Starting mix of solid oxygen generator

An oxygen generator and propellant technology, applied in explosives and other directions, can solve the problems of not meeting the requirements of long-term storage of products, easy decomposition and instability of barium peroxide, easy moisture absorption and deterioration of barium nitrate, etc. Good, the effect of reducing electrostatic flame sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Chemical Name

[0018] Zirconium powder

[0019] recipe two

[0020] Chemical Name

[0022] Recipe three

[0023] Chemical Name

[0024] Recipe four

[0025] Chemical Name

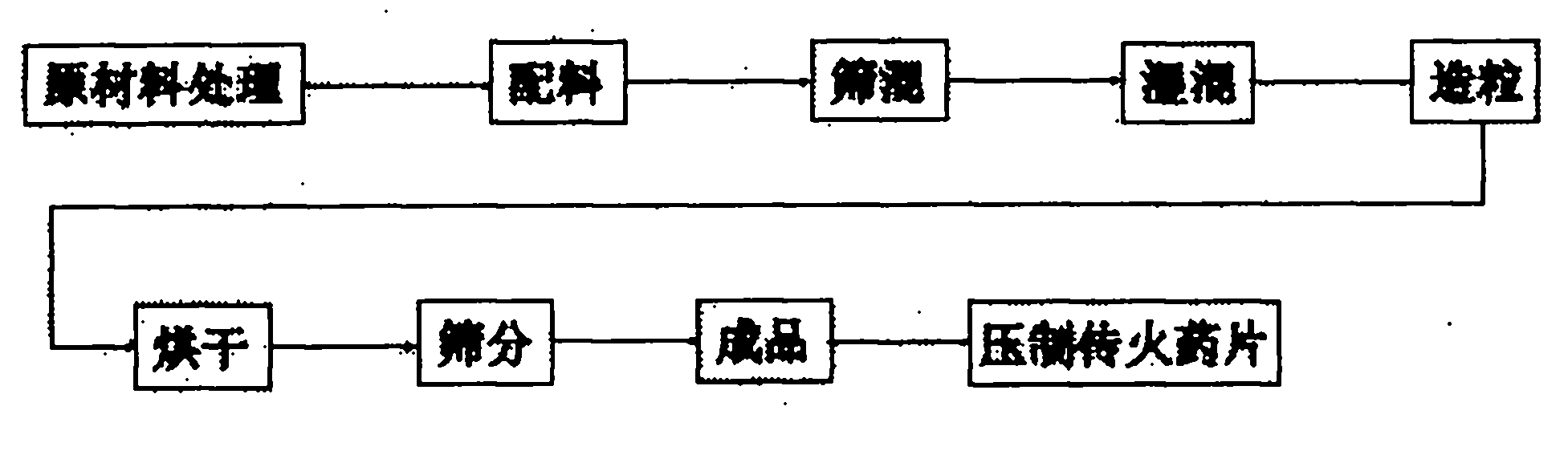

[0026] The technological process of making solid oxygen generator of the present invention to pass gunpowder tablet sees attached figure 1 .

[0027] In the above formulas 1, 2, 3 and 4, when processing raw materials, zirconium powder and zirconium hydride are first dehydrated, dried at 80°C, ferric oxide is dried at 100°C, zirconium powder, zirconium hydride , ferric oxide, and diatomaceous earth are mixed according to the formula ratio. After mixing and sieving, the average particle size is 0.15-0.85mm. Add 8-10% shellac alcohol solution, stir evenly, and bake at 60°C for 3 Hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com