Power promoter special for industrial TNT-free powder explosive and manufacturing method thereof

A technology of ladder powder and accelerator, which is applied in the field of special power accelerator for industrial ladder-free powder explosives and its manufacturing field. Sensitivity and dust, simple process formula, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

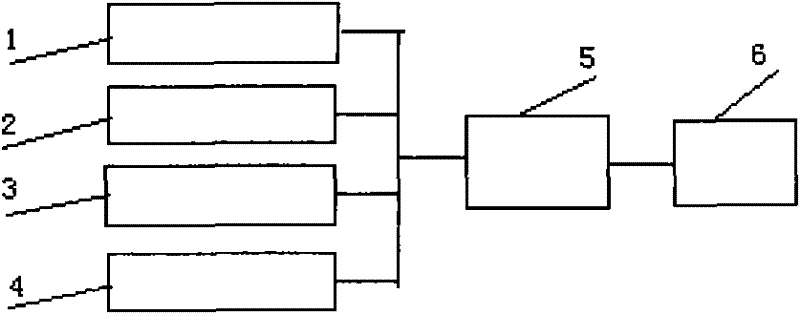

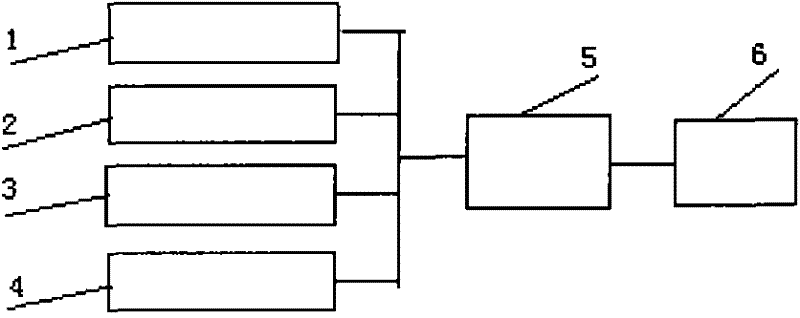

Image

Examples

Embodiment 1

[0035] The special power accelerator for industrial stepless powder explosives is characterized in that its raw materials are composed of stearic acid, emulsifier, compound wax, phosphoric acid, octadecylamine, diatomite, aluminum powder, and raw gypsum powder, and the weight ratio is as follows: Calculation in kilograms:

[0036] Stearic acid 0.27, emulsifier 0.44, compound wax 2.52, phosphoric acid 1.10

[0037] Octadecylamine 4.40, diatomaceous earth 1.80, aluminum powder 26.40, raw gypsum powder 4.95

[0038] The molecular formula of each raw material

[0039] stearic acid CH 3 (CH 2 ) 16 COOH, emulsifier C 8 h 17 C 6 h 4 O(CH 2 CH 2 O) 10 h

[0040] Composite wax is a market product Phosphoric acid H 3 PO 4 ,

[0041] octadecylamine C 18 h 39 N, diatomaceous earth is mainly SiO 2

[0042] Aluminum powder Al raw gypsum powder CaSO 4 .2H 2 o

[0043]The production method of the power accelerator special for industrial stepless powdery explosives is cha...

Embodiment 2

[0052] Embodiment 2: the power accelerator special for industrial stepless powdery explosives, it is characterized in that: its raw material is made up of stearic acid, emulsifier, composite wax, phosphoric acid, octadecylamine, diatomite, aluminum powder, raw gypsum powder, The weight ratio is calculated in kilograms:

[0053] Stearic acid 0.33, emulsifier 0.36, complex wax 3.08, phosphoric acid 0.90,

[0054] Octadecylamine 3.60, diatomaceous earth 2.20 aluminum powder 21.60, raw gypsum powder 6.05,

[0055] Manufacturing method is the same as embodiment 1.

Embodiment 3

[0056] Embodiment 3: the power accelerator special for industrial stepless powdery explosives is characterized in that: its raw material is made up of stearic acid, emulsifier, compound wax, phosphoric acid, octadecylamine, diatomite, aluminum powder, raw gypsum powder, The weight ratio is calculated in kilograms:

[0057] Stearic acid 0.28, emulsifier 0.38-0.42, compound wax 2.66,

[0058] Phosphoric acid 0.95, octadecylamine 3.80-4.20, diatomaceous earth 1.90

[0059] Aluminum powder 22.80-25.20, raw gypsum powder 5.22.

[0060] Manufacturing method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com