High-temperature fuel gas energy-saving die-casting system

A gas-fired, high-temperature technology, applied in the field of high-temperature gas-fired energy-saving die-casting systems, can solve the problems of blackened workshop walls, adverse effects of the atmosphere, and performance temperatures that cannot reach 40°C, and achieve the effect of improving die-casting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

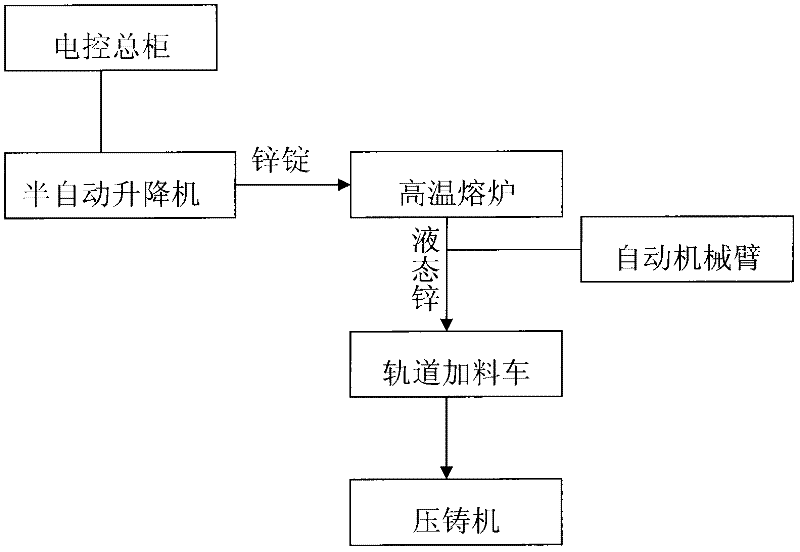

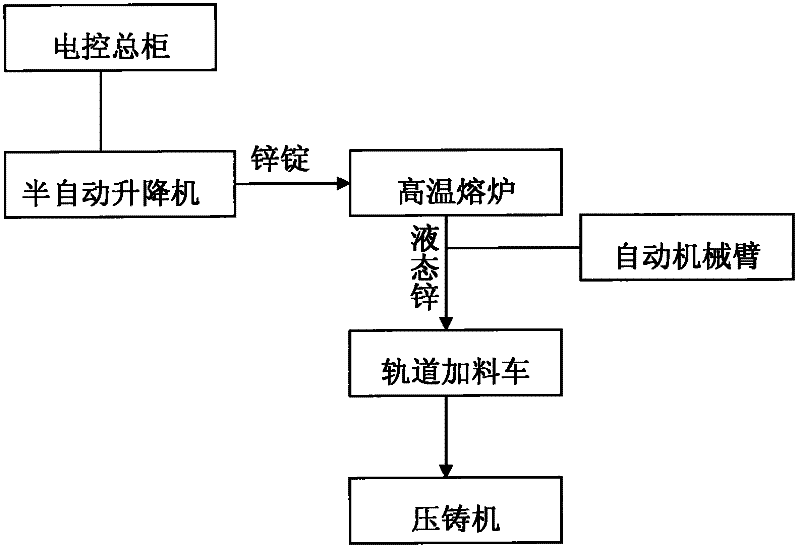

[0016] Example: see figure 1 , a high-temperature gas-fired energy-saving die-casting system of the present invention, which includes a high-temperature furnace, a track for conveying molten liquid metal, a track feeding car and several die-casting machines, the high-temperature furnace uses natural gas as fuel, and the several die-casting machines The machines are arranged in a straight line, and the track is connected between the high-temperature furnace and the die-casting machine. The liquid metal in the high-temperature furnace is transferred from the high-temperature furnace to the rail feeding car by an automatic device.

[0017] The high-temperature melting furnace is provided with a sealing cover, so that the temperature in the sealed high-temperature melting furnace reaches 475° C., so that the zinc ingot can be melted into a liquid state.

[0018] One side of the high-temperature melting furnace is equipped with a semi-automatic elevator, which is controlled by an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com