Aluminum alloy die-casting die easy to rapidly cool

A technology for die-casting molds and aluminum alloys, applied in the field of die-casting molds, can solve the problems of long cooling time, influence of die-casting efficiency, etc., and achieve the effects of fast heat dissipation efficiency, improved water repellency, and fast cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

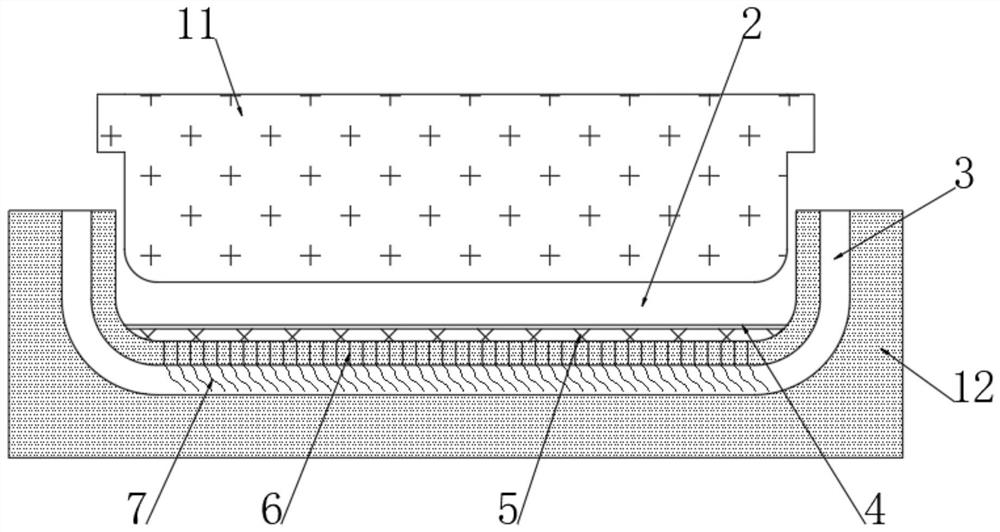

[0041] see figure 1 , an aluminum alloy die-casting mold that is easy to quickly cool down, including an upper movable mold 11 and a lower fixed mold 12 that match each other, a mold cavity 2 is formed between the upper movable mold 11 and the lower fixed mold 12, and a copper mesh is laid on the bottom of the mold cavity 2 5. The upper end of the copper mesh 5 is fixedly connected with the bottom plate 4, the outer edge of the bottom plate 4 is fixedly connected with the inner wall of the mold cavity 2 and matched with each other, and the lower end of the copper mesh 5 is fixedly connected with a plurality of evenly distributed air-stretching sleeve rods 6, and the lower fixed mold 12 is excavated inside There is a cooling chamber 3, and the air-stretching rod 6 fixes the lower fixed mold 12 that runs through the cooling chamber 3 and the mold cavity 2, and the lower end of the air-stretching rod 6 is flush with the inner top of the cooling chamber 3.

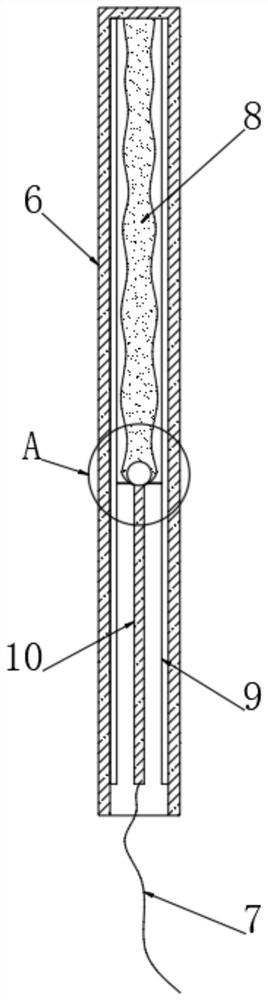

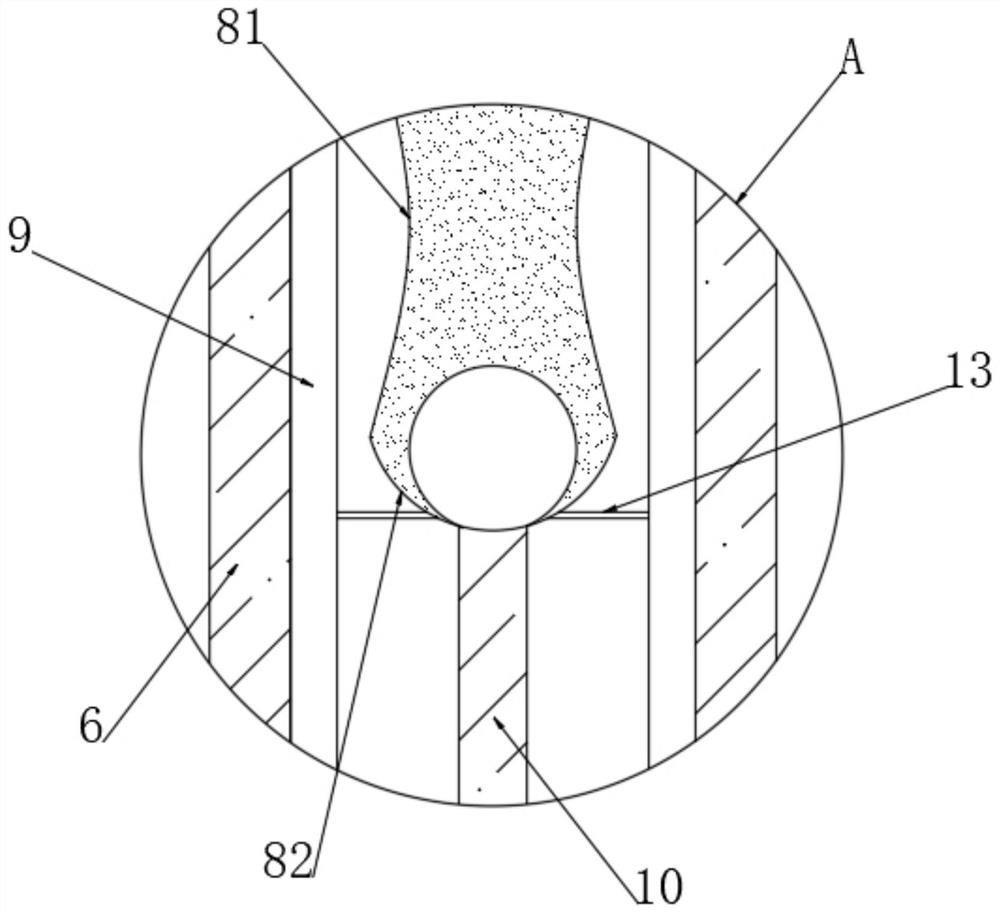

[0042] see Figure 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com