Cast spun aluminum alloy hub rim spinning formation method

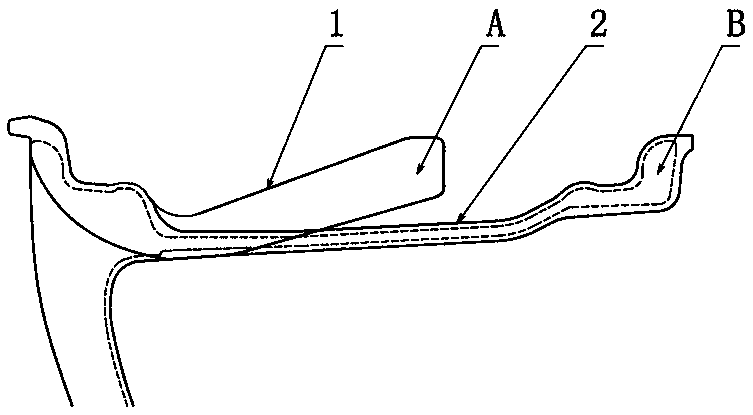

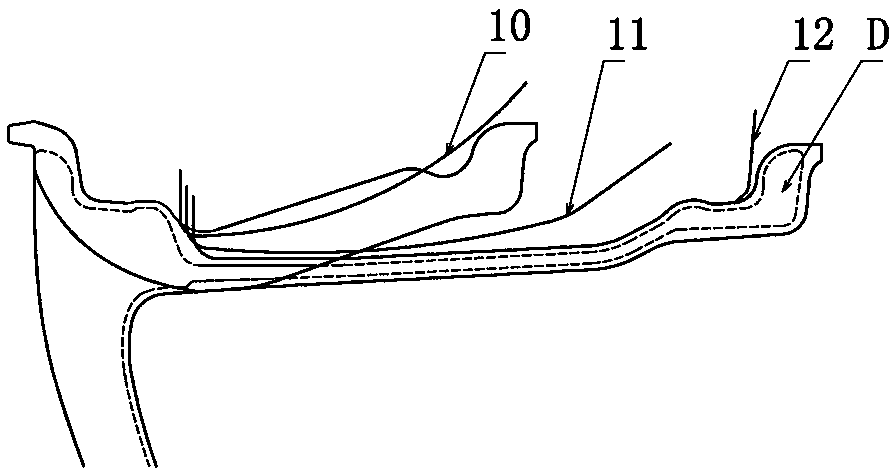

An aluminum alloy wheel hub and spinning forming technology is applied in the field of compound spinning forming of the rim of the cast aluminum alloy wheel hub, which can solve the problems of inconspicuous flow lines of the spinning structure, insufficient deformation of the as-cast structure, affecting the safety of automobiles, etc. , to achieve the effect of improving the metal streamline organization, promoting the value, and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

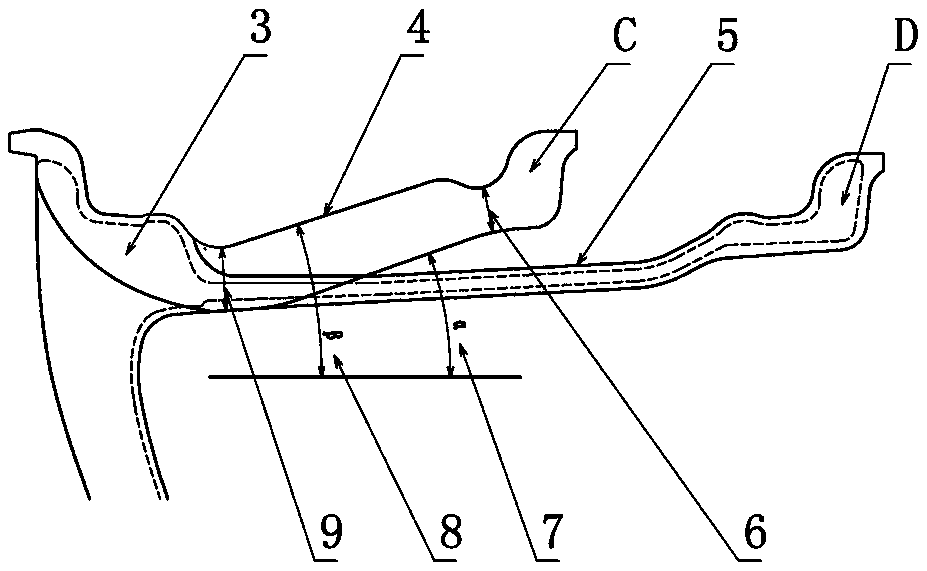

[0017] Example 1: The feeding channel 6 of the newly cast rim 4 is set to 13.5mm; in order to ensure the sequential solidification of the cast rim, the inclination angle 7α of the blank of the newly cast rim 4 is 19°, and the outside inclination angle 8β of the blank of the newly cast rim 4 is 18°. The thickness at well 9 is 18.6 mm, which makes it have a certain structural gradient.

[0018] The casting process of the newly cast rim 4 adopts a water cooling method to cool the casting mold, especially the position of the inner rim. The casting mold preheating temperature is 320°C, the aluminum liquid temperature is 690°C, the holding pressure is 830mbar, the holding time is 130s, the cooling time after pressure relief is 25s, and the production cycle is increased from the original 5.5min / piece to 3.8 min / piece, casting production efficiency increased by 30.9%. The elongation rate of the rim is increased to more than 10%, and the elongation rate of the inner rim can be increas...

Embodiment 2

[0024] Example 2: The feeding channel 6 of the newly cast rim 4 is set to 15 mm; in order to ensure the sequential solidification of the cast rim, the inclination angle 7α of the blank of the newly cast rim 4 is set to 19°, and the outside angle of the blank of the newly cast rim 4 8β is set to 16° 1. The thickness of wheel well 9 is set to 19.5 mm, so that it has a certain structural gradient.

[0025] The casting process of the newly cast rim 4 adopts a water cooling method to cool the casting mold, especially the position of the inner rim. The casting mold preheating temperature is 380°C, the aluminum liquid temperature is 700°C, the holding pressure is 860mbar, the holding time is 150s, the cooling time after pressure relief is 35s, and the production cycle is increased from the original 6.5min / piece to 4.5 min / piece, the casting production efficiency is increased by 30.7%, the elongation rate of the rim is increased to more than 11%, and the elongation rate of the inner r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com