Patents

Literature

44results about How to "Improve die casting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

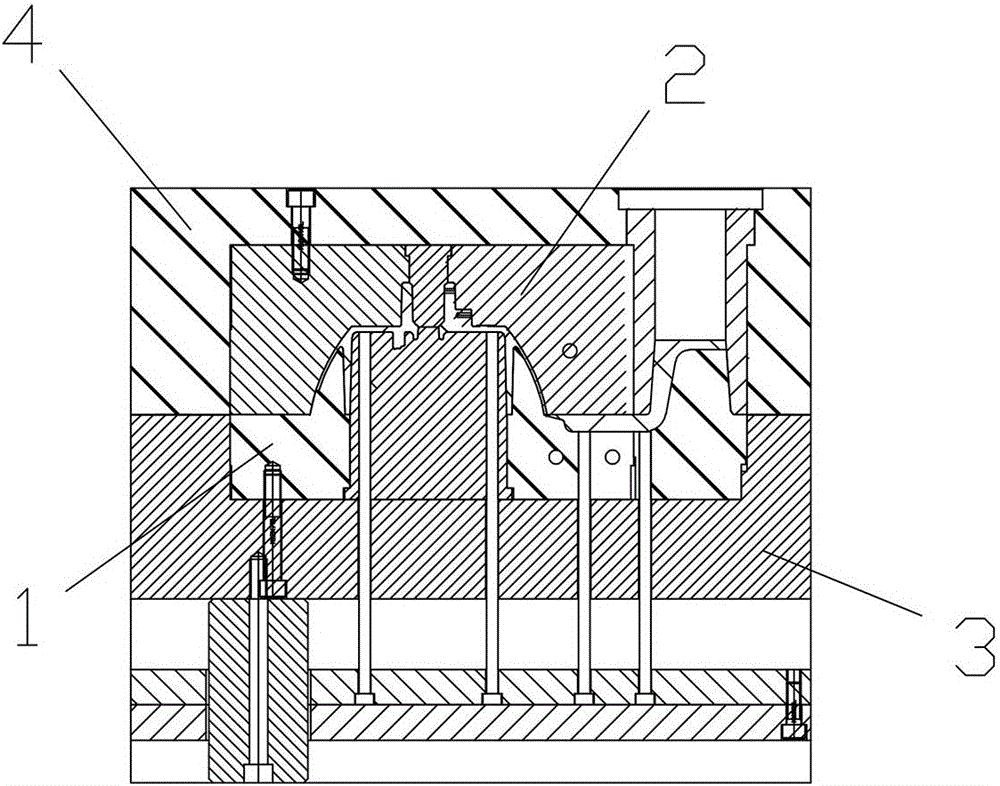

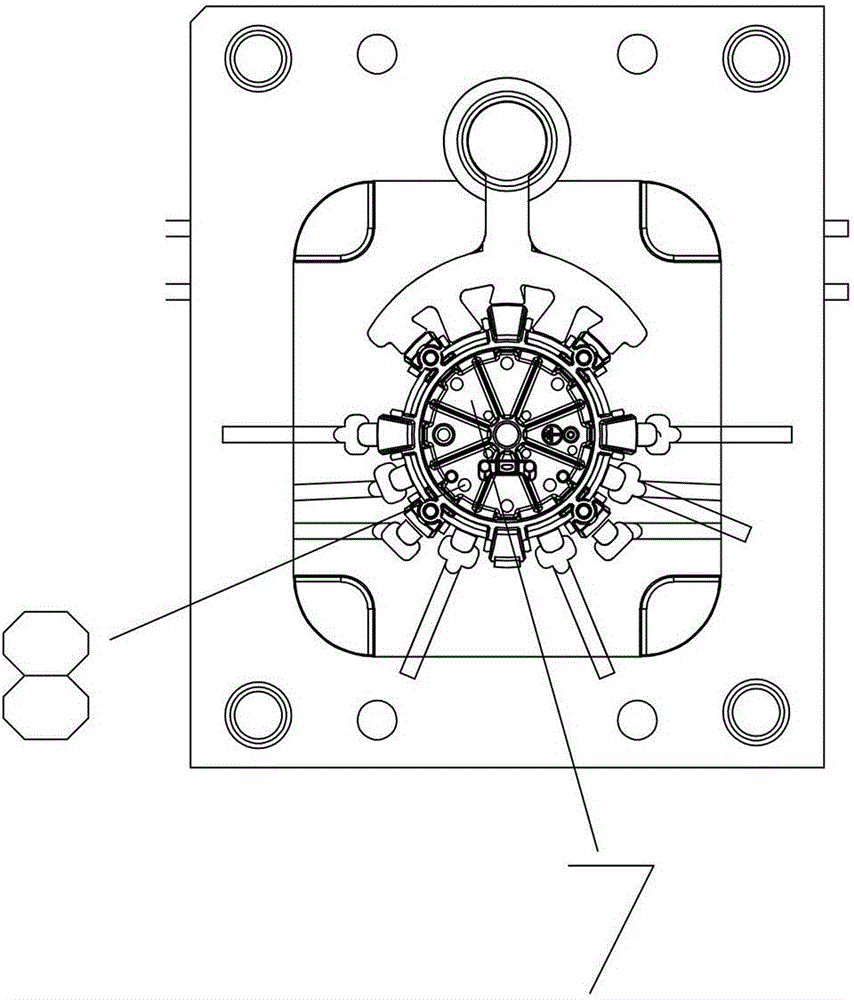

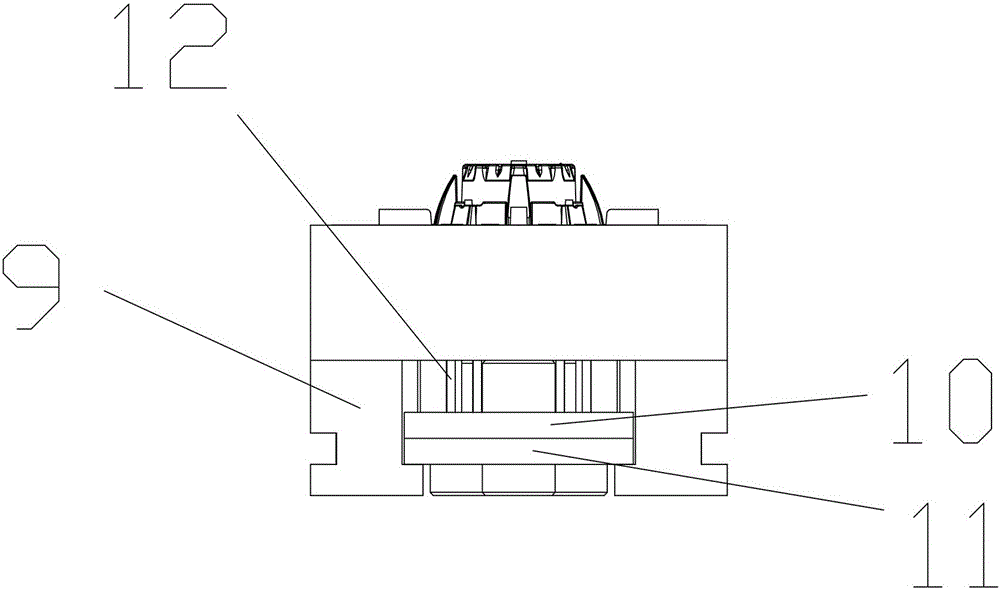

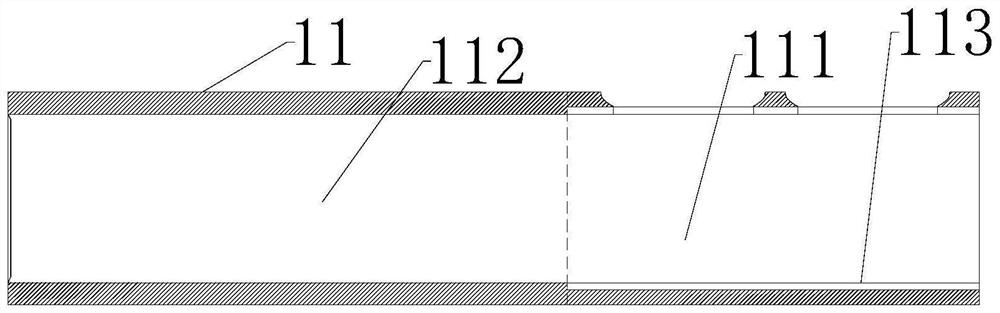

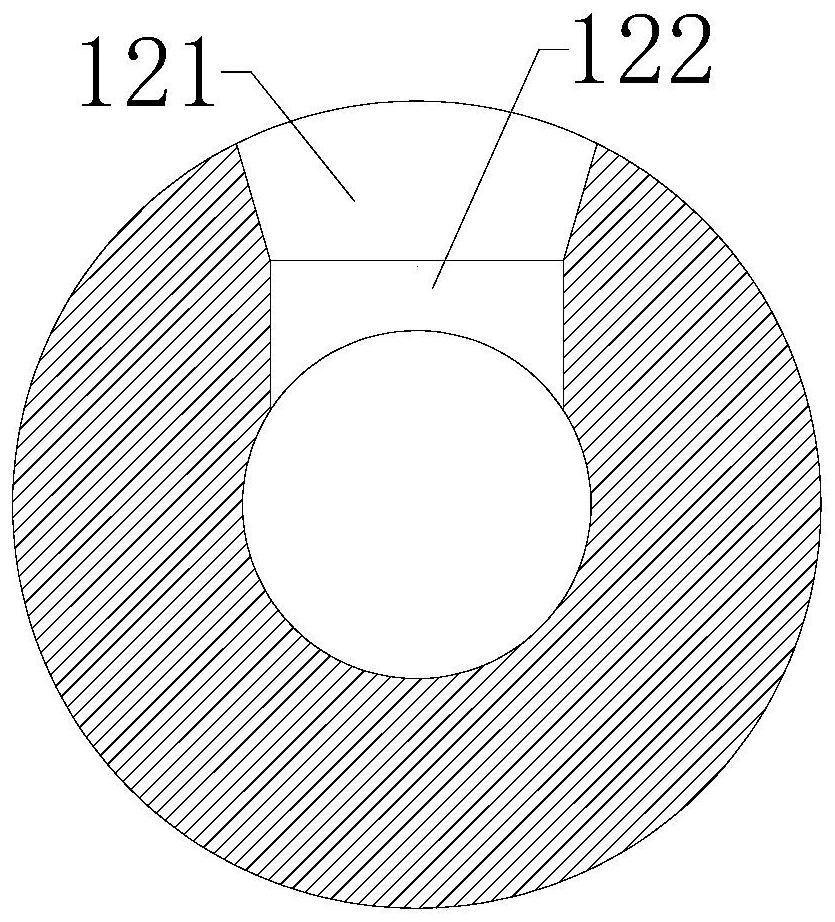

Die-casting mould

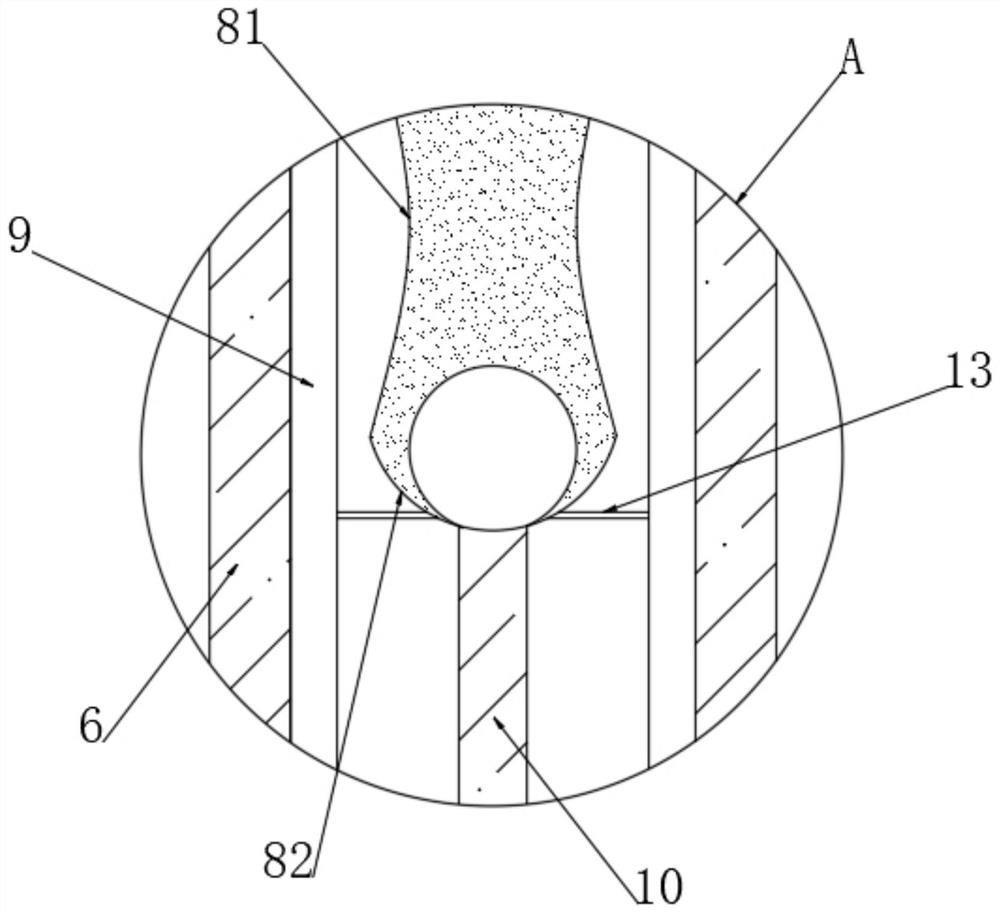

The invention discloses a die-casting mould. The die-casting mould comprises a moving mould, a fixed mould, a moving mould sleeve plate and a fixed mould sleeve plate; a first mould core insert is arranged at the central position of a moving mould plane; the bottom of the moving mould sleeve plate is connected with a pair of bases in a matched manner; an ejector pin panel and an ejector pin base plate are arranged between the base plates; the ejector pin base plate is arranged below the ejector pin panel; the ejector pin base plate and the ejector pin panel are adhered to each other closely; guide posts are arranged at the four corners of the fixed mould sleeve plate; a second through hole which penetrates through the fixed mould sleeve plate is formed in the inside wall of the fixed mould sleeve plate; a sprue bush is arranged in the second through hole; guide sleeves which are matched with the guide posts are correspondingly arranged at the four corners of the moving mould sleeve plate; a transverse pouring channel and an inner pouring gate are formed in the moving mould. According to the die-casting mould, components can be in different shapes for production by replacing small mould cores in different shapes; the temperature can be reduced by arranging a water pipe at a mould cavity, and the die-casting efficiency and the yield can be improved.

Owner:徐鹏威

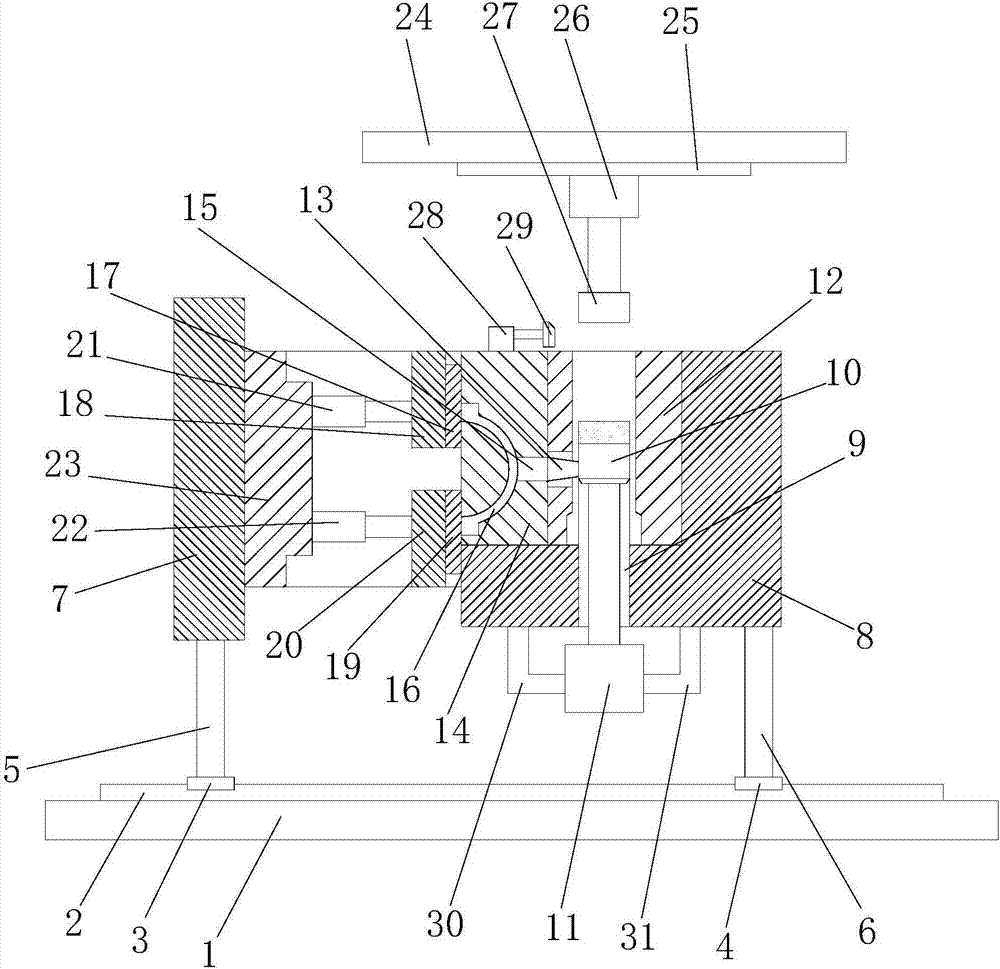

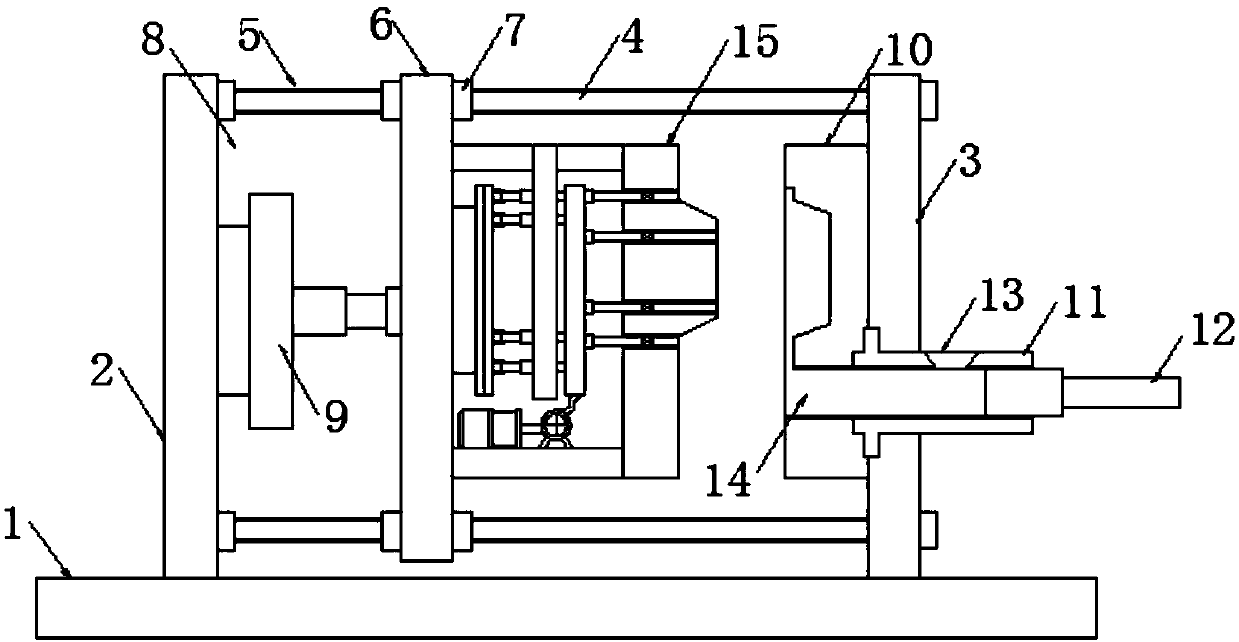

Aluminum alloy die-casting die

The invention discloses an aluminum alloy die-casting die. The aluminum alloy die-casting die comprises a bottom supporting seat, a slide rail, a first sliding seat, a second sliding seat, a first vertical supporting column, a second vertical supporting column, a vertical die holder, a die-casting die holder, a slide way, a lower punch, a hydraulic cylinder A and an inner barrel. One end of the inner barrel is provided with a liquid through nozzle, a die-casting part with an inner center gate is mounted on one side of the inner barrel and internally provided with a die-casting cavity passage with a first flow through port and a second flow through port, a first seal block is mounted on one side of the first flow through port, and a first fixing block is mounted at one end of the first seal block. A transverse seat is arranged above the die-casting die holder, a rail is mounted at the bottom end of the transverse seat, a hydraulic cylinder B is slidably mounted on the rail, and an upper punch is mounted at the bottom end of a hydraulic rod of the hydraulic cylinder B. The aluminum alloy die-casting die has advantages that die casting efficiency of the aluminum alloy die-casting die can be improved, and residual materials can be ejected conveniently.

Owner:昆山篙陵兴金属制品有限公司

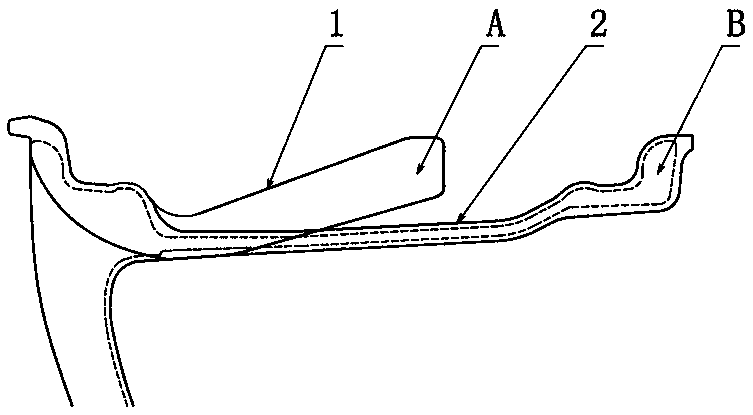

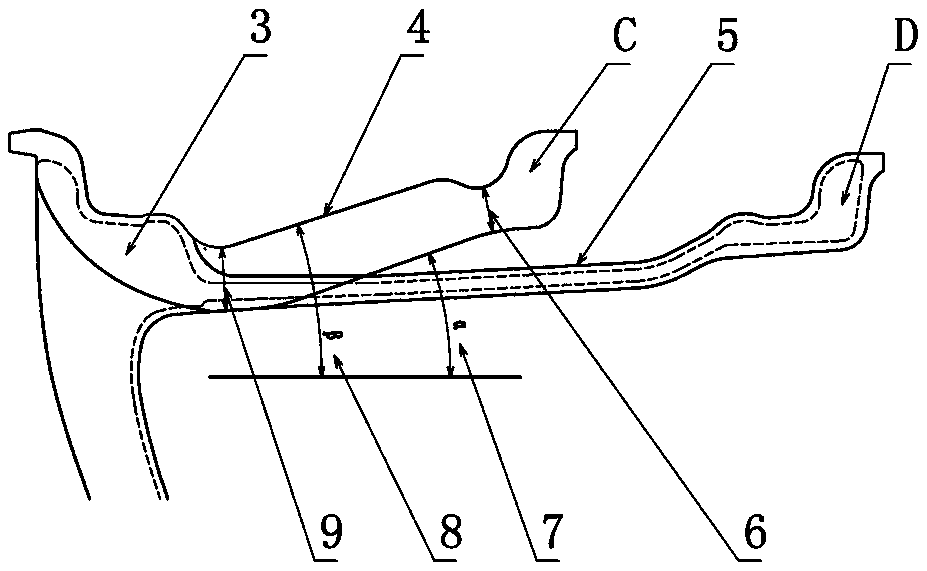

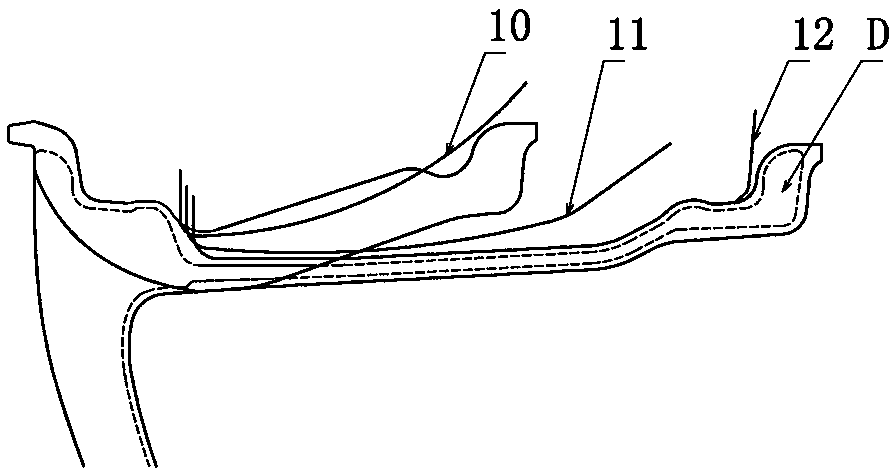

Cast spun aluminum alloy hub rim spinning formation method

InactiveCN108526283AMiniaturizationHigh strengthRimsMetal-working apparatusSpinningUltimate tensile strength

The invention discloses a cast spun aluminum alloy hub rim spinning formation method, that is, a special spinning composite processing method that a spoke and inn edge of a hub are manufactured in a cast manner and the middle of a rim is of a spun structure. By adopting the method, properties, strength and cast structures of inner edges can be prevented from being damaged, the impact resistance ofa cast spun hub at inner edges can be effectively improved, the inner edge of the hub can be prevented from cracking under radial impact, the properties of the hub spun structures can be improved, the hub can be thinned, and lighting of hubs can be achieved.

Owner:CITIC DICASTAL

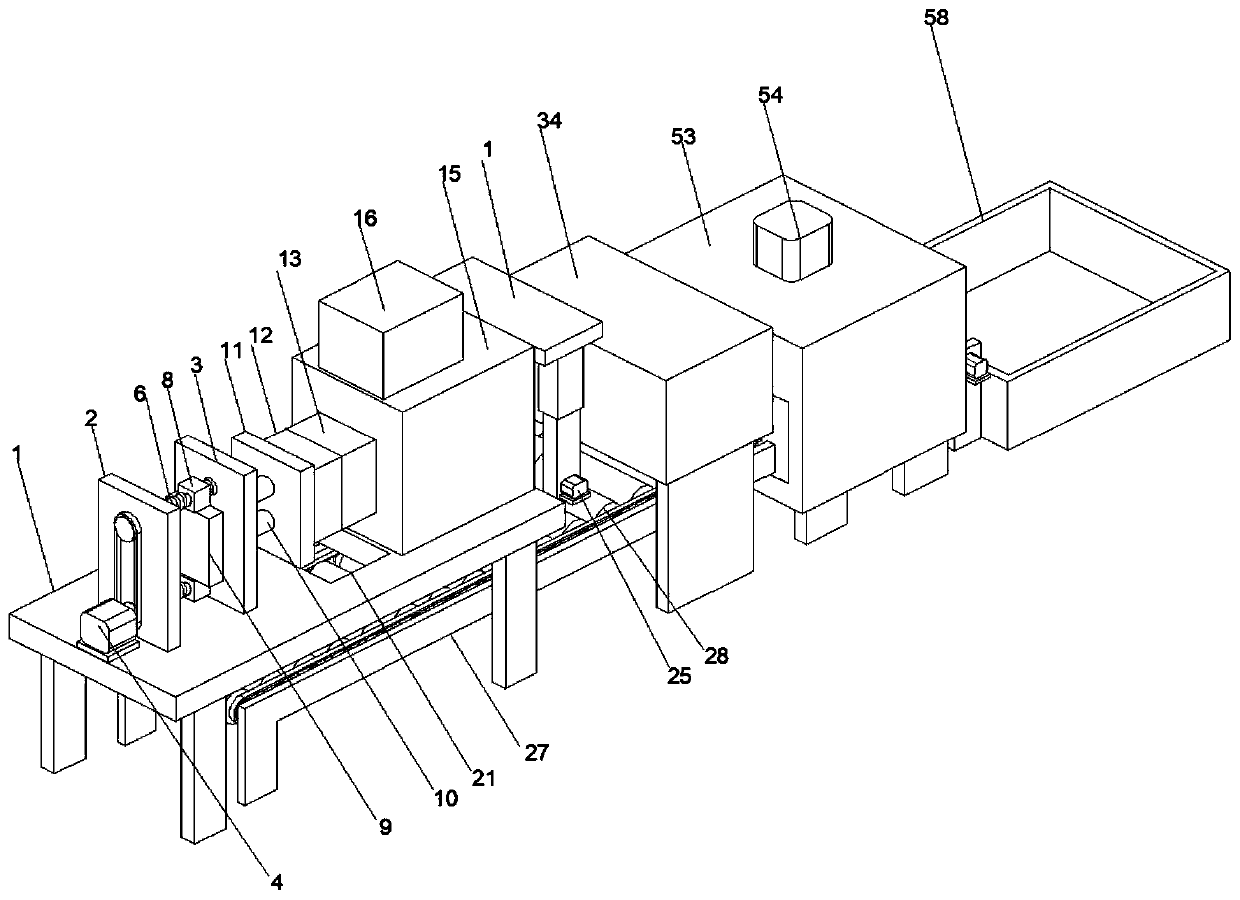

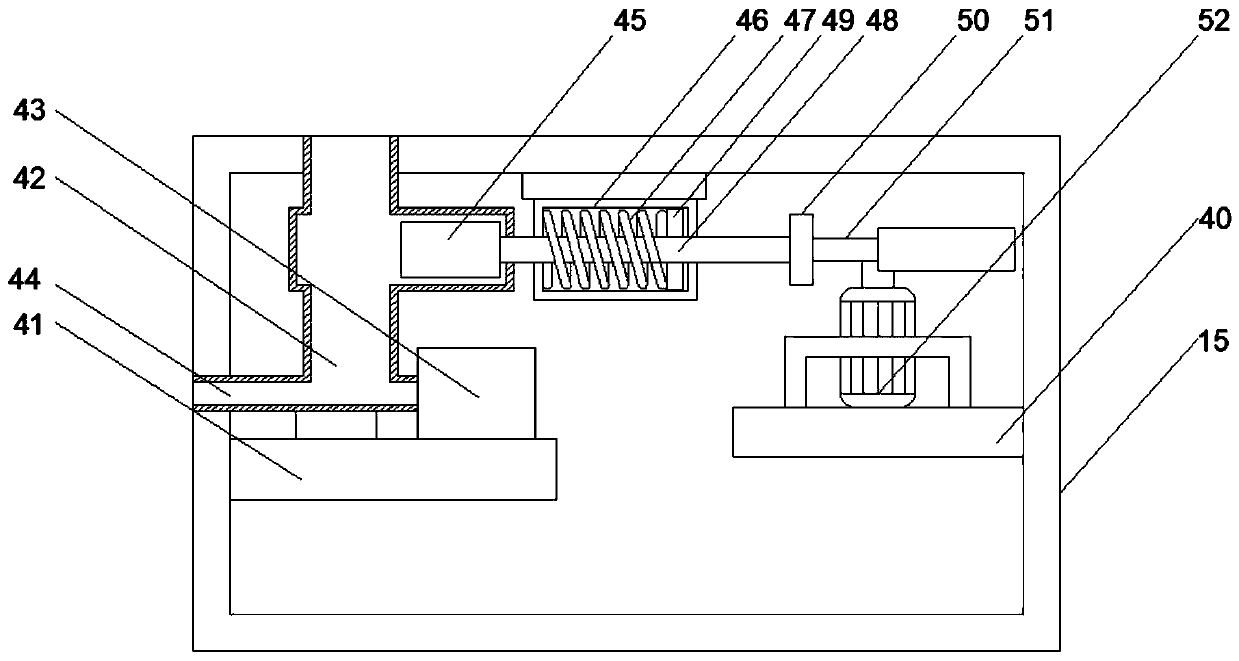

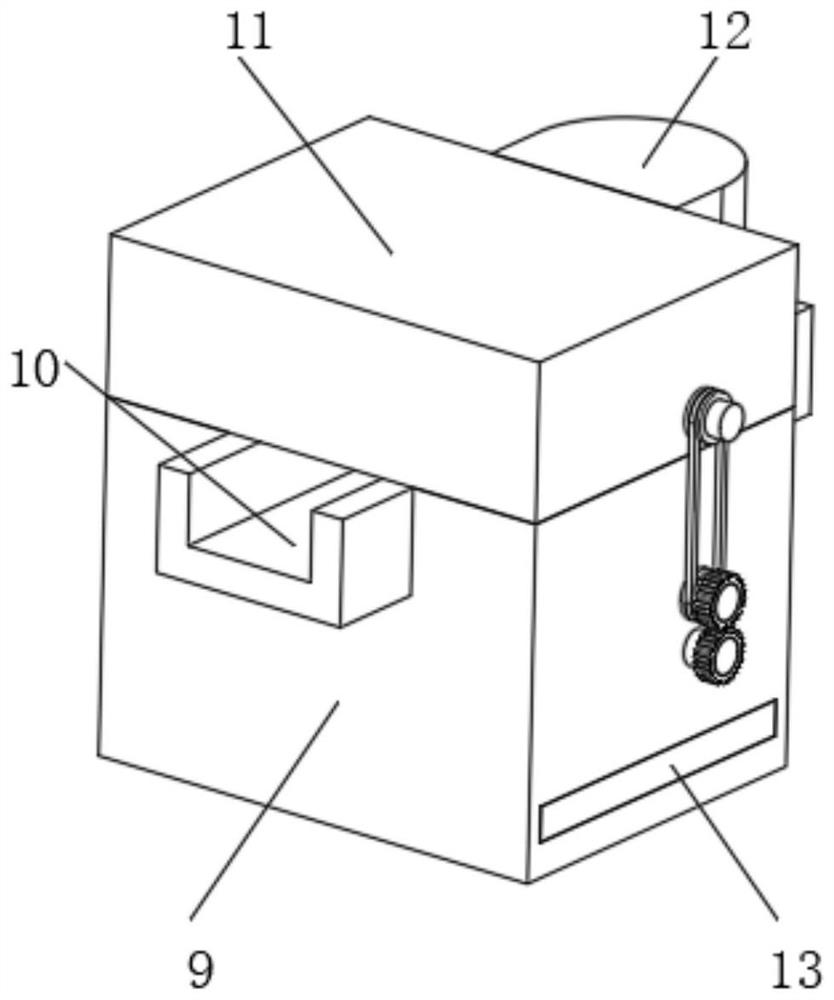

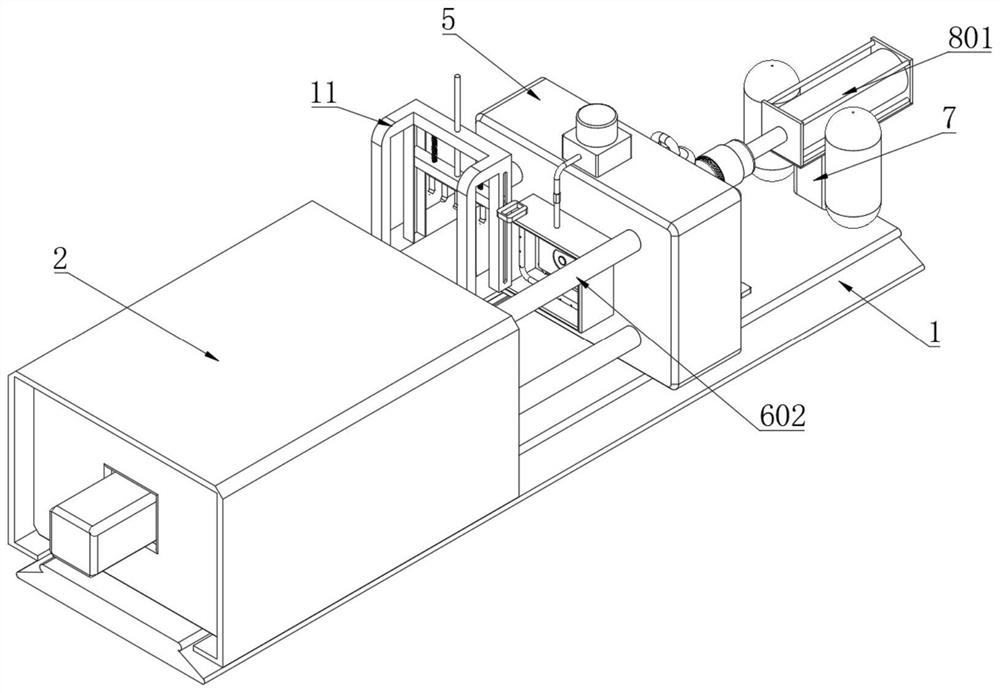

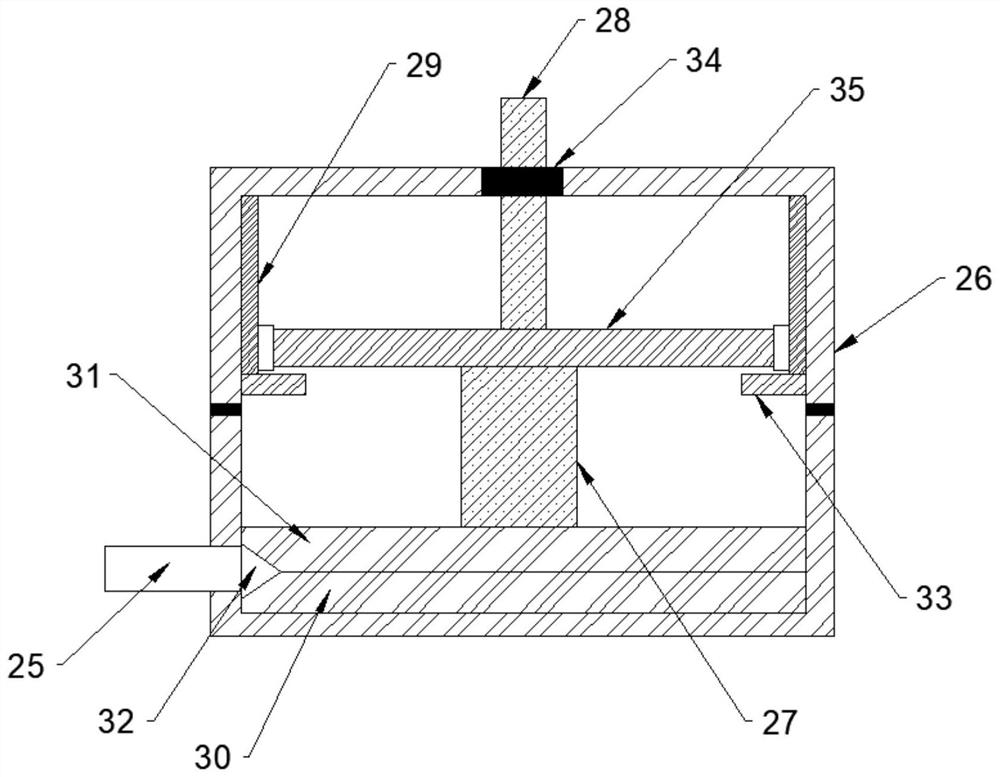

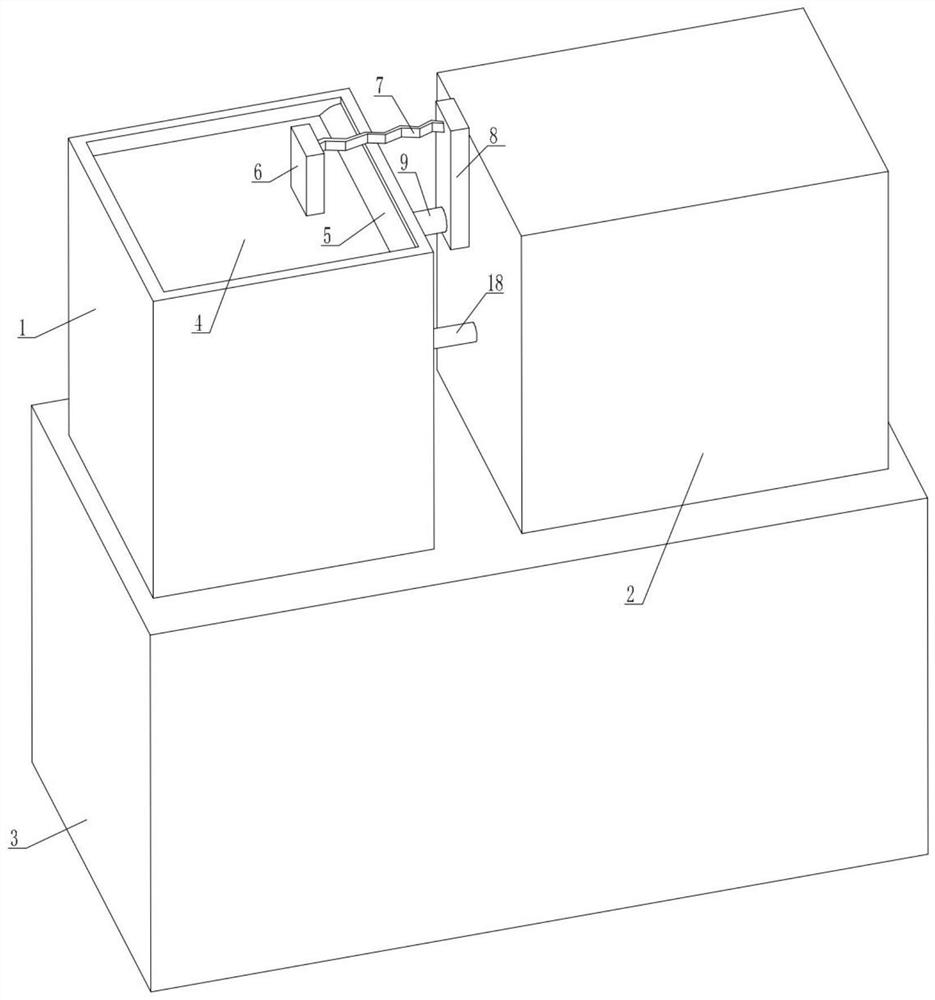

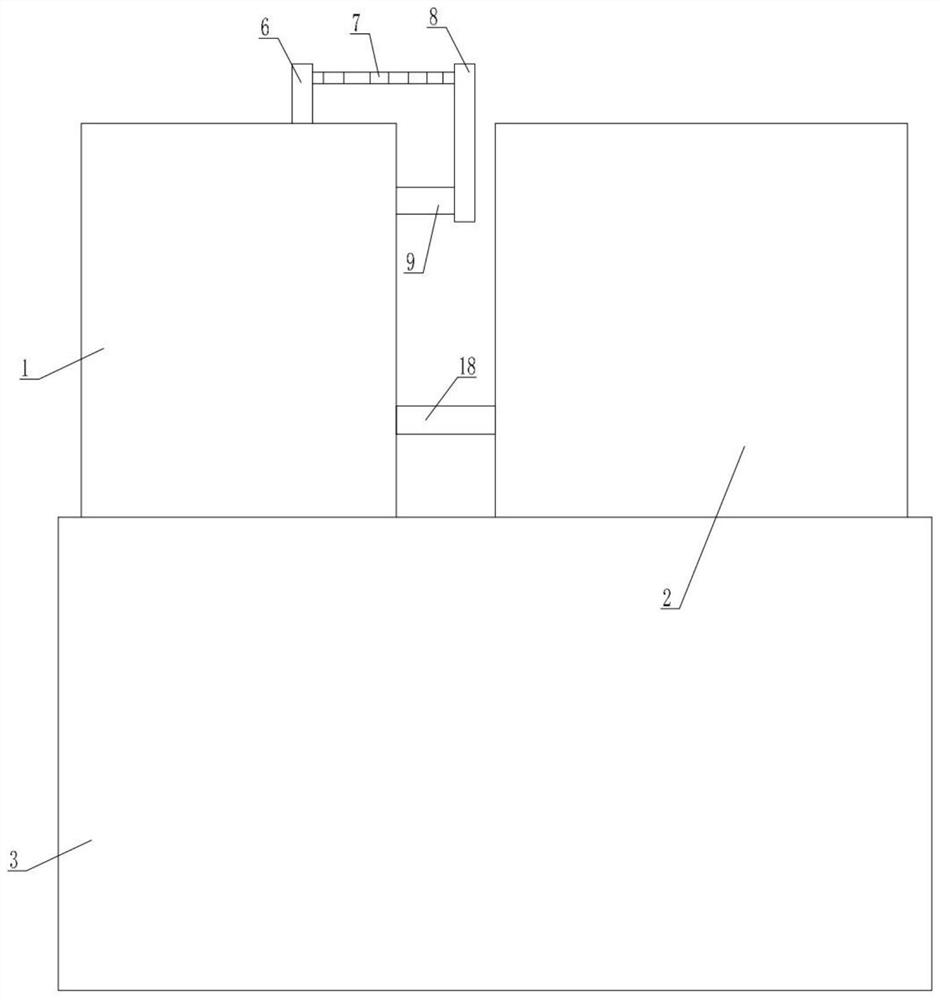

Integrated machining equipment of die-casting machine for button machining

The invention discloses integrated machining equipment of a die-casting machine for button machining. The integrated machining equipment of the die-casting machine for button machining comprises a rack, wherein a first fixed plate, a second fixed plate and a first motor are fixedly installed at the upper side of the rack; a first thread is fixedly connected to an output end of the first motor; a second thread rod is connected to the first motor in a transmission manner and through a first chain; moving blocks are connected to the surfaces of the first thread and the second thread through threads separately, and a moving plate is fixedly connected between the two moving blocks; a support rod is fixedly connected to the right side of the moving plate; the support rod is slidably connected with the second fixed plate; and a connection plate is fixedly installed at the other end of the support rod. According to the integrated machining equipment of the die-casting machine for button machining, through arrangement of a stirring box, molten liquid metal is temporarily stored, and continuous multiple die-casting operation can be carried out; through arrangement of a quantification device,the metal liquid needed for completing one die-casting can be regularly and quantitatively conveyed, so that waste for materials is avoided, time and labor are saved, the labor intensity of working personnel is reduced, and the die-casting efficiency of the die-casting machine is increased.

Owner:东莞市恒兴隆实业有限公司

Cold-chamber die casting machine

The invention discloses a cold-chamber die casting machine which comprises a machine seat, a first mounting frame, a second mounting frame, guiding columns, sliding rails, a transverse-moving slidingplate, sliding sleeves, a squeezing cavity, a die casting air cylinder, a concave die plate, a liquid inlet pipe, a supercharging piston, a liquid inlet pipe orifice, a material filling hole, a convexdie block, an ejecting air cylinder, a positioning partition plate, an ejecting plate, a convex die main body plate, through holes, ejecting pins, sealing vales, a high-pressure air pump, a cooler and a concave surface plate. The cold-chamber die casting machine disclosed by the invention is compact in structure and convenient to use; by adoption of the structural design that an ejecting device is additionally arranged on the convex die plate, a casting can be directly ejected, the trouble that the casting needs to be directly taken by people out of a die can be avoided, the die casting efficiency can be improved, and the personal safety of an operating worker can be guaranteed; through high-pressure cooling airflow jetted from air ports of the ejecting pins, a finished workpiece can be quickly cooled, the cooling speed in a die casting process of the workpiece can be improved, and the more uniform cooling effect can be achieved; and meanwhile, waste scraps on the workpiece can be effectively removed and the quality of a finished die casting product can be improved.

Owner:嘉瑞金属制品(深圳)有限公司

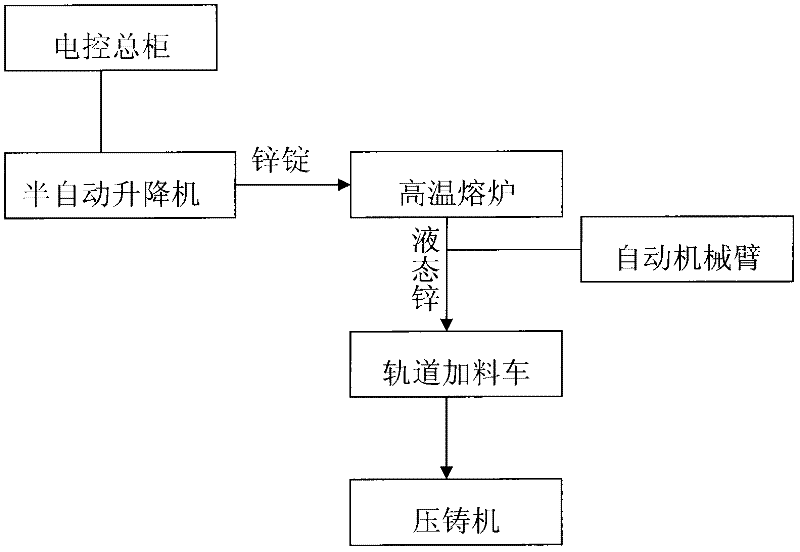

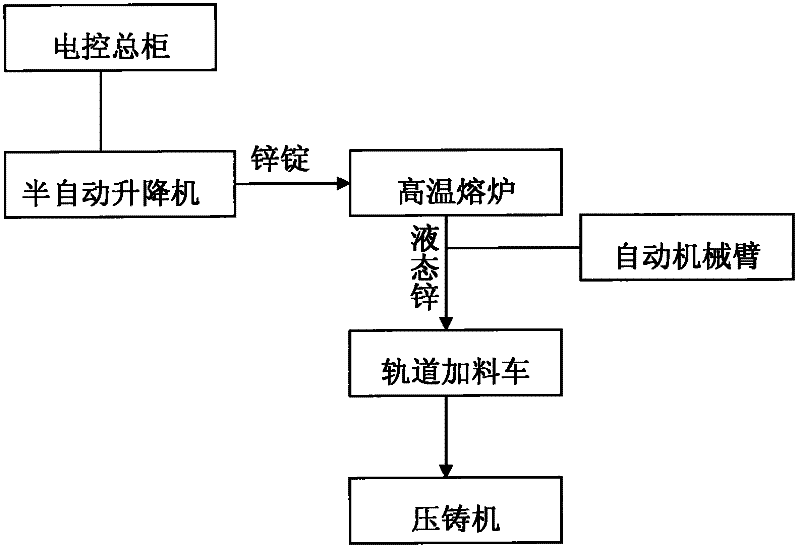

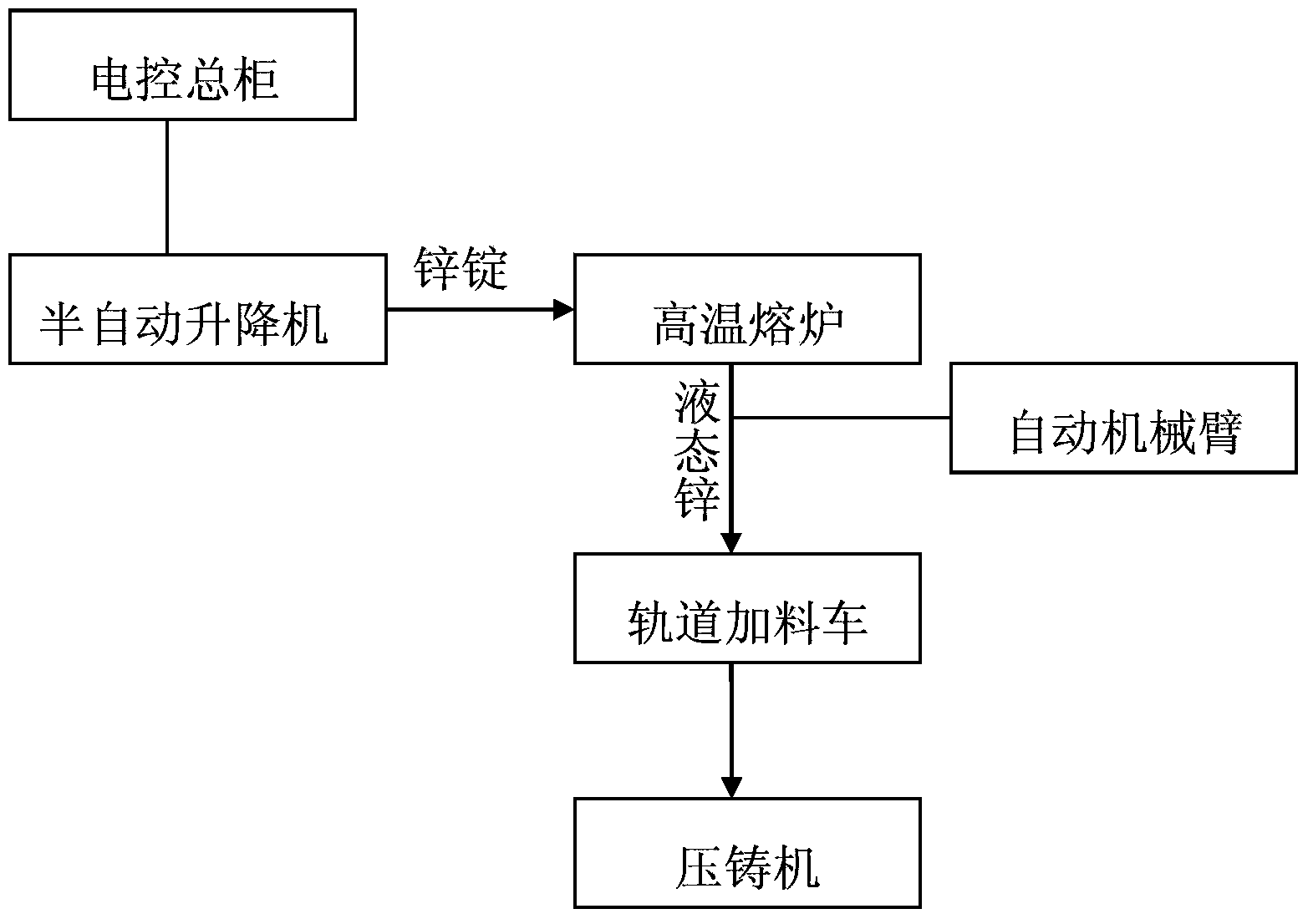

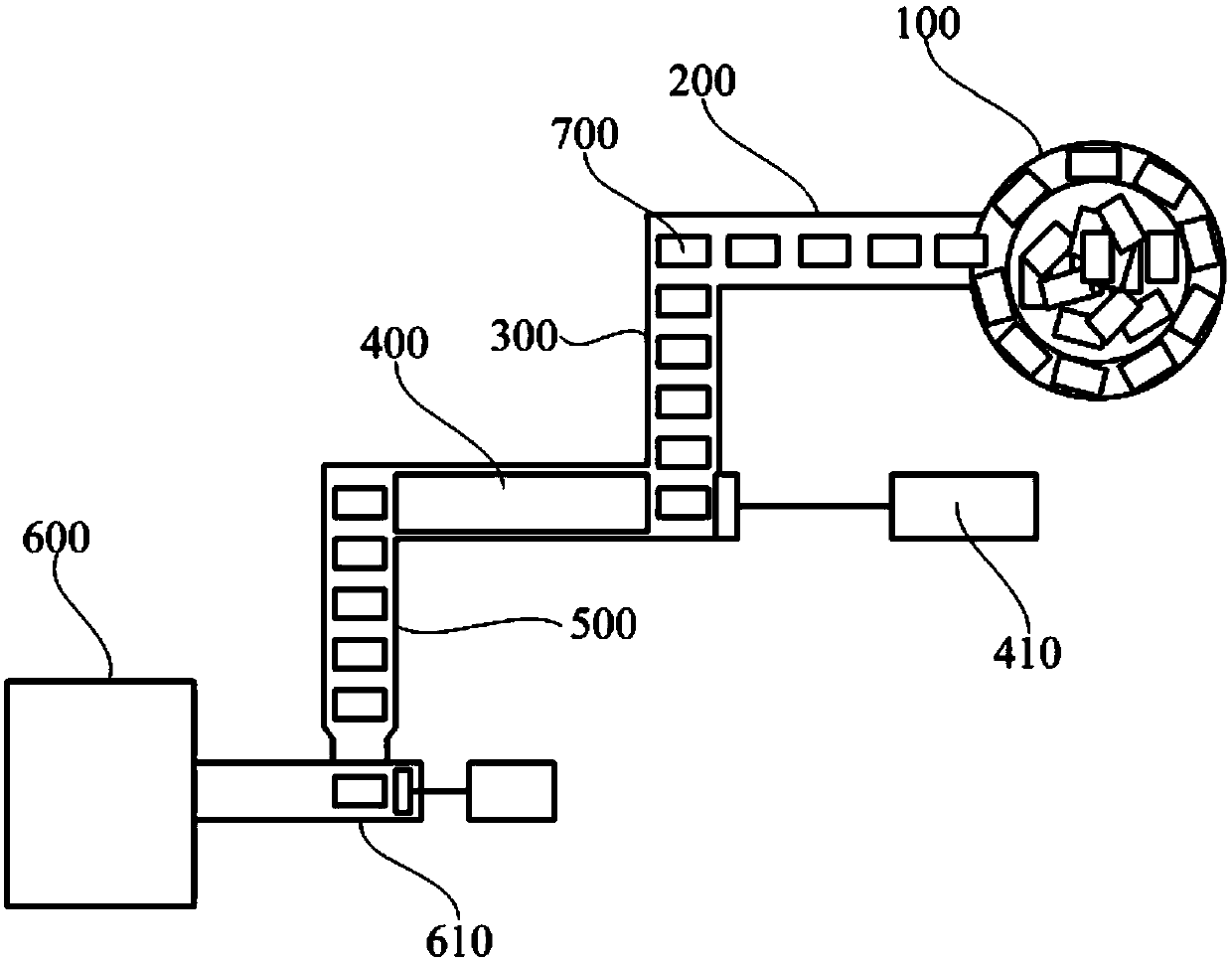

High-temperature fuel gas energy-saving die-casting system

InactiveCN102183145AImprove die casting efficiencyCharge manipulationFurnace typesSemi automaticLiquid metal

The invention discloses a high-temperature fuel gas energy-saving die-casting system, comprising a high-temperature smelting furnace, a rail for transporting smelted liquid metal, a rail feeding car and a plurality of die-casting machines, wherein natural gas is used as the fuel in the high-temperature smelting furnace and the plurality of die-casting machines are arrayed as a straight line; the rail is connected between the high-temperature smelting furnace and the die-casting machines and the liquid metal in the high-temperature smelting furnace is transported into the rail feeding car from the high-temperature smelting furnace through an automatic device; in the system provided by the invention, the natural gas is used as the fuel to replace the diesel oil, so that after the natural gas is combusted, the substances such as the waste gas, the dust and the like which are harmful to the environment can not be generated. A semi-automatic lifter is designed and is controlled by an electric control general cabinet; a zinc ingot is directly put into a tray of the lifter and the zinc ingot is manually lifted to the smelting furnace opening from long distance through the electric control cabinet and then is poured into the high-temperature smelting furnace cylinder, so that the system provided by the invention is safe and reliable. According to the high-temperature fuel gas energy-saving die-casting system, by utilizing high automatic work the die-casting efficiency can be effectively improved without excessive intervention by manual modes.

Owner:DONGGUAN GUANHUI HARDWARE

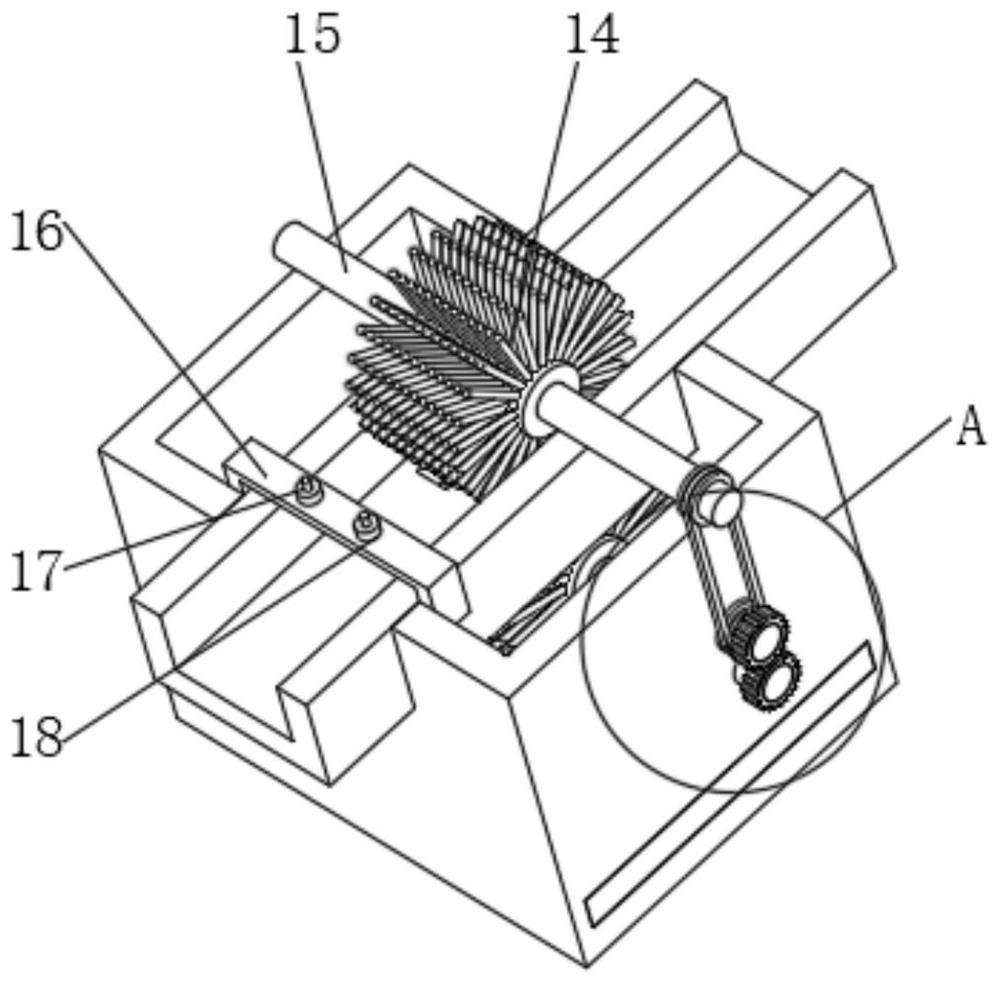

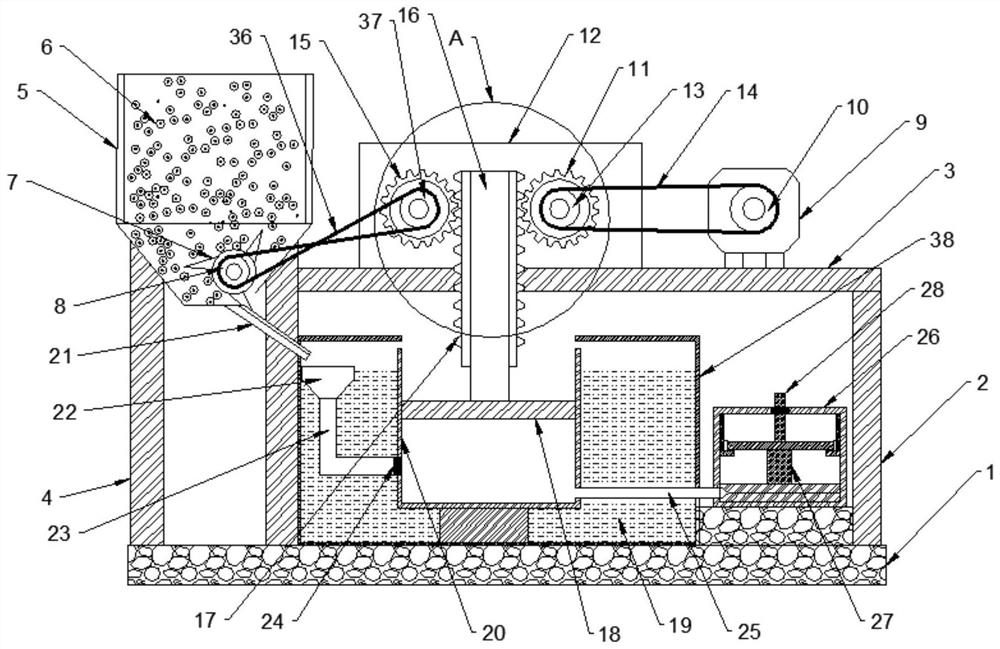

Building metal waste recycling equipment with die-casting forming mechanism

InactiveCN111644408AImprove cleanlinessPlay the role of conveyingConstruction waste recoverySolid waste disposalArchitectural metalsDie casting

The invention discloses building metal waste recycling equipment with a die-casting forming mechanism, and relates to the technical field of building waste recycling processing. In order to solve theproduct impurity problem, the building metal waste recycling equipment comprises a cleaning mechanism, a crusher, an injection machine, a die casting mechanism and a smelting furnace. The cleaning mechanism comprises a cleaning assembly and a transmission assembly. The die casting mechanism comprises a die casting assembly and a moving fixing assembly. The injection machine and the smelting furnace are both fixed to the ground. The crusher is fixedly mounted on the outer wall of the top of the smelting furnace. An outlet of the crusher and an inlet of the smelting furnace are located on the same position. According to the building metal waste recycling equipment, due to the arrangement of a first nozzle and a second nozzle, a water pump is started and pumps water in a tank body out; metalis flushed through the first nozzle and the second nozzle, so that the cleanliness of the metal during heating and smelting is ensured; and a motor is started and drives a brush to rotate through a driving shaft, so that when the brush rotates, waste can be brushed, and the cleanliness of the metal is further improved.

Owner:沈永成

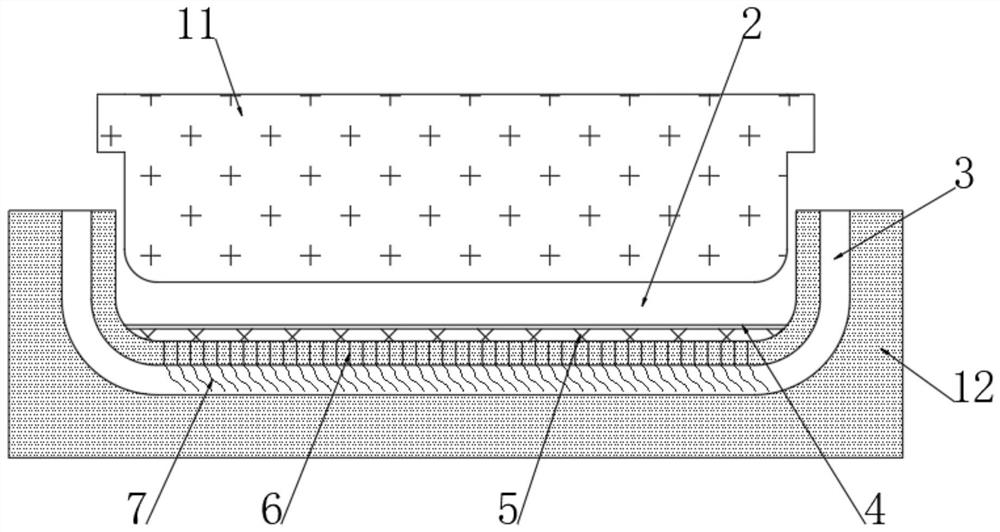

Aluminum alloy die-casting die easy to rapidly cool

The invention discloses an aluminum alloy die-casting die easy to rapidly cool, and belongs to the field of die-casting dies. According to the aluminum alloy die-casting die easy to rapidly cool, after the die is used for die-casting of aluminum alloy liquid, heat in the alloy liquid is adsorbed by a copper net and transmitted to air stretching sleeve rods, so that air stretching bags are heated and transversely expands at present, the contact area of the air stretching bags and an adherent heat pipe is increased, then the air stretching bags continue to expand downward under the action of heat to drive the adherent heat pipe to move down and gradually extend to a heat reducing chamber, so that the air stretching sleeve rods are dislocated with the adherent heat pipe; and compared with the prior art, according to the aluminum alloy die-casting die easy to rapidly cool, the contact area of condensate water in the heat reducing chamber is significantly increased, the cooling is faster, the die-casting efficiency of aluminum alloy is effectively improved, in addition, in cooperation with the effect of a water stirring rod, the water stirring capacity in the condensate water is effectively improved, the condensate water below the multiple air stretching sleeve rods is in a certain shaking state, and the heat taking-away effect is better.

Owner:叶立容

High-toughness self-strengthening aluminum alloy die-casting device and production process thereof

The invention discloses a high-toughness self-strengthening aluminum alloy die-casting device and a production process thereof, and relates to the technical field of aluminum alloy production, the high-toughness self-strengthening aluminum alloy die-casting device comprises a bottom plate, and a limiting plate is arranged at the top of the bottom plate. The output end of a first servo motor drives a rotating plate to rotate, so that the rotating plate drives a lower mold to rotate, the lower mold rotates to a discharging station on the lower side, an arc-shaped rack drives a second transmission gear to rotate, a first rotating rod rotates reversely, a fixed box moves upwards, and one end of an upper mold moves out of a mold cavity; and the first rack drives the first transmission gear to reset and rotate, the first connecting rod drives the second bevel gear to rotate through the first bevel gear, so that the second transmission rod drives the upper mold to rotate to one side of the mold cavity, the aluminum alloy part formed in the mold cavity falls out of the mold cavity for discharging, and discharging operation is facilitated.

Owner:清苑县中久有色金属合金制造有限公司

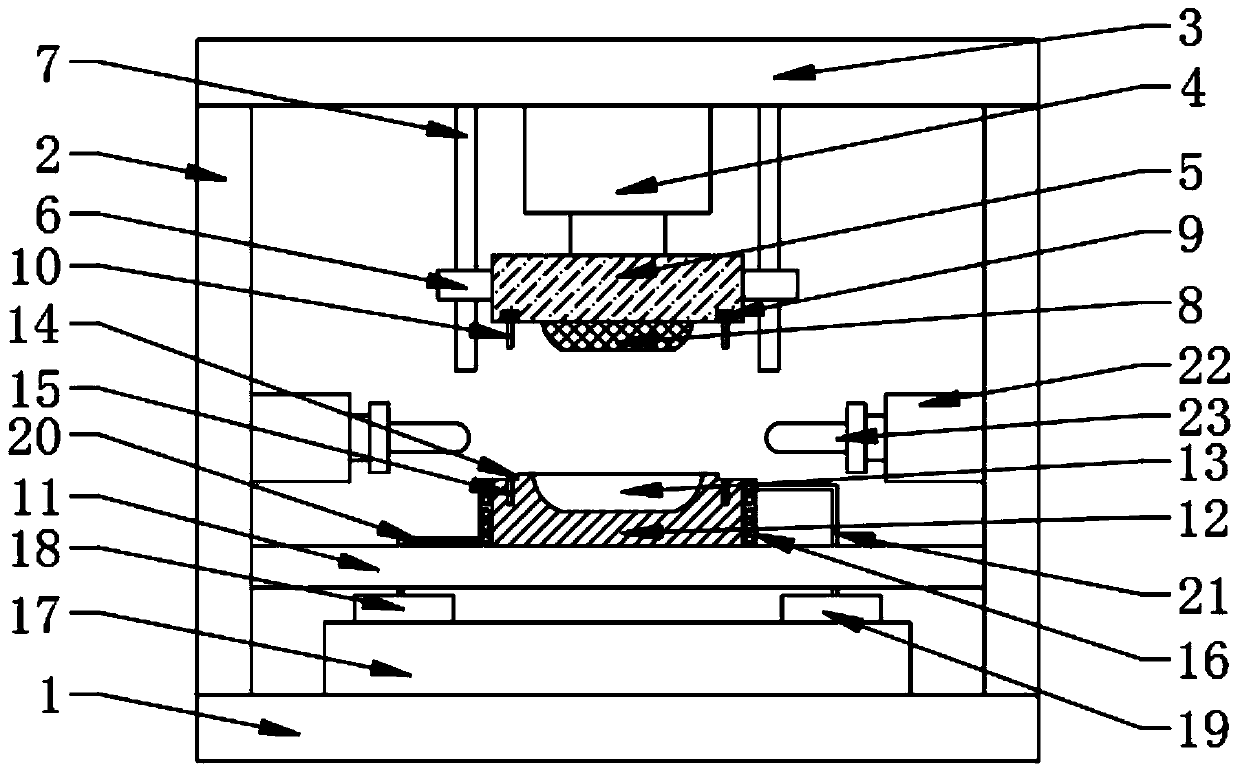

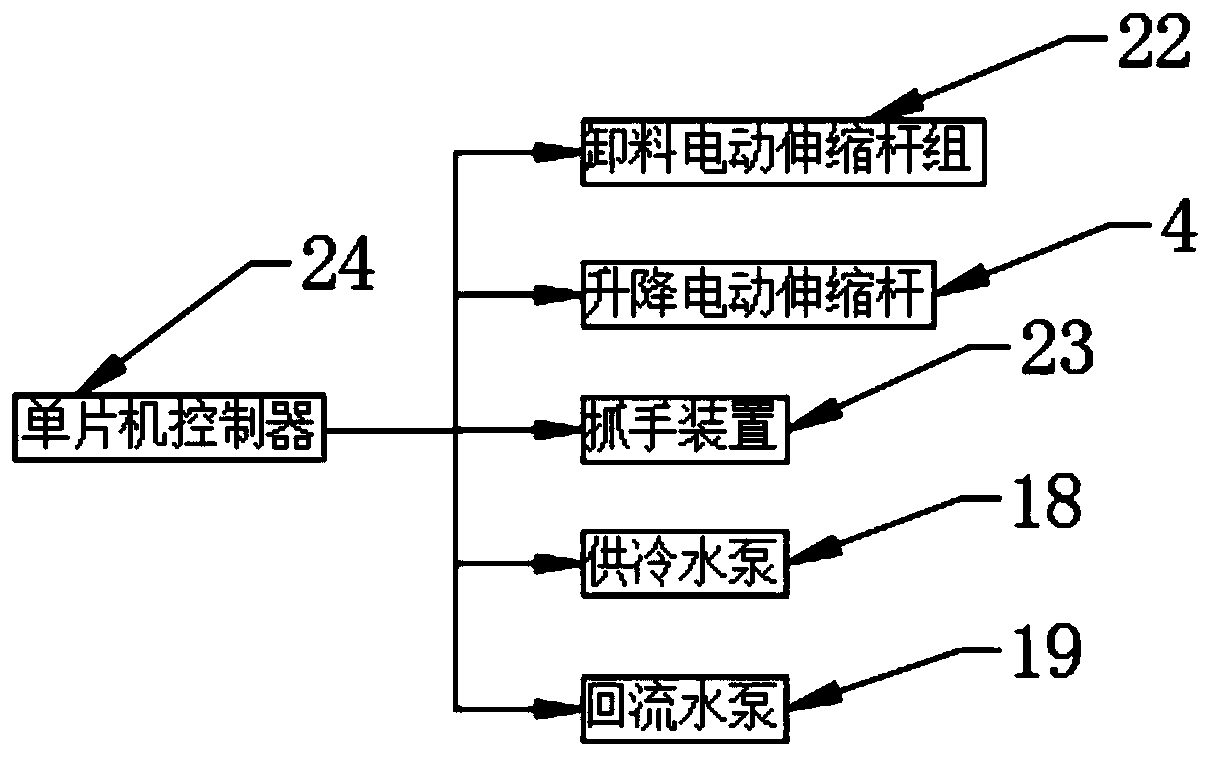

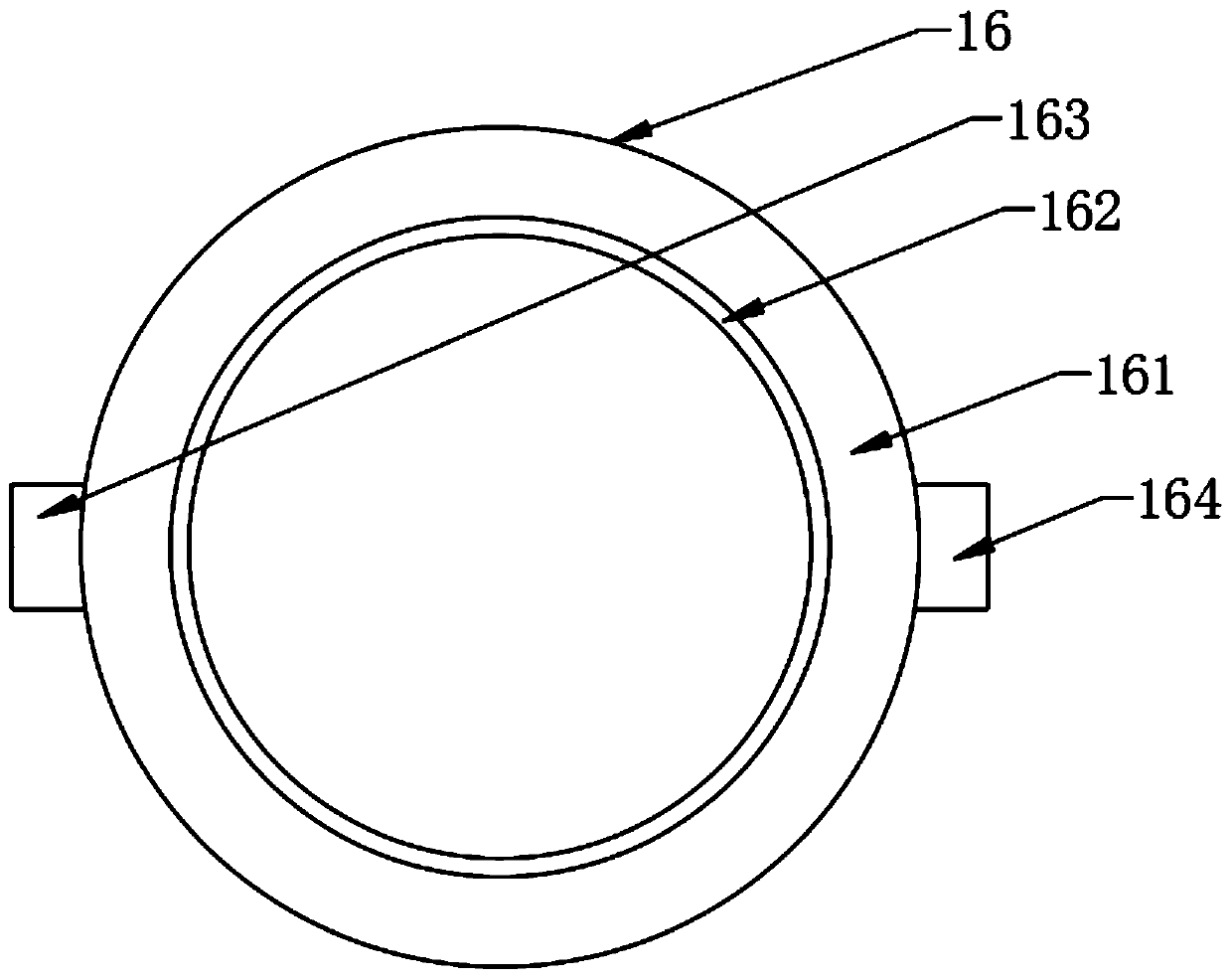

Rear cover casting positioning and forming die and forming and processing method

The invention discloses a rear cover casting positioning and forming die and belongs to the technical field of rear cover casting positioning and forming dies. A die casting groove adapted to a die core is formed in the center of the top of a lower die; a process step is formed in the outer side of the top of the lower die; positioning holes, adapted to positioning columns respectively, are formedin the left side and the right side of the top of the lower die respectively; the outer wall of the lower die is fixedly provided with a water cooling ring; the top of the base is fixedly provided with a water tank; the left side and the right side of the top of the water tank are fixedly provided with a cooling water pump and a backflow water pump respectively; a water inlet pipe and a backflowpipe which are fixedly connected with the water cooling ring are fixedly assembled on the cooling water pump and the backflow water pump respectively; the side walls of the opposite sides of the two groups of brackets are fixedly provided with discharging electric telescopic rod groups respectively; and gripper devices are fixedly assembled on the discharging electric telescopic rod groups respectively. The rear cover casting positioning and forming die can achieve the accurate positioning effect during workpiece blanking, can enable the die casting precision of a workpiece to be higher and improves the precision of a product.

Owner:南通华东油压科技有限公司

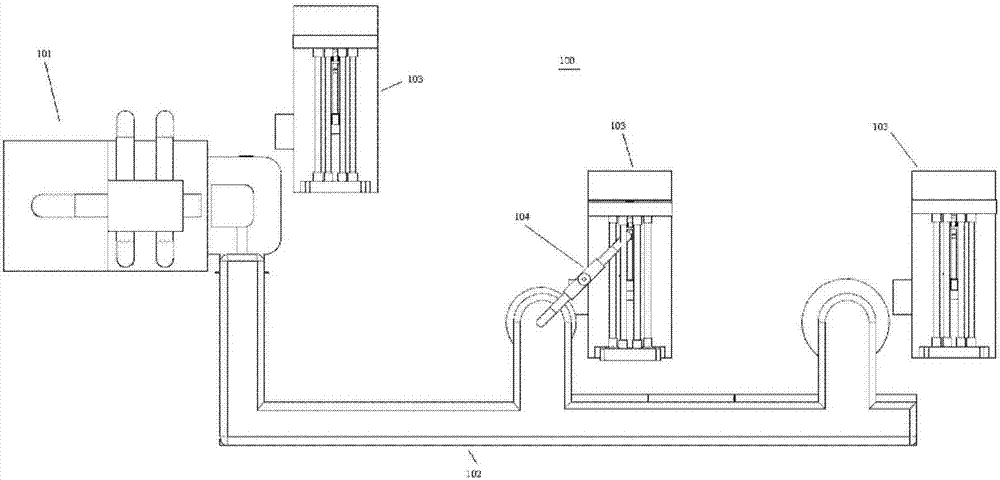

Metal casting system and method

The invention discloses a metal casting system and method. The metal casting system comprises a melting furnace, one or more pressure casting devices and a pretreatment device, wherein the melting furnace is used for melting metal and comprises a melting furnace outlet; each pressure casting device is used for forming a metal blank; the pretreatment device is used for transferring the molten metal to the one or more pressure casting devices and can communicate with the melting furnace so that the molten metal in the melting furnace can flow into the pretreatment device through the melting furnace outlet; and the pretreatment device communicates with the one or more pressure casting devices so that the molten metal can be conveyed into the pressure casting devices for casting.

Owner:郭俊峰

Die-casting forming equipment facilitating exhausting and used for thin-walled workpiece machining

The invention discloses die-casting forming equipment facilitating exhausting and used for thin-walled workpiece machining, the die-casting forming equipment comprises a base, a fixing base is fixedlyinstalled on the side, away from a protective shell, of the top end of the base, an exhaust assembly is installed on the side end face of the fixing base, a sealing box is fixedly welded to the end face, close to a control box, of the fixing base, an annular air suction pipe is embedded into the inner side of the sealing box, an exhaust pipe is fixedly connected to the outer side of the top of the annular air suction pipe, and an air extracting pump is fixedly installed at the top end of the fixing base. The die-casting forming equipment is scientific and reasonable in structure and safe andconvenient to use, the sealing box and a sealing block can be clamped into a whole by being closed, and moreover, the annular air suction pipe and air suction holes are uniformly distributed in the inner side of the sealing box, so that the exhaust efficiency can be improved, air can be prevented from flowing back into the sealing box, air in a die during die casting can be effectively avoided, sand holes and air holes in a formed die casting are avoided, and the success rate of die casting is increased.

Owner:江苏富航钢结构有限公司

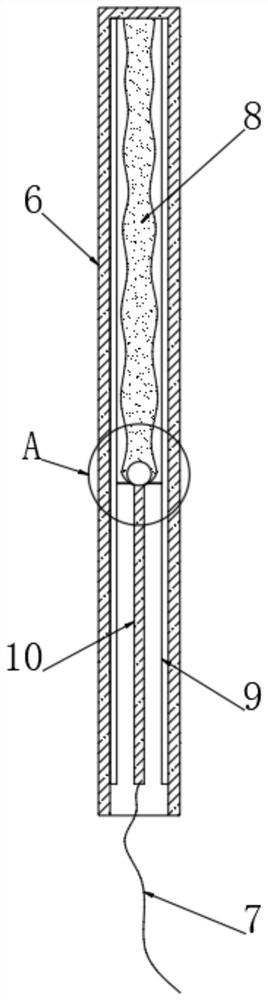

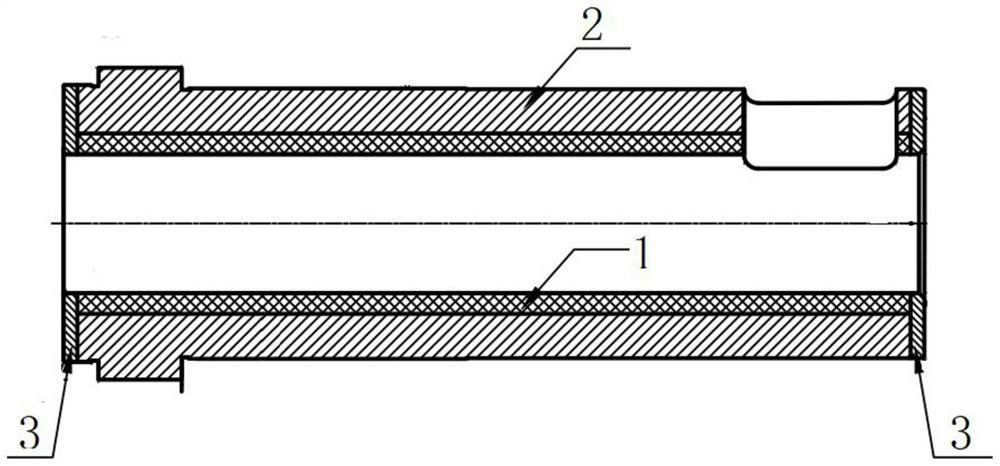

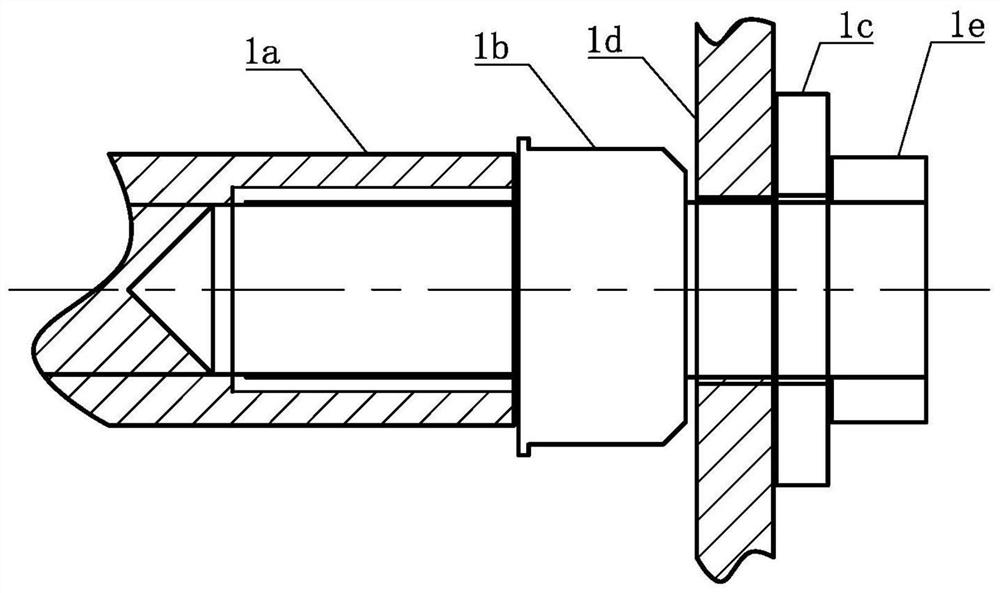

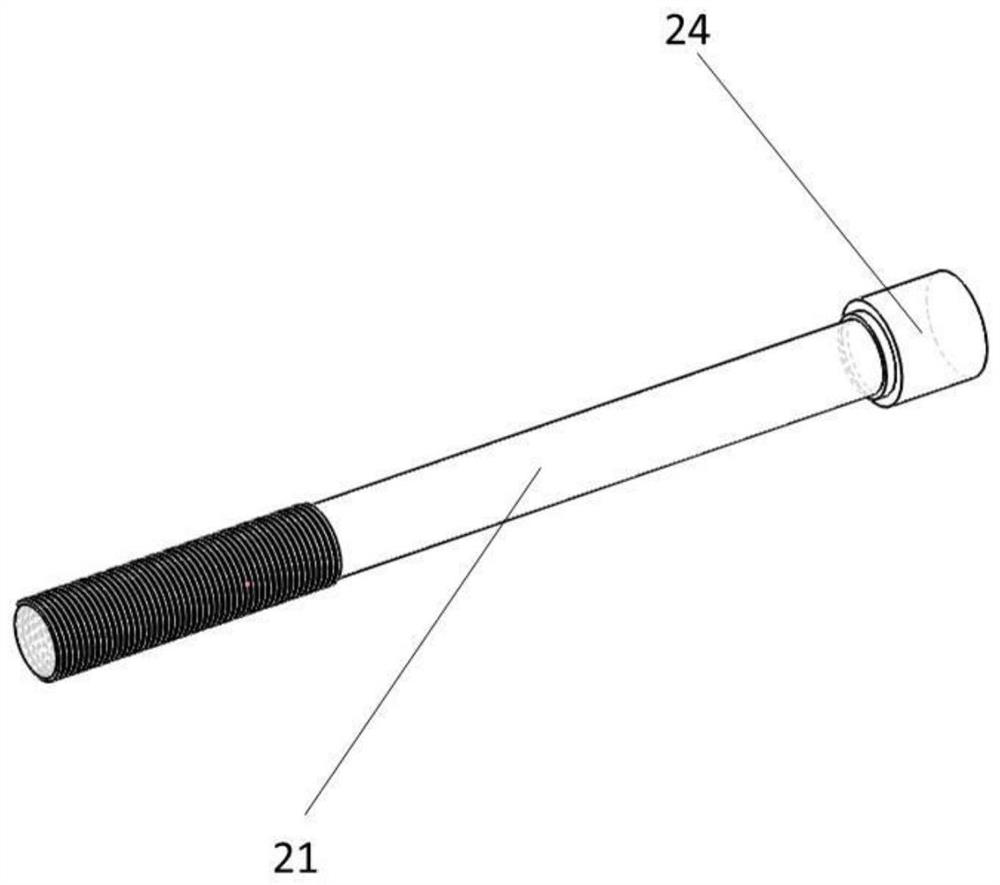

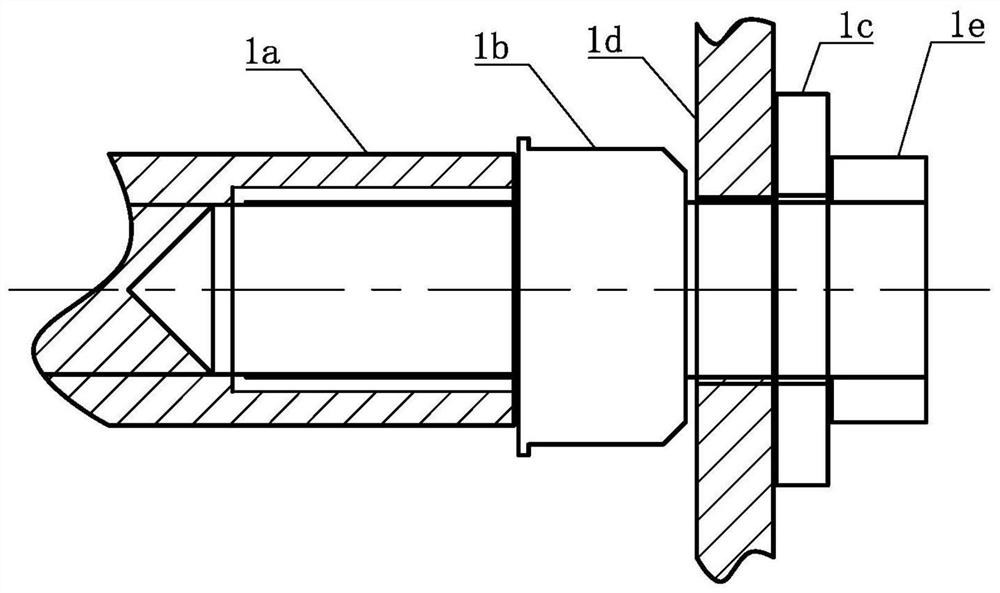

Production process of high-temperature structural ceramic/metal composite material tube for aluminum alloy die casting machine

ActiveCN113649772AExtended service lifeSimple production processFurnace typesHeat treatment furnacesDie castingCeramic metal

The invention relates to a production process of a high-temperature structural ceramic / metal composite material tube for an aluminum alloy die casting machine. The composite material tube comprises a ceramic lining, a metal jacket and an end cover. The production process of the composite material tube comprises the steps of machining the ceramic lining, machining the metal jacket and the end cover, and assembling and matching the ceramic lining, the metal jacket and the end cover. A ceramic lining machining process comprises the steps of raw material preparation, grinding and pulping, workpiece forming, green body drying, high-temperature firing and inner and outer circle machining. A metal jacket and end cover machining process comprises the steps of metal tube and end cover cutting and blanking, metal tube and end cover inner and outer circle rough machining, heat treatment and metal tube and end cover inner and outer circle finish machining. A ceramic lining, metal jacket and end cover assembling and matching process includes the steps of measurement inspection, combined assembly and thermal adaptation testing. A metal tube and a ceramic tube are compounded, so that the alloy melt corrosion resistance and the wear resistance of the material tube are greatly improved, and the service life is long; the composite material tube is low in heat conductivity coefficient, and energy consumption is reduced; and strength and toughness are good, the manufacturing cost is low, and production period is short.

Owner:江苏三条鱼新材料科技有限公司 +1

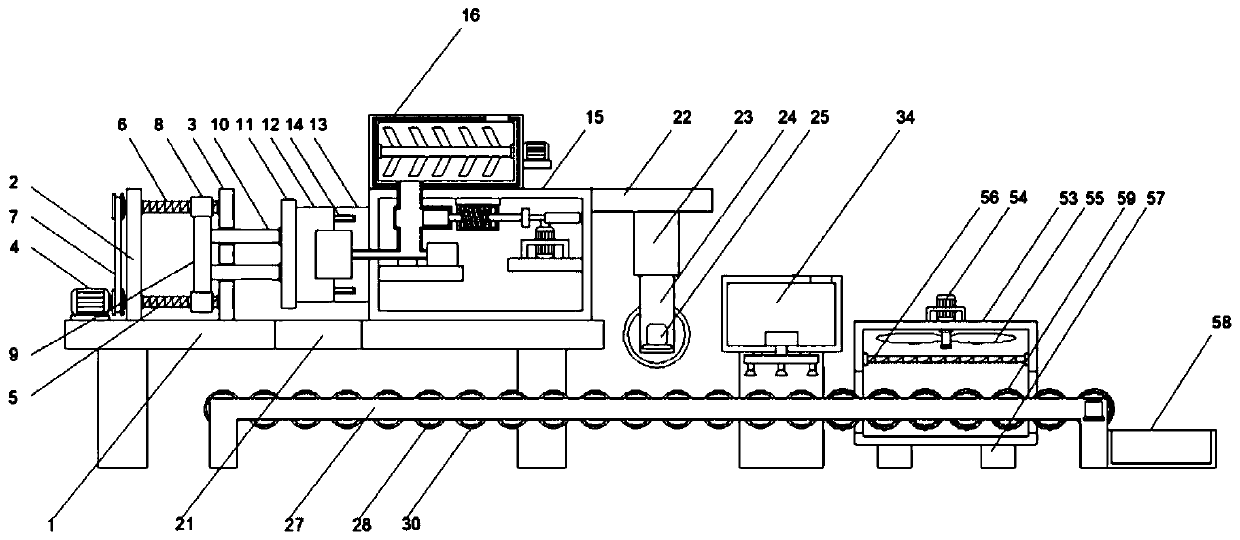

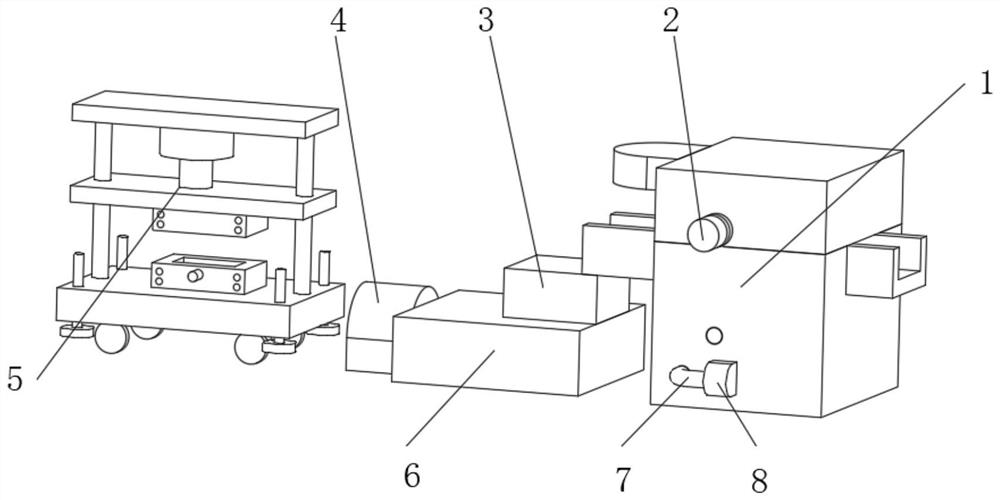

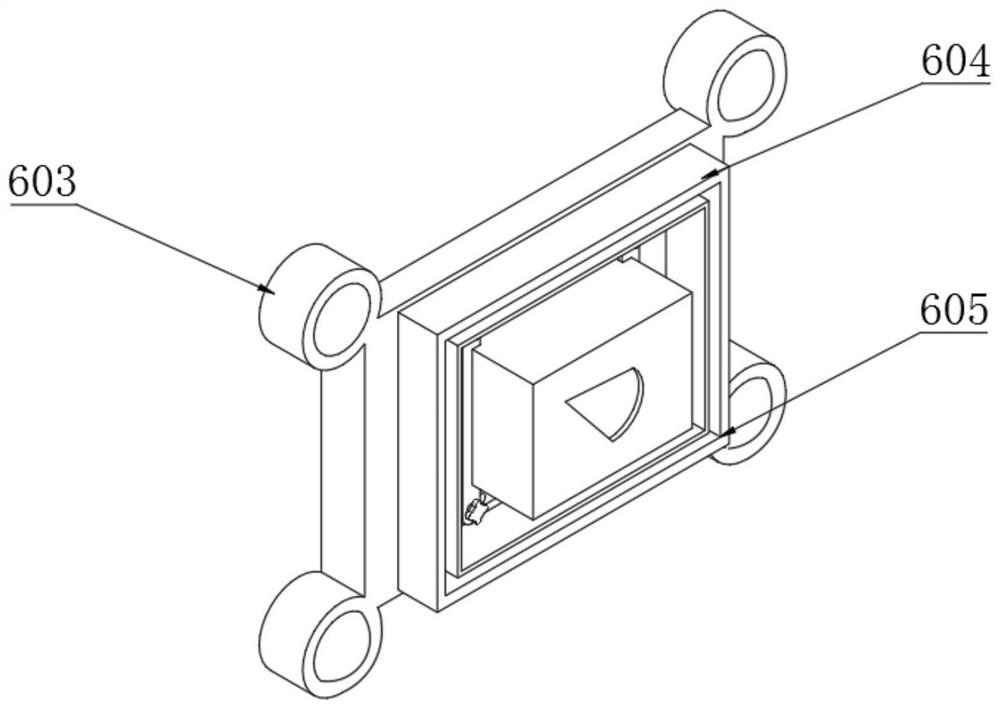

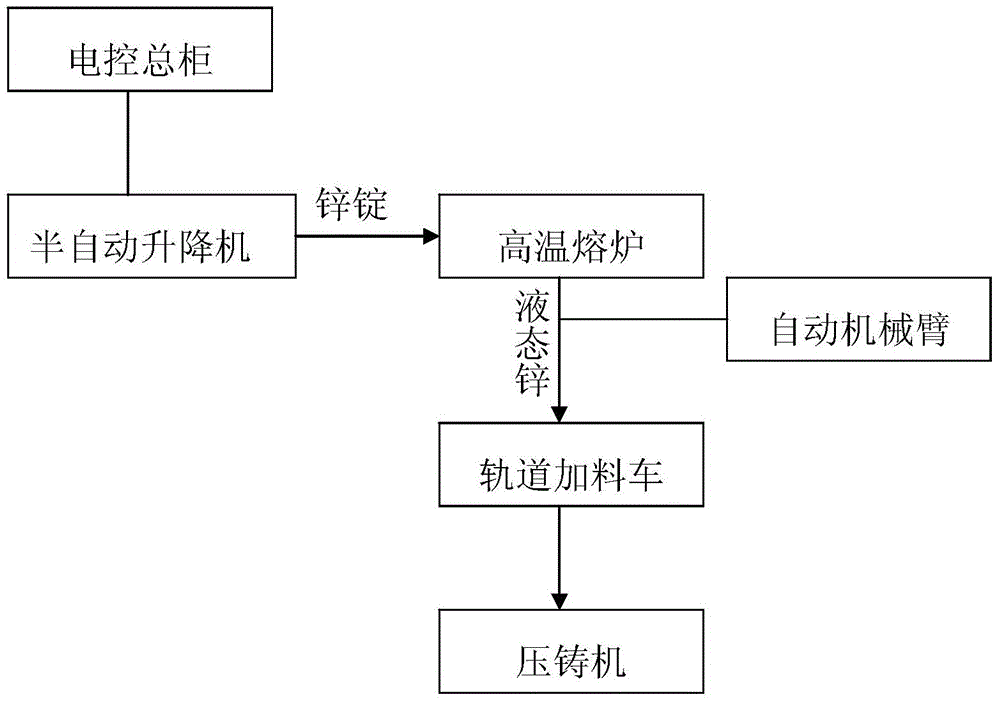

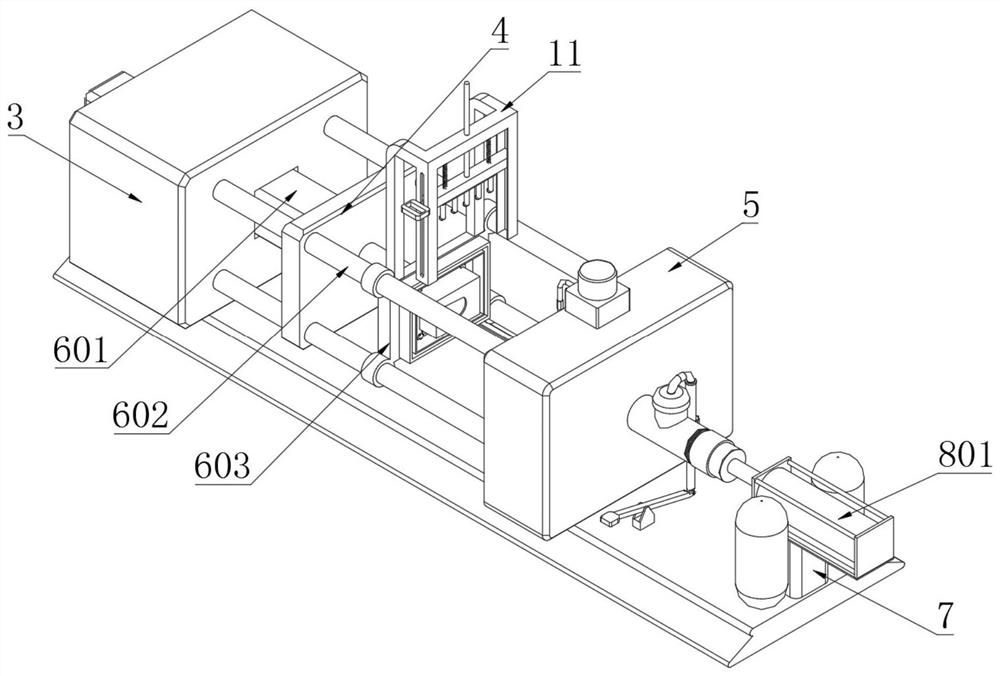

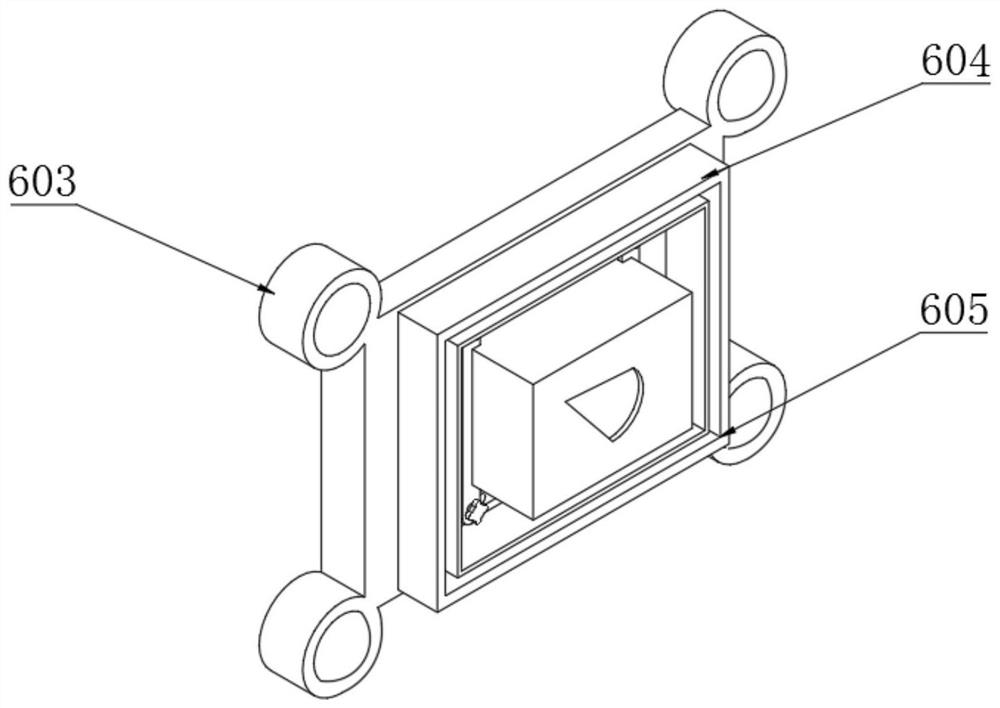

Full-automatic die-casting device

The invention discloses a full-automatic die-casting device which comprises a high-temperature smelter, a track for conveying molten liquid metal, a track charging cart and a plurality of die-casting machines, wherein the high-temperature smelter adopts natural gas to serve as fuel, the plurality of die-casting machines are arranged in a straight line, the track is connected between the high-temperature smelter and the die-casting machines, and the liquid metal in the high-temperature smelter is transferred into the track charging cart from the high-temperature smelter through an automatic device. The full-automatic die-casting device adopts the natural gas serving as fuel to replace diesel oil, matters harmful to the environment, such as waste gas, dust and the like can not be produced after burning of the natural gas, the environment is protected, and energy is saved. A semi-automatic lifter controlled by an electric control cabinet is designed, zinc ingots are placed in a tray of the lifter directly, workers enable the zinc ingots to ascend to the opening of the smelter through the electric cabinet remotely and pour the zinc ingots into a cylinder of the high-temperature smelter, and therefore, the full-automatic die-casting device is safe and reliable. Furthermore, high automatic operation is adopted, no excessive manual interference is needed, and die-casting efficiency can be increased effectively.

Owner:陈伟陵

Remote monitoring high-temperature die casting machine

The invention discloses a remote monitoring high-temperature die casting machine. The remote monitoring high-temperature die casting machine comprises a high-temperature smelting furnace, a track for conveying smelted liquid metal, a track feeding vehicle and a plurality of die casting machine bodies, natural gas is adopted as fuel of the high-temperature smelting furnace, the die casting machine bodies are arranged linearly, the track is connected between the high-temperature smelting furnace and the die casting machine bodies, and the liquid metal located in the high-temperature smelting furnace is transferred into the track feeding vehicle from the high-temperature smelting furnace through an automatic device. According to the remote monitoring high-temperature die casting machine, the natural gas is adopted as the fuel to replace diesel, the natural gas generate no environmentally hazardous substances such as waste gas or dust after being combusted, and environmental protection and energy conservation are achieved. A semi-automatic elevator is designed and controlled by an electric control main cabinet, zinc ingots are directly placed on a tray of the elevator, manually and remotely lifted into the mouth of the smelting furnace through the electric control main cabinet, and poured into a cylinder of the high-temperature smelting furnace, and safety and reliability are achieved. Highly automatic operation is adopted, no much intervention of a manual mode is needed, and die casting efficiency can be improved effectively.

Owner:陈浠

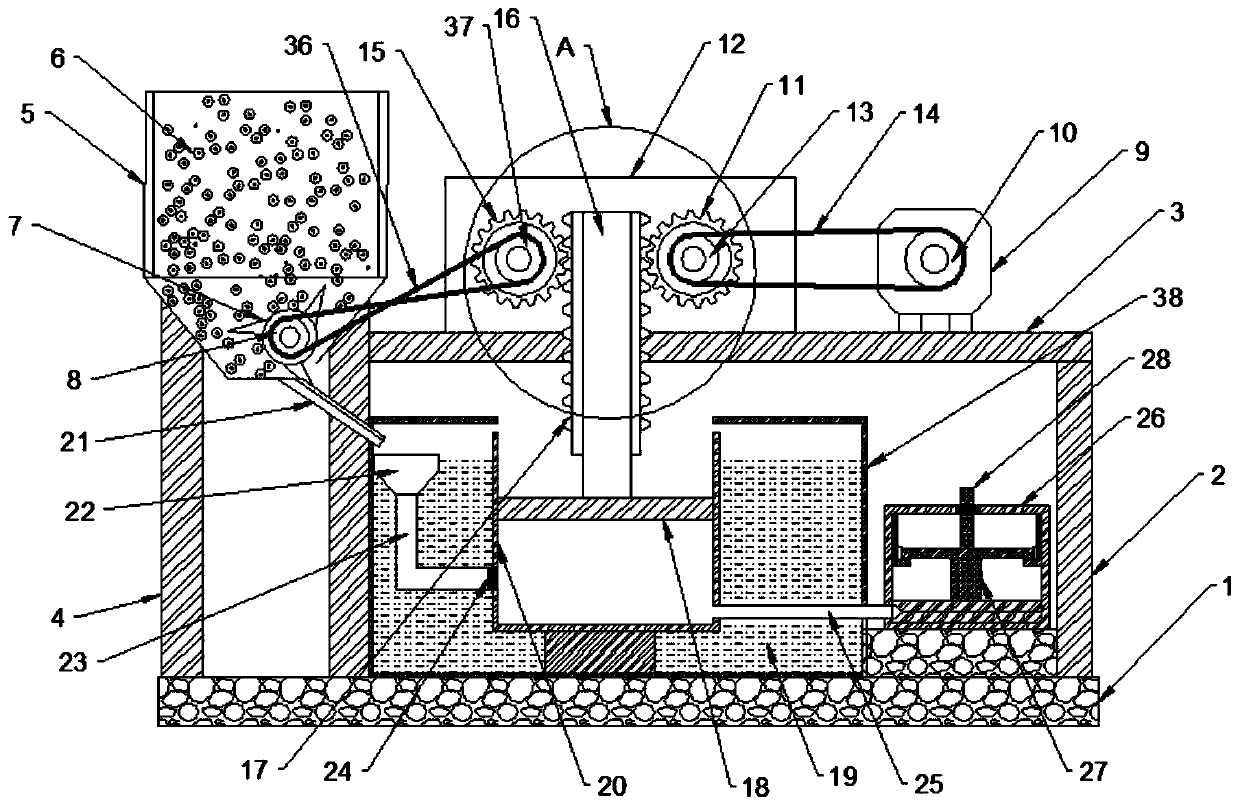

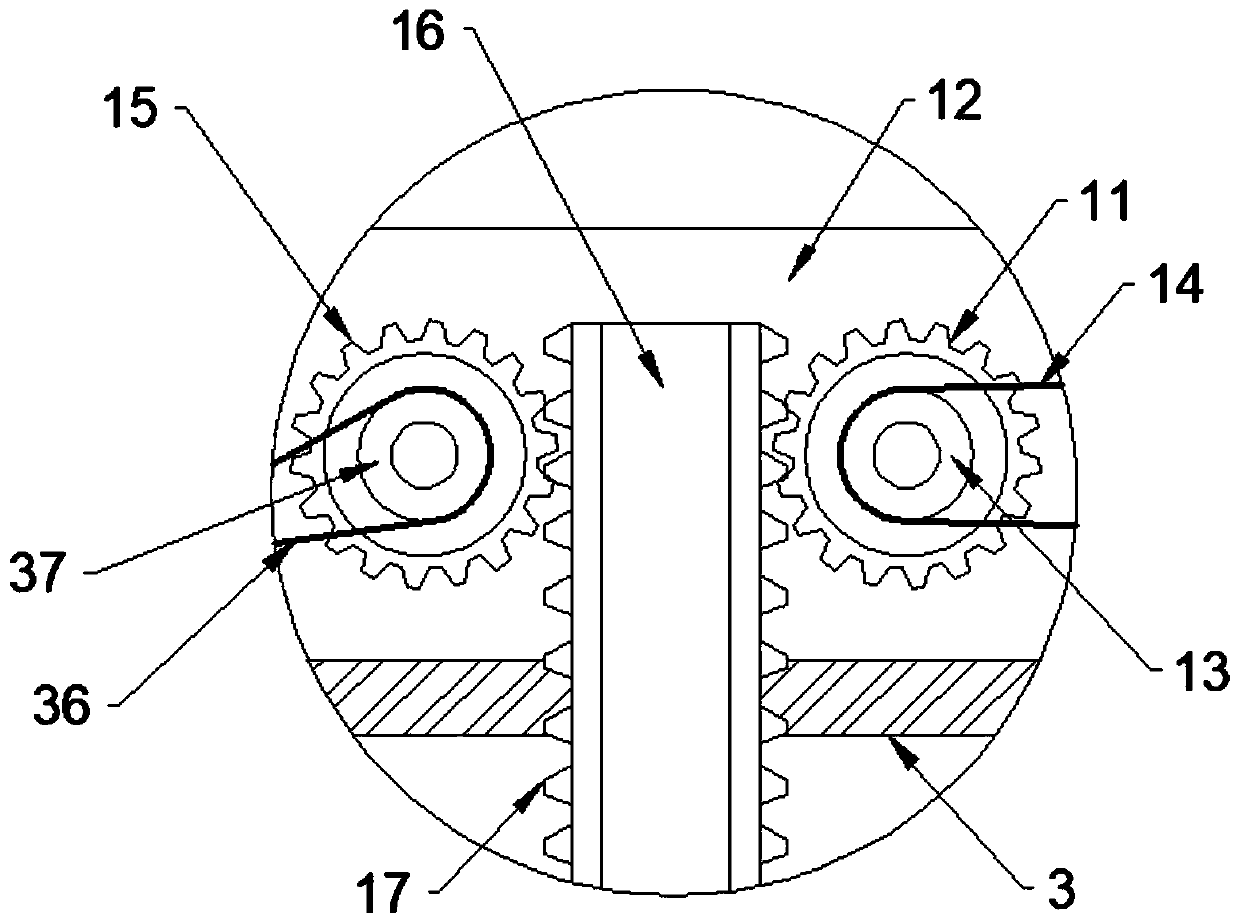

Pressure casting device achieving automatic feeding

The invention discloses a pressure casting device achieving automatic feeding. The pressure casting device comprises a base, wherein two charging-box support frames are fixed on the left side of the base; a charging box is fixed on the upper sides of the two charging-box support frames; a kickoff wheel is mounted at a discharge outlet in the lower side of the charging box; a first belt pulley is mounted on the side face of the kickoff wheel; a conveying plate is arranged on the lower side of the kickoff wheel; a high-temperature melting furnace is filled with a high-temperature solution; a pressure casting barrel is inserted in the high-temperature solution; an inlet pipe is connected to the left side of the pressure casting barrel; a collecting hopper is mounted at the other end of the inlet pipe; a piston is inserted in the pressure casting barrel; the upper end of the piston is connected with a pressure column; gear racks are fixed on two sides of the pressure column; a gear fixing plate is connected with the pressure column in a sliding manner; a motor is mounted on a top fixing frame; the right side of the pressure casting barrel is connected with an outlet pipe, the right side of which is connected with a molding frame; a lower die is fixed at the bottom of the molding frame; and an upper die is arranged on the upper side of the lower die and connected with the molding frame in a sliding manner. The pressure casting device achieving automatic feeding is convenient to use and has high pressure casting efficiency.

Owner:佛山市同向智能装备有限公司

A die-casting equipment for processing thin-walled parts with convenient exhaust

The invention discloses a die-casting molding equipment for processing thin-walled parts which is convenient for exhausting. It includes a base. A fixing seat is fixedly installed on the side of the top of the base away from the protective shell, and an exhaust assembly is installed on the side end surface of the fixing seat. The end face of the fixed seat close to the control box is fixedly welded with a sealed box, an annular suction pipe is embedded in the inner side of the sealed box, and an exhaust pipe is fixedly connected to the outer position of the top of the annular suction pipe. An air suction pump is fixedly installed on the top of the air pump. The structure of the present invention is scientific and reasonable, and it is safe and convenient to use. By closing the sealing box and the sealing block, the two can be clamped into a whole, and because the inner side of the sealing box is evenly arranged with annular air suction The pipe and air suction hole can improve the exhaust efficiency, prevent the air from flowing back into the sealed box, effectively avoid the air in the mold during die casting, and ensure that the molded die casting will not have trachoma and pores, which improves the success rate of die casting.

Owner:江苏富航钢结构有限公司

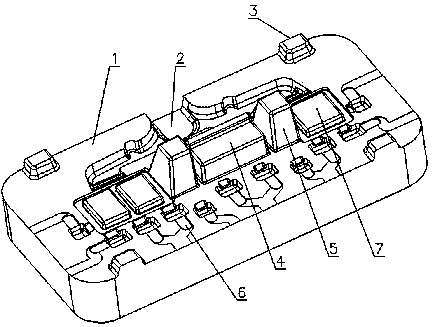

Radiator pressure-casting die

InactiveCN108788074AImprove structural performanceImprove die casting efficiencyPressure castingCasting mold

The invention relates to the technical field of pressure-casting dies, in particular to a radiator pressure-casting die. The radiator pressure-casting die comprises a rectangular die body, the die body is provided with a Y-shaped first runner, the first runner communicates with a pressure casting molding zone, the middle portion of the pressure casting molding zone is provided with a rectangular first boss, the two sides of the first boss are provided with second bosses in a shape of a pyramid trustum with the small top and the large bottom, one side of each second boss is provided with a plurality of cuboid third bosses, and the outer sides of the first boss, the second bosses and the third bosses in the pressure casting molding zone are provided with a plurality of Y-shaped second runners. The radiator pressure-casting die is arranged, the pressure casting molding zone on the die body is reasonably arranged, the overall structure performance of the pressure casting die is better, thepressure casting efficiency is high, and the molding effect is good. Meanwhile, under the limiting effect of the supporting table, pressure casting machining is more accurate.

Owner:湖北广泰精密压铸有限公司

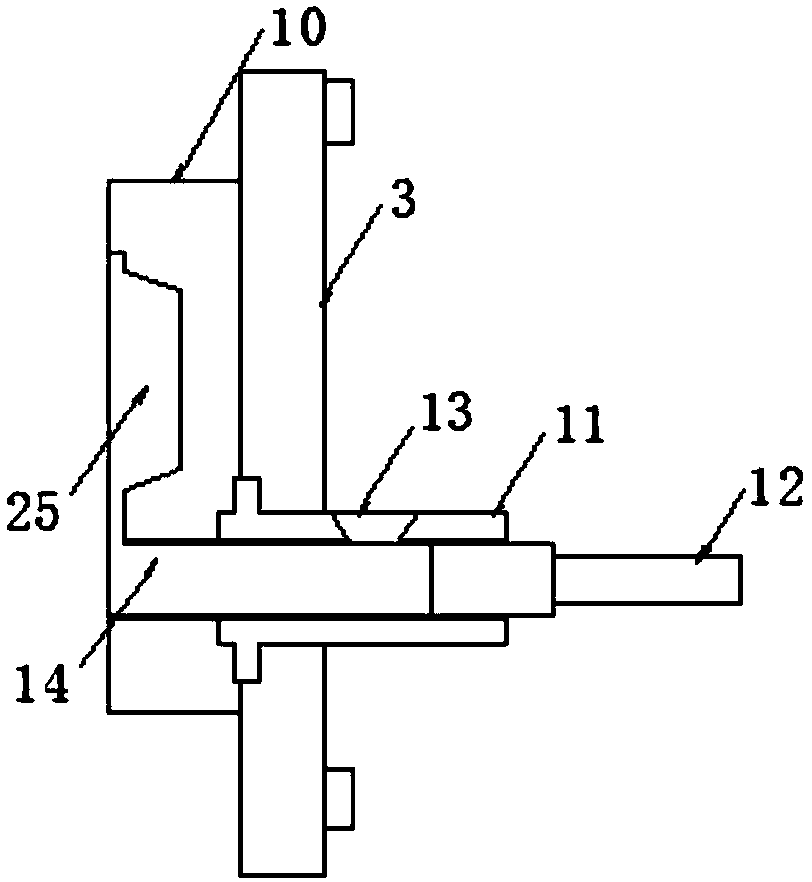

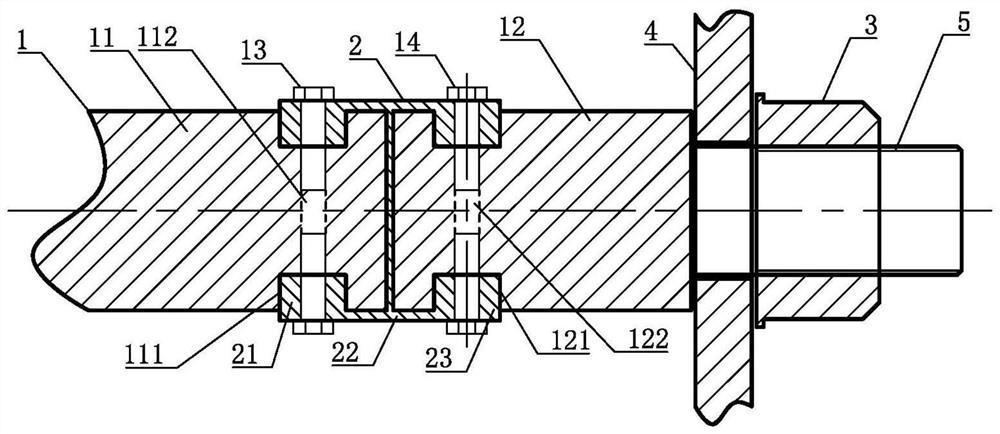

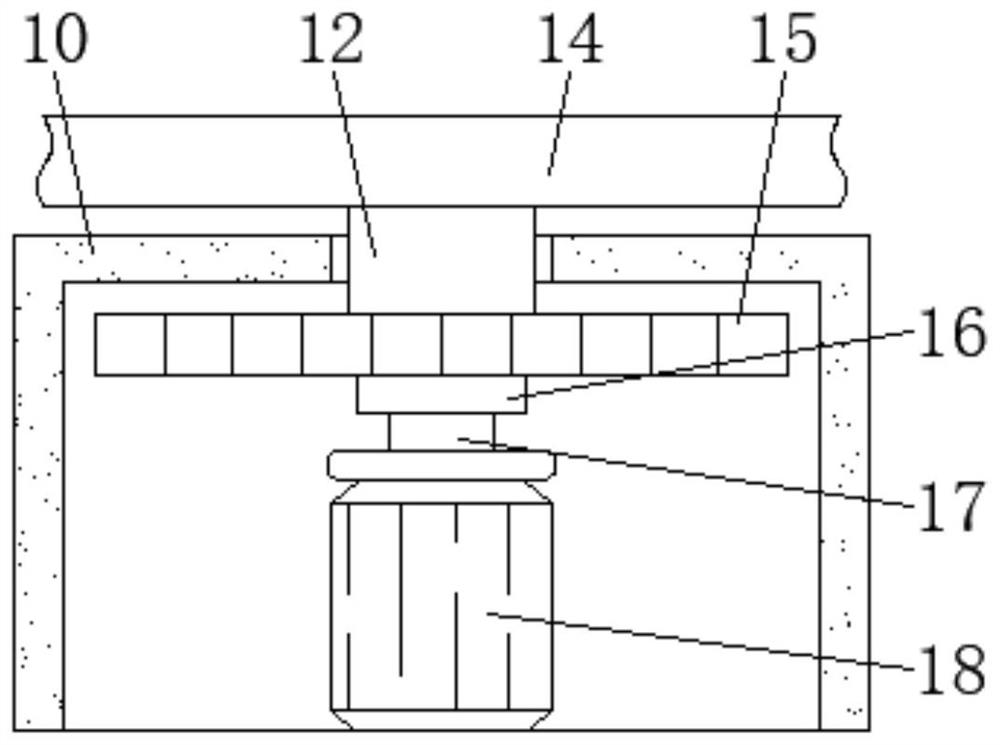

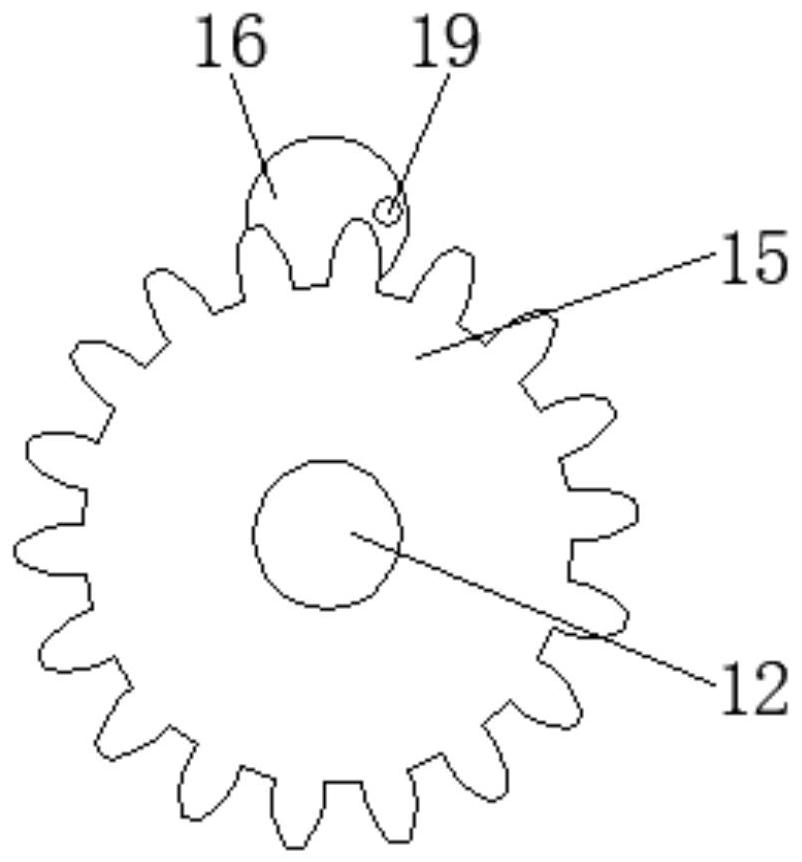

Quick release die-casting mold ejection mechanism

The invention discloses a quick-detachable die-casting mold ejection mechanism, which includes an ejector rod, a concave block, a fixing nut and an ejector plate. The ejector rod includes a first connector and a second connector; the first connector One end of a connector close to the second connector is provided with a first card slot and a first locking threaded hole, and the end of the second connector close to the first connector is provided with a second card slot and a second locking screw hole ; The concave block includes an integrally formed first card platform, a card platform connecting part and a second card platform; the end of the second connector away from the first connector is integrally formed with a screw; the ejector plate passes through The fixing nut is locked on the second connecting head. The invention can effectively solve the problem that the sliding teeth of the screw are locked and difficult to disassemble, and the ejector rod and the ejector plate are easy to replace and disassemble, which can greatly improve the die-casting efficiency, reduce the efficiency of mold replacement, and also reduce the time for abnormal stop operation.

Owner:广东鸿图武汉压铸有限公司 +1

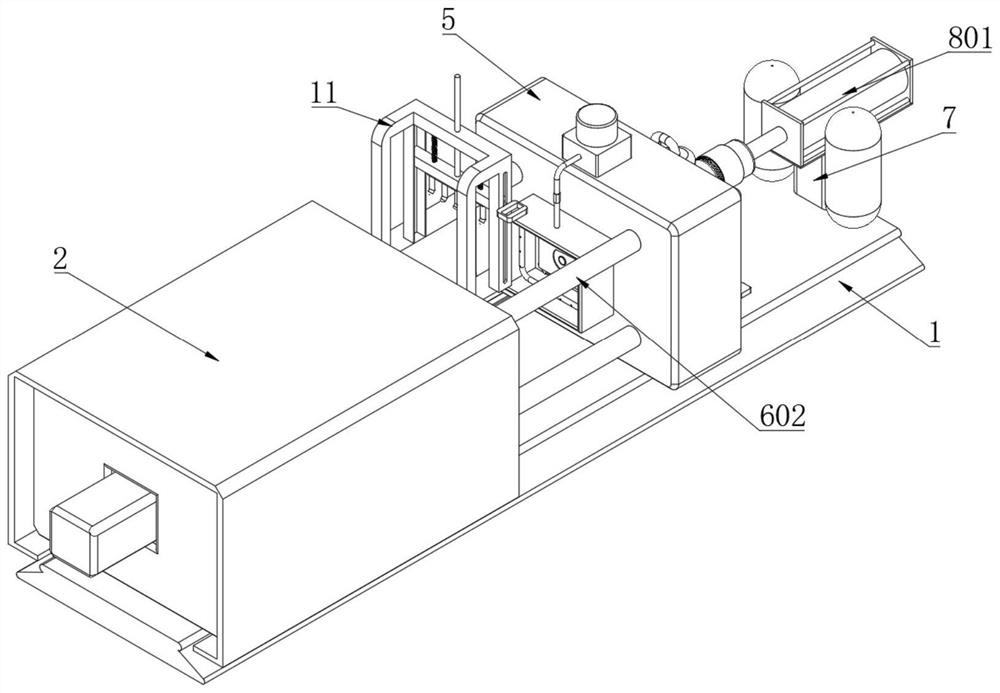

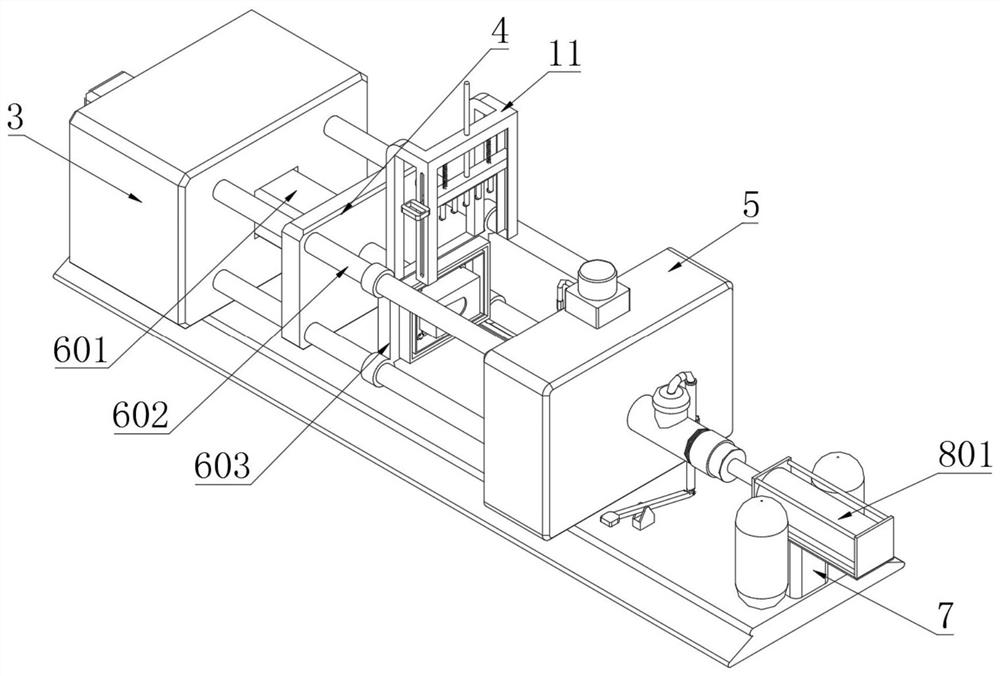

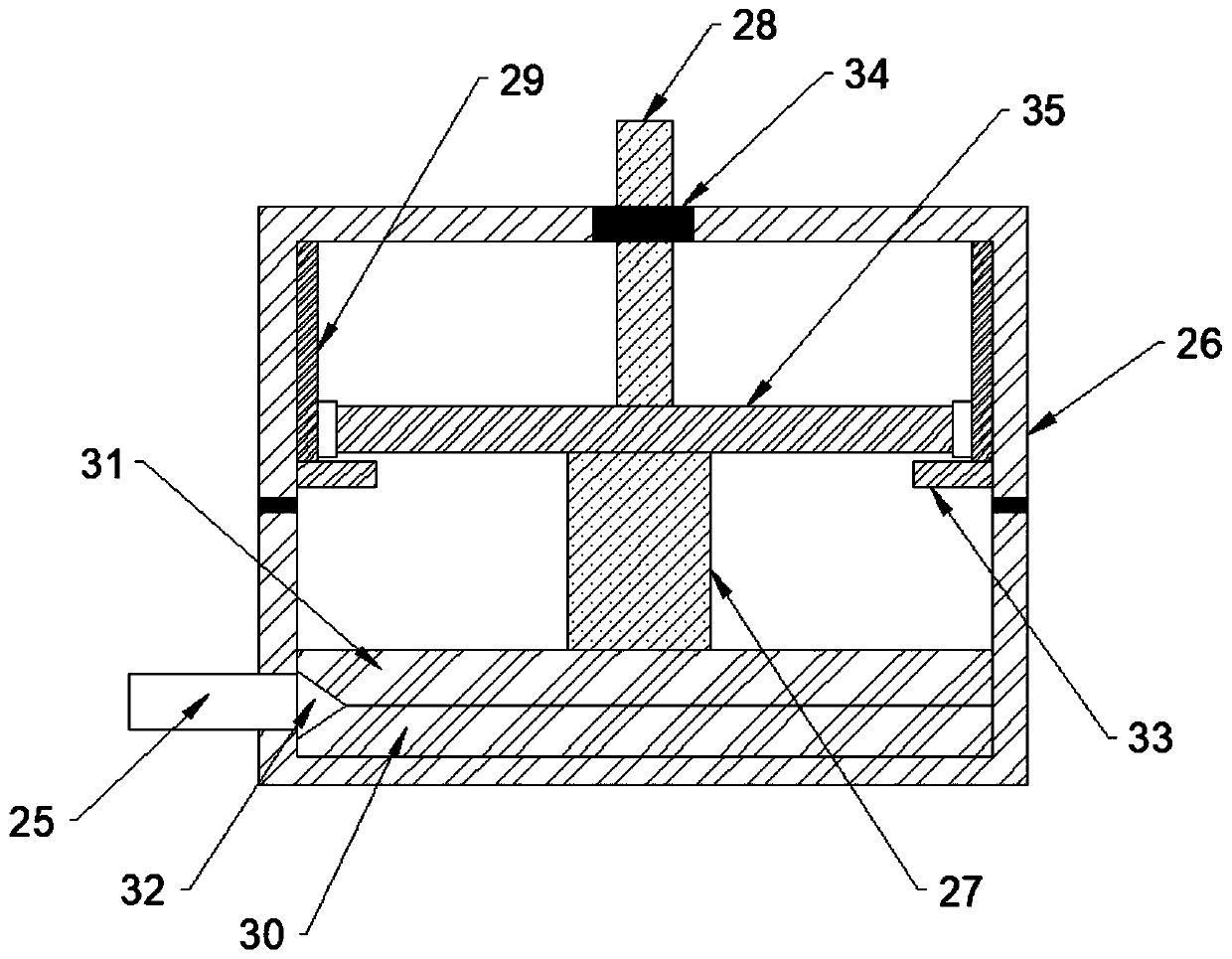

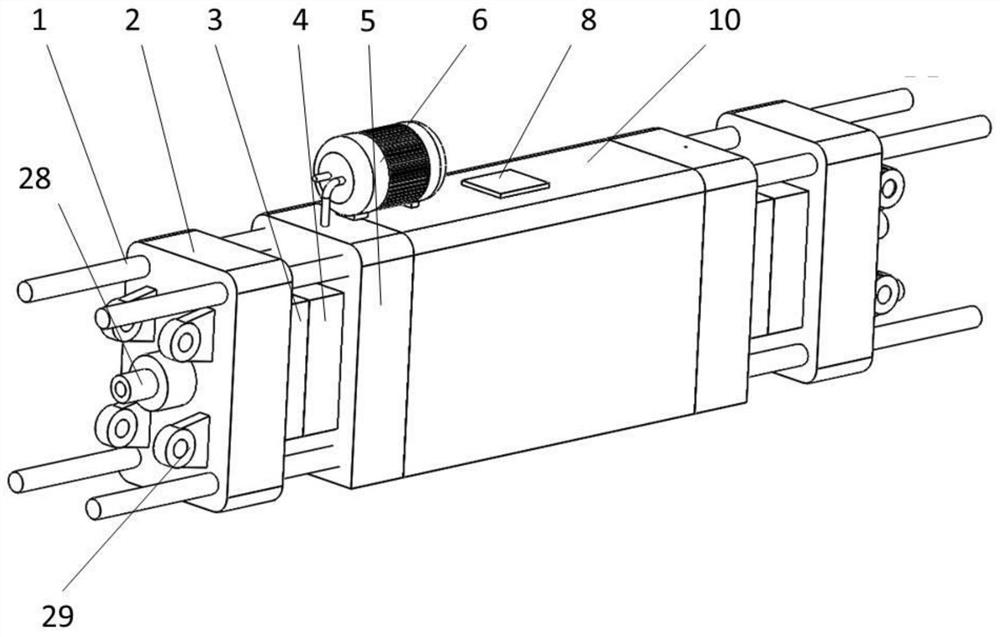

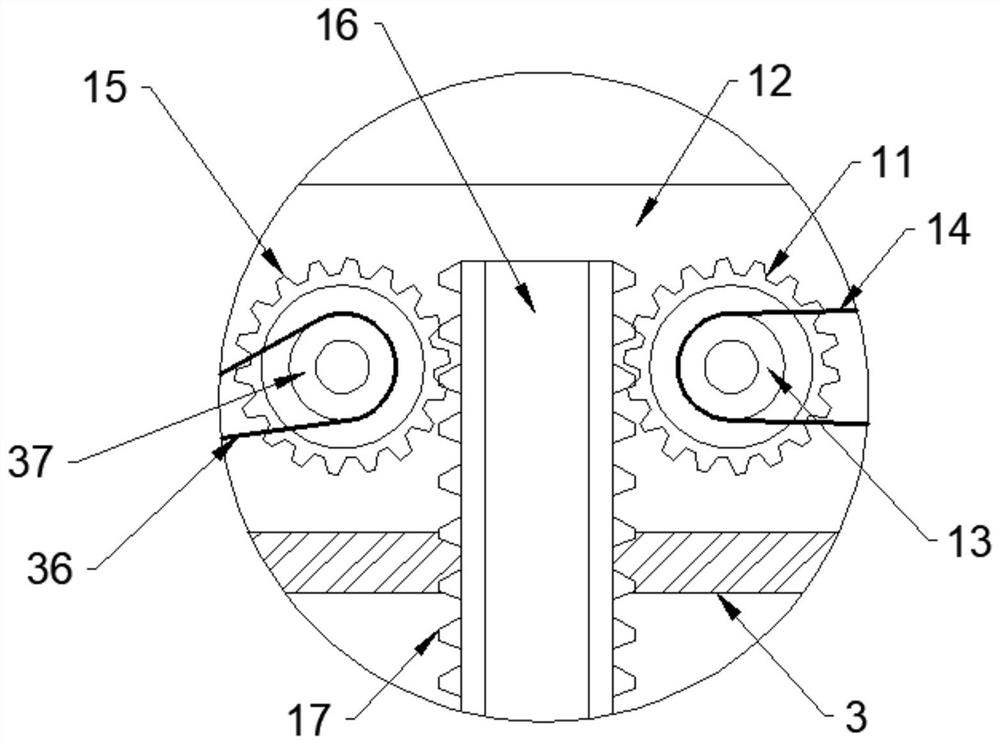

Double station vacuum die casting machine

ActiveCN111451474BImprove die casting efficiencySolve the problem of poor vacuum sealingDie castingEngineering

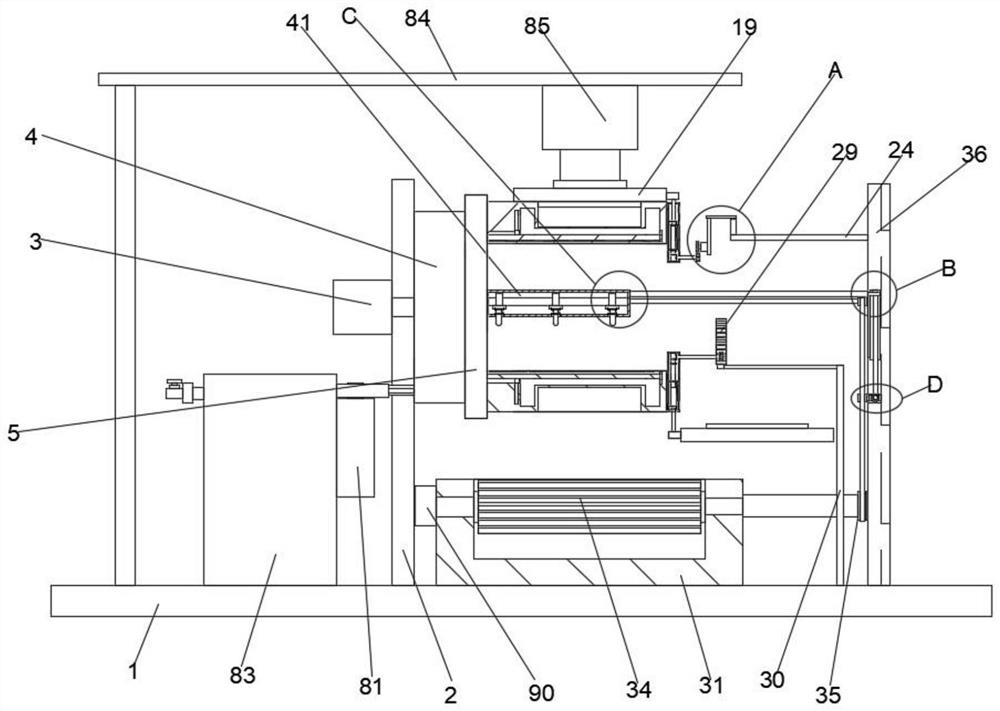

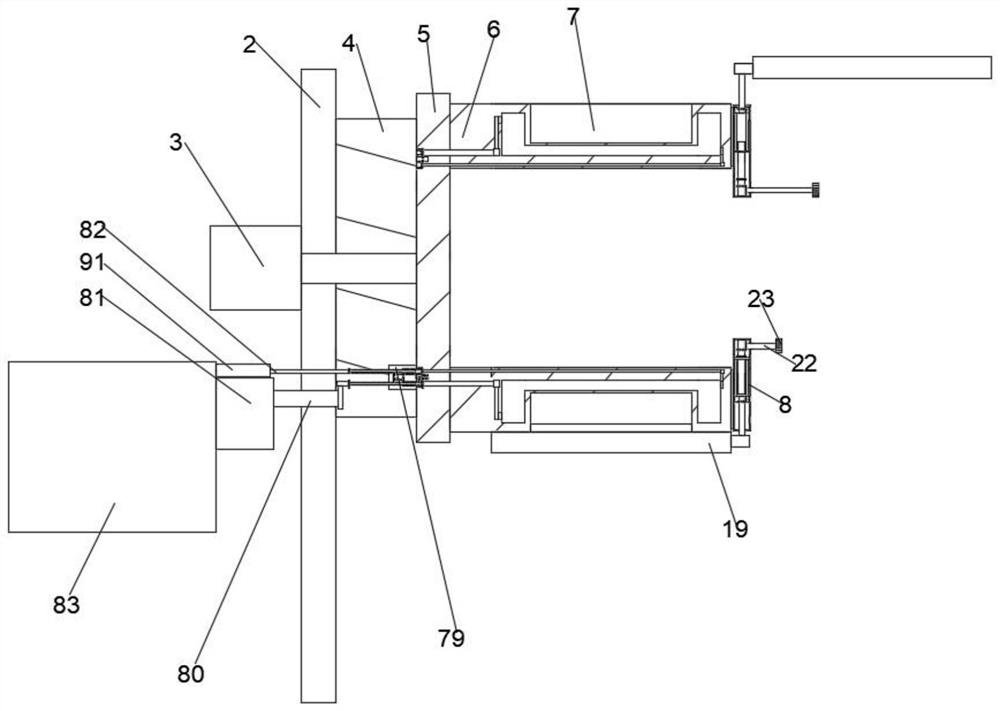

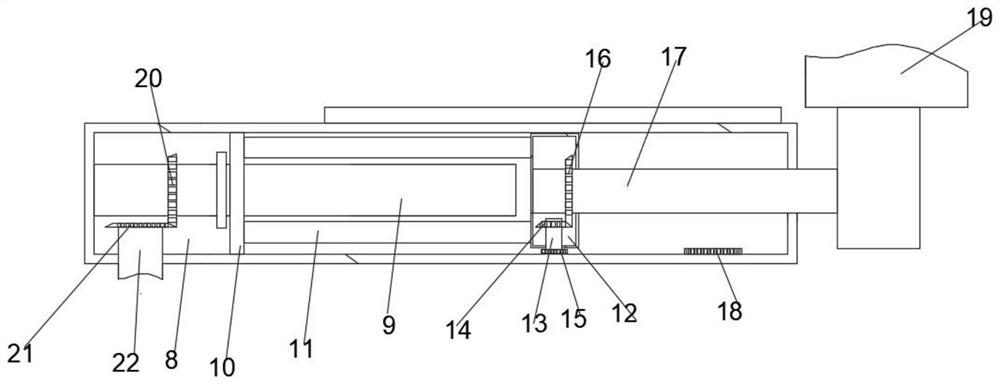

The invention provides a double-station vacuum die-casting machine, which includes a driving device, a first die-casting unit, a second die-casting unit, a feeding part, a vacuum pump and a casing, the vacuum pump is arranged outside the casing, and the driving device is arranged on the casing Inside, the first die-casting unit and the second die-casting unit are respectively arranged on both sides of the driving device; the driving device includes the driving unit, the first injection rod assembly and the second injection rod assembly, the first injection rod assembly and the second injection rod assembly The injection rod assemblies are respectively arranged on both sides of the drive unit, the first injection rod assembly is used to provide power for the die-casting of the first die-casting unit, and the second injection rod assembly is used to provide power for the second die-casting unit; the present invention does not need to use The injection rod drives the injection punch to carry out the process of maintaining pressure on the die-casting during die-casting and the process of maintaining the vacuum in the working room when the mold is opened, and the driving device can make the mover sleeve reversely move to drive the injection rod assembly to carry out another process. The same die-casting work in one direction can greatly improve the efficiency of die-casting.

Owner:YANSHAN UNIV

A die-casting machine integrated processing equipment for button processing

The invention discloses an integrated die-casting machine processing equipment for button processing, which comprises a frame, a first fixed plate, a second fixed plate and a first motor are fixedly installed on the upper side of the frame, and the output end of the first motor is fixedly connected to the There is a first threaded rod, the first motor is connected to the second threaded rod through the first chain transmission, the surfaces of the first threaded rod and the second threaded rod are threaded with moving blocks, and a moving block is fixedly connected between the two moving blocks. plate, the right side of the moving plate is fixedly connected to the support bar, the support bar is slidingly connected to the second fixed plate, and the other end of the support bar is fixedly installed with a connecting plate. In the present invention, the molten liquid metal is temporarily stored by setting a stirring box, and multiple die-casting operations can be carried out without interruption. By setting a quantitative device, the metal liquid required for one die-casting can be delivered regularly and quantitatively, which avoids the waste of materials and saves time and effort. , Reduce the labor intensity of the staff, and improve the die-casting efficiency of the die-casting machine.

Owner:东莞市恒兴隆实业有限公司

Aluminum Alloy Die Casting Blank Precision Forming Technology

ActiveCN107866548BEasy to integrateConducive to lightweightFoundry mouldsFoundry coresWaxPressure casting

The invention provides an aluminum alloy pressure casting blank precise forming process method. The method comprises the following steps that (1), a mould is fabricated according to the structure of acasting; (2), a wax mould, a pouring cup, a horizontal pouring channel, a straight pouring channel and an inner pouring gate are pressed through a wax injector, the wax mould is subjected to shape trimming, the wax mould is subjected to mould combination according to a combination diagram, and then the combined wax mould is subjected to oil removal; (3), the wax mould subjected to mould combination is subjected to multi-layer san suspension; (4), dewaxing is performed, a mould shell obtained after dewaxing is dried by 20 hours or more in the ventilation condition, the mould shell is subjectedto calcination in a chamber type electric resistance furnace, and the mould shell is inspected after the mould shell is cooled to the room temperature; (5), the washed mould shell is required to be subjected to a shell drying process; (6), sodium silicate-bonded sand is adopted for modelling, and then the sand mould is subjected to drying treatment; (7), a molten aluminum alloy is smelted, pressure-regulating pouring is adopted, when half of the crystallization period is reached, the temperature of the sand mould is lowered by 5-10 s, and the temperature of the sand mould is decreased by 2-4DEG C; (8), the casting is cleaned; (9), the casting is subjected to heat treatment.

Owner:JIANGSU XIANGHE ELECTRONICS SCI & TECH

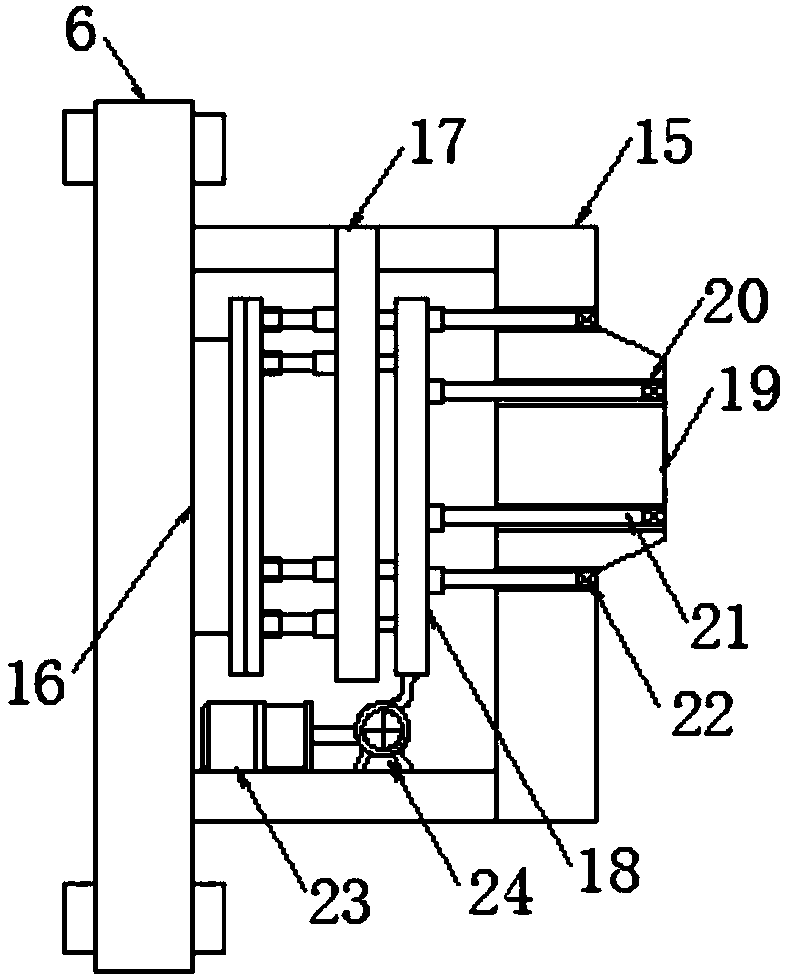

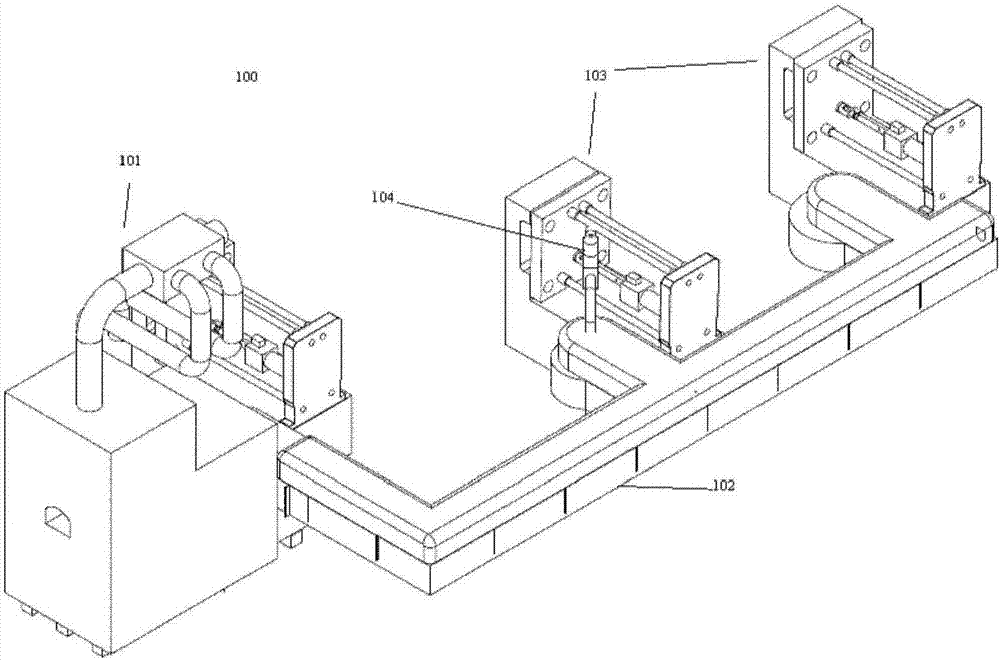

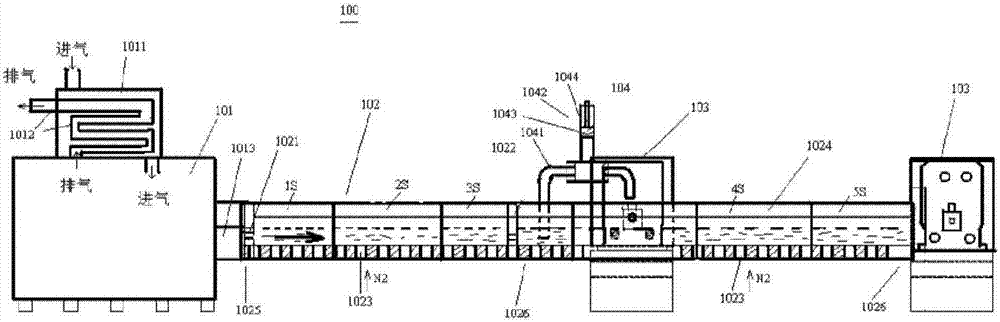

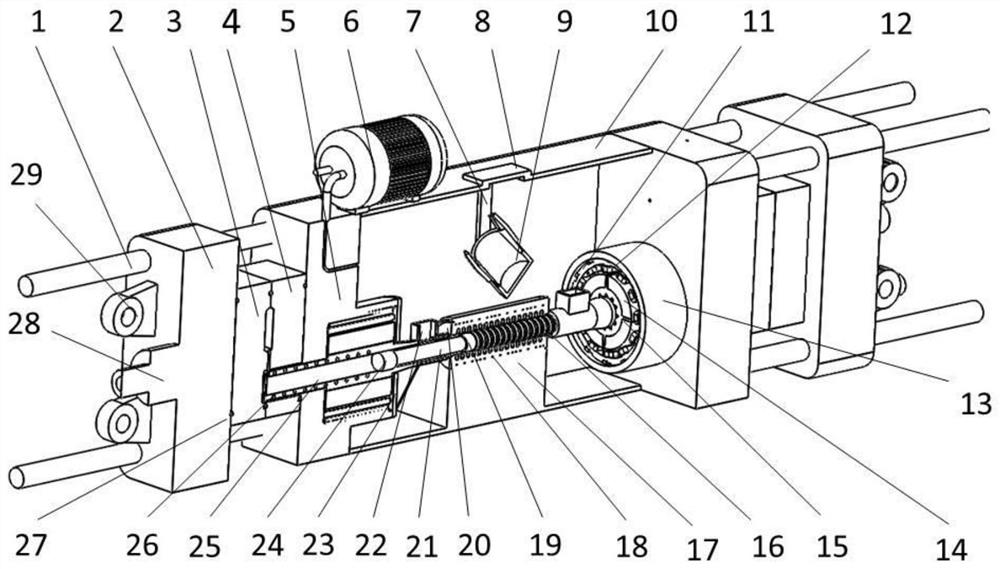

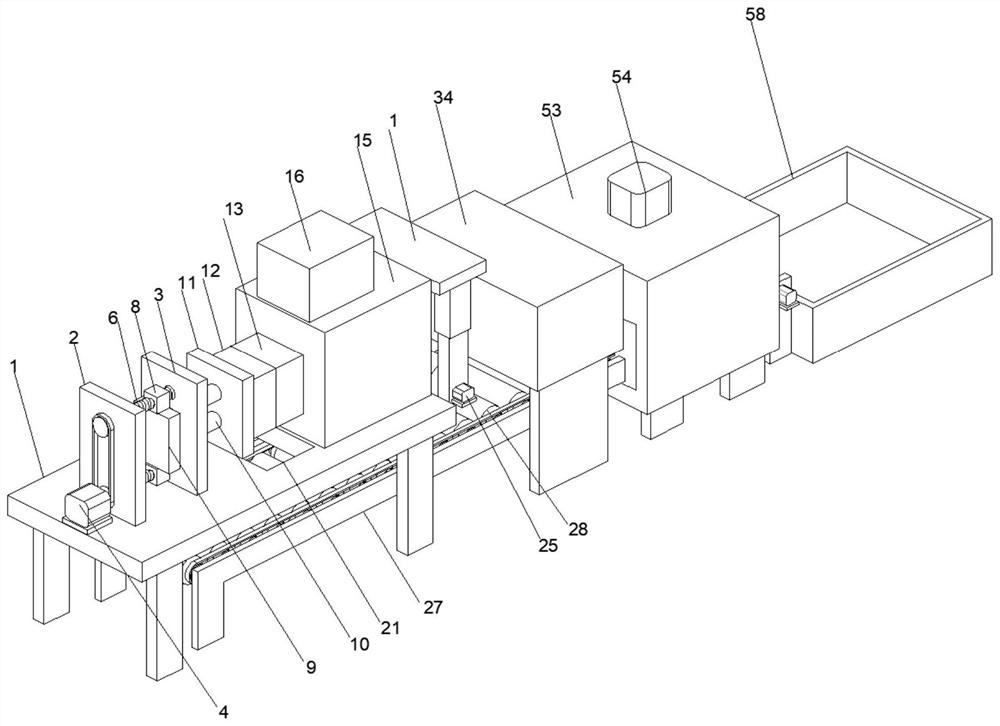

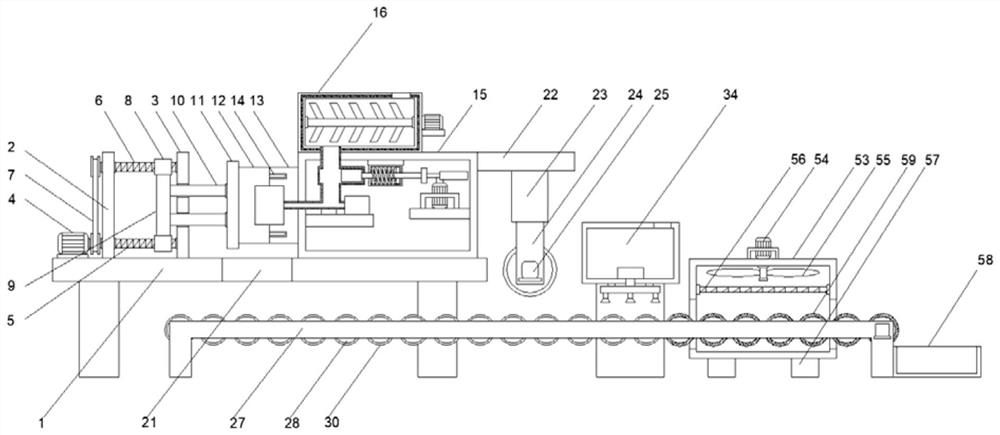

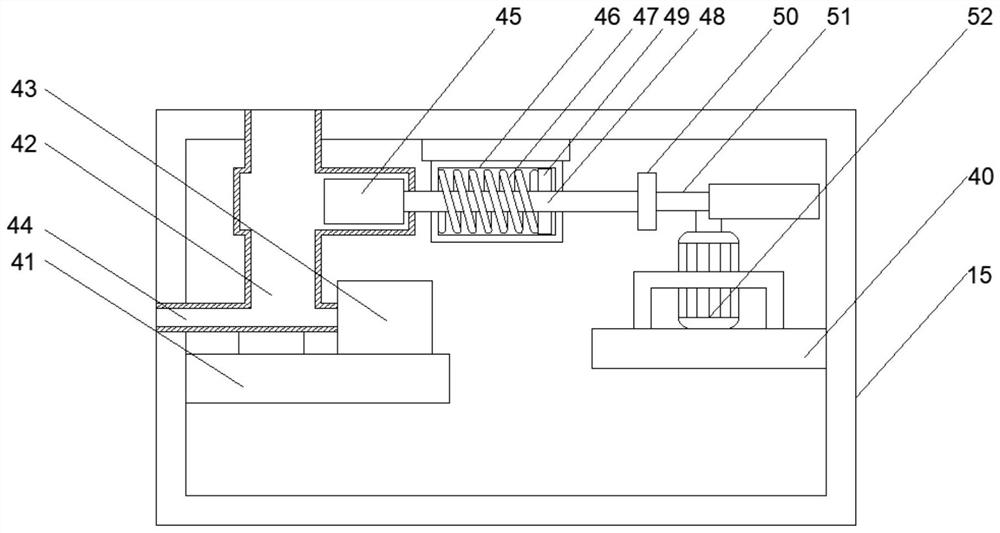

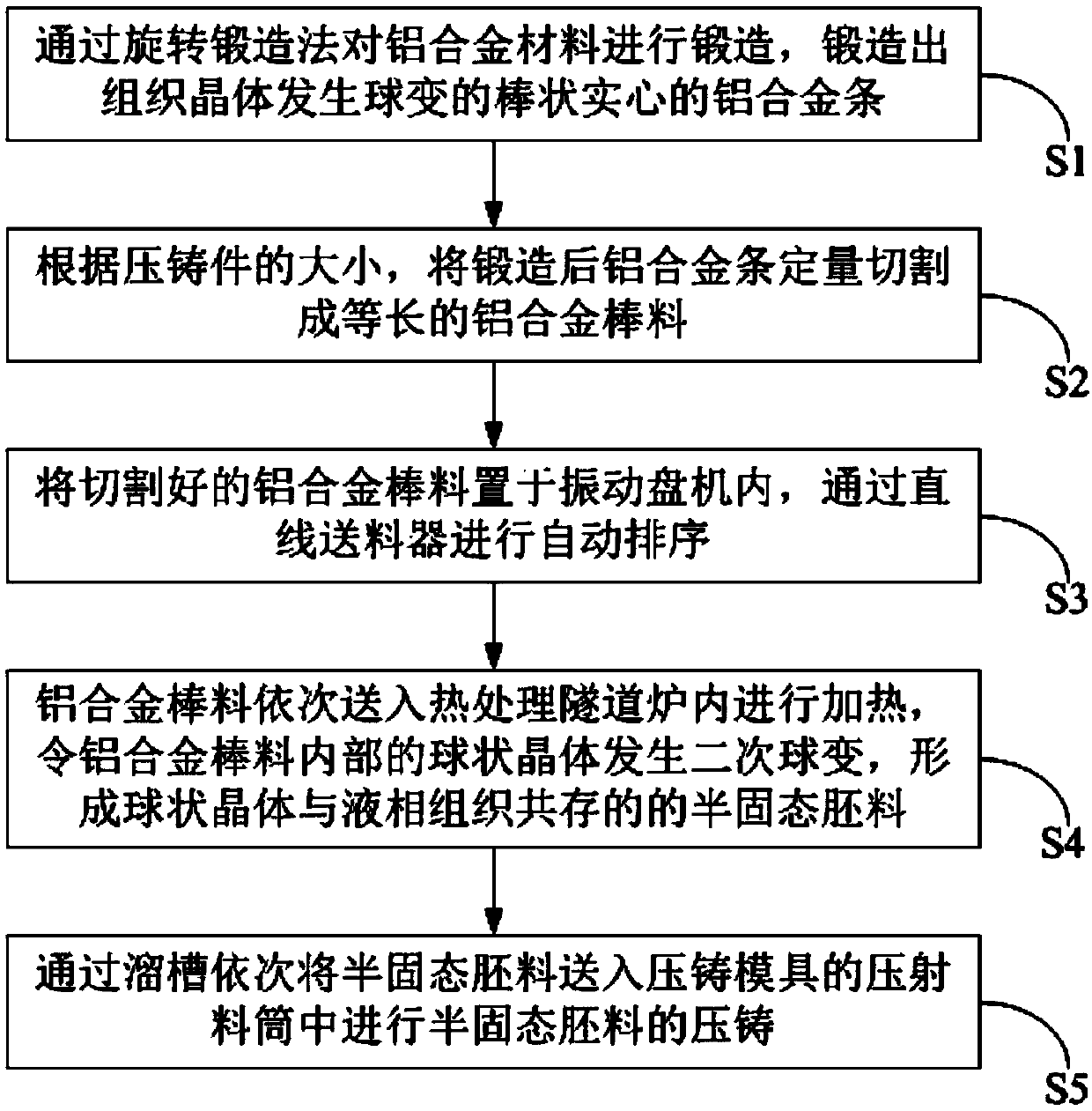

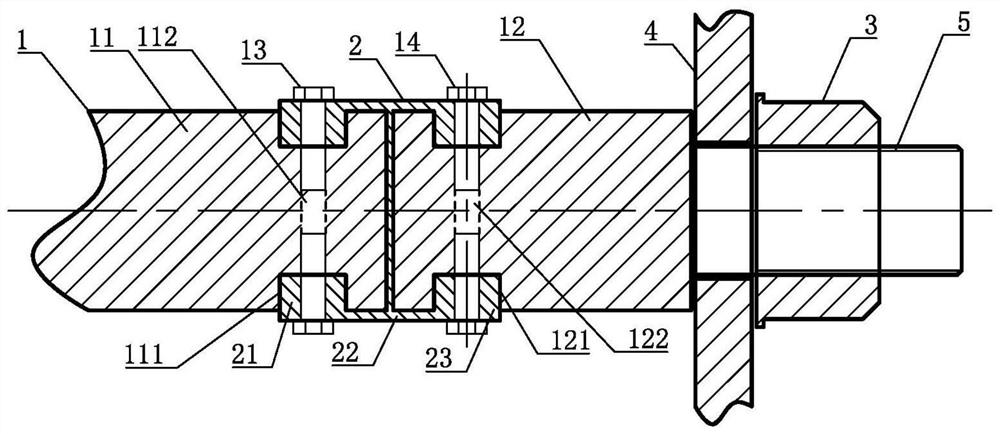

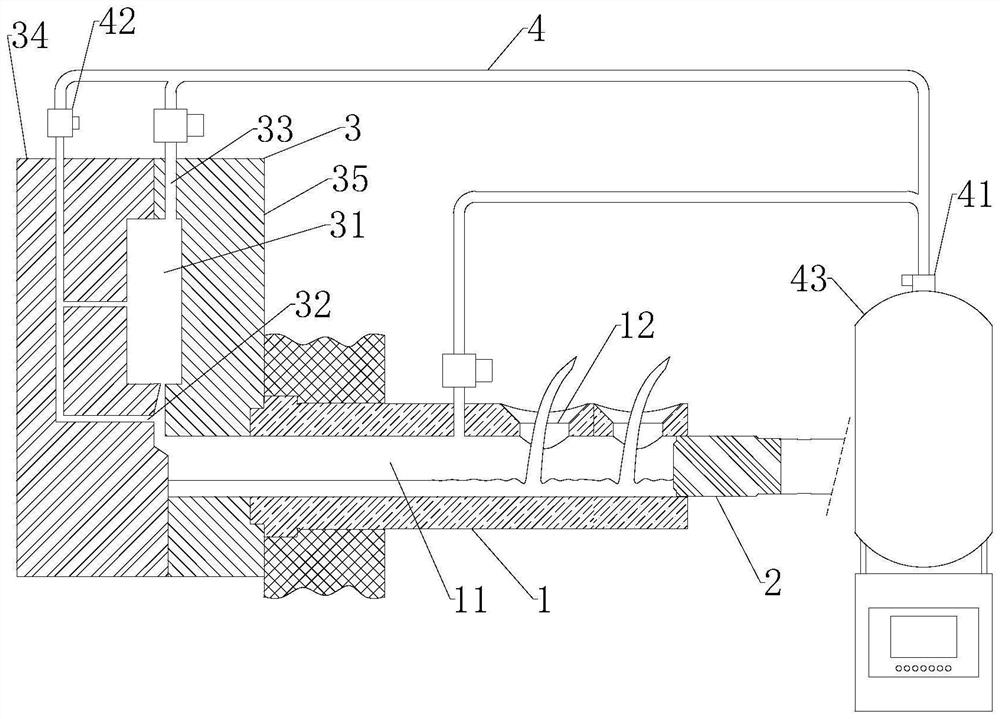

Aluminum alloy semi-solid blank material continuous-heating die casting method and device

PendingCN109248998AMeet the technological requirements of die-castingImprove die casting efficiencyDie castingThermal treatment

The invention discloses an aluminum alloy semi-solid blank material continuous-heating die casting method. The method includes steps: S1, adopting a rotating forging method for forging an aluminum alloy material to obtain a rodlike solid aluminum alloy strip with texture crystal deformation; S2, quantitatively cutting the forged aluminum alloy strip into aluminum alloy bars in equal length according to sizes of die castings; S3, placing the cut aluminum alloy bars into a vibrating disc machine, and adopting a linear feeder for automatic sorting; S4, sequentially sending the aluminum alloy barsinto a thermal treatment tunnel furnace, heating to enable secondary deformation of spherical crystal in the aluminum alloy bars to form a spherical crystal and liquid-phase texture co-existing semi-solid blank material; S5, sequentially sending the semi-solid blank material into a pressure barrel of a die-casting die through a chute, and performing die casting of the semi-solid blank material. By adoption of the method, the uniform and non-defective aluminum alloy semi-solid blank material can be obtained, and the requirement of aluminum alloy thin-walled parts on the aluminum alloy semi-solid blank material can be met.

Owner:金雅豪精密金属科技(东莞)有限公司

Quick disassembly and assembly type die-casting mold ejection mechanism

The invention discloses a quick disassembly and assembly type die-casting mold ejection mechanism. The ejection mechanism comprises an ejection rod, concave clamping blocks, a fixing nut and an ejection plate; the ejection rod comprises a first connector and a second connector, first clamping grooves and first locking threaded holes are formed in the end, close to the second connector, of the first connector, and second clamping grooves and second locking threaded holes are formed in the end, close to the first connector, of the second connector; and the concave clamping blocks comprise firstclamping tables, clamping table connecting parts and second clamping tables which are integrally formed, a screw is integrally formed at the end, away from the first connector, of the second connector, and the ejection plate is locked on the second connector through the fixing nut. The quick disassembly and assembly type die-casting mold ejection mechanism can effectively solve the problem that the screw is difficult to disassemble due to screw loose locking, and the ejector rod and the ejector plate are easy to replace and disassemble so that the die-casting efficiency can be greatly improved, the mold replacing efficiency is reduced, and meanwhile, the time for abnormally stopping operation is shortened.

Owner:广东鸿图武汉压铸有限公司 +1

Die-casting die of cast steel bucket teeth

The invention discloses a die-casting die of cast steel bucket teeth. The die-casting die comprises a fixed die base, a fixed die, a movable die, a material cavity, a movable die cavity, a fixed die cavity and an ejection block, wherein the fixed die is fixed to the upper part of the fixed die base, the fixed die cavity is formed in the upper end of the fixed die, a fixed die sand core is fixed to one side of the fixed die cavity, the material cavity is arranged under the fixed die cavity, the ejection block is arranged inside the material cavity, the bottom of the ejection block is connected to one end of an ejection rod, the other end of the ejection rod is connected to a hydraulic cylinder, the movable die is arranged on the fixed die, the movable die cavity symmetric with the fixed die cavity is formed in the bottom end of the movable die, a movable die sand core is arranged on one side of the movable die cavity, the movable die sand core and the fixed die sand core are provided with transverse blind holes, and transverse exhaust holes are formed in the part, located on the outer side of the movable die sand core, of the movable die and in the part, located on the outer side of the fixed die sand core, of the fixed die. The die-casting die of the cast steel bucket teeth has the advantages that the ejection speed is high, the forming period is short, the die-casting efficiency is high and the surface quality of the bucket teeth is guaranteed.

Owner:天津卡斯特机械有限公司

An automatic feeding die-casting device

The invention discloses a pressure casting device achieving automatic feeding. The pressure casting device comprises a base, wherein two charging-box support frames are fixed on the left side of the base; a charging box is fixed on the upper sides of the two charging-box support frames; a kickoff wheel is mounted at a discharge outlet in the lower side of the charging box; a first belt pulley is mounted on the side face of the kickoff wheel; a conveying plate is arranged on the lower side of the kickoff wheel; a high-temperature melting furnace is filled with a high-temperature solution; a pressure casting barrel is inserted in the high-temperature solution; an inlet pipe is connected to the left side of the pressure casting barrel; a collecting hopper is mounted at the other end of the inlet pipe; a piston is inserted in the pressure casting barrel; the upper end of the piston is connected with a pressure column; gear racks are fixed on two sides of the pressure column; a gear fixing plate is connected with the pressure column in a sliding manner; a motor is mounted on a top fixing frame; the right side of the pressure casting barrel is connected with an outlet pipe, the right side of which is connected with a molding frame; a lower die is fixed at the bottom of the molding frame; and an upper die is arranged on the upper side of the lower die and connected with the molding frame in a sliding manner. The pressure casting device achieving automatic feeding is convenient to use and has high pressure casting efficiency.

Owner:佛山市同向智能装备有限公司

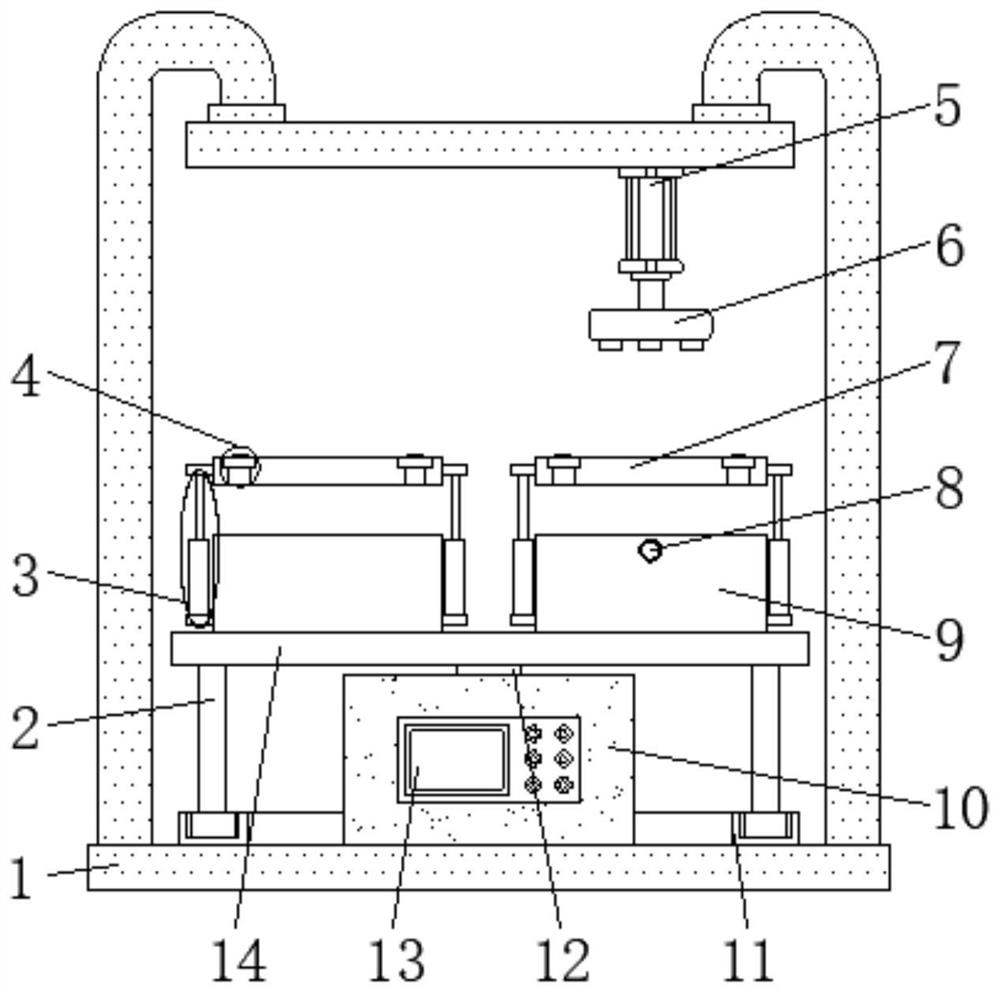

Vertical die-casting machine of multi-station structure

The invention discloses a vertical die-casting machine of a multi-station structure. The vertical die-casting machine comprises a rack, movable dies, fixed dies, a base table and a control panel, wherein the base table is fixed to the center of the bottom of the rack, a bearing table is arranged above the base table, the fixed dies are arranged on two sides of the top end of the bearing table, a liquid injection opening is formed in one end of the surface of each fixed die, one end of the liquid injection opening extends into the fixed die, the movable dies are arranged above the fixed dies, limiting structures are arranged on two outer side walls of the movable dies, ventilation structures are arranged on two sides of the interiors of the movable dies, an air cylinder is installed on oneside of the top of the rack, a die-casting disc is installed at the bottom end of the air cylinder, the control panel is installed in the center of the surface of the base table, and the output end ofa single-chip microcomputer in the control panel is electrically connected with the input end of the air cylinder. The die-casting efficiency of the die-casting machine in use is improved, the stability of the die-casting machine in use is ensured, and meanwhile, the phenomenon that bubbles are generated by die-casting objects when the die-casting machine is used is reduced.

Owner:启东捌友精密汽车部件有限公司

Precise die-casting die for automobile transmission parts

InactiveCN112846146AFirmly connectedEasy inspection and maintenanceGrinding feed controlGrinding machinesDie castingEngineering

The invention provides a precise die-casting die for automobile transmission parts, which comprises an intelligent die-casting box; a waste recycling box is arranged on the left portion of the top face of the intelligent die-casting box; a grinding and polishing box is arranged on the right portion of the top face of the intelligent die-casting box; a first transverse arm is fixed to the right side face of the waste recycling box, and a second longitudinal arm is fixed to the right end of the first transverse arm; the top of the left side face of the second longitudinal arm is fixedly connected with the right end of a first return spring; the left end of the first return spring is fixedly connected with the top of the right side face of a first longitudinal arm; the bottom end of the first longitudinal arm is fixedly connected with the right portion of the upper surface of a rotating plate; the right end of the rotating plate is connected with the left portion of a first connecting half shaft; and the right portion of the first connecting half shaft is fixedly connected with the top of the right side face in the waste recycling box. According to the technical scheme disclosed by the invention, the technical problems that in the prior art, the metal part waste recycling capacity is not achieved, and intelligent die casting, intelligent grinding and polishing cannot be achieved are effectively solved, and application and popularization are facilitated.

Owner:贺俊威

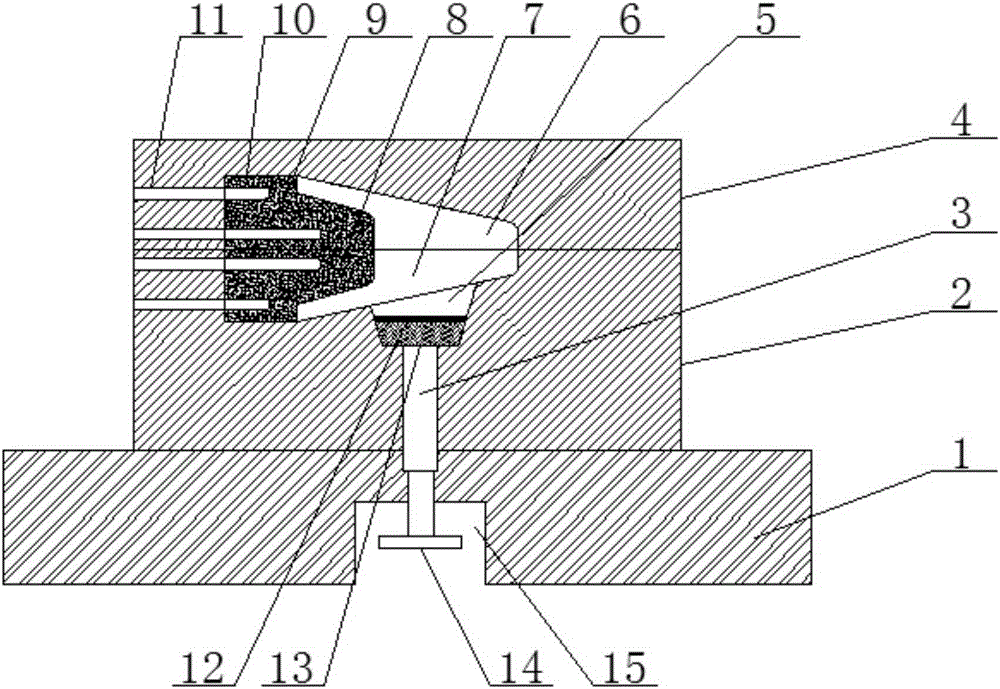

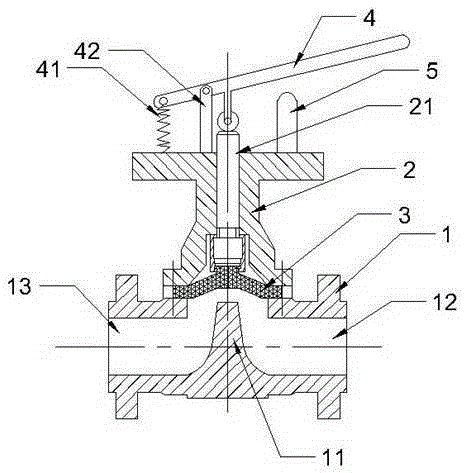

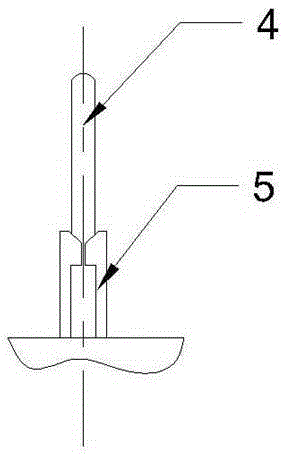

Lever diaphragm vacuum valve for die casting

InactiveCN105240600AOpen quicklyQuick closeOperating means/releasing devices for valvesPressure castingEngineering

The invention relates to the technical field of diaphragm cutoff devices and discloses a lever diaphragm vacuum valve for die casting. The lever diaphragm vacuum valve comprises a valve body, a diaphragm and a valve rod. The valve rod is sleeved with the valve body. The lower end of the valve rod is connected with the diaphragm. A valve element is arranged below the diaphragm. An air inlet and an air outlet are formed beside the valve element. The air inlet and the air outlet are communicated with a gap between the valve element and the diaphragm. A lever handle is arranged above the valve rod and hinged to the valve rod through a stand column on the valve body. One end of the lever handle is connected with the valve body through a tension spring. The middle segment, located over the valve rod, of the lever handle is provided with a sliding wheel. The sliding wheel makes contact with the valve rod. The end, away from the tension spring, of the valve body is provided with clamping pieces. By the adoption of the scheme, lever downwards-pressing replaces screw rotating downwards-pressing, opening and closing are faster, operation is efficient, control is more convenient and faster, and die casting efficiency is improved effectively.

Owner:CHONGQING YINGRUISHENG DIE CASTING

Ultra-large aluminum alloy vacuum die-casting system and method

The invention discloses an ultra-large aluminum alloy vacuum die-casting system and method.The system comprises a pressure chamber body internally provided with a pressure chamber, a punch arranged in the pressure chamber, a die mechanism internally provided with a die cavity, a vacuum generation mechanism and a controller, the pressure chamber body comprises at least one material pouring opening communicated with the pressure chamber, the pressure chamber is connected with the die cavity, and the controller is connected with the punch. The end, close to the pressure chamber, of the die cavity is connected with at least one first air exhaust channel, the end, away from the pressure chamber, of the die cavity is connected with a second air exhaust channel, the first air exhaust channel and the second air exhaust channel are both connected with a vacuum generation mechanism, and the punch and the vacuum generation mechanism are both connected with a controller. According to the pouring device, the efficiency of molten aluminum entering the pressure chamber is improved by additionally arranging the pouring opening, meanwhile, the molten aluminum is driven to dissipate heat during pouring, the erosion of the molten aluminum to the pressure chamber is reduced, comprehensive air exhaust is conducted on the mold cavity through the first air exhaust channel and the second air exhaust channel, and the vacuum degree of the mold cavity is improved.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com