Chlorine dioxide generator

A chlorine dioxide and generator technology, applied in chlorine dioxide, chlorine oxide and other directions, can solve the problems of increasing operation difficulty and equipment cost, destroying the flow status of chlorine dioxide, affecting the conversion rate of chlorine dioxide, etc., and achieving a good industrial Application prospect, saving user investment, not limited by raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

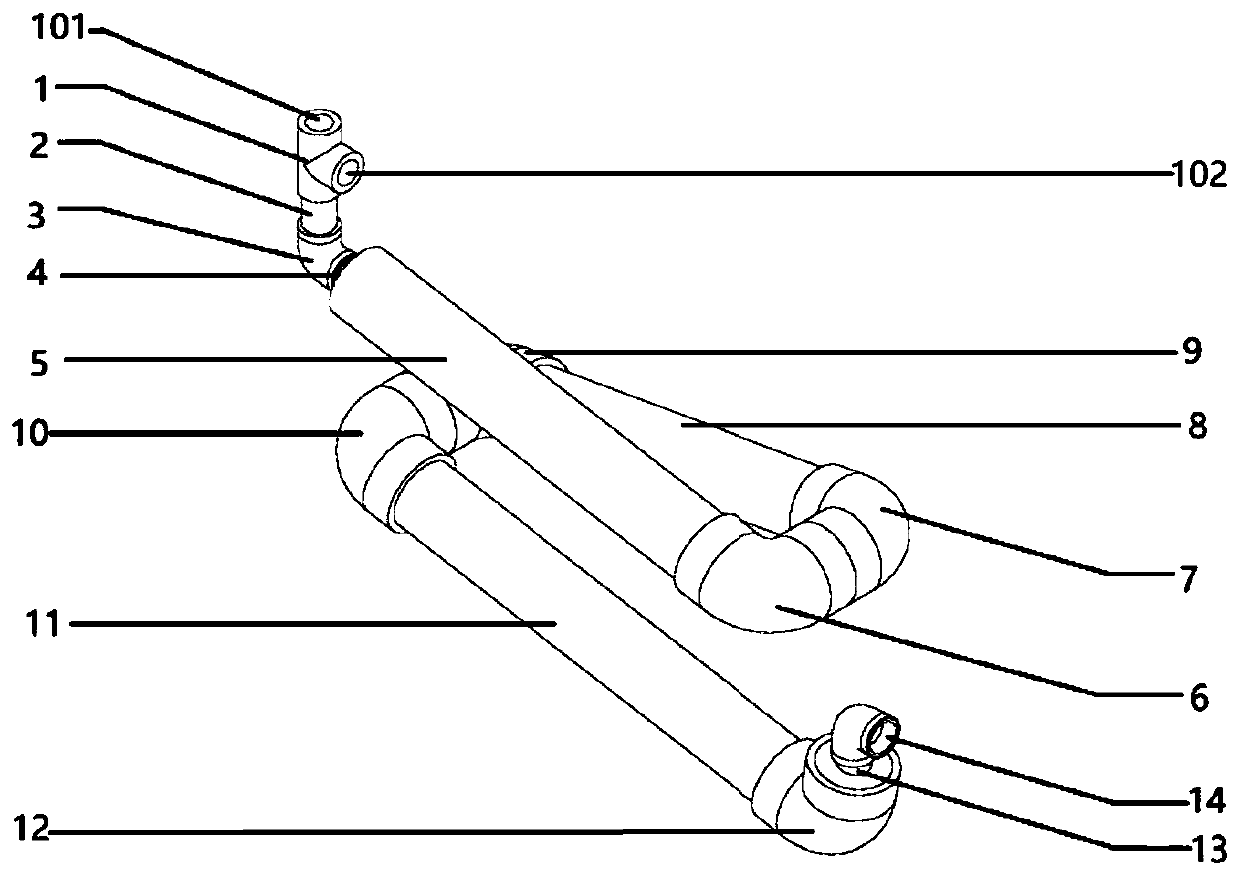

[0087] Embodiment 1 of the present invention provides a kind of chlorine dioxide generator, as figure 1 As shown, it includes a feed device, a reaction device and a discharge device; the feed device, the reaction device and the discharge device are connected in sequence.

[0088] The feeding device includes a tee 1 , a connecting pipe 2 , a feeding elbow 3 , and a first reducing pipe 4 .

[0089] The tee includes a first feed port 101, a second feed port 102, and an outlet;

[0090] The outlet of the tee 1 is connected to the upper end of the connecting pipe 2; the lower end of the connecting pipe 2 is connected to the upper end of the feed elbow 3; the first reducing pipe 4 is connected to the lower end of the feed elbow 3; The outlet diameter of the tee 1 is smaller than the inlet diameter of the first pipe 5 .

[0091] The reaction device comprises a reaction unit A, a first reaction unit B and a second reaction unit B; the reaction unit A comprises a first pipeline 5 and...

Embodiment 2

[0098] Embodiment 2 of the present invention provides a kind of chlorine dioxide generator as described in embodiment 1, described tee, connecting pipe, feed elbow, elbow, discharge elbow, the first reducing pipe, The materials of the second reducing pipe, the first pipe, the first elbow and the pipe are all PVC.

[0099] The outlet diameter of the tee 1 is 2 / 3 smaller than the inlet diameter of the first pipe 5 .

[0100] The pipe has a diameter of 125 mm and a length of 1800 mm.

[0101] The horizontal gradient of the pipeline from the inlet to the outlet is 11%.

[0102] The inlet diameter of the outlet elbow 14 is 2 / 3 smaller than the outlet diameter of the third pipeline 11 .

[0103] This example also provides a method for using the chlorine dioxide generator, and the steps are as follows:

[0104] Step 1: Connect the discharge elbow 14 with the injector;

[0105]Step 2: After adding the raw material A solution and the raw material B solution through the first feed p...

Embodiment 3

[0110] Embodiment 3 of the present invention provides a kind of chlorine dioxide generator, and it is similar to embodiment 2, and difference is that the outlet diameter of described tee 1 is 1 / 2 smaller than the inlet diameter of pipeline; The inlet diameter of the elbow is 1 / 2 smaller than the inlet diameter of the pipe.

[0111] According to the test method described in Example 2, the chlorine dioxide conversion rate is 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com