Stirring device for livestock manure full-mixing type fermentation tank

A technology of livestock and poultry manure and stirring device, which is applied in the direction of fertilization device, organic fertilizer preparation, organic fertilizer, etc., can solve the problems of troublesome operation, high concentration, and many intermediate links, and achieve convenient installation and maintenance, simple operation, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

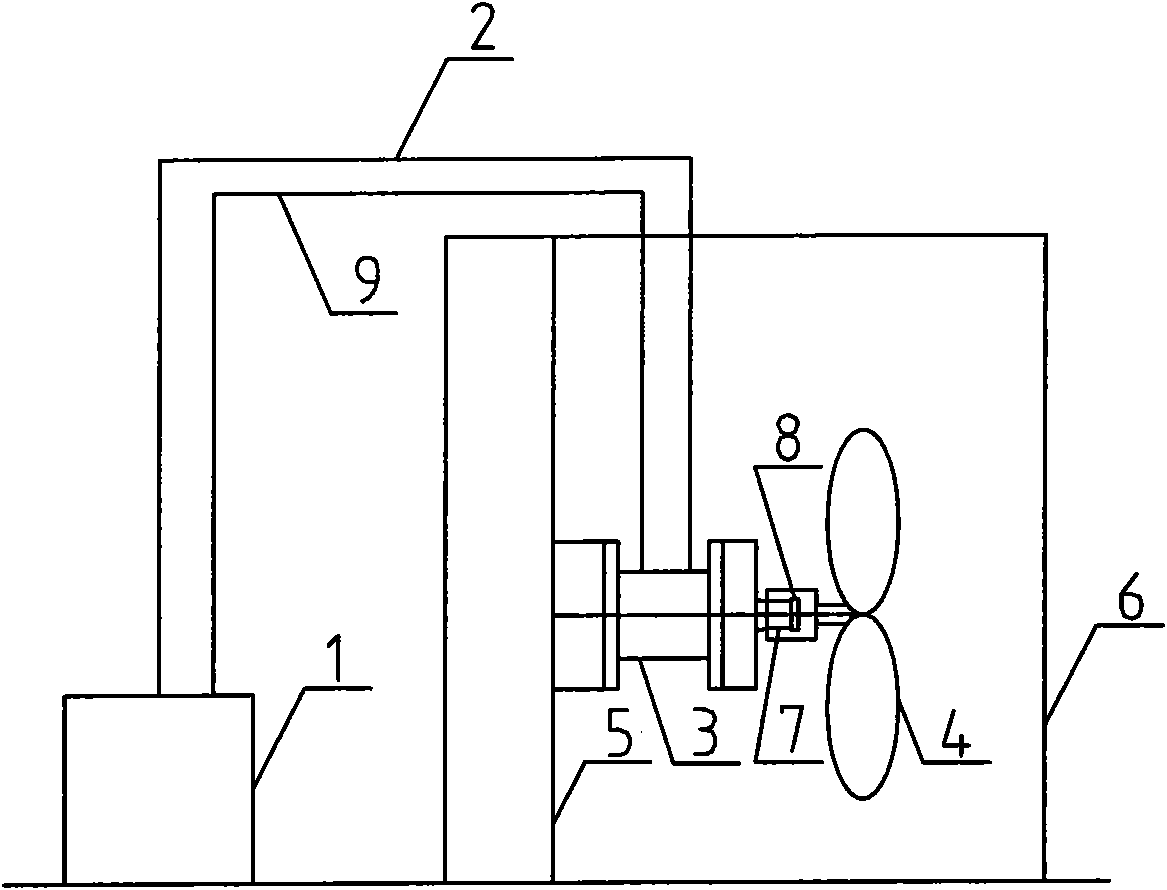

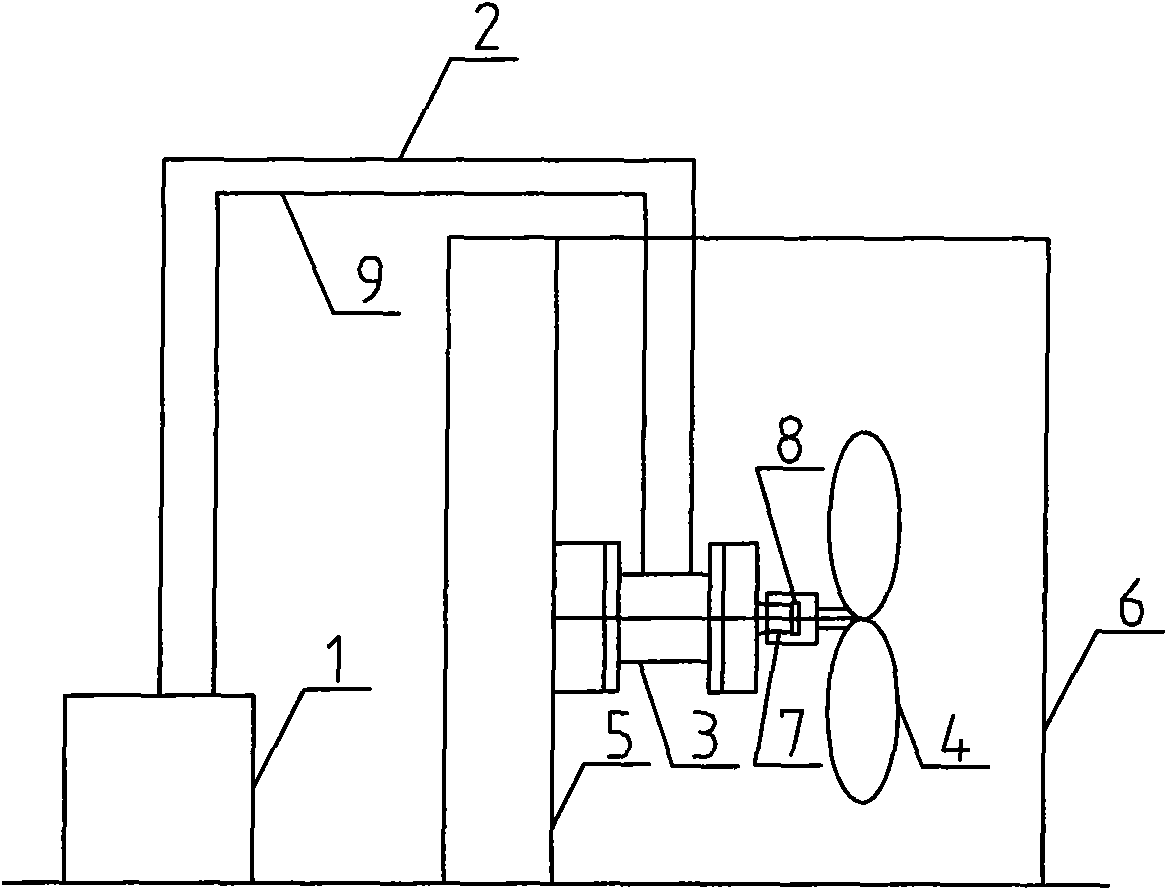

[0037] Refer to the attached figure 1 : The hydraulic pump station 1 supplies oil to the hydraulic motor 3 through the oil delivery pipe 2, and controls the pressure, flow and direction of the oil flow; the hydraulic motor 3 converts hydraulic energy into mechanical energy as a power actuator, and drives the stirring shaft 5 through the spline, thereby driving The stirring paddle 6 rotates to realize medium stirring.

[0038] The hydraulic motor 3 is connected to the inner spline 5 of the stirring shaft through the outer spline shaft 4; the whole set of stirring device is set in the fermenter 8 except the hydraulic pump station 1, wherein the hydraulic motor 3 is fixed on the fermenter 8 through the support wall 7 In the mixed medium of livestock and poultry manure.

[0039] The rotational speed of the agitating blade 6 of this agitator is about 10~120r / min, even the highest can reach 500r / min, the preferred rotational speed is 60r / min, and its rotational power and rotational...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com