Gasification furnace for producing biomass charcoal

A technology of biomass charcoal and gasification furnace, which is applied in the manufacture of combustible gas and petroleum industry, etc. It can solve the problems such as the difficulty of reusing waste residues, and achieve an environment that is not easy to spray or burst the furnace, has high safety, and has a small gas storage space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

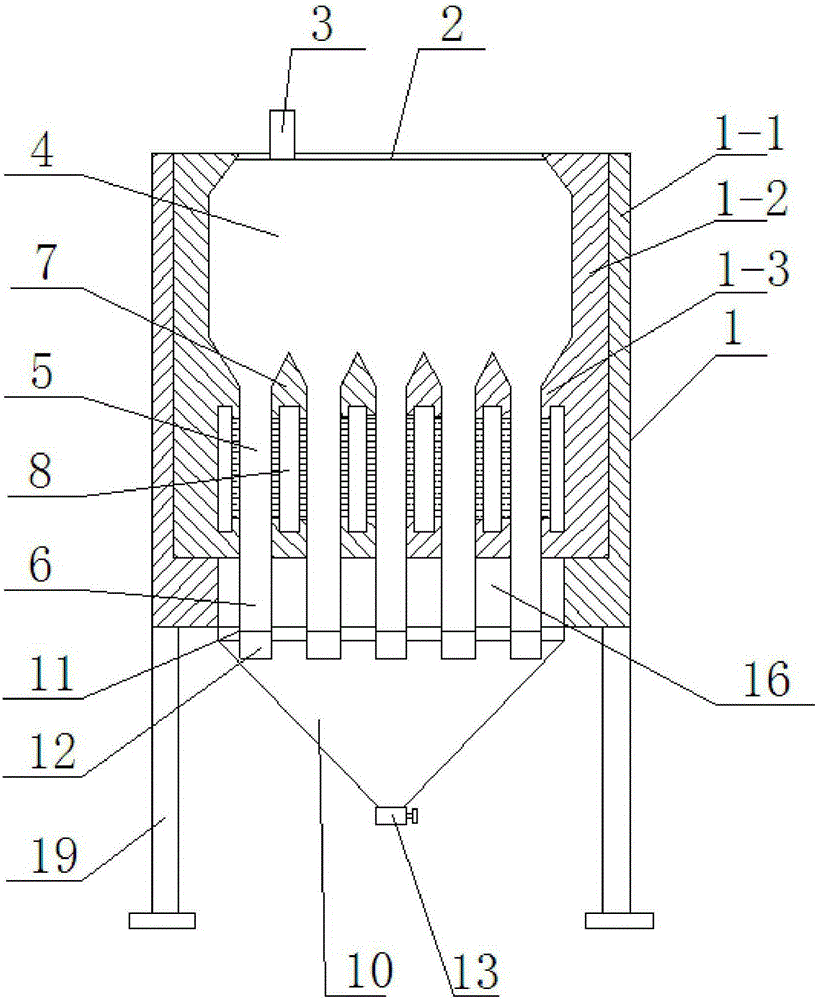

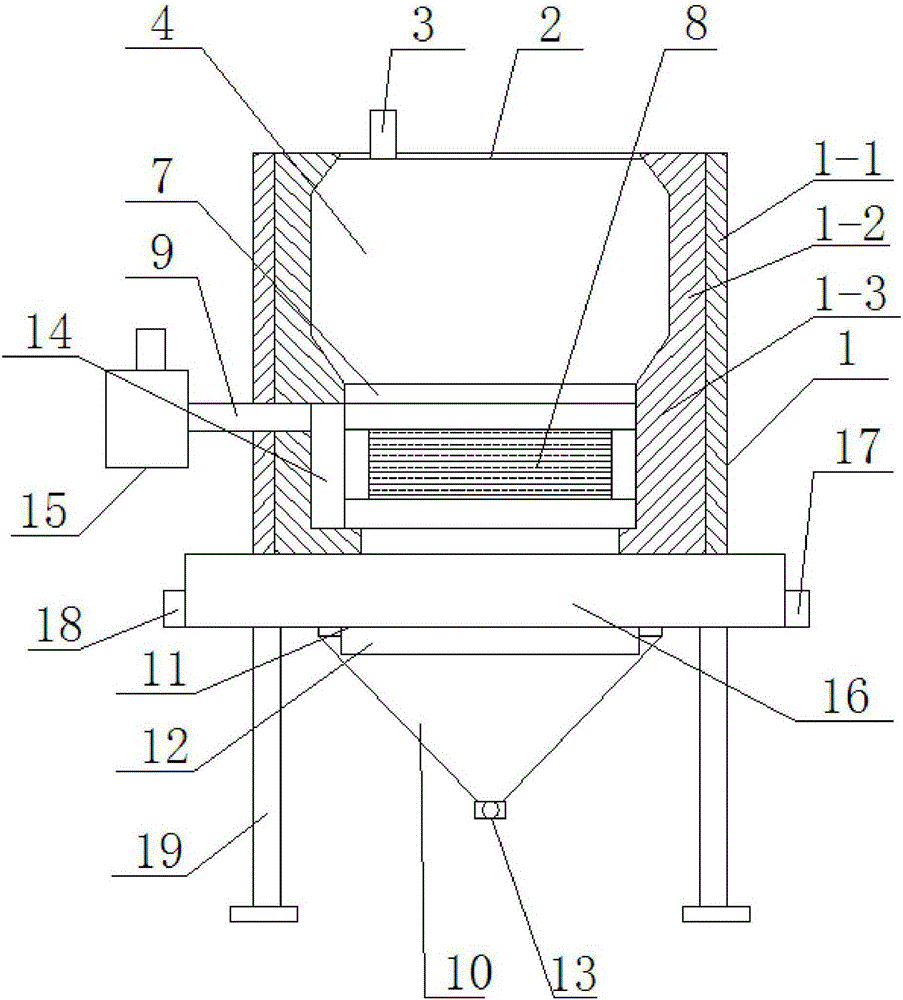

[0024] Such as figure 1 , figure 2 As shown, the present invention includes a body of furnace 1 and a bracket 19, the body of furnace 1 is fixed on the bracket 19, the top of the body of furnace 1 is provided with a furnace cover 2, and the top of the body of furnace 1 is provided with an air inlet mouth 3, the inner cavity of the furnace body 1 is divided into a raw material section 4, a combustion section 5 and a cooling section 6 from top to bottom, and a number of parallel vertical beams 7 are arranged in the combustion section 5, two adjacent A gap is provided between the two vertical beams 7, and a gasification reaction chamber 8 is arranged inside the vertical beam 7, and the gas reaction chamber communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com