Spring compensation type soft seal device for external floating-roof oil tank

A technology of spring compensation and external floating roof, which is applied in packaging, large containers, transportation and packaging, etc., can solve the problems of huge cost, poor performance such as crude oil corrosion resistance and air aging, and achieve good effect, strong wear resistance, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

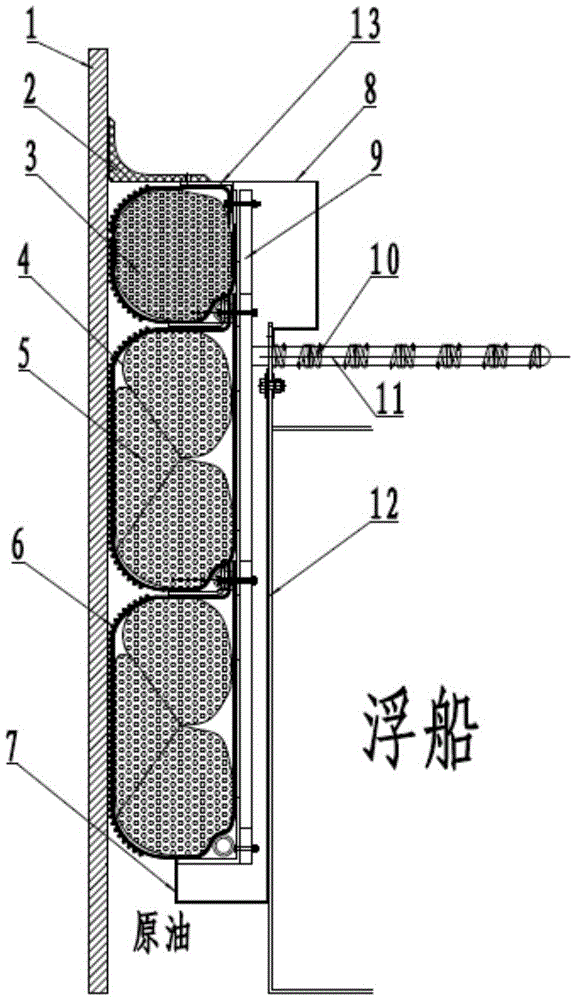

[0037] With reference to the accompanying drawings, a spring-compensated soft sealing device for an external floating roof oil tank includes a plurality of sealing components arranged around the floating roof 12, and the plurality of sealing components form an annular sealing body. The floating top 12 is provided with a spring compensating mechanism connected with each sealing assembly. The spring compensation mechanism includes a pressurizing connecting rod 11 and a return spring 10, the pressurizing connecting rod 11 is arranged above the floating top 12, one end of the pressurizing connecting rod 11 is connected with the sealing assembly, and the other end of the pressurizing connecting rod 11 One end is connected with the return spring 10, and the elastic force of the return spring 10 makes the pressurizing connecting rod 11 press the sealing assembly toward the outside of the floating top 12 all the time. The side of the floating roof 12 is provided with a rib, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com