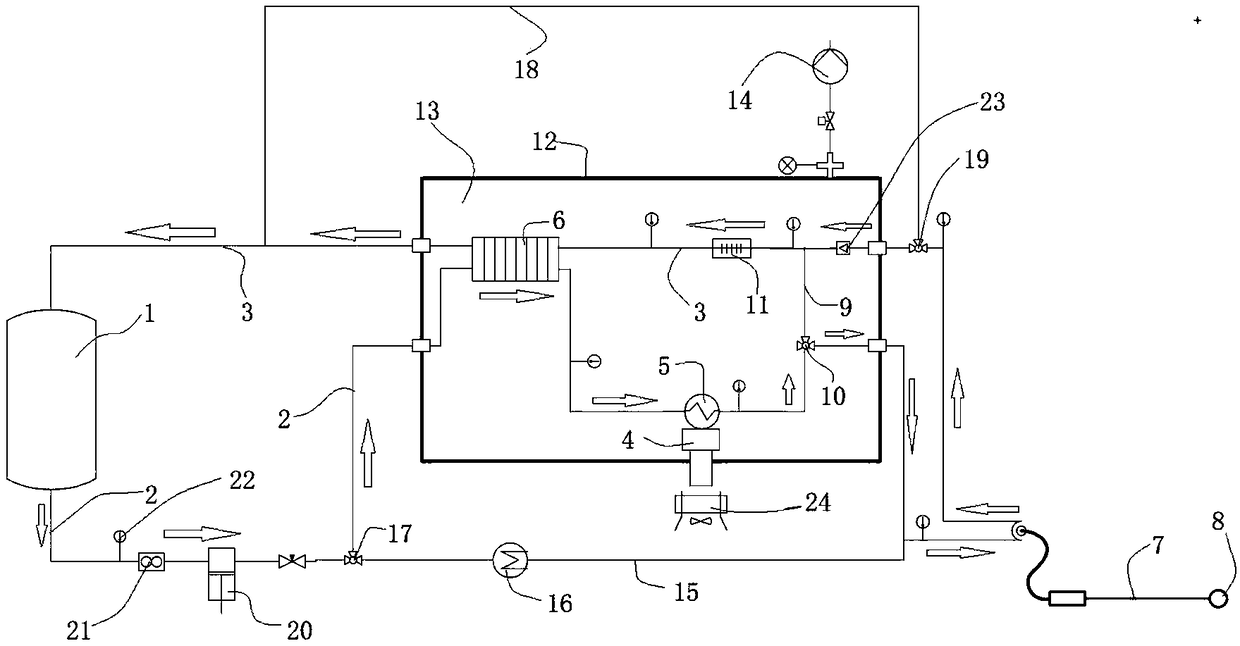

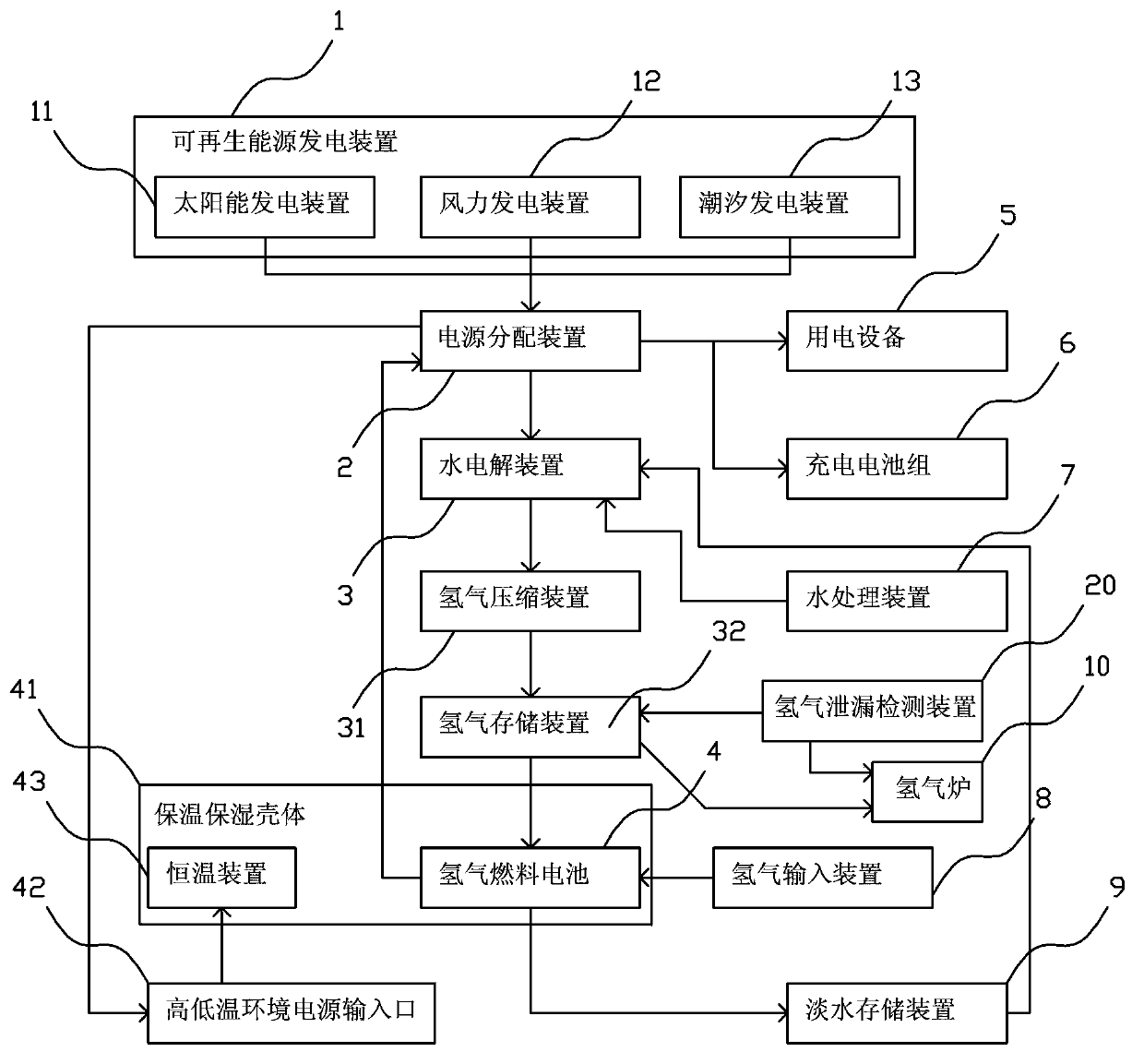

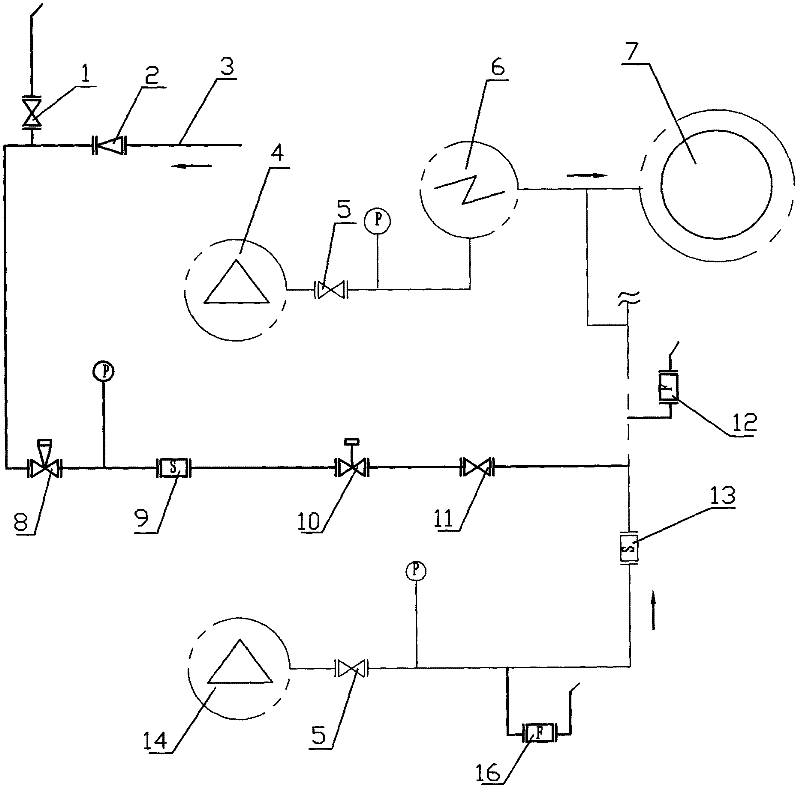

Method and system of utilizing multiple energy sources to prepare hydrogen and supply green energy source

ActiveCN103427468AReduce pollutionProtect water resourcesBatteries circuit arrangementsElectrolysis componentsThermal energyHydrogen fuel cell

The invention relates to a method and a system of utilizing multiple energy sources to prepare hydrogen and supply a green energy source. The method comprises the steps of 1) utilizing a renewable energy source to generate electricity to supply power to the power equipment and a water electrolysis device separately; 2) using the water electrolysis device to prepare the hydrogen by the commercial power and / or by utilizing the electric energy obtained by the renewable energy source, and compressing and storing the hydrogen; 3) using a hydrogen fuel cell to generate electricity via the hydrogen prepared in the step 2 to supply power to the power equipment and the water electrolysis device, and combusting the hydrogen to supply heat energy; 4) purifying and storing the water generated by the hydrogen fuel cell and by combusting the hydrogen. According to the present invention, various energy sources supply power, the spare electric power and the electric power at the power consumption low ebb are stored in the hydrogen manner via the sewage after the electrolytic treatment, the hydrogen fuel cell supplies the power when the electric power is insufficient or the electric power cost is higher, and fresh water also can be generated during the power supply process, thereby reducing the pollution and protecting the water resource.

Owner:高幼苏 +5

Starting mix of solid oxygen generator

InactiveCN101898924ARaise the ignition pointLow mechanical sensitivityExplosivesZirconium hydrideExplosive Agents

The invention discloses a starting mix of a solid oxygen generator, belonging to the technical field of explosives. The starting mix of the invention is mainly suitable for quickly igniting an oxygen generating grain to generate oxygen when the solid oxygen generator is impacted and ignited, and has the main technical characteristic of comprising the following components in percentage by weight: 40-70 of ferric oxide, 5-25 of zirconium powder, 10-30 of zirconium hydride, 1-15 of kieselguhr and 1-10 of shellac varnish, wherein the zirconium powder is substituted for magnesium powder, and the ferric oxide is substituted for barium nitrate and barium peroxide as oxidizers. The starting mix has the characteristics of moisture protection, water resistance, oxidation protection and the like, has good ignition property and safety, and can meet the requirement of long-term storage of products.

Owner:江南工业集团有限公司

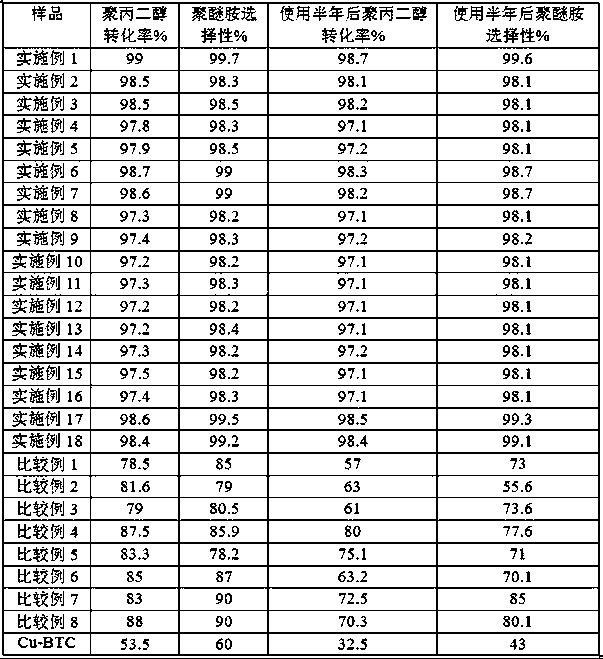

Catalyst for synthesizing polyether amine and preparation method of catalyst

The invention relates to a catalyst for synthesizing polyether amine and a preparation method of the catalyst. The preparation method comprises the following steps: (1) dissolving a metal salt A, a metal salt B and a metal salt C in an organic solvent, and conducting stirring to obtain a metal salt solution; (2) dissolving an organic ligand in an organic solvent, and conducting stirring to obtainan organic ligand solution; and (3) adding the organic ligand solution into the metal salt solution, conducting reacting at a certain temperature, and conducting filtering, washing and drying on the product to obtain the catalyst for synthesizing polyether amine. The catalyst disclosed by the invention is prepared by the method disclosed by the invention. The catalyst prepared by the invention hasbetter physical and chemical properties, is formed by complexing and coordinating of metal ions and ligands, avoids metal loss, is prolonged in service cycle, and has a good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solar heat collecting cake

InactiveCN101762086AEvenly heatedHigh thermal efficiencySolar heating energySolar heat devicesElectric energyEngineering

The invention discloses a solar heat collecting cake, which comprises a cake body and heat storage materials in the cake body. A transparent cover plate is arranged on the upper surface of the cake body. A heat absorbing plate is arranged in the cake body and is in contact with the heat storage materials. The invention takes solar energy as source energy, rays are transmitted to the heat absorbing plate through a transparent plate, the heat absorbing plate converts optical energy into heat energy and the heat energy is transferred to the heat storage materials through heat transfer medium. The cake body can be made of hard material, the heat storage materials can be solid heat storage materials, and the heat storage materials are enclosed by hard cake materials. The structure and the materials are not apt to cause explosion. Even though explosion occurs, the external hard materials enclosing the heat storage materials are just cracked, the internal heat storage materials are not spilt disorderly and the safety of other people is not endangered. The invention has the advantages that the natural resource is fully utilized, the electric energy and the hydraulic energy are saved, the occurrence probability of serious accidents is reduced, and the safety factor and the thermal efficiency are improved.

Owner:HANGZHOU LIUYI TECH

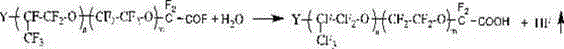

A kind of perfluorooctanoic acid-free fluorine-containing surfactant and its preparation method and process system

ActiveCN105170018BSolve pollutionPromote decompositionPreparation from carboxylic acid halideTransportation and packagingProcess systemsPerfluorooctanoic acid

The invention discloses a fluorine-containing surfactant without perfluorooctanoic acid and its preparation method and process system. A repeating structural unit with a carboxyl group or a carboxylate at one end formed by one or more combinations of radicals and oxygen perfluorovinyl groups. The fluorine-containing surfactants involved in the present invention have a C-O-C ether bond structure Fluoropolymer is the main structure. It can be seen from the indicators that this fluorosurfactant does not contain perfluorooctanoic acid and its salts with an 8-carbon linear structure. It is easily decomposed in nature and has been proven to be harmless to the human body. , the peroxide value satisfies 0.001-1%, the surface tension satisfies 10-30mN / m, and has the amphiphilic structure of surfactant.

Owner:成都晨光博达新材料股份有限公司

Blast furnace oxygen adding coal injection method and apparatus thereof

InactiveCN102409122AHigh economic valueThe economic value is higher than one coke ratioBlast furnace componentsBlast furnace detailsHigh pressure oxygenHigh pressure

The invention discloses a blast furnace oxygen adding coal injection method and an apparatus thereof, and relates to a blast furnace coal injection method. According to the apparatus, a pressure stabilizing nitrogen tank is communicated with a blowing tank by a manual nitrogen valve; the blowing tank is communicated with the blast furnace by a blowing pipe; an air feeding nitrogen tank is communicated with an air feeding total pipe by the manual nitrogen valve and a nitrogen flow meter; the air feeding total pipe is communicated with the blowing pipe. The apparatus is characterized in that: a high pressure oxygen pipe is additionally arranged, and is communicated with the air feeding total pipe sequentially by a check valve, a fast switch electromagnetic valve, an oxygen flow meter, an electromagnetic regulating valve and a manual oxygen valve; the air feeding total pipe forms a bypass communication with an oxygen analyzer for oxygen amount detection; the pipeline between the manual nitrogen valve and the nitrogen flow meter forms a bypass communication with an oxygen analyzer for inverted fleeing oxygen detection; the information output ends of the two flow meters and the two oxygen analyzers are respectively communicated with the input end of a PLC central processing unit; the output end of the PLC central processing unit is connected with the information input ends of the electromagnetic regulating valve and the fast switch electromagnetic valve. With the present invention, the coke ratio and the fuel ratio are substantially reduced, and the burning rate of the coal fines is significantly improved.

Owner:福建三钢闽光股份有限公司 +1

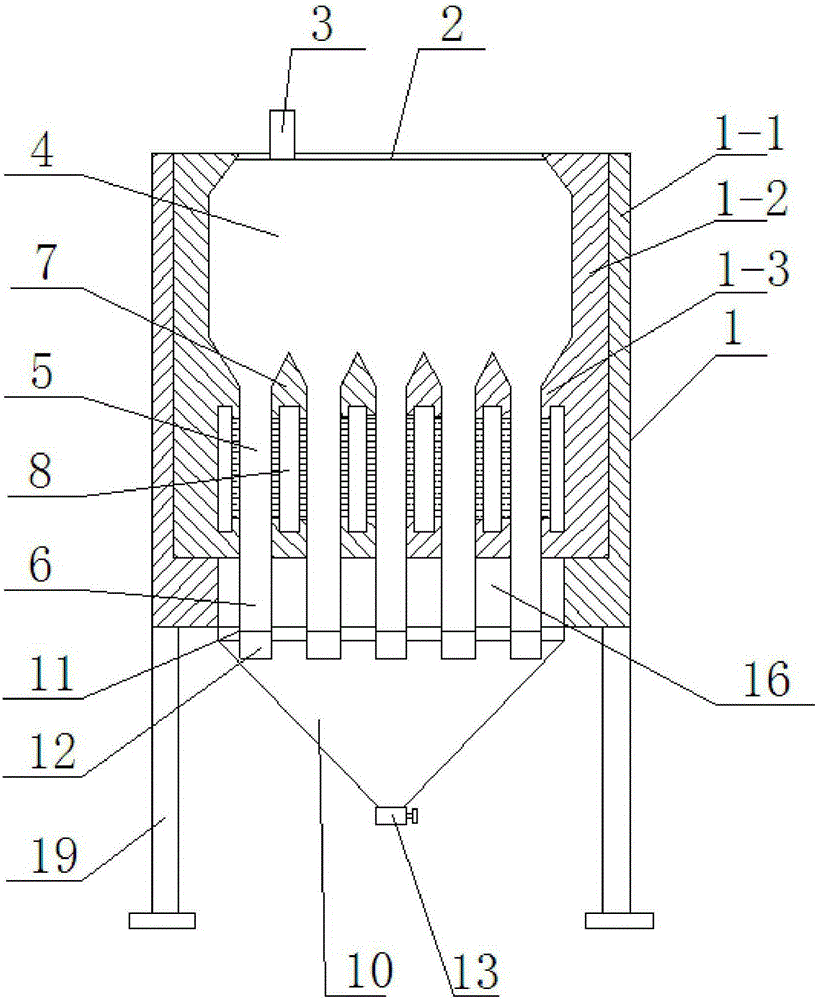

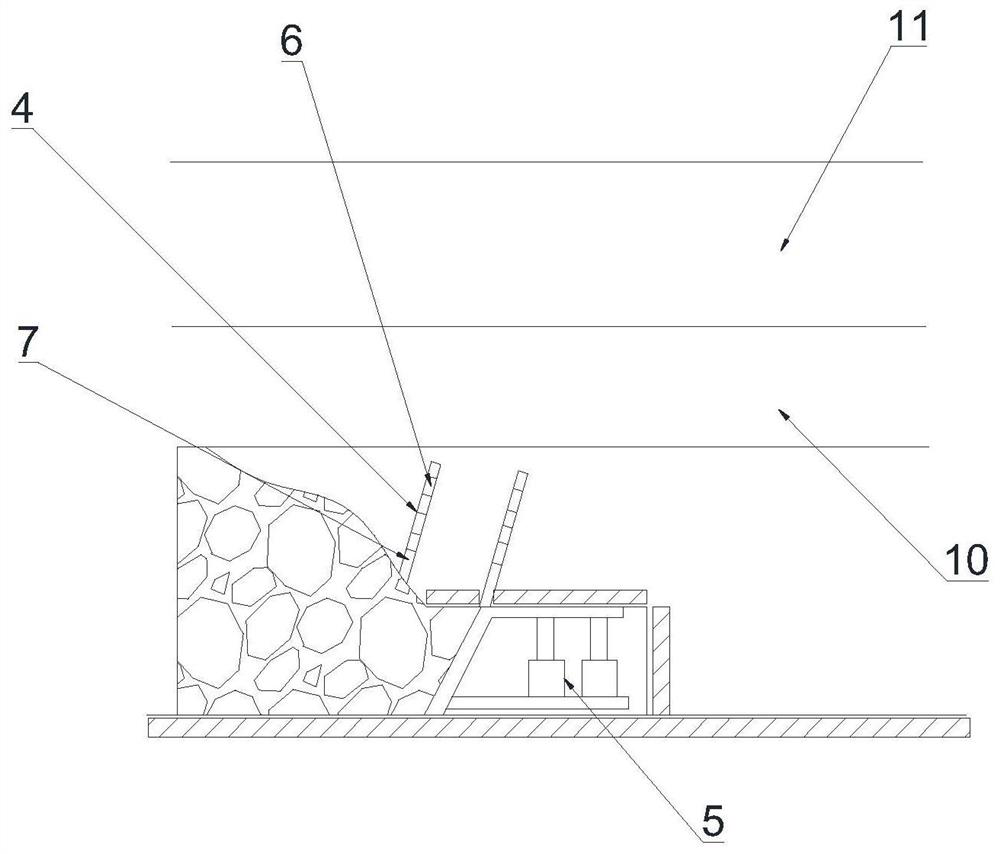

Gasification furnace for producing biomass charcoal

ActiveCN105219438AIncrease concentrationImprove securityCombustible gas productionCarbon storageEngineering

The invention relates to a gasification furnace for producing biomass charcoal. The gasification furnace comprises a furnace body and a support, the furnace body is fixed to the support, a furnace lid is arranged at the top of the furnace body, an air inlet is formed in the furnace lid, an inner chamber of the furnace body is divided into a raw material section, a burning section and a cooling section in sequence from top to bottom, multiple vertical beams which are arranged in parallel are arranged in the burning section, a gap is formed between every two adjacent vertical beams, a gasification reaction chamber is formed in each vertical beam, the gasification reaction chambers are communicated with the inner chamber of the furnace body, a fuel gas outlet communicated with the burning section is formed in the side wall of the furnace body, a cooling device is arranged at the bottom of the inner chamber of the furnace body, the vertical beams are arranged on the cooling device, a carbon storage bin is arranged at the bottom of the furnace body, a discharge opening communicated with the carbon storage bin is formed in the bottom of the inner chamber of the furnace body, a discharger is arranged at the discharge opening, and a dump valve is arranged at the bottom of the carbon storage bin. According to the gasification furnace, biomass such as straw, nut shells and wood is adopted as raw materials, the raw materials can be gasified for being made into combustible gas and can further be made into carbonized materials for being recycled, and full utilization of the raw materials is achieved.

Owner:承德华净活性炭有限公司

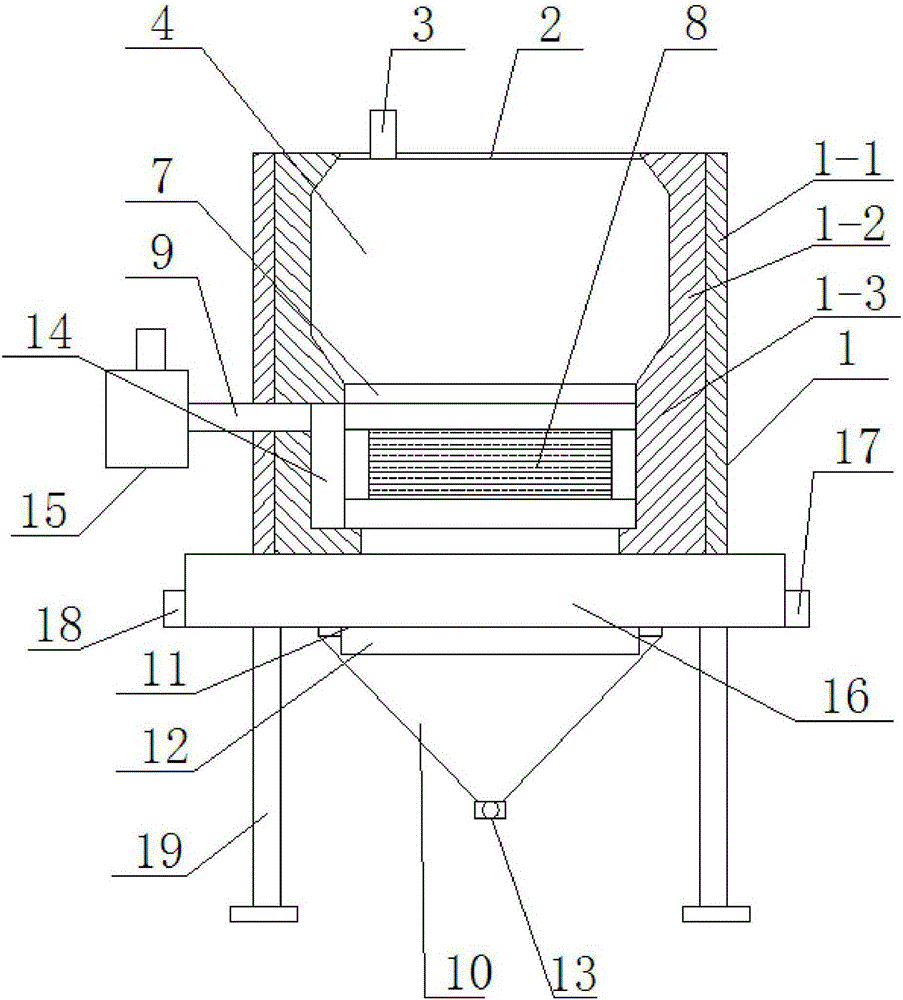

High temperature explosion-proof device of supercapacitor

InactiveCN108878157APrevent high temperature explosion phenomenonQuick job swapProtecting/adjusting hybrid/EDL capacitorHybrid cases/housings/encapsulationsCold airSupercapacitor

The invention relates to a high temperature explosion-proof device of a supercapacitor. The device comprises a main body, a capacitor body and connecting pieces, wherein a fixing plate is mounted in the main body, and a cavity is fixed to an inner side of the main body, the capacitor body is disposed inside the cavity, and pins are disposed at the top end of the capacitor body. The high-temperature explosion-proof device of the supercapacitor has the following beneficial effects: according to the invention, the main body, the cavity, the capacitor body, the fixing plate, a baffle plate, a reserved port and a spring shaft are disposed, the baffle constitutes an elastic rotating structure through the spring shaft and the fixing plate, and by the action of the cavity, the capacitor body can be placed. When the capacitor body is in the working state, a high temperature is generated, so that the airflow around the capacitor body expands, the outward thrust of the baffle can be given, and the rotation of the spring shaft can drive he baffle to rotate to create a gap with the fixing plate, so that the hot air flow can be quickly exchanged with the cold air flow inside the main body, thereby effectively preventing the high temperature explosion phenomenon of the capacitor body.

Owner:HUNAN NEPUENERGY SCI & TECH

Convenient solar heat-accumulating cake

InactiveCN101769602AEasy to carryWill not endangerSolar heating energySolar heat devicesThermal energyLight energy

The invention discloses a convenient solar heat-accumulating cake, which comprises a cake body and a solar collector device. A heat-accumulating material is arranged in the cake body, the solar collector device is a solar cooker, and a heat-collecting heat conductive plate is arranged in the cake body, and is contacted with the heat-accumulating material. The heat accumulated by the solar cooker is transferred to a heat-accumulating substance in the heat-accumulating cake; and solar energy is taken as energy, rays are transmitted to the heat-collecting heat conductive plate through a transparent plate, and the heat-collecting heat conductive plate converts light energy into heat energy. The cake body can be made of hard materials, the heat-accumulating substance can be a solid heat-accumulating material packaged by a hard cake-shaped material, so the structure and the material are not easy to explode; even if the structure and the material are exploded, the hard material packaged outside the cake body is only cracked, and the internal heat-accumulating material is not splashed and cannot endanger other persons. Besides, the structural design of the foldable solar cooker structure with the small volume is conveniently carried and used. The convenient solar heat-accumulating cake fully utilizes natural resources, saves electric energy and water energy and reduces occurrence probability of serious accidents with high security coefficient.

Owner:HANGZHOU LIUYI TECH

Aluminum alloy die-casting die easy to rapidly cool

The invention discloses an aluminum alloy die-casting die easy to rapidly cool, and belongs to the field of die-casting dies. According to the aluminum alloy die-casting die easy to rapidly cool, after the die is used for die-casting of aluminum alloy liquid, heat in the alloy liquid is adsorbed by a copper net and transmitted to air stretching sleeve rods, so that air stretching bags are heated and transversely expands at present, the contact area of the air stretching bags and an adherent heat pipe is increased, then the air stretching bags continue to expand downward under the action of heat to drive the adherent heat pipe to move down and gradually extend to a heat reducing chamber, so that the air stretching sleeve rods are dislocated with the adherent heat pipe; and compared with the prior art, according to the aluminum alloy die-casting die easy to rapidly cool, the contact area of condensate water in the heat reducing chamber is significantly increased, the cooling is faster, the die-casting efficiency of aluminum alloy is effectively improved, in addition, in cooperation with the effect of a water stirring rod, the water stirring capacity in the condensate water is effectively improved, the condensate water below the multiple air stretching sleeve rods is in a certain shaking state, and the heat taking-away effect is better.

Owner:叶立容

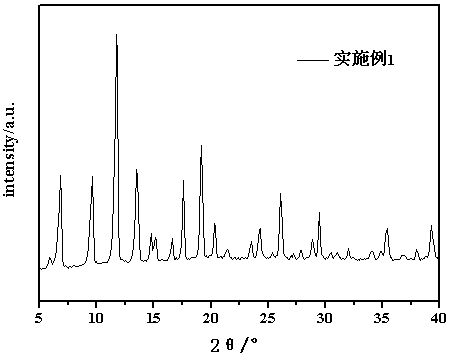

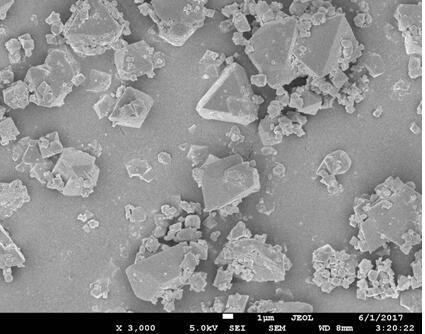

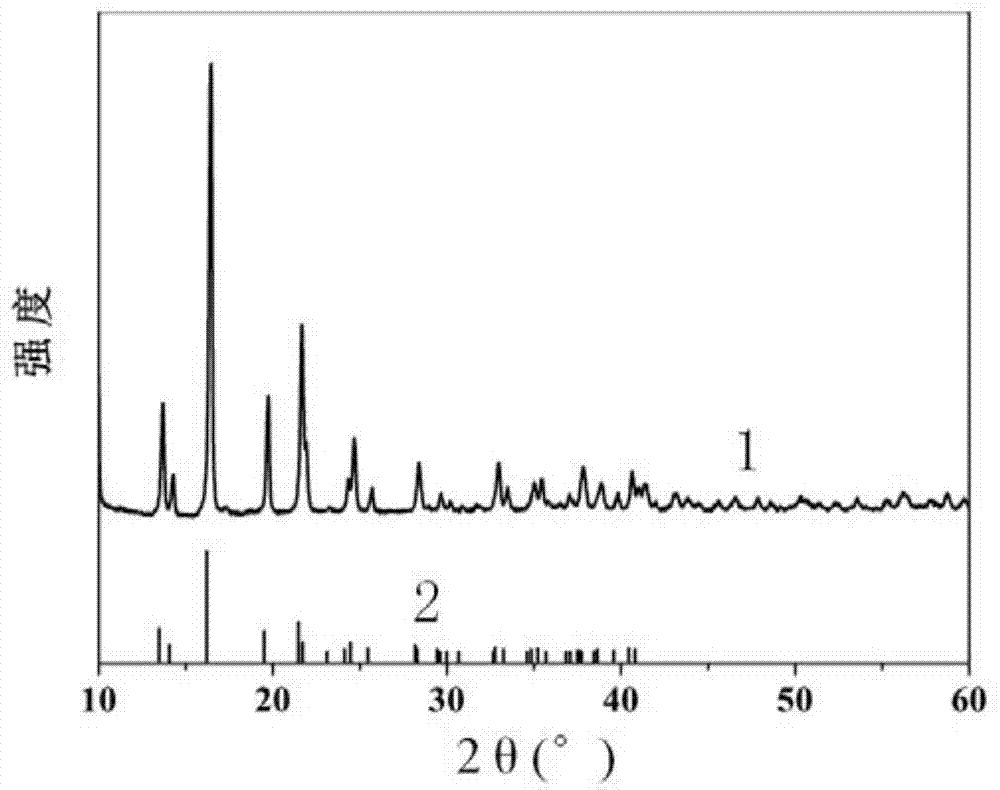

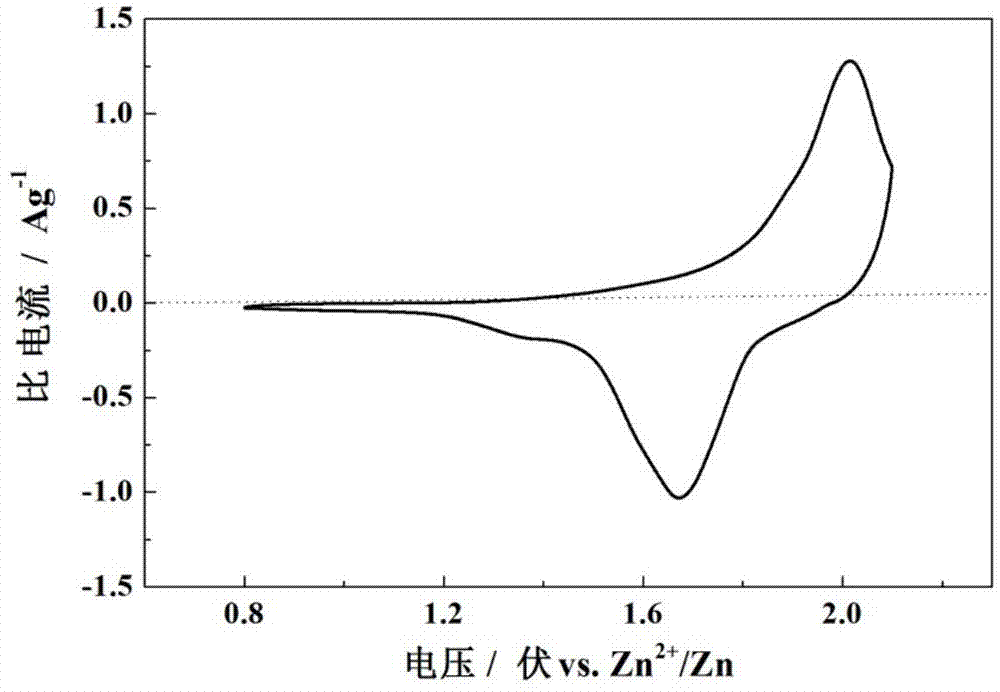

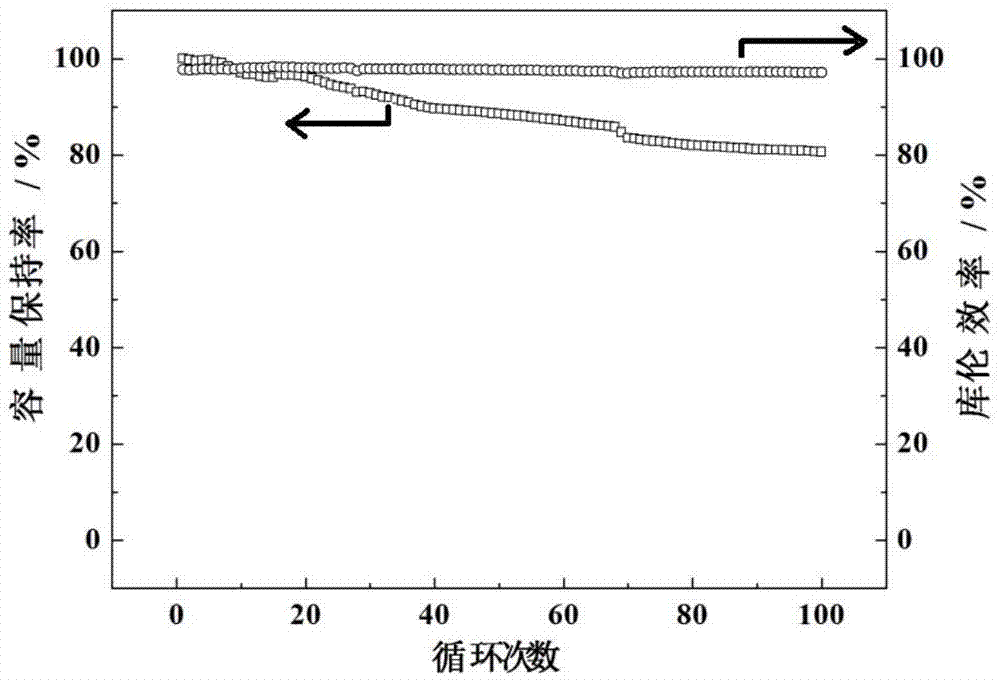

Secondary battery

ActiveCN103972582AImprove Coulombic efficiencyNot prone to explosionCell electrodesSecondary cellsSpace groupIron cyanide

The invention provides a secondary battery. The secondary battery comprises a positive electrode, a negative electrode, and an isolating membrane and electrolyte which are arranged between the positive electrode and the negative electrode; the positive electrode comprises a divalent metal ion iron cyanide complex; the secondary battery adopts the divalent metal ion iron cyanide complex as an positive electrode active material; the divalent metal ion iron cyanide complex is of a rhombohedral structure, belongs to the R-3c space group, and uses (Fe(CN)6) as a structural unit so that a three-dimensional frame network with a special pore passage structure is formed. positive ions can be rapidly embedded into and released from pore passages in a three-dimensional frame, and the three-dimensional frame is stable during embedding and releasing of the positive ions; the secondary battery adopting the divalent metal ion iron cyanide complex as the positive electrode active material has the high coulombic efficiency and the long cycle life; the divalent metal ion iron cyanide complex has the low reaction activity and the prepared battery is difficult to explode.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

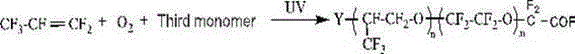

Production technology for preparing fluorine-containing surfactant free from perfluoro caprylic acid

InactiveCN105148794ASolve pollutionPromote decompositionTransportation and packagingMixingPerfluorooctanoic acidOxygen

The invention discloses a production technology for preparing a fluorine-containing surfactant free from perfluoro caprylic acid. The production technology includes the steps of photooxidation, hydrolysis, peroxide removing treatment and neutralization, perfluoroolefine, oxygen and a third monomer serve as reaction raw materials and are prepared into a fluorine-containing surfactant finished product with a C-O-C ether bond structure as the structural body, the finished product index meets the requirement that the surfactant is free from perfluoro caprylic acid and salts thereof, the surfactant is easy to decompose in the nature, the finished product index meets the data range that the peroxide value is 0.001-1%, and the surface tension is 10-30 mN / m; the fluorine-containing surfactant is of an amphiphilic structure of surfactants and suitable for industrial mass production.

Owner:成都晨光博达新材料股份有限公司

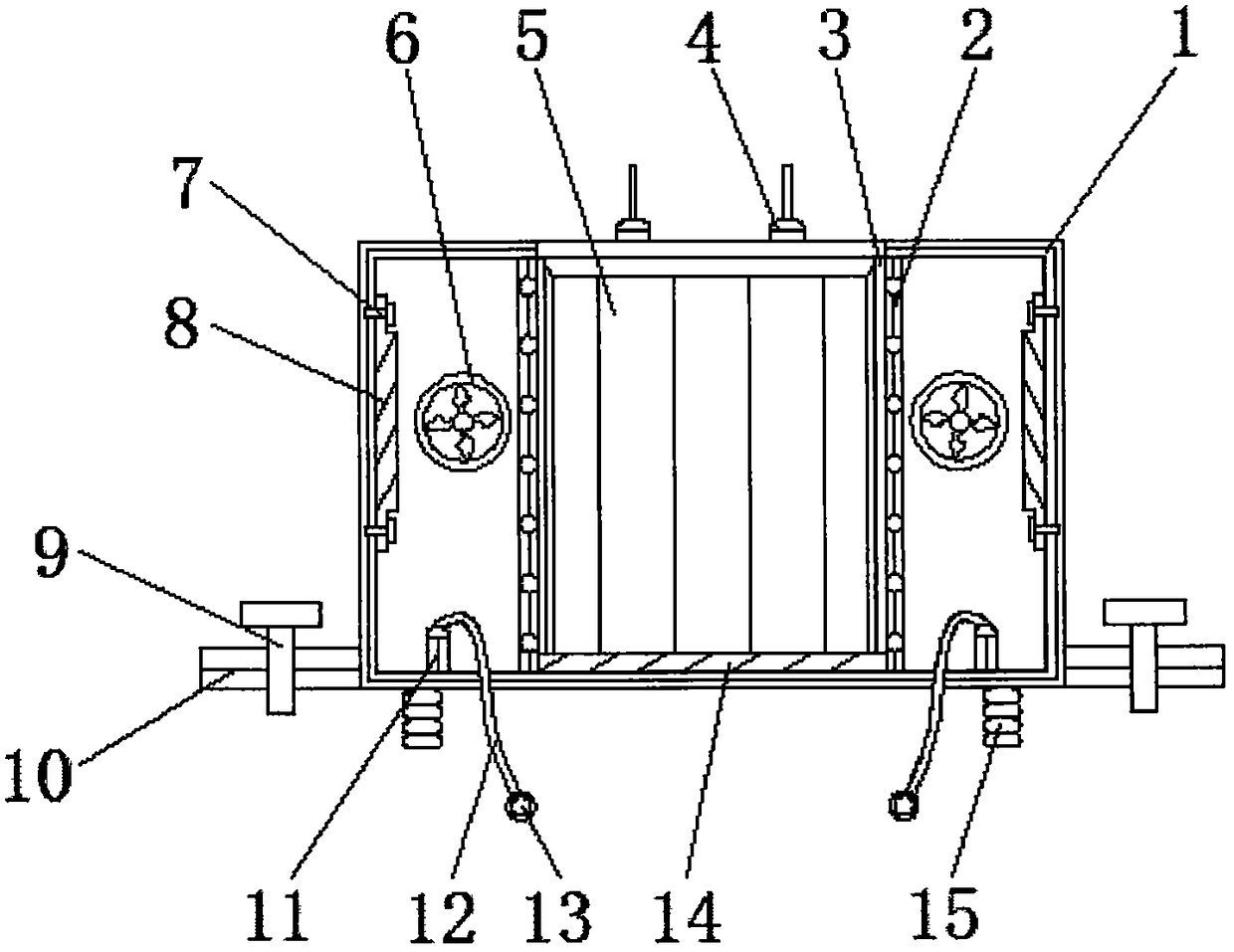

Chlorine dioxide generator

InactiveCN110615406ANot easy to break downNot prone to explosionChlorine dioxideChlorine dioxideGas phase

According to a chlorine dioxide generator provided by the invention, a tubular reactor is adopted, and a reaction solution flows and turns at a certain speed in a pipeline by controlling the flow direction of the reaction solution and the parameters of a reaction tube, so that sufficient stirring is realized, and the reaction is uniform. Chlorine dioxide conversion rate tests show that the chlorine dioxide generator provided by the invention can enable the chlorine dioxide conversion rate to be greater than or equal to 95%, which is much higher than the national performance requirements on thechlorine dioxide generator. The chlorine dioxide generator provided by the invention is in a liquid phase and does not contain a gas phase, chlorine dioxide is not easy to decompose and explode, no leakage risk exists, and the safety of the reaction process is high; and a mixed liquid can flow out by adopting a water ejector with a lower vacuum degree, so that the energy consumption is reduced. In addition, the chlorine dioxide generator provided by the invention is stable and reliable in operation and stable in chlorine dioxide yield; the manufacturing cost is low, the structure is simple, and the industrial application prospect is good.

Owner:SICHUAN QILI LVYUAN WATER TREATMENT TECH CO LTD

Method for treating top coal, immediate roof and upper roof

ActiveCN112127888ANot prone to explosionNo harm to healthDisloding machinesUnderground miningMining engineeringPetroleum engineering

The invention discloses a method for treating top coal, an immediate roof and an upper roof, and relates to the technical field of coal mining. The method comprises the following steps of: 1, constructing a plurality of first fracturing holes in an open-off cut in the length direction of the open-off cut; 2, mounting a fully mechanized mining support; 3, mounting a first carbon dioxide fracturingpipe in each first fracturing hole, and fracturing the open-off cut through the first carbon dioxide fracturing pipes; 4, constructing a plurality of second fracturing holes in an air return roadway in advance, and constructing a plurality of third fracturing holes in a transportation roadway in advance; 5, mounting second carbon dioxide fracturing pipes and third carbon dioxide fracturing pipes in the second fracturing holes and the third fracturing holes correspondingly, and fracturing one part of the air return roadway and one part of the transportation roadway through the second carbon dioxide fracturing pipes and the third carbon dioxide fracturing pipes correspondingly; and 6, starting coal mining, and fracturing the remaining part of the air return roadway and the remaining part ofthe transportation roadway while coal mining is conducted. The method is suitable for high gas and coal-gas outburst mines, and meanwhile harmful gas cannot be generated.

Owner:SHANXI XINQIAO TECH CO LTD

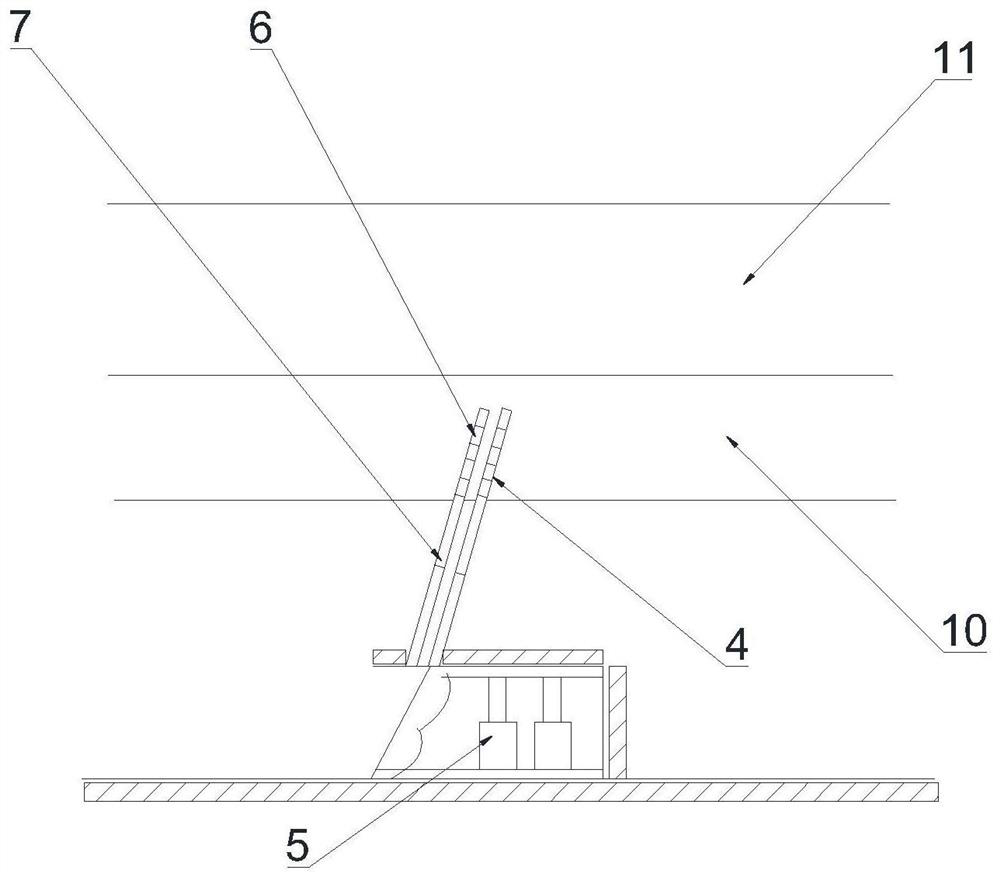

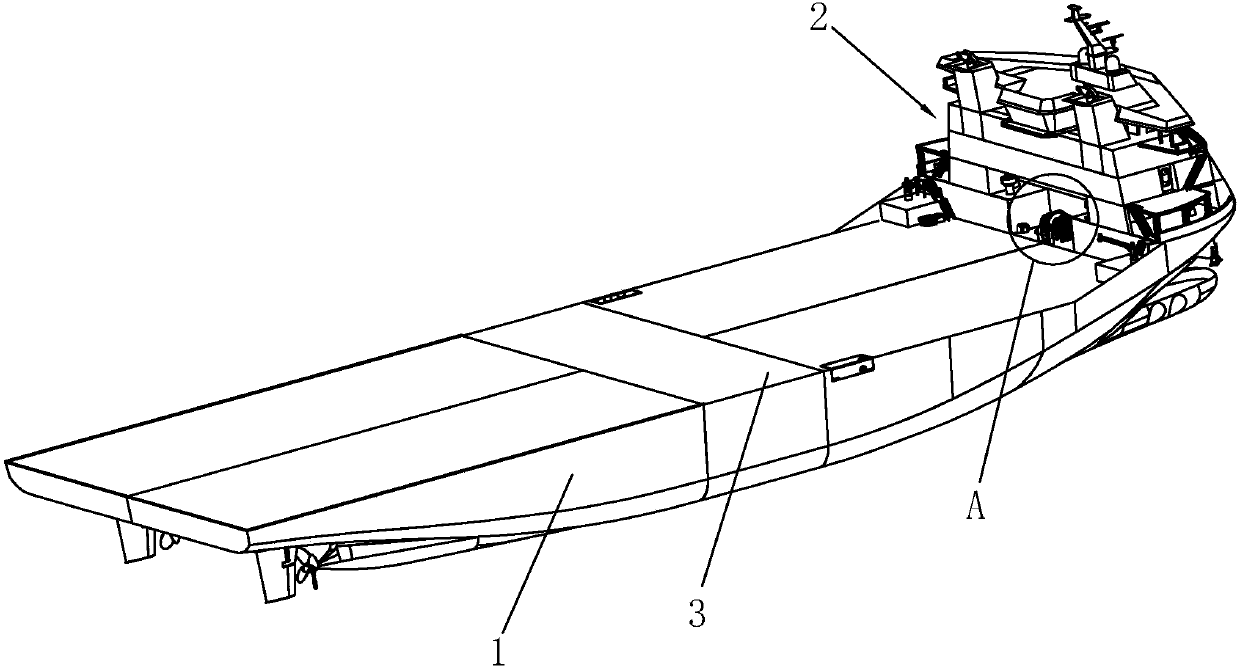

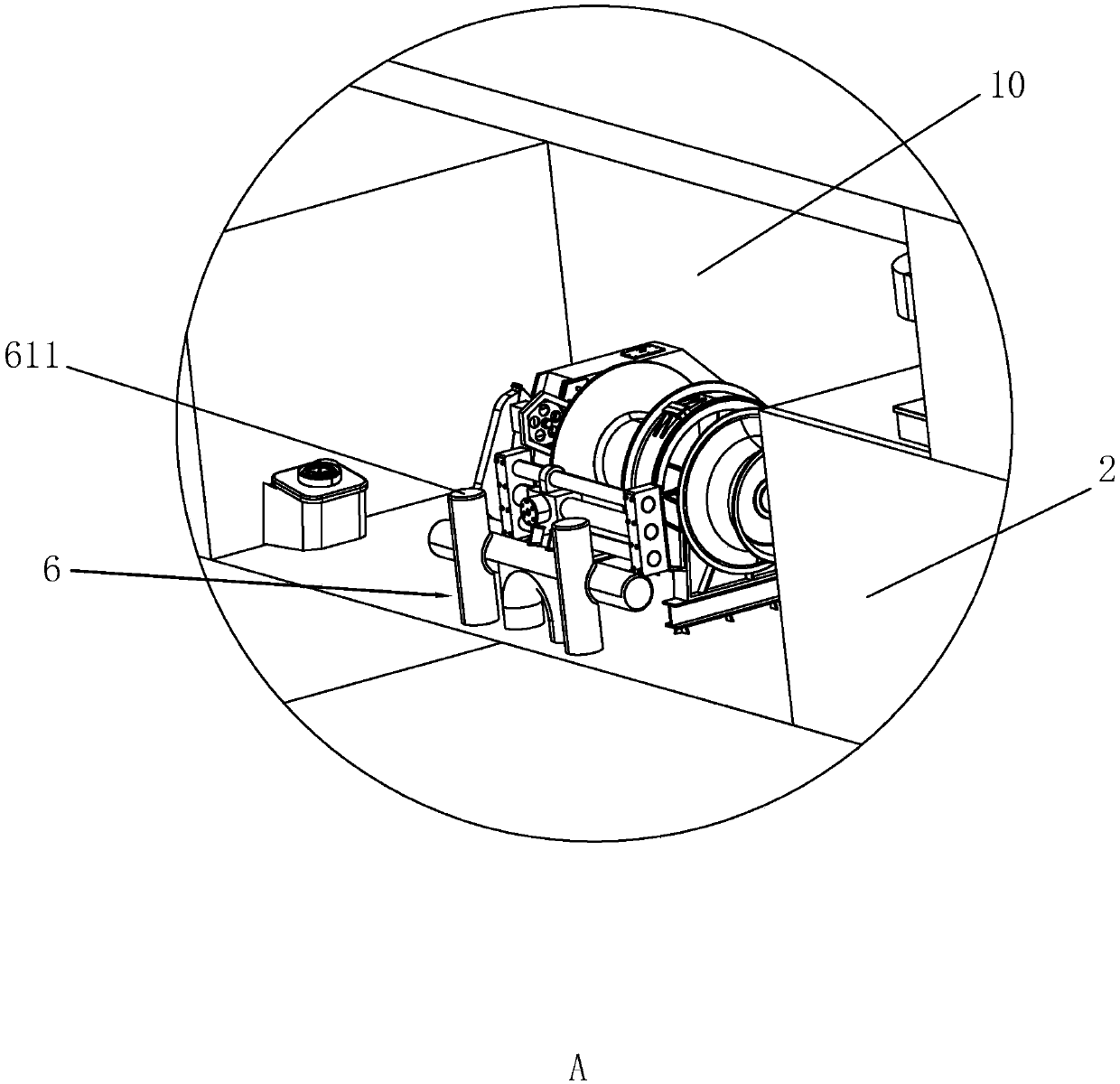

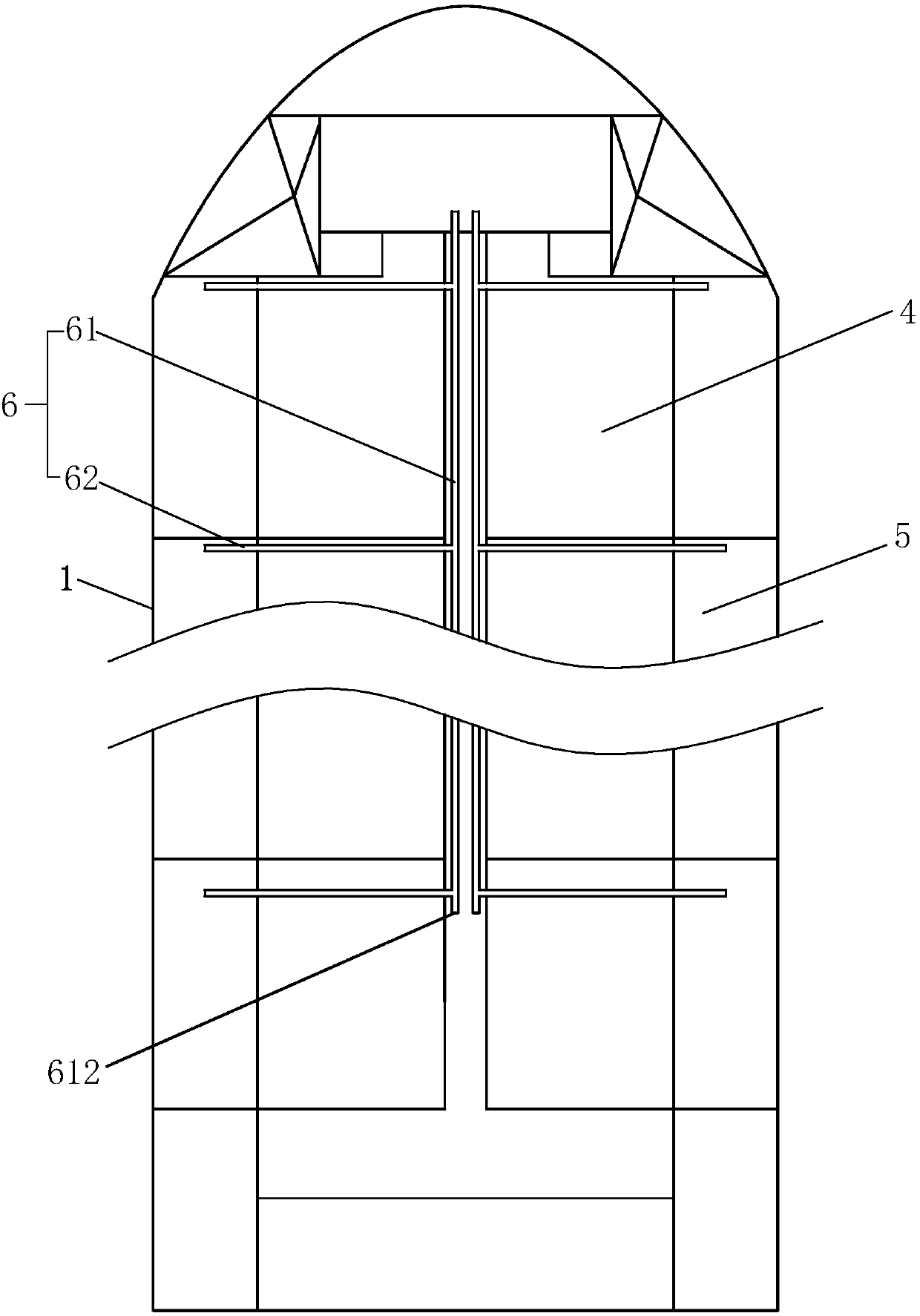

Deck carrier

PendingCN107839841AImprove securityNon-flammablePreventing unwanted cargo movementHull decksSolderingFuel tank

Owner:浙江宏盛造船有限公司

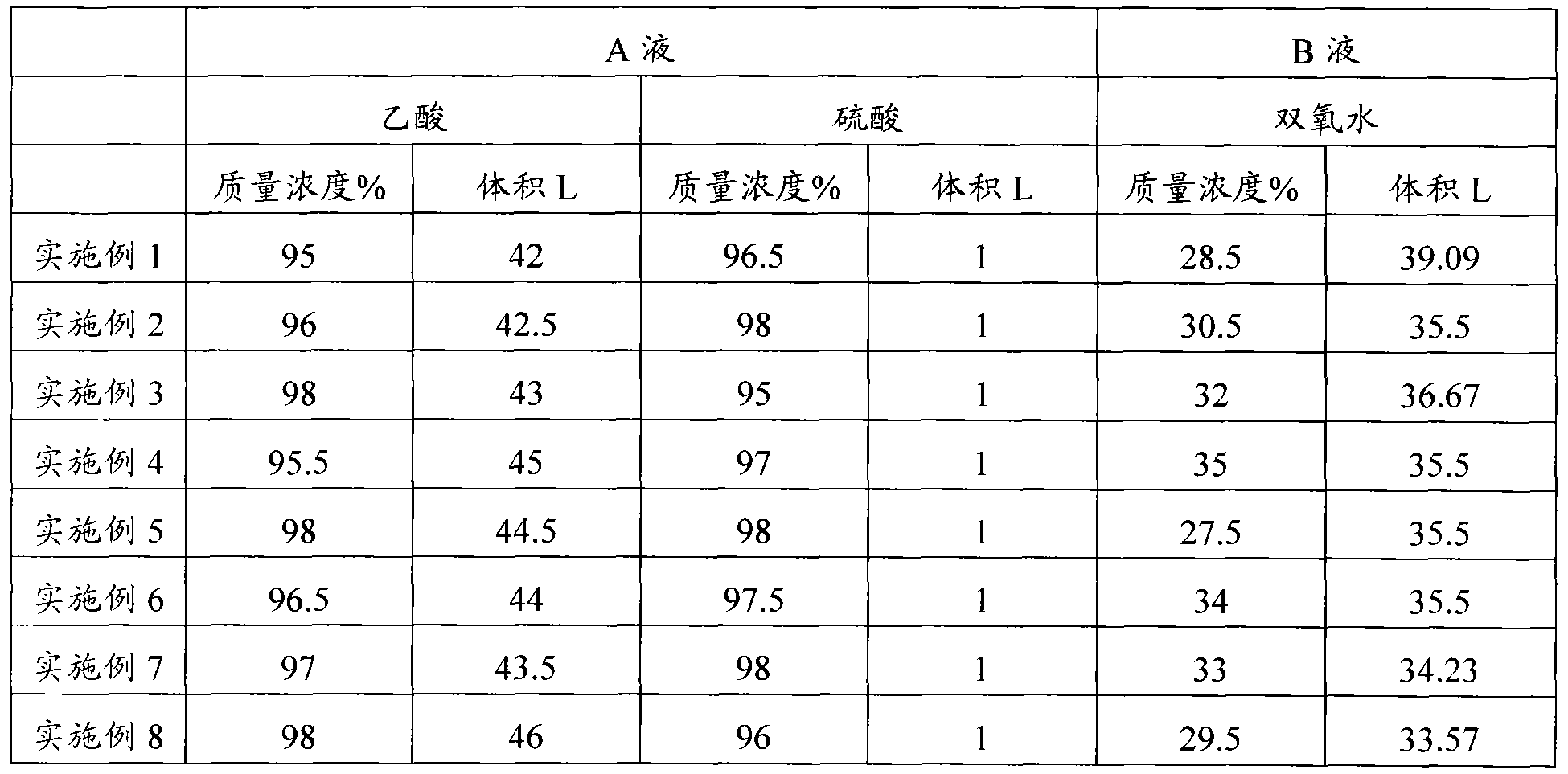

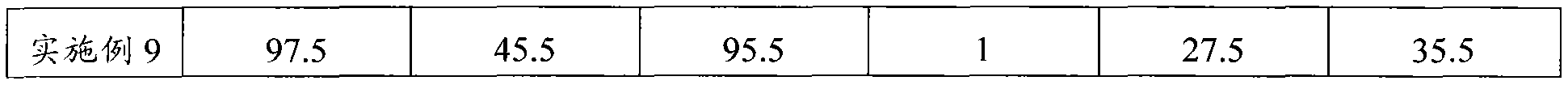

Binary disinfectant

InactiveCN104137830AImprove stabilityImprove the bactericidal effectBiocideDisinfectantsEscherichia coliDisinfectant

The invention discloses a binary disinfectant. The binary disinfectant comprises a liquid A and a liquid B, wherein the liquid A comprises acetic acid having the mass concentration of 95-98% and sulfuric acid having the mass concentration of 95-98%, while the liquid B is hydrogen peroxide having the mass concentration of 27.5-35%. The invention also discloses a preparation method of the binary disinfectant. The binary disinfectant is characterized in that glacial acetic acid and hydrogen peroxide taken as the major raw materials and prepared into the binary packaged disinfectant so that the sterilization effect and the stability of the disinfectant can be enhanced and then the disinfectant is capable of killing hepatitis A and B viruses, persistent viruses, influenza viruses and bacterial spores, and also capable of killing salmonella typhi, vibrio cholera, diarrhea and escherichia coli. The binary disinfectant can be used as the major disinfectant for controlling various viruses and the hospital cross infection, and can be applied to the disinfection and sterilization of viral pollutants, indoor and outdoor environments, hospital wards, common bathing pools, kindergartens, public places, breeding industry, hog houses, food processing industry, sewage treatment and the like.

Owner:高桂菊

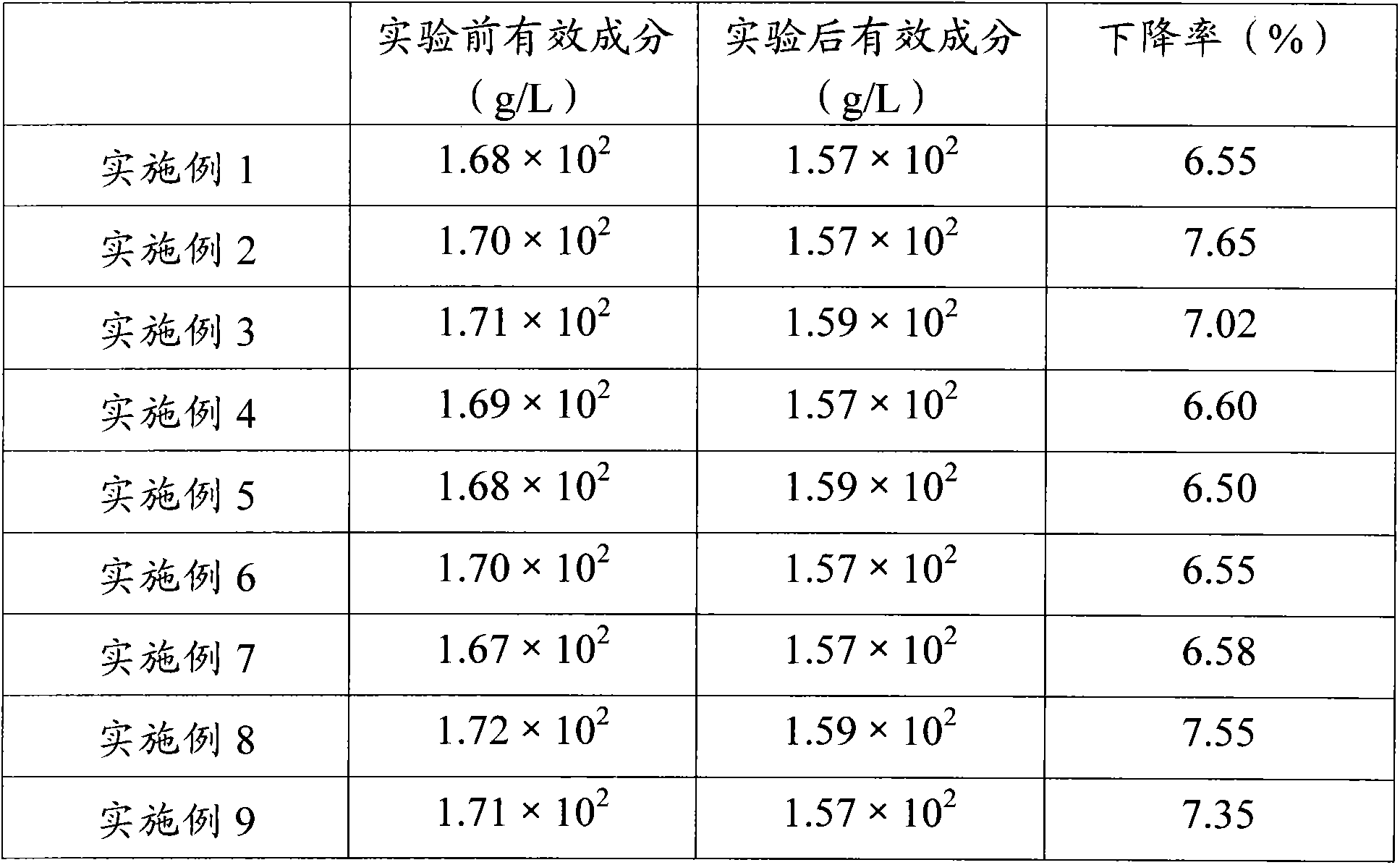

Industrial welding and cutting gas with environmental-protective and energy-saving functions

ActiveCN1896200AExpand the scope of useNot easy to explodeGaseous fuelsFuel additivesMethoxypropaneProduct gas

An environmental-protective and energy-saving welding and cutting gas consist of liquefied petroleum gas containing C3 and C4 and improver, the improver comprises 2-methoxy-propane and diamylene and other organic compounds mixed. It is safe, convenient and cheap, has better combustion stability and no environmental pollution.

Owner:BENFANG SCI & TECH DEV BEIJING

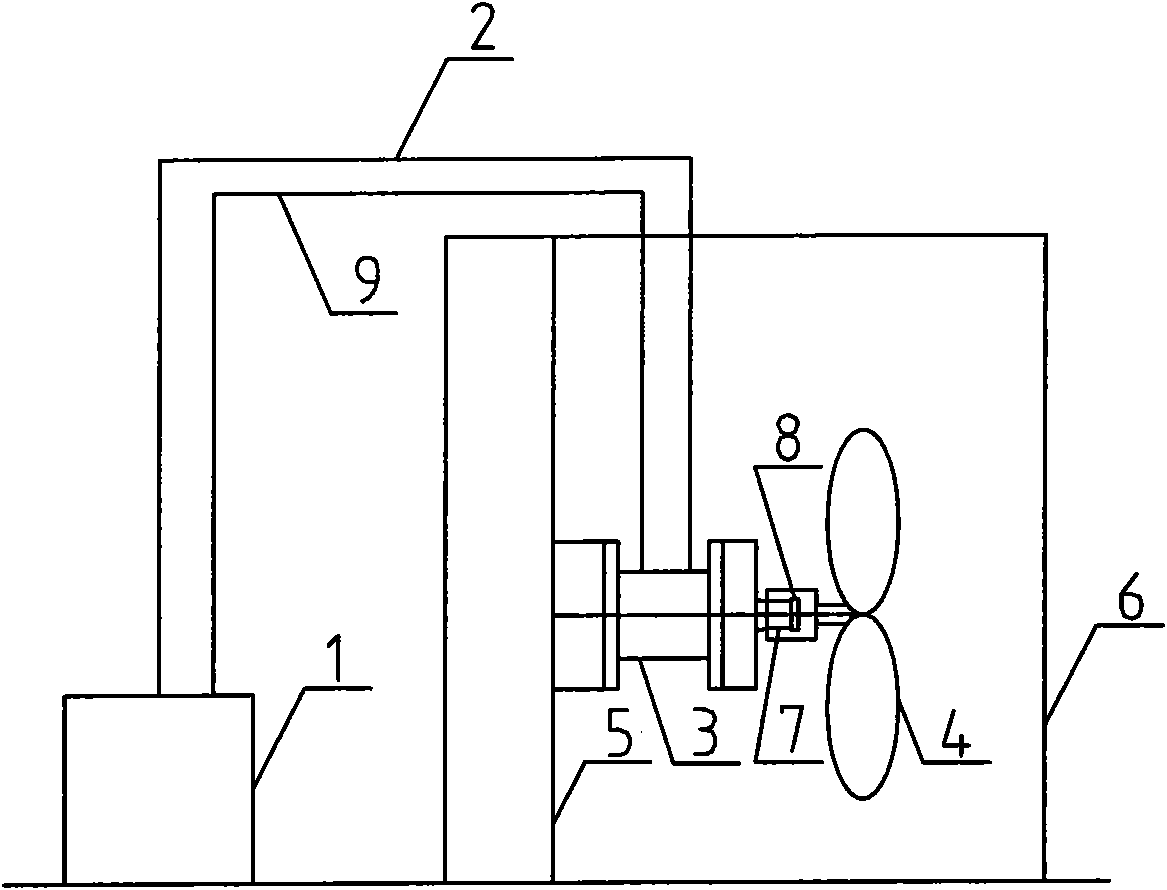

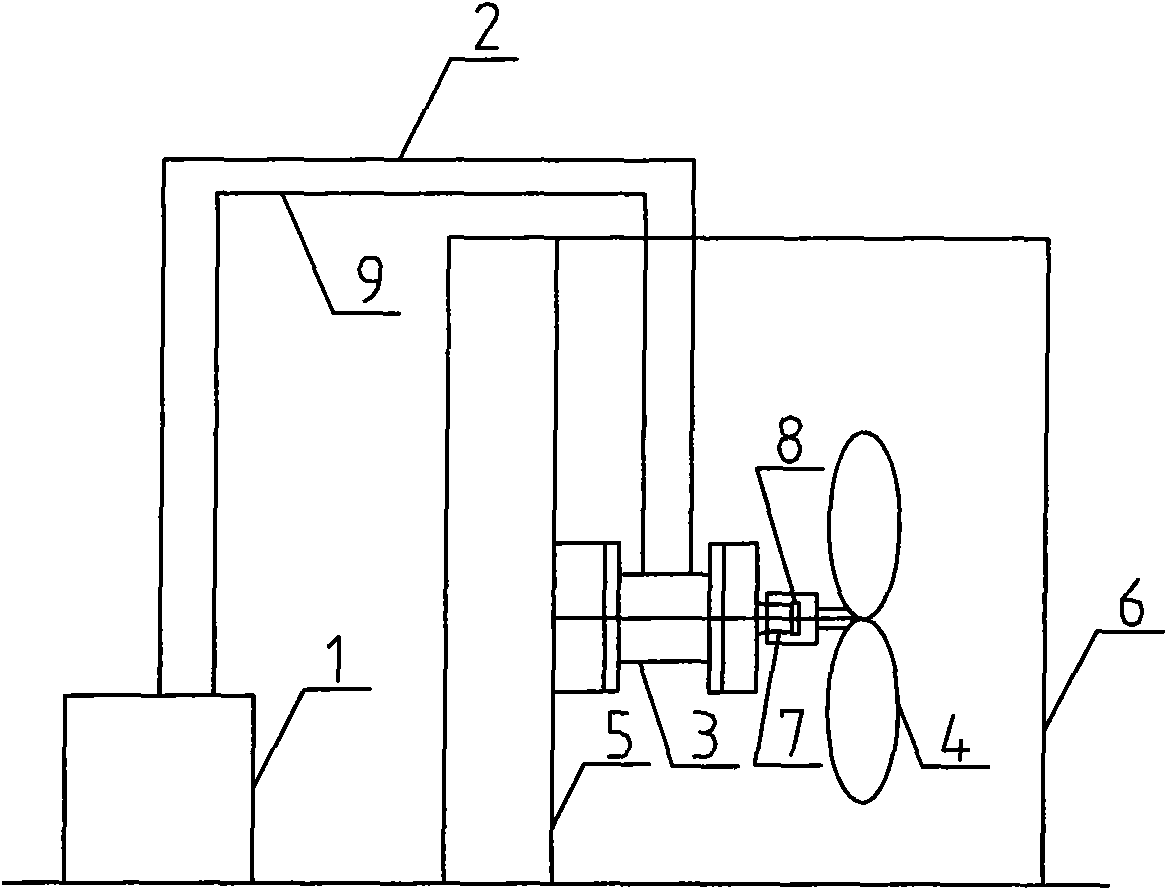

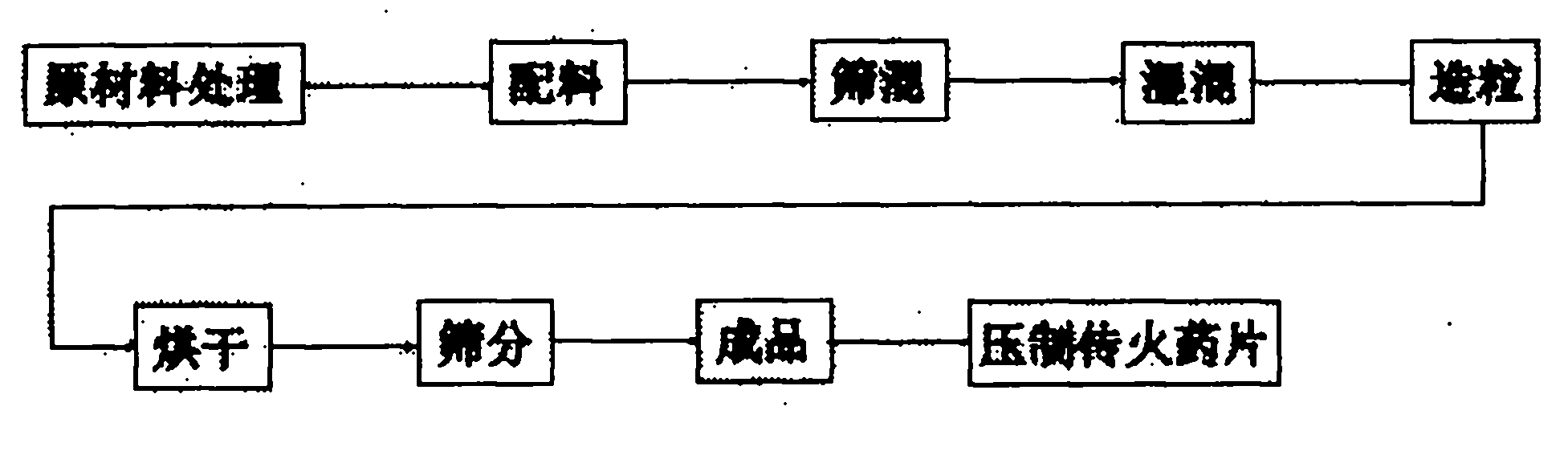

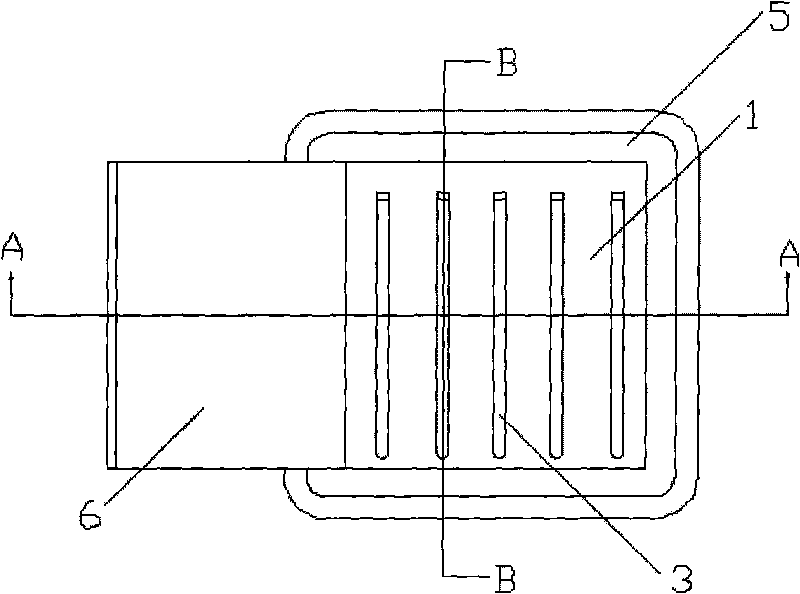

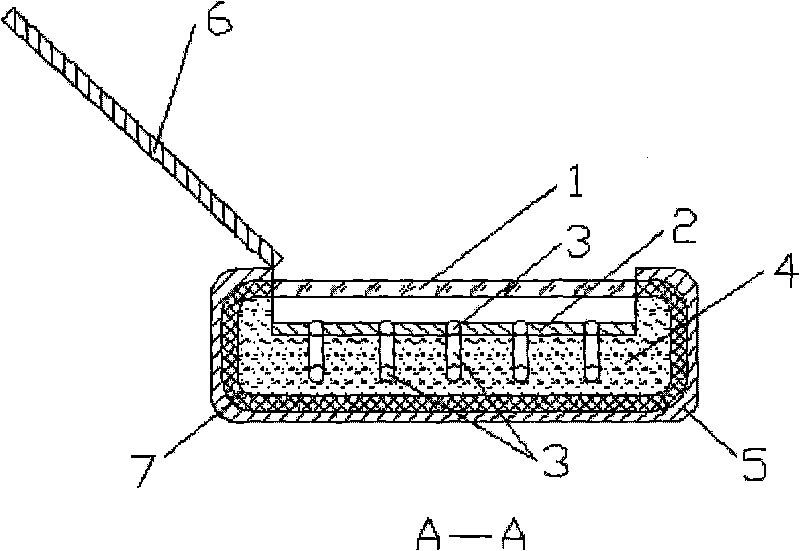

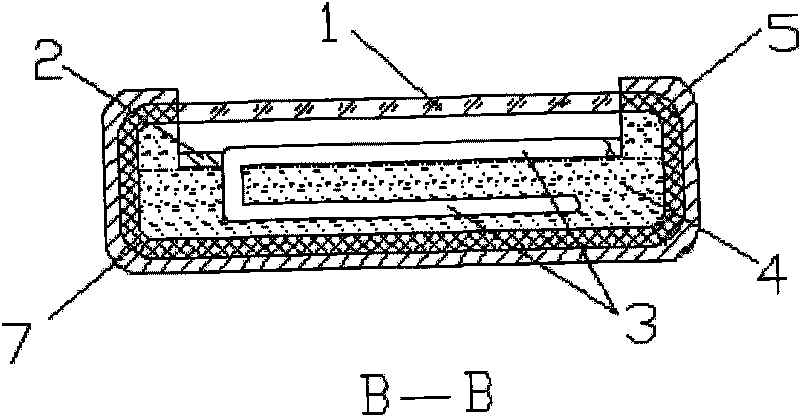

Power promoter special for industrial TNT-free powder explosive and manufacturing method thereof

InactiveCN102452863AReduce surface sensitivity and dustHigh detonation velocityNon-explosive/non-thermic compositionsGypsumPhosphoric acid

A power promoter special for industrial TNT-free powder explosives and a manufacturing method thereof are characterized in that raw materials comprise aluminium powder, gypsum powder, an emulsifier, stearic acid, complex wax, phosphoric acid, octadecylamine, and diatomite; the preparation method comprises the following steps: respectively adding the prepared aluminium powder and gypsum powder into a grinding mixing machine (5), boiling the emulsifier, stearic acid, and complex wax according to the ratios and adding into the grinding mixing machine (5) based on metering, boiling the prepared phosphoric acid, octadecylamine, and diatomite, processing into a modified moisture resistant agent, adding into the grinding mixing machine (5) based on metering, then stirring in a low speed, packaging the finished product by a packaging machine (6). During explosive production, the power promoter special for industrial TNT-free powder explosives is added into explosives; according to the invention, the ratio of the power promoter special for industrial TNT-free powder explosives in explosives is 3-4%; because the added aluminium powder is less, and is uniformly distributed in explosives, thegeneration of explosion accidents is prevented as long as production is performed strictly according to safety operation rules during production, and the risk is less.

Owner:肖代军 +2

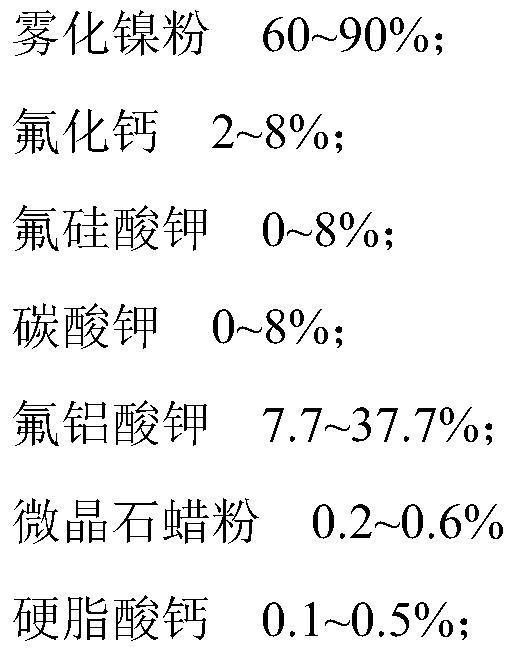

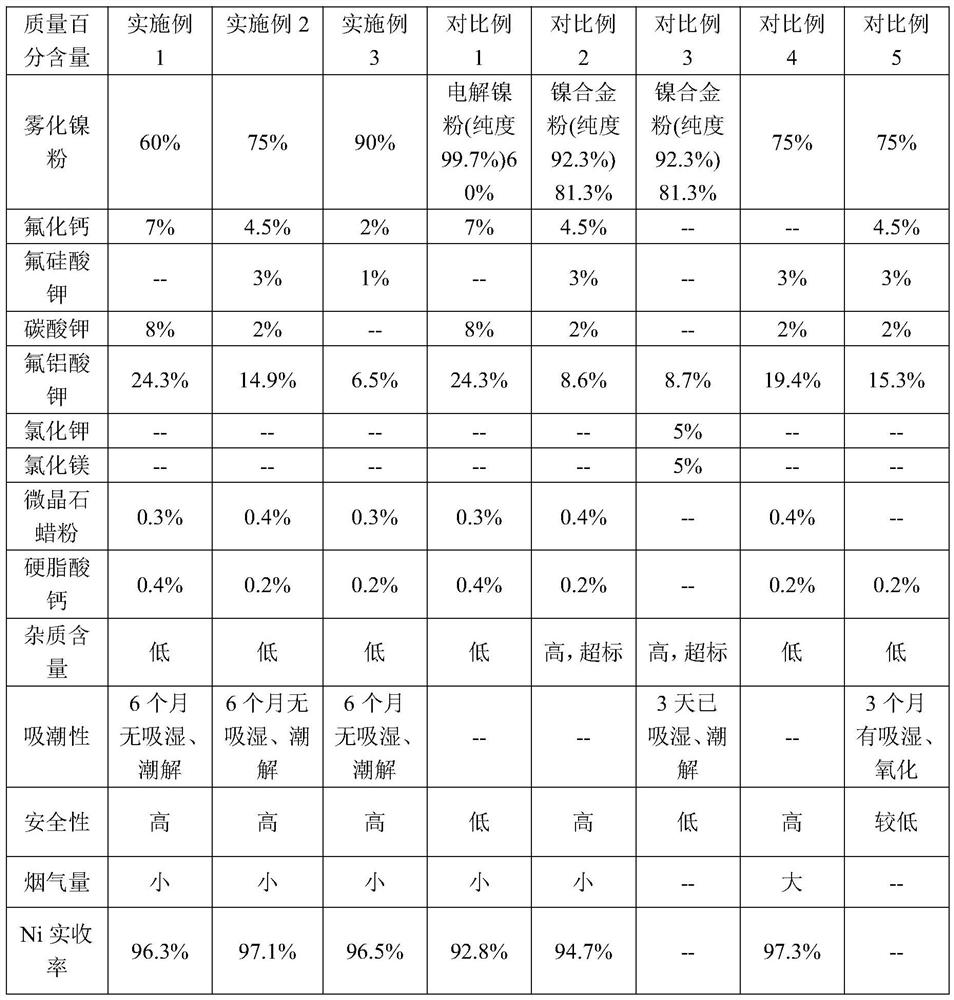

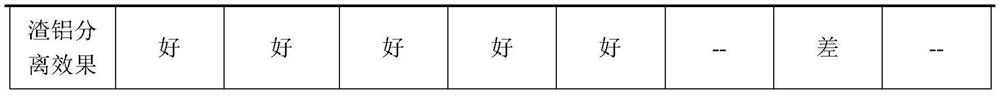

Nickel element additive for aluminum alloy

The invention relates to a nickel element additive for an aluminum alloy, comprising the following components in percentage by mass: 60-90% of atomized nickel powder; 2-8% of calcium fluoride; 0-8% of potassium fluosilicate; 0-8% of potassium carbonate; 7.7%-37.7% of potassium fluoroaluminate; 0.2-0.6% of microcrystalline wax powder; and 0.1-0.5% of calcium stearate. The mixed materials are pressed into a round cake shape through a hydraulic machine, the weight of a single block is 500-1500 g, and the density is 4.0-5.5 g / cm3. According to the nickel element additive, under the condition of 700-740 DEG C, when the Ni content is 0.5-2.3%, the casting yield of 96% or above can be achieved within 10-20 min, the impurity content is low, the melting speed is high, the casting yield is high, the smoke amount is small, and safety is good.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD

Novel green building interior wall board and surface treatment process thereof

ActiveCN112916354AHigh strengthImprove surface strengthLamination ancillary operationsSynthetic resin layered productsSurface strengthCeramic particle

The invention discloses a novel green building interior wall board and a surface treatment process thereof, and belongs to the field of building boards. According to the novel green building interior wall board and the surface treatment process thereof, a plurality of triangular supports can be formed in the board through the arrangement of an inner supporting clamping net and the cooperation of a supporting ball frame in the inner supporting clamping net, and then the strength of the board is remarkably improved, and the situation that the surface of the board is not easy to fall off when the board is used for the interior wall is effectively guaranteed; meanwhile, before the board is used as an interior wall board, firstly, the surface of the outer surface layer is subjected to multi-through-hole treatment, then the connection strength of the inner supporting clamping net in the outer surface layer is enhanced through heating, and then latex paint doped with nano ceramic particles is extruded and filled into the outer surface layer, so that an embedded interlayer is formed, and the surface strength of the board is improved; meanwhile, the latex paint permeates into the surface of the plate through the through holes, a plurality of protruding points are formed, the surface smoothness is reduced, and paint brushing is facilitated; and compared with the prior art, the influence on the service life of the board is effectively reduced.

Owner:深圳华创建筑装饰股份有限公司

Coloured light safety firecrackers

InactiveCN1590351AReduce pollutionNot prone to explosionFirecrackersExplosivesFirecrackerCopper oxide

A high-safety color-light firecracker with less pollution of SO2 to atmosphere is prepared from charcoal, lead red, copper oxide, Mg-Al alloy, and oxidizing aid.

Owner:沈晴

Novel firecracker

Owner:蚌埠知聪信息技术有限公司

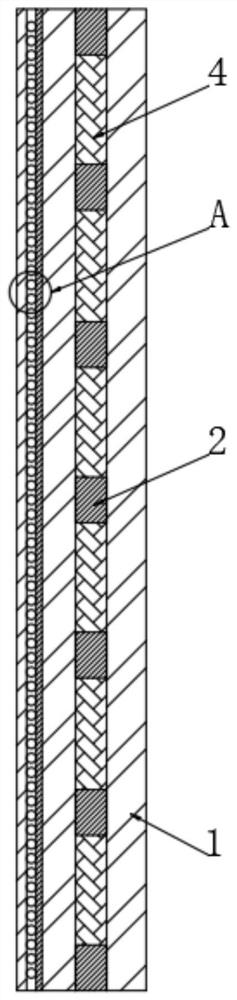

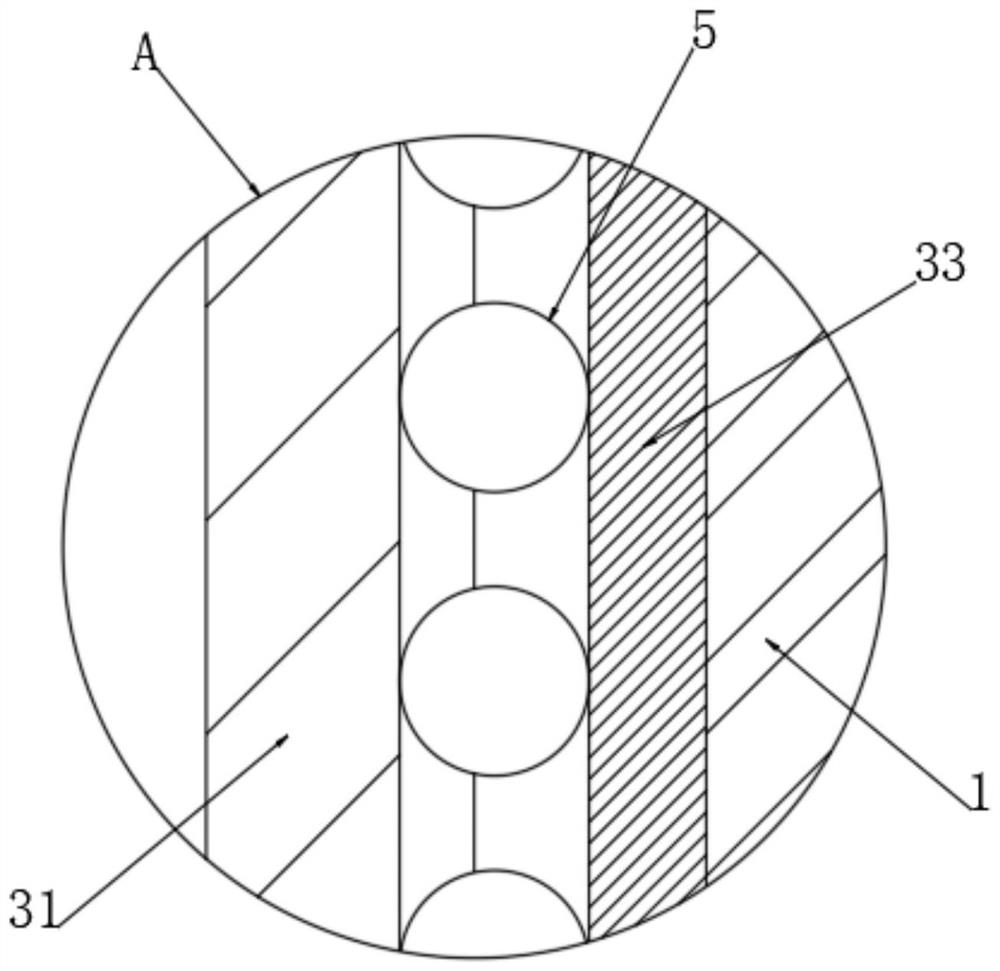

Electromagnetic shielding film, circuit board and preparation method of electromagnetic shielding film

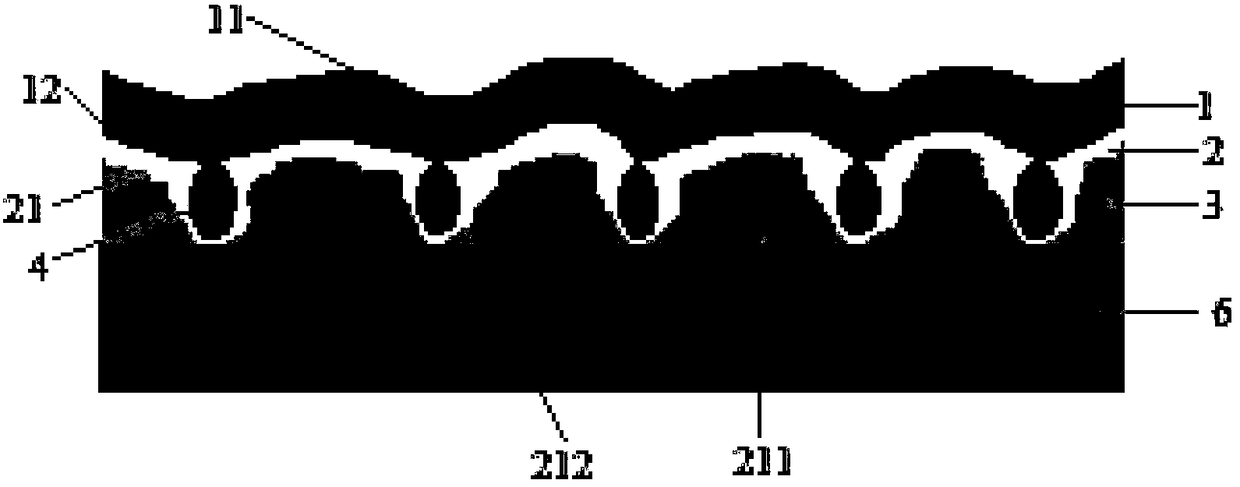

PendingCN110691498AGuaranteed groundingAvoid difficult dischargeMagnetic/electric field screeningFilm/foil adhesivesElectromagnetic shieldingElectronics

The invention relates to the technical field of electronics, and discloses an electromagnetic shielding film, a circuit board, and a preparation method of the electromagnetic shielding film. The electromagnetic shielding film comprises a shielding layer and an adhesive film layer. The adhesive film layer is arranged on the shielding layer. The surface, which is near the adhesive film layer, of theshielding layer is a non-flat surface. The shielding layer is provided with through holes penetrating the upper and lower surfaces thereof, which is beneficial for volatiles in the adhesive film layer to be exhausted through the through holes in the adhesive film layer at high temperature. Volatiles in the adhesive film layer can be easily discharged at high temperature. The electromagnetic shielding film is prevented from being peeled off from the ground layer of the circuit board due to bubbling and delamination of the electromagnetic shielding film. The electromagnetic shielding film is grounded, and interference charges are led out. In addition, the non-flat surface of the shielding layer pierces the adhesive film layer and is connected with the ground of the circuit board when the electromagnetic shielding film and the circuit board are pressed together. At the same time, gel substances are squeezed to the recesses of the non-flat surface to increase the adhesive capacity, whichprevents board burst, and ensures the connection of the shielding layer and the ground layer of the circuit board.

Owner:GUANGZHOU FANGBANG ELECTRONICS

Explosion-proof electric heater installing process

The invention discloses an explosion-proof electric heater installing process, which is characterized by comprising the following steps that an explosion-proof electric heating rod is in horizontal installation, an installation nipple is welded on an oil tank, the electric heating rod is arranged on a tank body through a connecting flange arranged on the installation nipple, an oil-resistant asbestos rubber pad is arranged between two flange plates and is connected and fastened through screw bolts, an explosion-proof electric heater is provided with a junction box, the junction box is fixedly arranged outside a manhole or an open opening through an installation support frame, the highest position of the installation of the electric heating rod needs to be controlled to be below the lowest work liquid level of the oil tank process design, a bracket is added in the tank for the electric heating rod, the bracket is prepared by a user, the distance from the center of a rod body to the tank bottom plane is 150 mm, and the rod body is fixed by the support frame. The explosion-proof electric heater installing process has the advantages that a heat system is simple, the number of water supply pumps is small, the operation is convenient and reliable, the monitoring workload is small, the service life is long, and explosion cannot easily occur.

Owner:ZHENJIANG YANGYI AUTOMOTIVE PARTS

Preparation method of mixed welding and cutting gas

The invention discloses a mixed welding and cutting gas preparation method which comprises the following components in percentage by mass: 50%-75% of acetylene gas, 20%-40% of propane, 0.1%-1% of hydrogen peroxide, 0.5%-1% of sodium bicarbonate, 0.2%-0.7% of a polymeric iron solution and 5%-10% of liquefied petroleum gas. The method comprises the following specific operation steps: uniformly mixing sodium bicarbonate and hydrogen peroxide, fully dissolving the sodium bicarbonate and the hydrogen peroxide to prepare a mixed solution, and performing gas-liquid mixing on gas and liquid of the mixed solution; adding a polymeric iron solution into the mixed solution, and uniformly mixing to obtain a new mixture; injecting a proper amount of new mixture into an empty acetylene gas cylinder; filling propane, liquefied petroleum gas and acetylene gas into the acetylene gas cylinder according to the proportion, and fully mixing; and warehousing after passing the inspection. Compared with the prior art, the preparation method has the advantages that all components in the preparation process are common chemicals, and the preparation method is low in cost, safe, energy-saving, environment-friendly and convenient to use.

Owner:严鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com