Organic-inorganic hybrid solar cell and preparation method thereof

A solar cell and organic technology, applied in the field of solar cells, can solve the problems of ineffective separation of the two-phase interface and poor contact between the two-phase interface, and achieve the effects of improving interface contact performance, improving photoelectric performance, and prolonging fluorescence life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Synthesis of triphenylamine dyes for interface modification. The synthetic route is as follows:

[0027]

[0028] Add 0.248 g (0.55 mmol) of the precursor distyryltriphenylamine monoaldehyde, 0.11 g (0.57 mmol) rhodanine acetic acid, 0.1 g (1.3 mmol) ammonium acetate, and 15 mL of glacial acetic acid to a 50 mL round bottom flask, Stir and reflux for 4 hours. After cooling to room temperature, the resulting red mixed solution was poured into ice water. The precipitate was filtered and washed with distilled water. After vacuum drying, the solid matter was dissolved in ethyl acetate, petroleum ether was slowly added dropwise, and a red organic compound dye was precipitated (0.24 g, yield 70%), with a melting point of 219.7 °C. IR (KBr): 3438, 2924, 2850, 1713, 1634, 1576, 1503, 1295. 1 H NMR (300 MHz, DMSO- d 6 ): δ (ppm) 7.76 (s, 1H), 7.54 (d, J= 9.0, 2H), 7.38-7.47 (m, 5H), 7.29-7.35 (m, 5H), 7.13-7.25 (m, 5H), 7.09 (s, 1H), 7.01 (d, J = 8.7, 2...

Embodiment 2

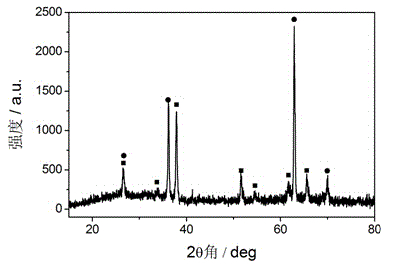

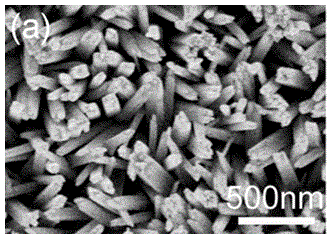

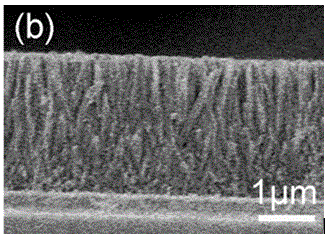

[0029] Example 2: TiO on FTO conductive glass 2 Fabrication of Nanorod Arrays

[0030] According to the volume ratio of deionized water and concentrated hydrochloric acid 1:1, a hydrochloric acid solution was formulated, and 2 ml tetrabutyl titanate was slowly added dropwise to the above 120 ml hydrochloric acid solution under stirring, and stirred at room temperature for 5 min. During the stirring process, a small amount of white flocculent precipitate was produced. This mixture was then poured into the reaction kettle. Place a cleaned FTO conductive glass 6 in the still, against the inner wall of the reaction kettle, and the conductive surface is downward, so that a large amount of precipitation produced by water and heat falls on the conductive surface. The reaction kettle was placed in a stainless steel sleeve, sealed well, placed in an oven, and subjected to hydrothermal reaction at 150°C for 20 h. After the reaction, the temperature was lowered to room temperatu...

Embodiment 3

[0032] Example 3: organic dye molecule dye in TiO 2 Adsorption on the surface of nanorod arrays, transient photocurrent and surface contact angle measurement of electrodes

[0033] The triphenylamine dye prepared in Example 1 was dissolved in acetonitrile to prepare a solution with a concentration of 0.5 mM. The TiO prepared by embodiment 2 2 The membrane electrode was immersed in it for 24 hours to get FTO / dye-TiO 2 electrode.

[0034] The photoelectrochemical experiment uses a three-electrode electrolytic cell with a quartz window, and the FTO / TiO prepared in Example 2 2 And the FTO / dye-TiO that embodiment 3 prepares 2 The electrode was used as the working electrode, the saturated calomel electrode (SCE) was used as the reference electrode, the Pt electrode was used as the counter electrode, and 0.1 M KSCN aqueous solution was used as the supporting electrolyte. A 500 W xenon lamp was used as the light source, and a monochromator (WDG30) was used to irradiate the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com