Die-casting mould

A die-casting mold and die-fixing technology, which is applied in the field of mechanical processing, can solve the problems of high cost and low molding rate, and achieve the effects of improving die-casting efficiency and yield, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

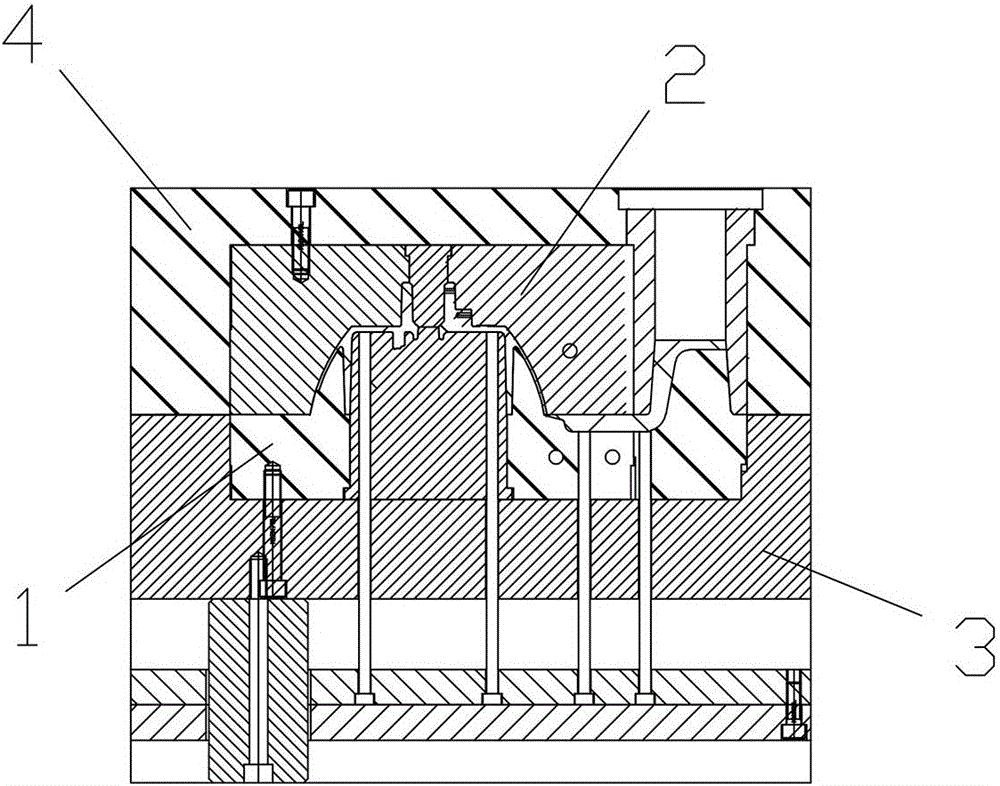

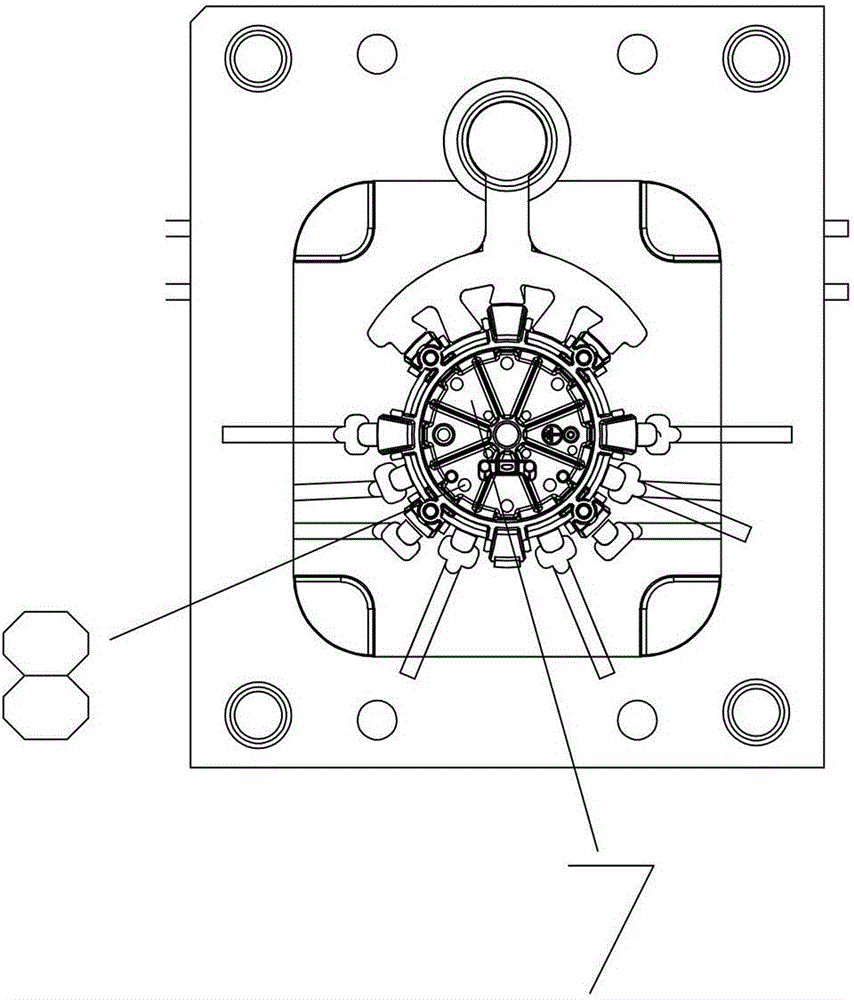

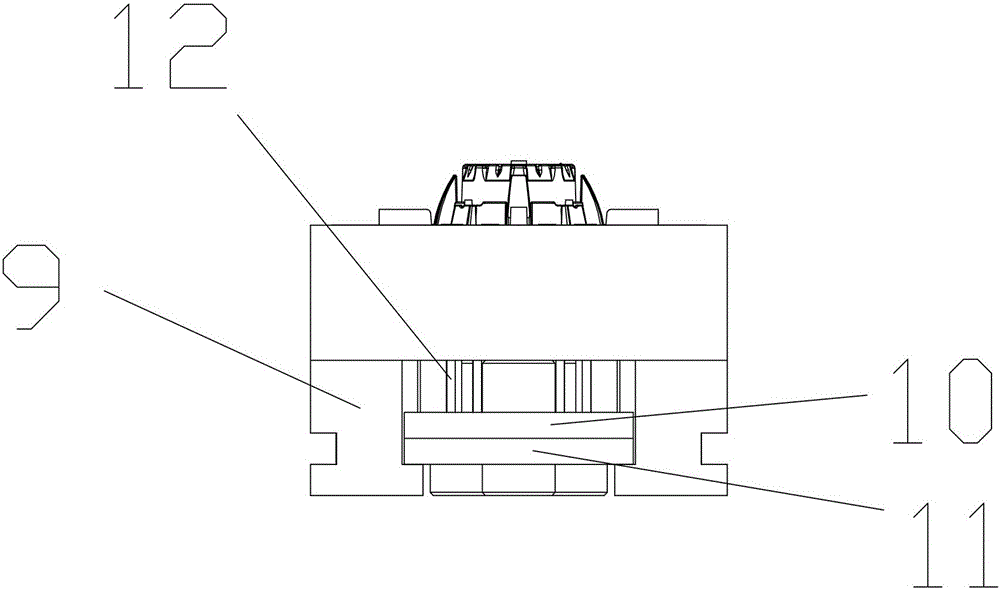

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the die-casting mold provided by the present invention includes a movable mold 1, a fixed mold 2, a movable mold cover plate 3 and a fixed mold cover plate 4, and the movable mold cover plate 3 is set next to the movable mold 1, and the fixed mold cover plate 4 sets Then the fixed mold 2, the above-mentioned movable mold 1 and the fixed mold 2 cooperate with each other, and the first core insert 5 is arranged on the center position of the plane of the movable mold 1, and at the first core insert 5, set There is a first through hole 6 through the first core insert 5 and the movable mold 1, a second core insert 7 is arranged in the first through hole 6, and a second core insert 7 is arranged in the second core insert 7 One side is provided with a plurality of thimble holes 8, and a pair of bases 9 are connected to the bottom of the movable mold cover plate 3, and a thimb...

Embodiment 2

[0030] Such as Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, the general structure of the die-casting mold provided in this embodiment is consistent with that of Embodiment 1, the difference is that in order to protect the mould, the fixed mold 2 is provided with the fixed mold 2 and the fixed mold cover plate 4. Water pipe 23; in order to discharge impurities and waste gas, a plurality of overflow grooves 24 and exhaust grooves 25 are provided at the movable mold 1. In order to speed up the heat dissipation effect of the parts, the above-mentioned overflow grooves 25 are connected with heat dissipation plates 26 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com