Ventilation flue, and preparation method and application thereof

A flue and system technology, applied in vertical pipes, building components, buildings, etc., to achieve the effect of smooth surface, simple preparation process and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A ventilation flue, the main material of the ventilation flue is magnesium sulfate heptahydrate, supplemented by inorganic and organic fillers.

[0031] In parts by weight, the ventilation flue includes 45 parts of magnesium sulfate heptahydrate, 13 parts of calcium silicate powder, 11 parts of perlite, 3 parts of gypsum, 3 parts of fine stone, 4 parts of sawdust, 1 part of phosphoric acid and 28 parts of water.

[0032] Among them, the technical indicators of magnesium sulfate heptahydrate are shown in Table 1, and the implementation standard is HG / T 2680-2009:

[0033] Table 1 Technical indicators of magnesium sulfate heptahydrate (%)

[0034] Test items main content Magnesium (Mg) Iron (Fe) Arsenic (As) pH value PB value Impurities Detection Indicator ≥99.90% ≥9% ≤0.015% ≤0.002% 5.0-9.2 ≤0.006% Excluding Test results 99.95% 9.39% 0.013% 0.0015% 7.3 0.0046% Excluding

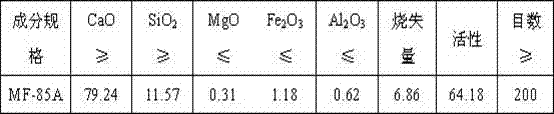

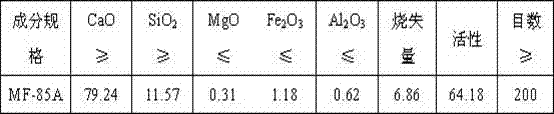

[0035] The technical indicators of silicon-cal...

Embodiment 2

[0048] A ventilation flue, the main material of the ventilation flue is magnesium sulfate heptahydrate, supplemented by inorganic and organic fillers.

[0049] In parts by weight, the ventilation flue includes 62 parts of magnesium sulfate heptahydrate, 21 parts of calcium silicate powder, 15 parts of perlite, 8 parts of gypsum, 6 parts of fine stone, 11 parts of sawdust, 3 parts of phosphoric acid and 33 parts of water.

[0050] Among them, the technical indicators of magnesium sulfate heptahydrate are shown in Table 1, and the implementation standard is HG / T 2680-2009:

[0051] Table 1 Technical indicators of magnesium sulfate heptahydrate (%)

[0052] Test items main content Magnesium (Mg) Iron (Fe) Arsenic (As) pH value PB value Impurities Detection Indicator ≥99.90% ≥9% ≤0.015% ≤0.002% 5.0-9.2 ≤0.006% Excluding Test results 99.95% 9.39% 0.013% 0.0015% 7.3 0.0046% Excluding

[0053] The technical indicators of silicon-c...

Embodiment 3

[0066] A ventilation flue, the main material of the ventilation flue is magnesium sulfate heptahydrate, supplemented by inorganic and organic fillers.

[0067] In parts by weight, the ventilation flue includes 70 parts of magnesium sulfate heptahydrate, 26 parts of calcium silicate powder, 19 parts of perlite, 12 parts of gypsum, 8 parts of fine stone, 15 parts of sawdust, 4 parts of phosphoric acid and 39 parts of water.

[0068] Among them, the technical indicators of magnesium sulfate heptahydrate are shown in Table 1, and the implementation standard is HG / T 2680-2009:

[0069] Table 1 Technical indicators of magnesium sulfate heptahydrate (%)

[0070] Test items main content Magnesium (Mg) Iron (Fe) Arsenic (As) pH value PB value Impurities Detection Indicator ≥99.90% ≥9% ≤0.015% ≤0.002% 5.0-9.2 ≤0.006% Excluding Test results 99.95% 9.39% 0.013% 0.0015% 7.3 0.0046% Excluding

[0071] The technical indicators of silicon-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com