Full-automatic die-casting device

A fully automatic and equipment-based technology, applied in the field of die-casting, can solve the problems of blackened workshop walls, performance temperature not reaching 40°C, adverse effects of the atmosphere, etc., and achieve the effect of improving die-casting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

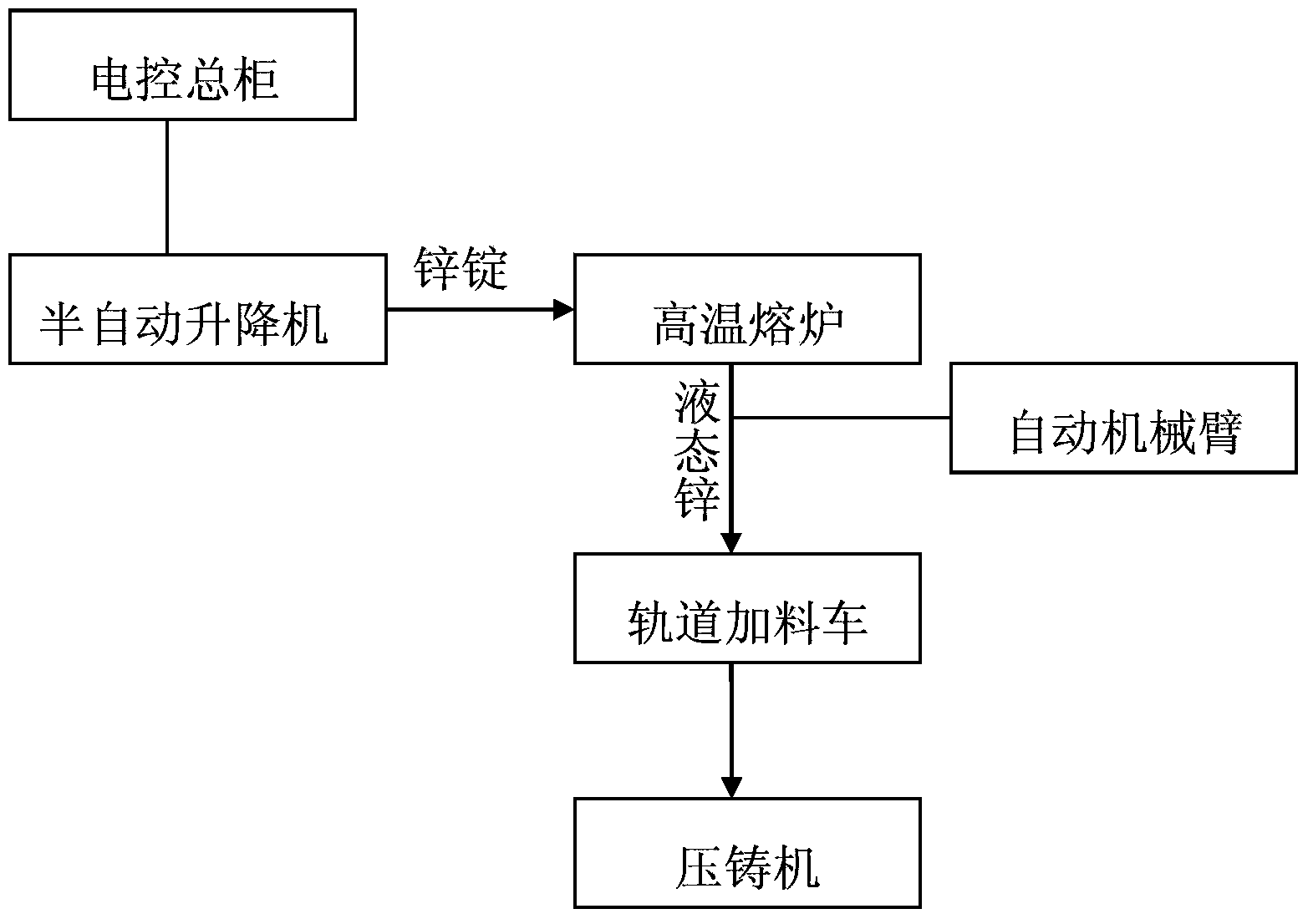

[0016] Example: see figure 1 , a fully automatic die-casting equipment of the present invention, it comprises a high-temperature melting furnace, a track for conveying molten liquid metal, a track feeding car and several die-casting machines, the high-temperature melting furnace uses natural gas as fuel, and the several die-casting machines Arranged in a straight line, the track is connected between the high-temperature furnace and the die-casting machine, and the liquid metal in the high-temperature furnace is transferred from the high-temperature furnace to the rail charging car through an automatic device.

[0017] The high-temperature melting furnace is provided with a sealing cover, so that the temperature in the sealed high-temperature melting furnace reaches 475° C., so that the zinc ingot can be melted into a liquid state.

[0018] One side of the high-temperature melting furnace is equipped with a semi-automatic elevator, which is controlled by an electric control cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com