Oil-soluble gravity cutting oil

A cutting oil, oil-soluble technology, applied in the field of lubricating oil, can solve the problem of not meeting the harsh requirements of gravity cutting, and achieve the effect of promoting lubrication and low chemical reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below.

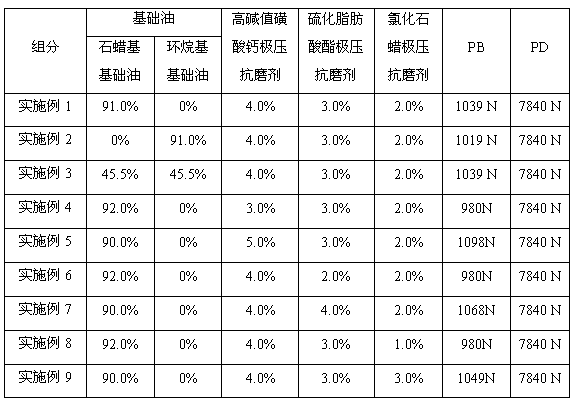

[0018] Table 1 Components and mass fractions of each embodiment of the present invention, PB value and PD value of each embodiment:

[0019]

[0020] The index to measure the extreme pressure lubrication performance of gravity cutting oil is usually "Determination of Lubricant Bearing Capacity (Four-Ball Method)" (GB / T 3142-1982), and the maximum non-seizing load PB of gravity cutting oil is measured on a four-ball friction and wear tester Value (in N) and sintering load PD value (in N), with PB value not less than 980N and PD value not less than 7840N as the lubricity control index of gravity cutting oil. It can be seen from Table 1 that the PB value and PD value of each embodiment of the present invention can reach the control index, indicating that the oil-soluble gravity cutting oil of the present invention can meet the severe requirements of gravity cutting.

[0021] In each of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com