High-strength stainless steel road guardrail

A highway guardrail, stainless steel technology, applied in the direction of roads, roads, road safety devices, etc., can solve the problems of not being able to provide good protection for drivers and passengers, the strength and corrosion resistance of highway guardrails are not high, and the safety protection performance is insufficient. The effect of reducing maintenance workload and cost, improving cost performance and environmental protection, and improving anti-shock capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

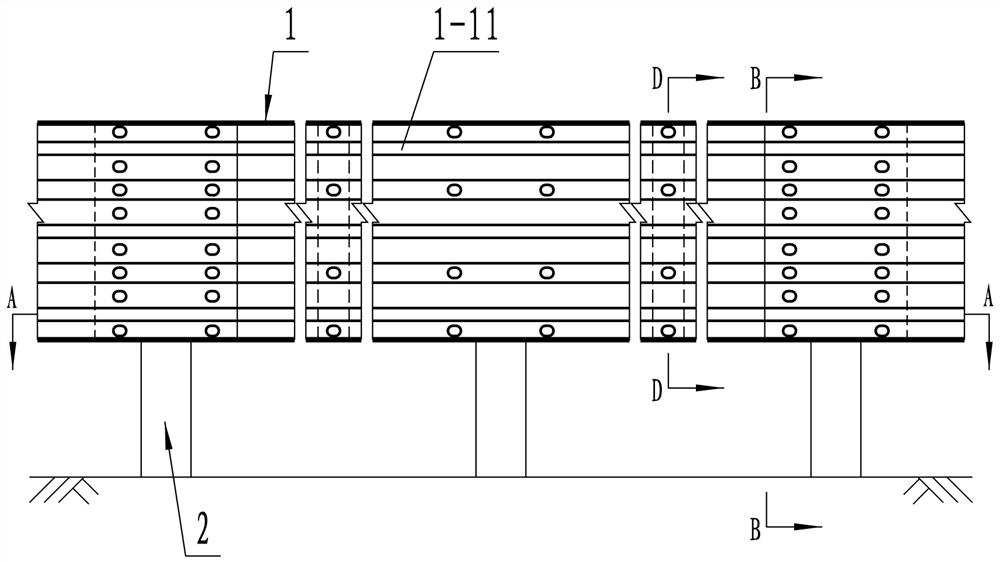

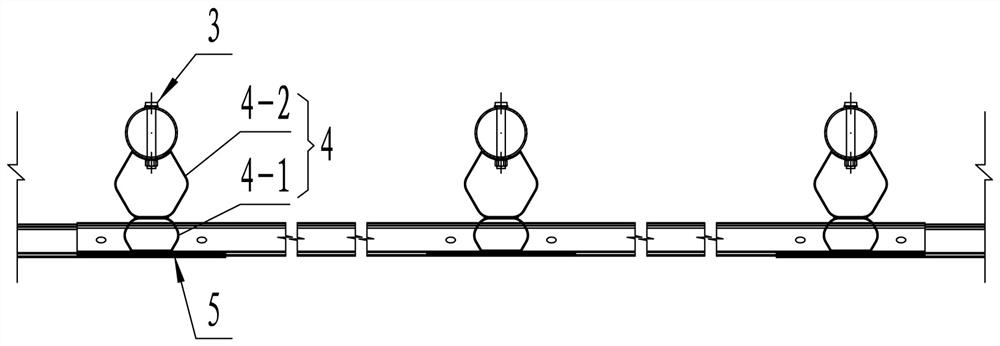

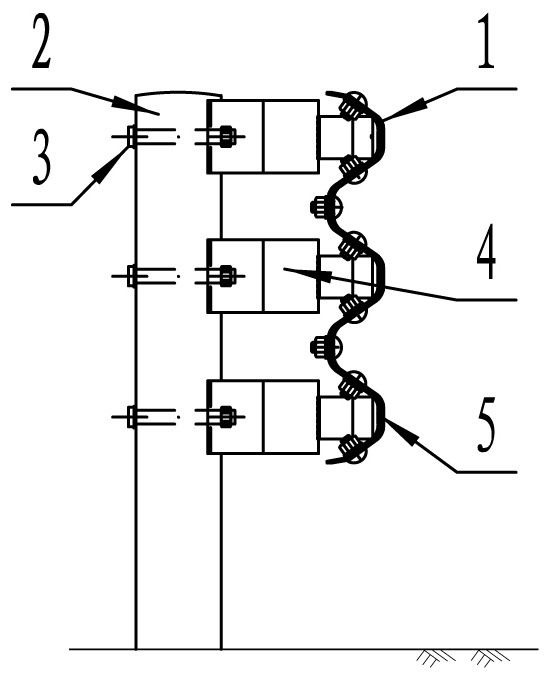

[0031] Figure 1 to Figure 3The high-strength stainless steel road guardrail shown mainly includes a guardrail 1, a column 2, an anti-resistance member 4 and a guardrail connection reinforcement plate 5, and the guardrail 1 is fixedly connected to one side of the column 2 through the guardrail connection reinforcement plate 5 and the anti-resistance member 4 , in the embodiment of the road guardrail installed in the isolation zone, a guardrail board 1 can be respectively arranged on opposite sides of the column 2, and the front of the guardrail board 1 faces the side of the road; each guardrail board 1 and at least two equidistant The uprights 2 are connected, and the adjacent guardrails 1 are lapped end to end, and the lapped parts are connected and fixed by welding or bolt connection. In order to improve the stability of the lap joints, the lapped parts are connected to the reinforcing plate 5 and the anti-blocking parts through the guardrail 4 is connected with column 2. I...

Embodiment 2

[0034] Such as Figure 9 As shown, the column of this embodiment can be buried in the soil foundation or cement roadbed, and the part of the column 2 buried under the soil foundation is welded with a column reinforcement plate 7 made of high-strength stainless steel to further improve the demolition resistance of the column , the plate surface of the column reinforcement plate 7 faces the road and is welded on the back of the column 2, which can increase the resistance of the foundation and make the column 2 difficult to collapse. The column 2 of this embodiment is buried underground and is not easy to corrode, and it is not necessary to use a relatively thick column material to resist corrosion, so it can save materials and reduce costs. All the other features are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com