Patents

Literature

82 results about "Plastic crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plastic crystal is a crystal composed of weakly interacting molecules that possess some orientational or conformational degree of freedom. The name plastic crystal refers to the mechanical softness of such phases: they resemble waxes and are easily deformed. If the internal degree of freedom is molecular rotation, the name rotor phase or rotatory phase is also used. Typical examples are the modifications Methane I and Ethane I. In addition to the conventional molecular plastic crystals, there are also emerging ionic plastic crystals, particularly organic ionic plastic crystals (OIPCs) and protic organic ionic plastic crystals (POIPCs). POIPCs are solid protic organic salts formed by proton transfer from a Brønsted acid to a Brønsted base and in essence are protic ionic liquids in the molten state, have found to be promising solid-state proton conductors for high temperature proton exchange membrane fuel cells. Examples include 1,2,4-triazolium perfluorobutanesulfonate and imidazolium methanesulfonate.

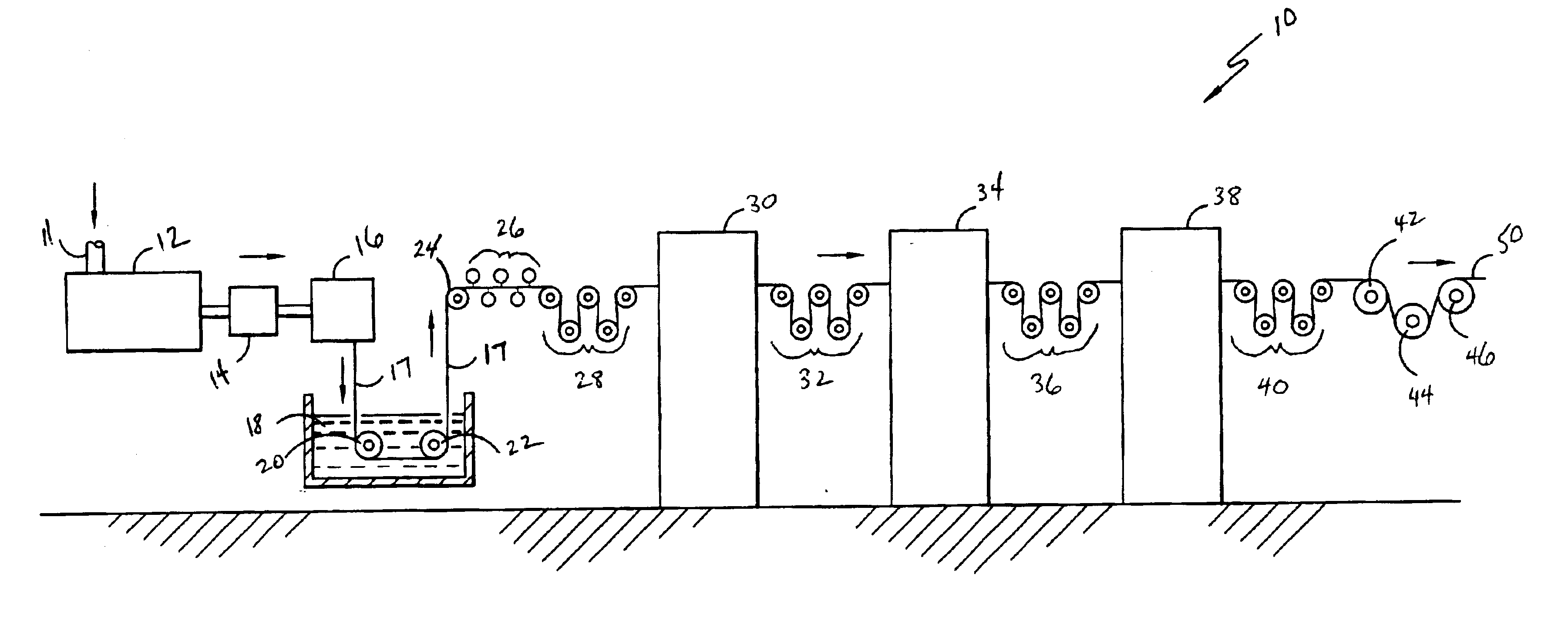

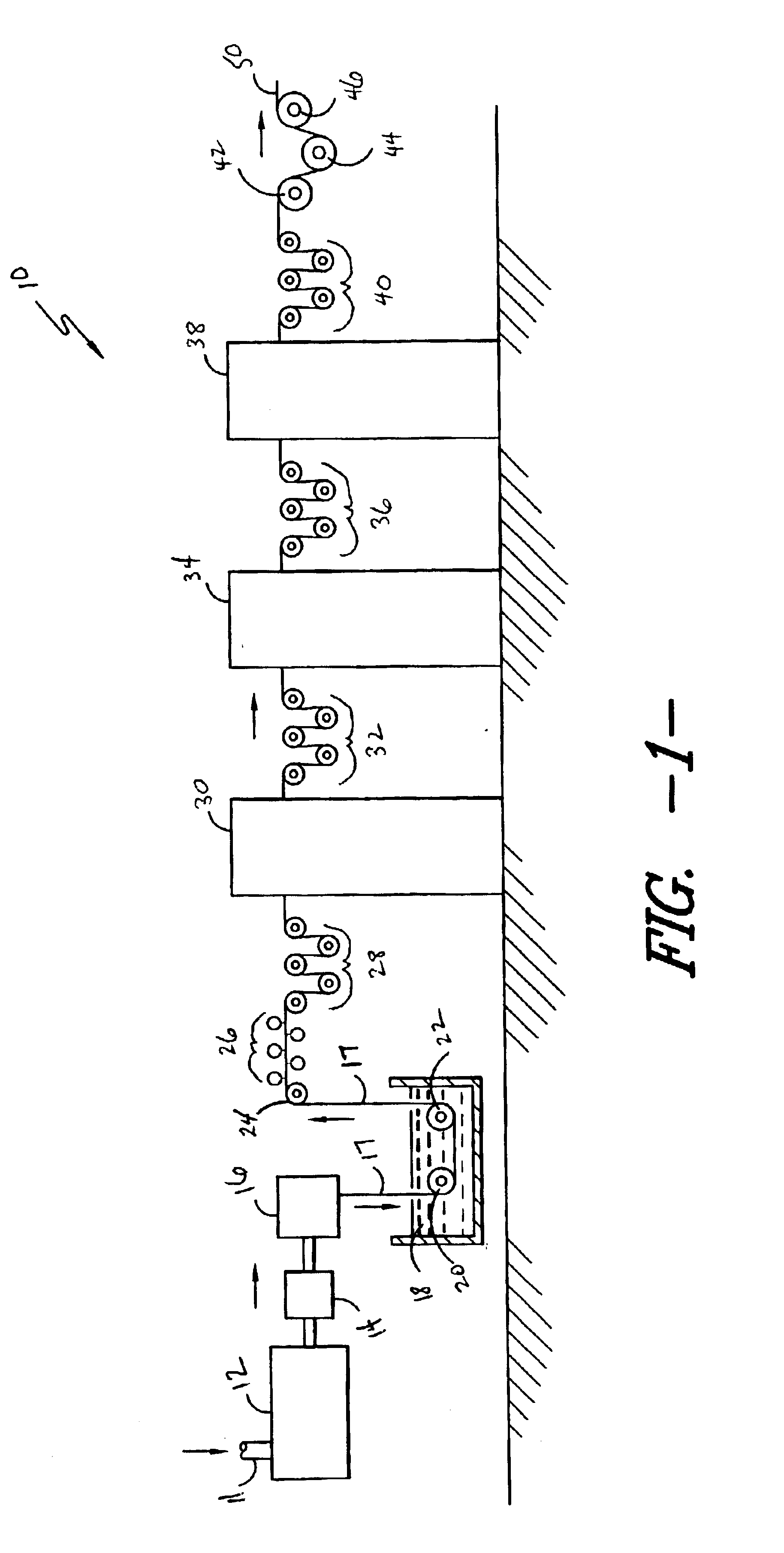

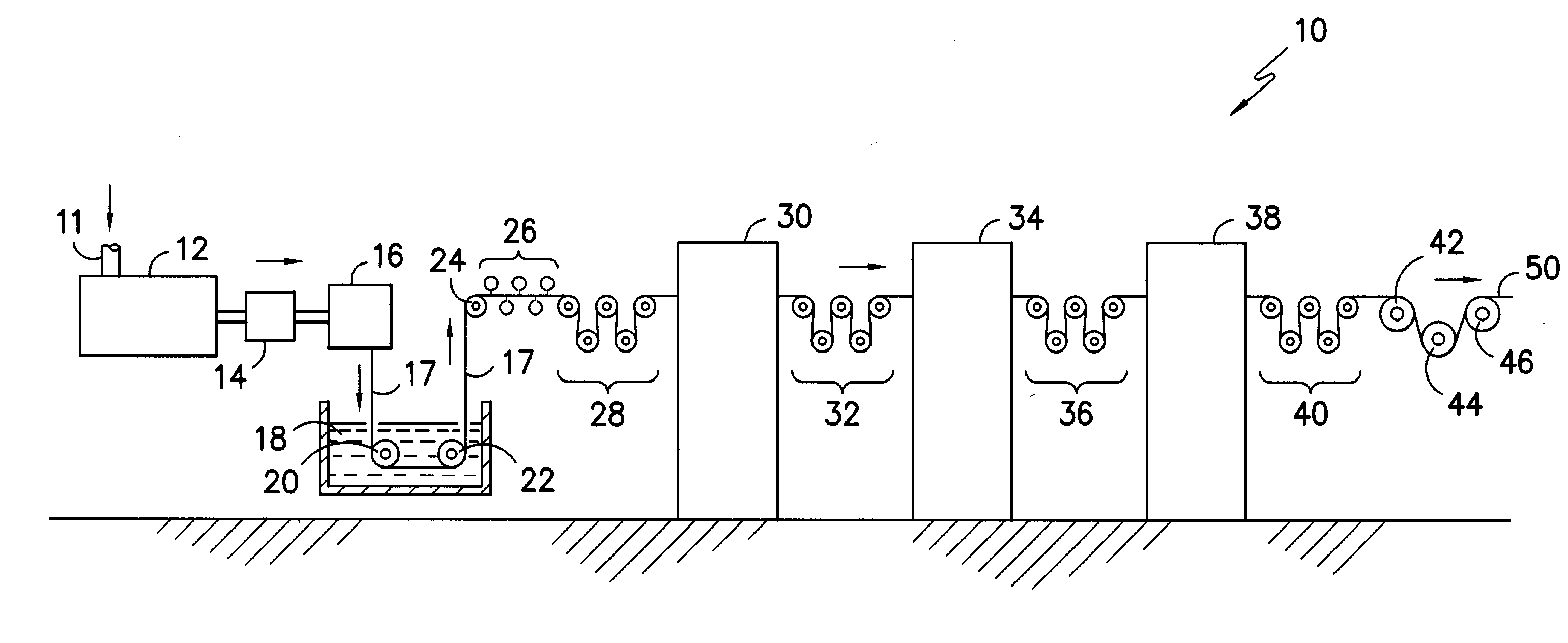

Thermoplastic monofilament fibers exhibiting low-shrink, high tenacity, and extremely high modulus levels

InactiveUS6759124B2High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingThermoplasticYarn

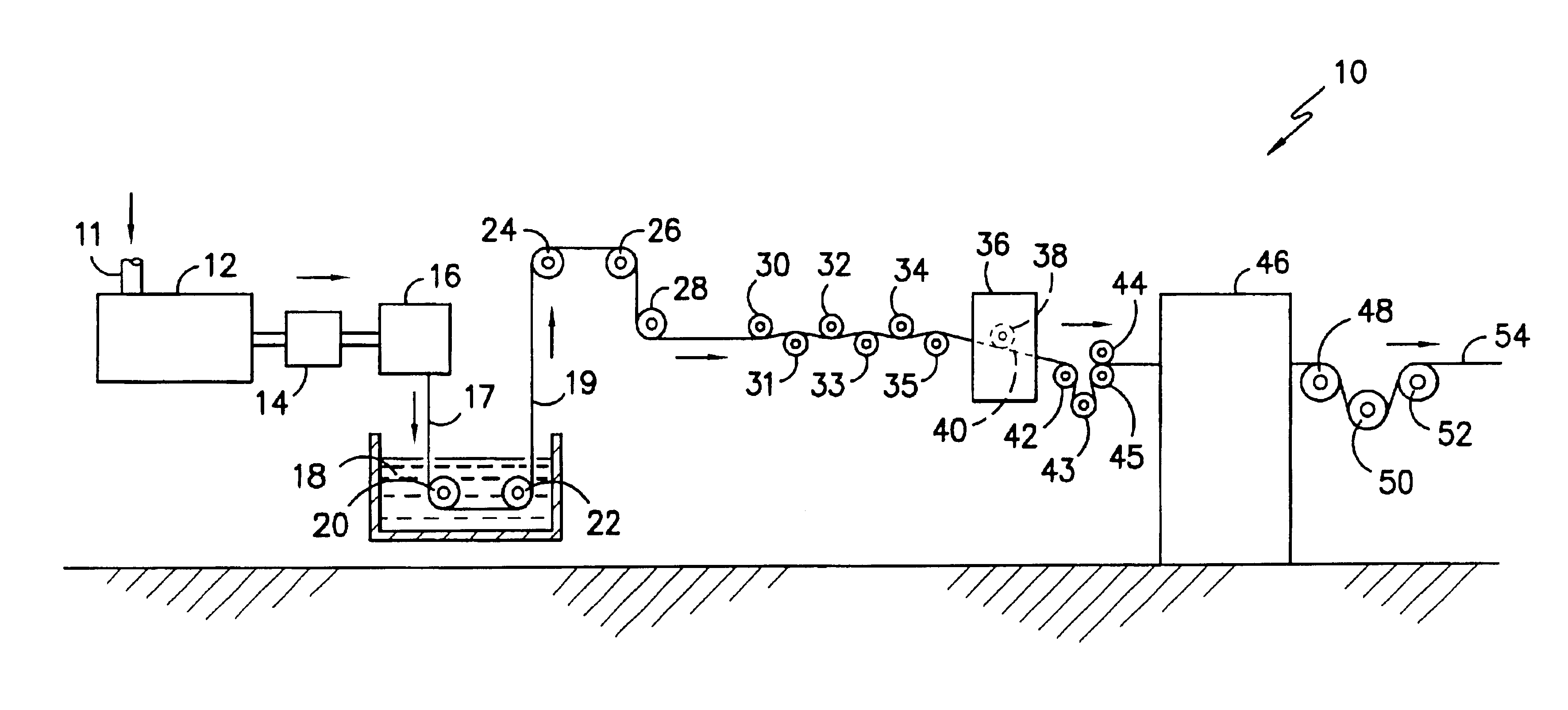

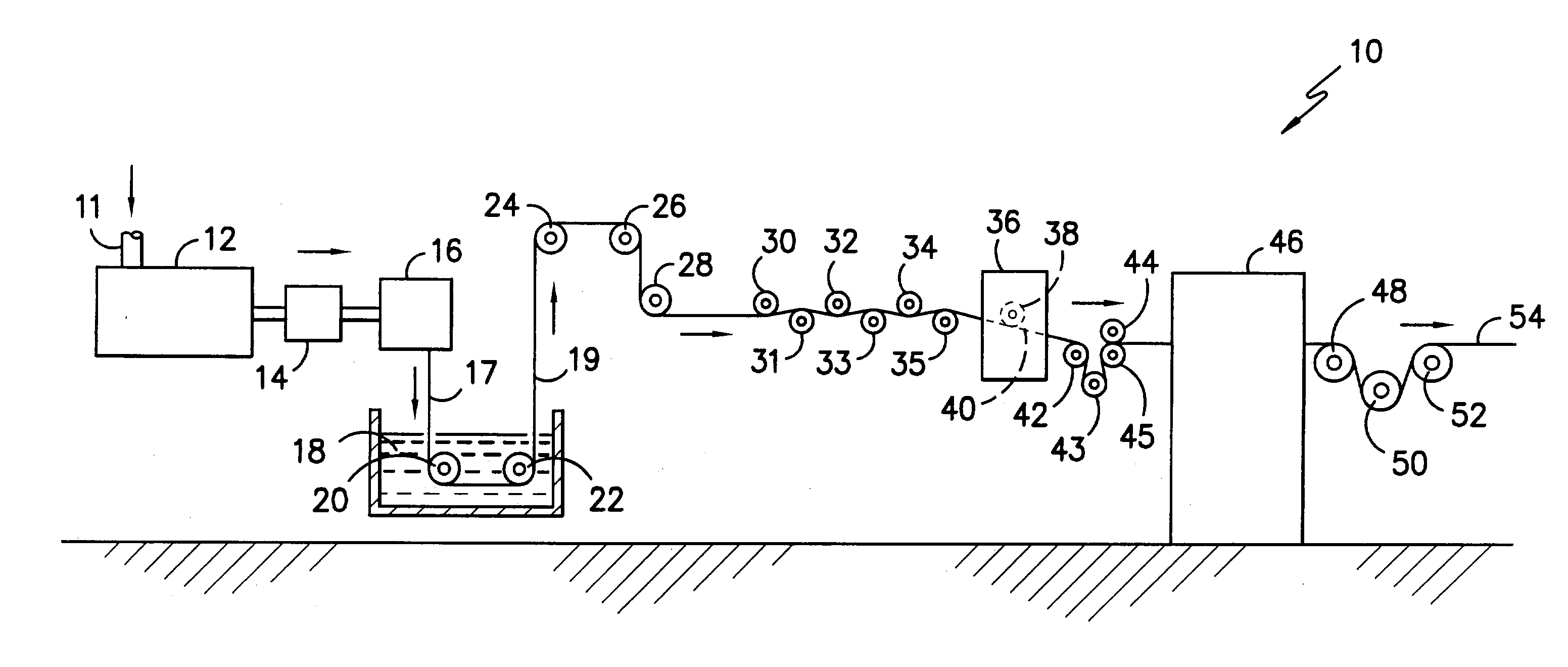

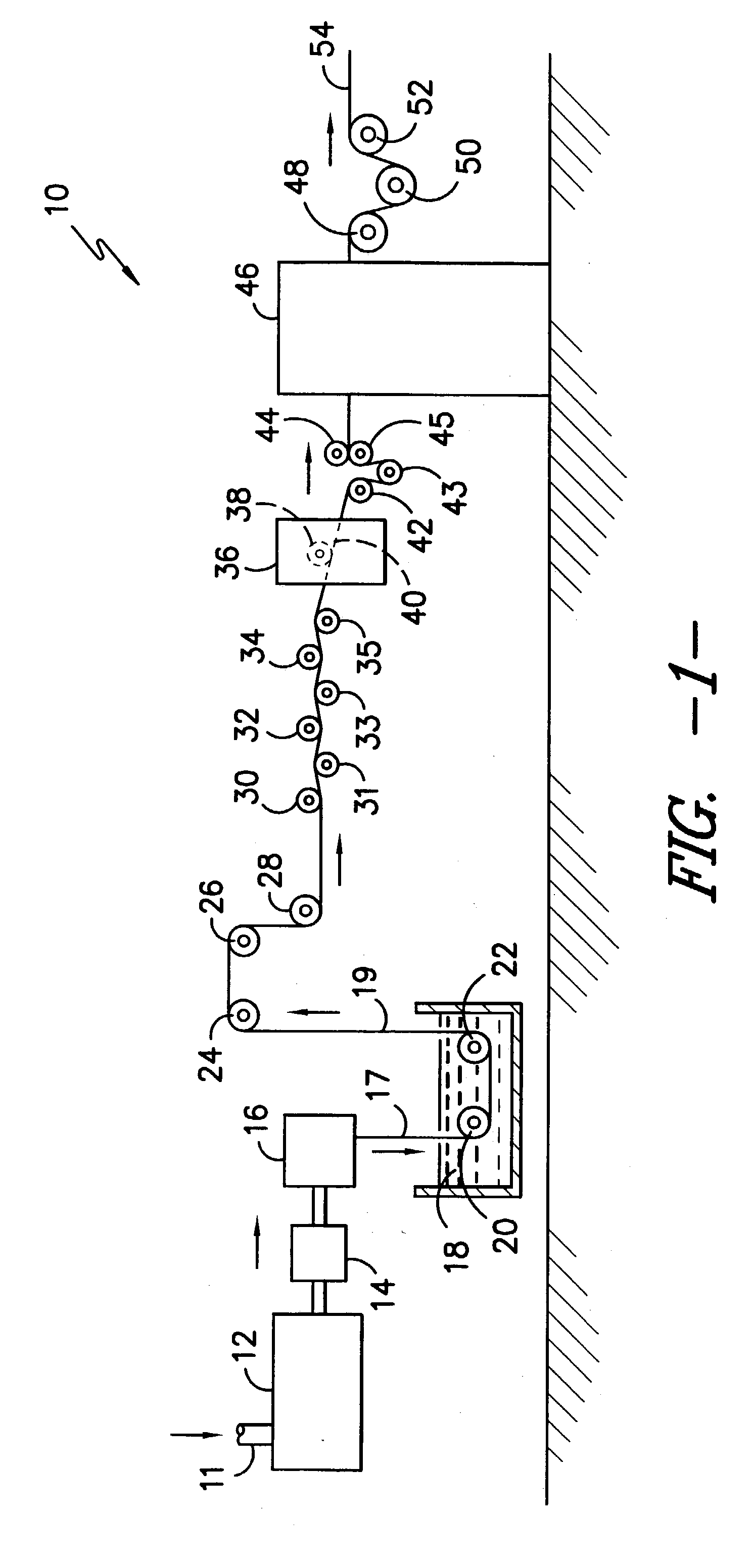

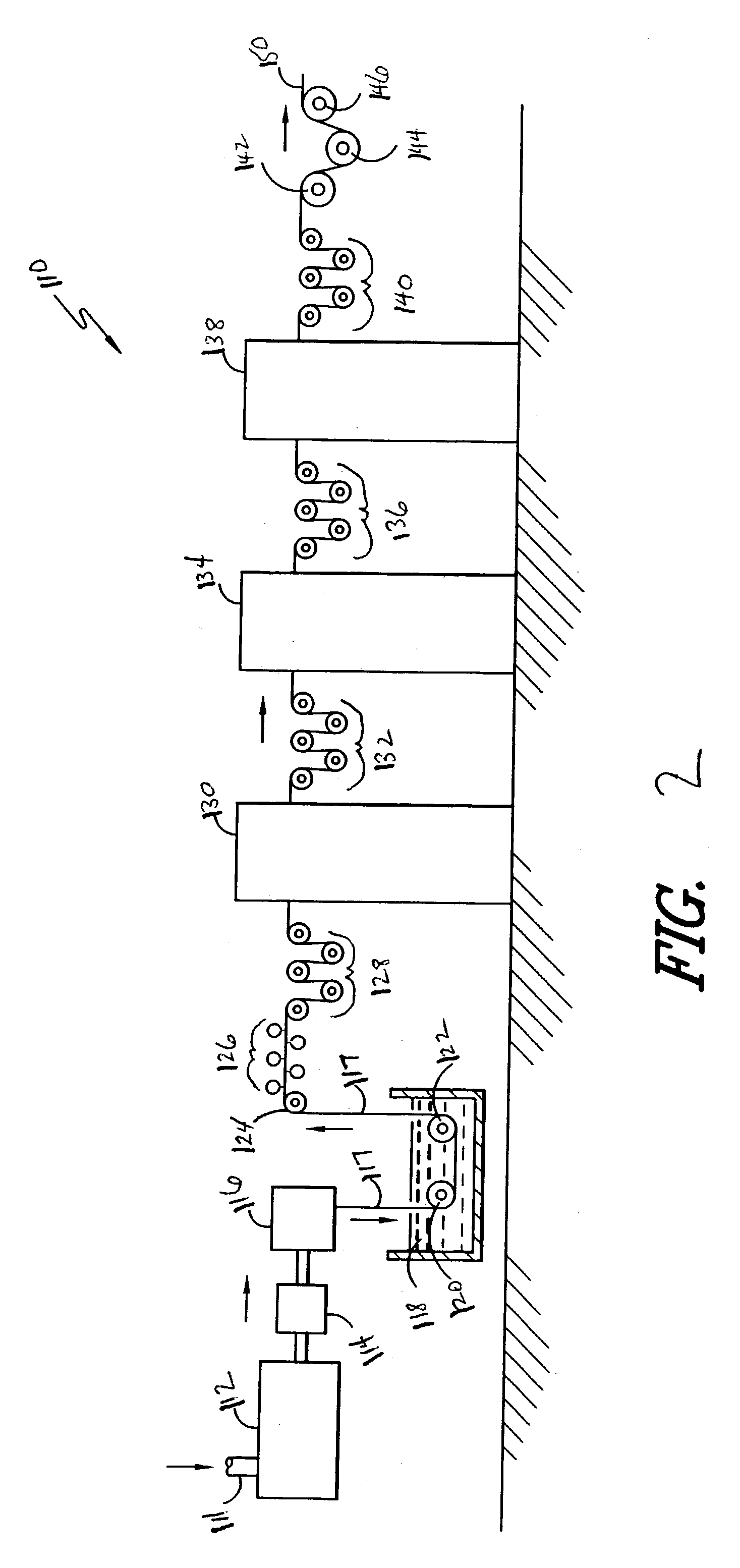

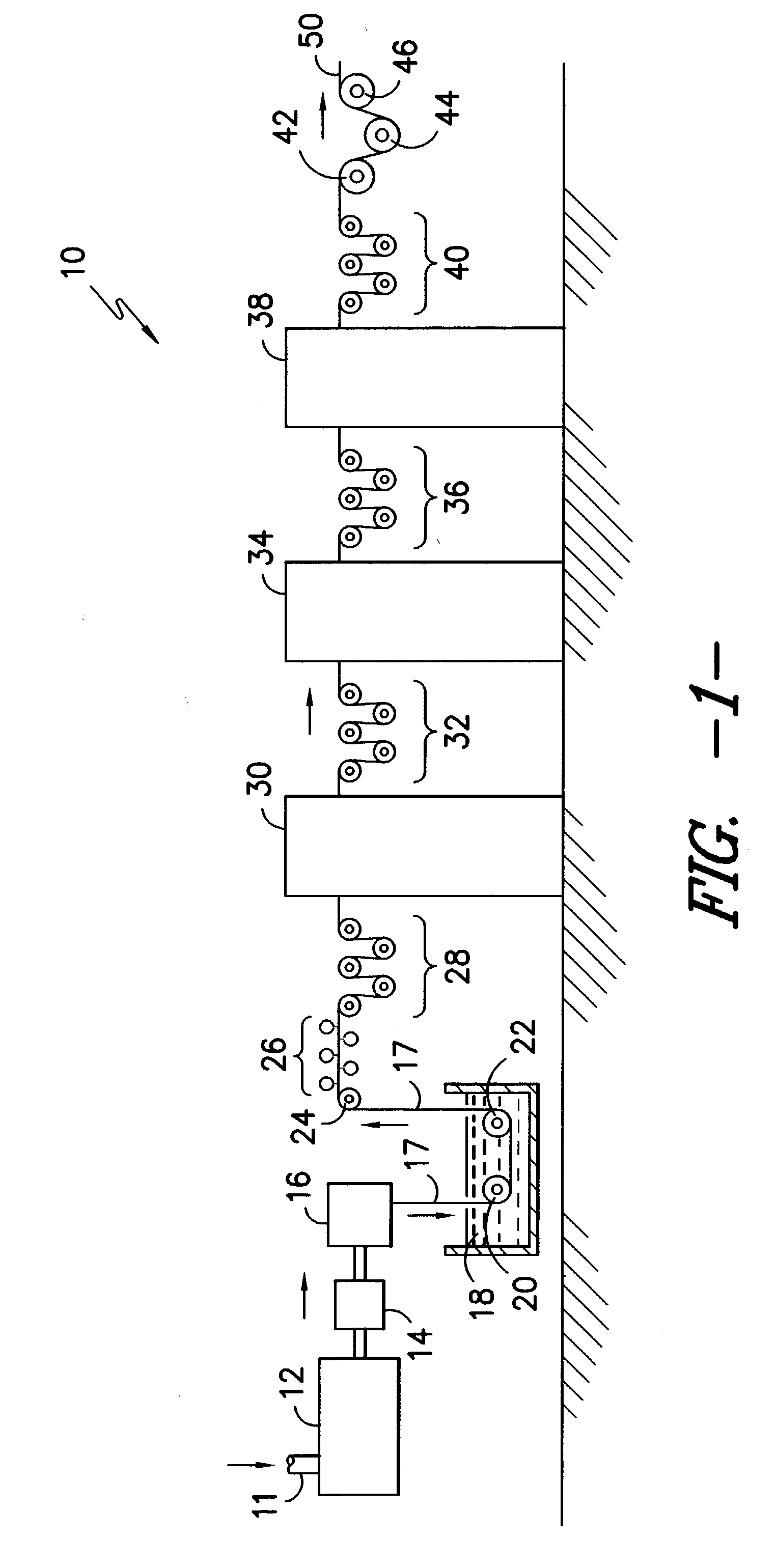

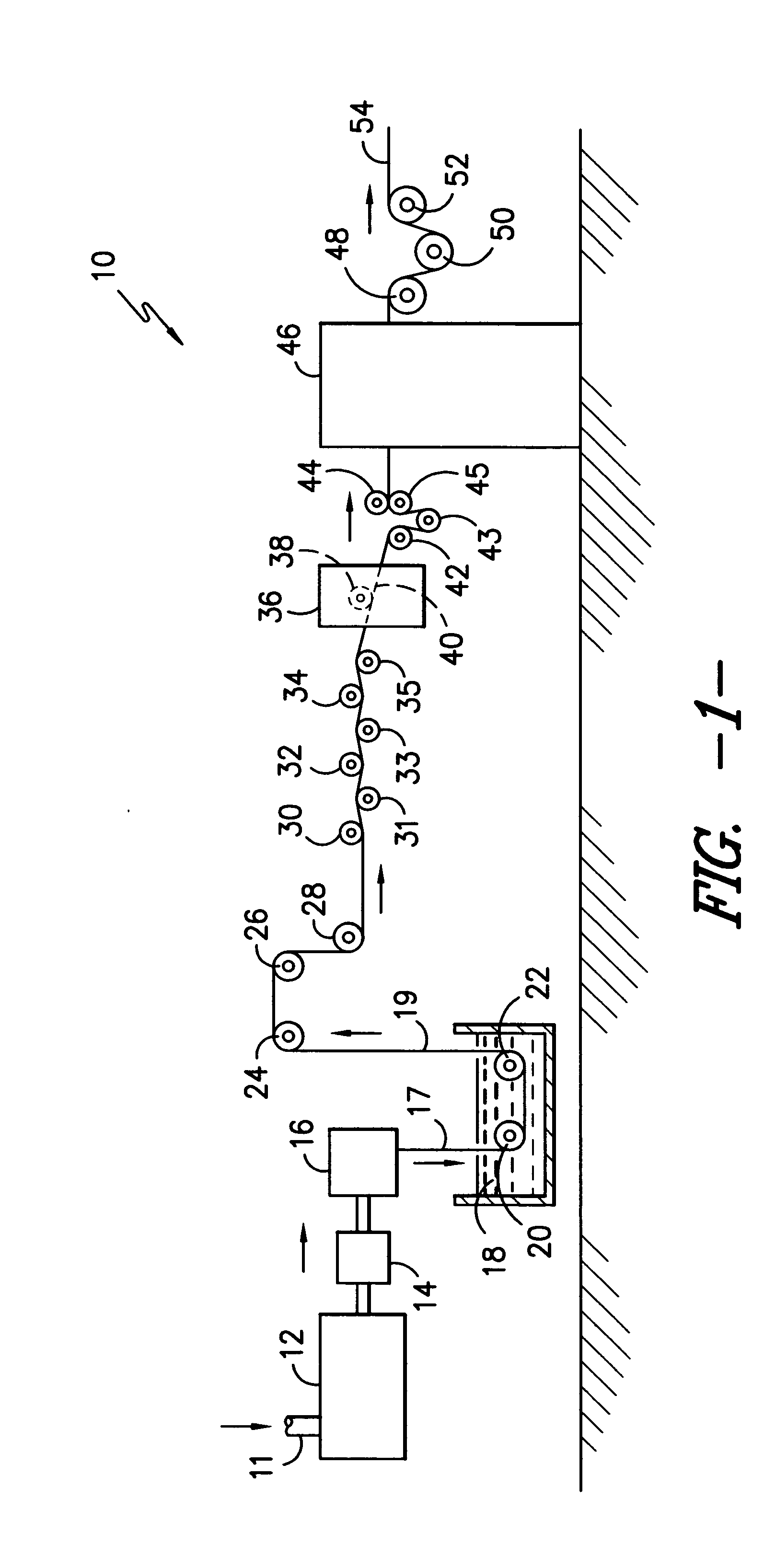

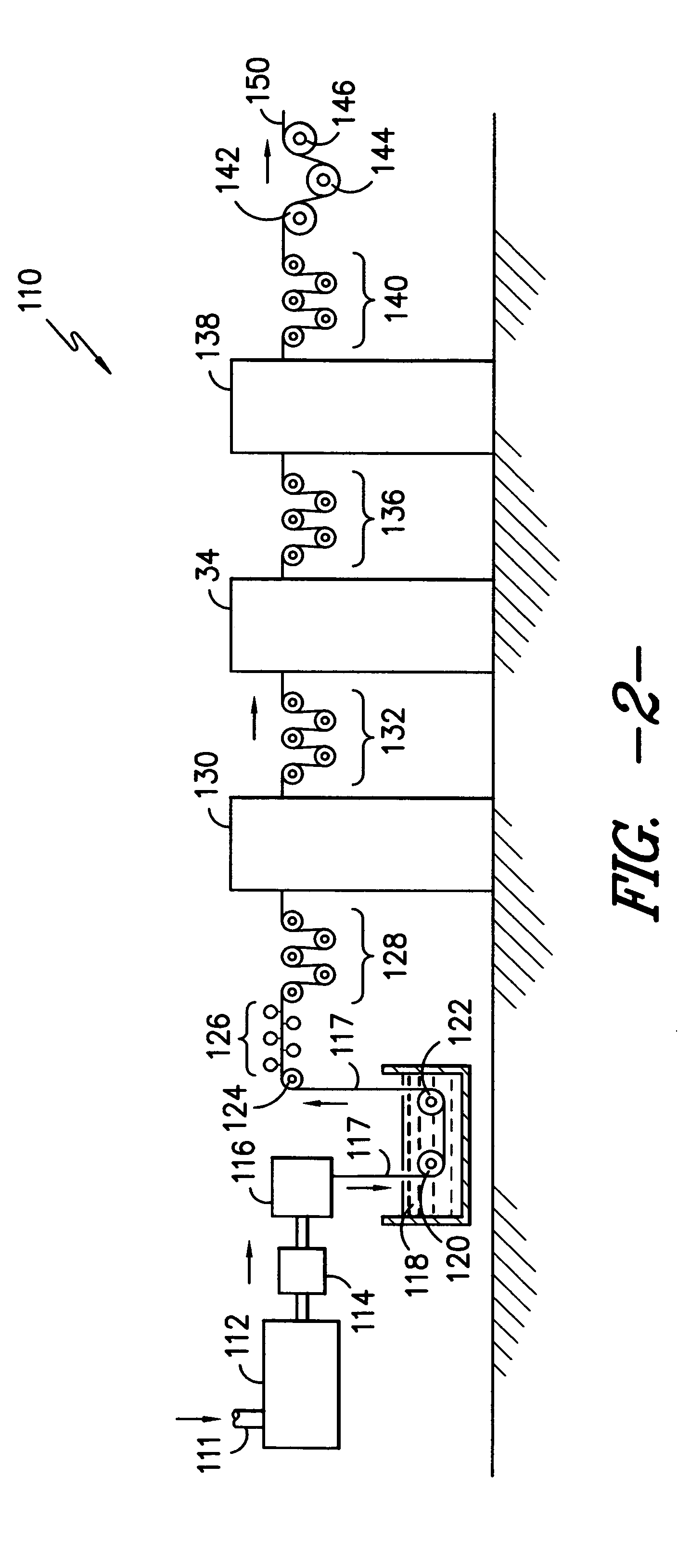

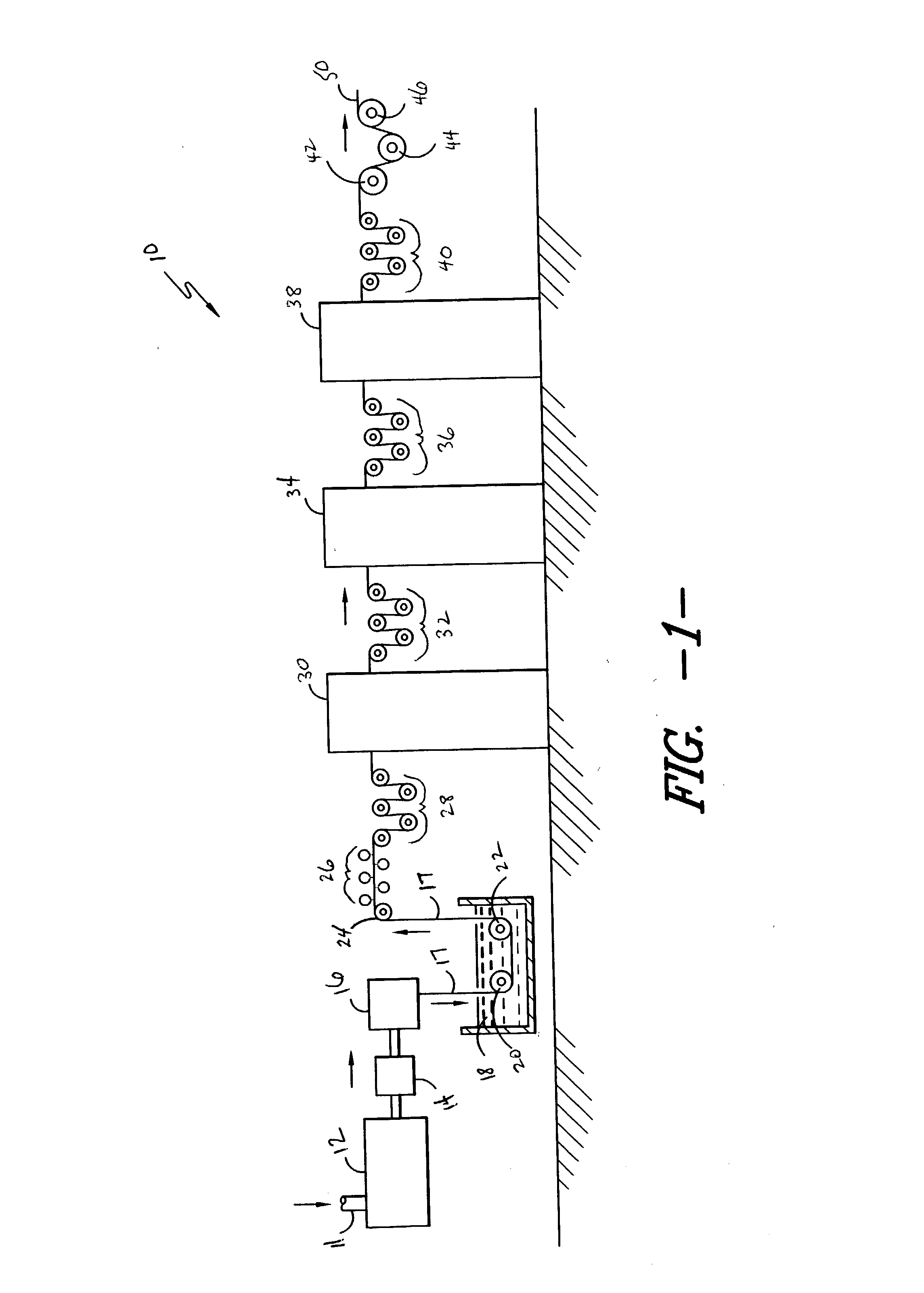

Unique thermoplastic monofilament fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present that the tenacity and modulus strength are much higher than any other previously produced thermoplastic fibers, particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

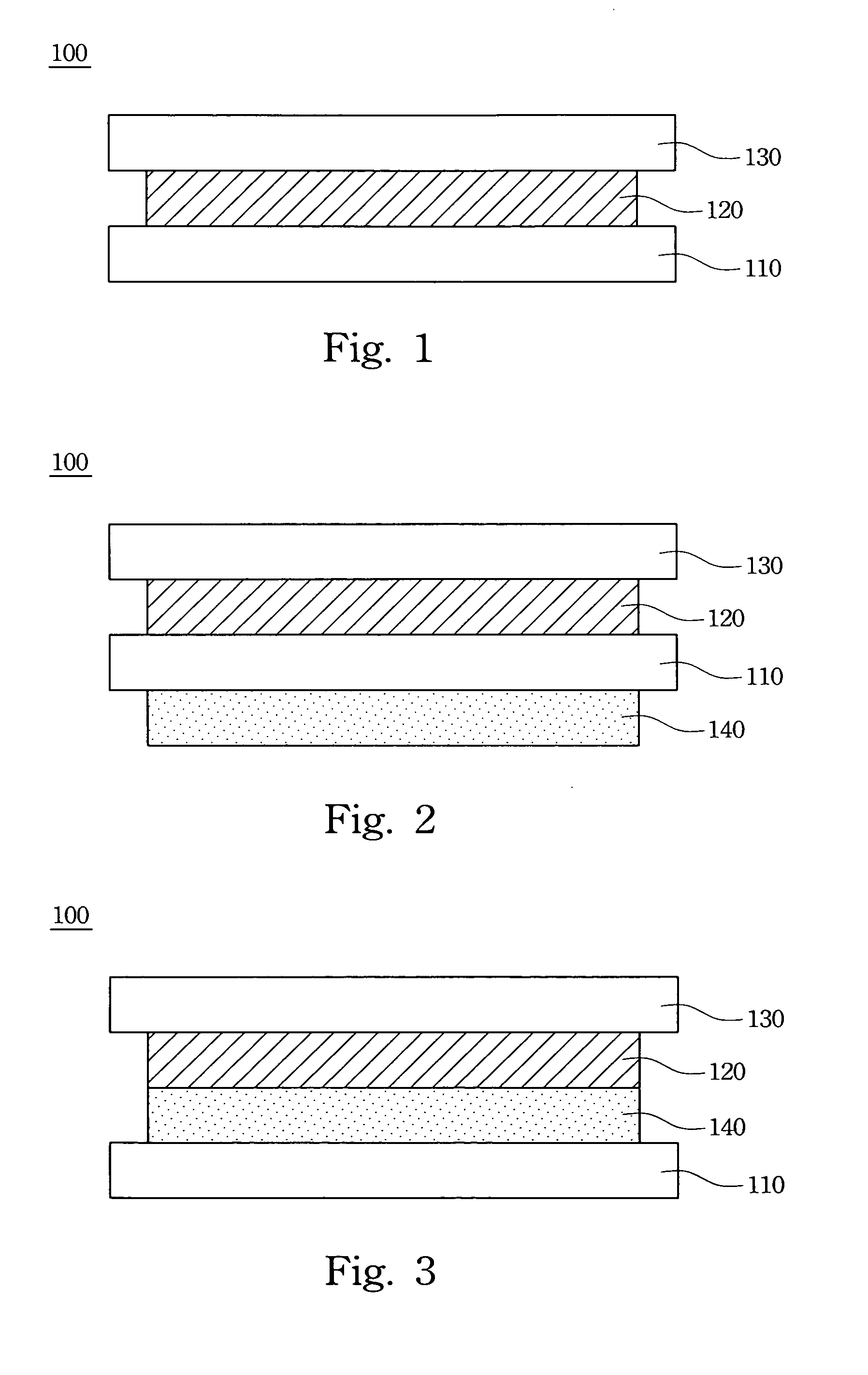

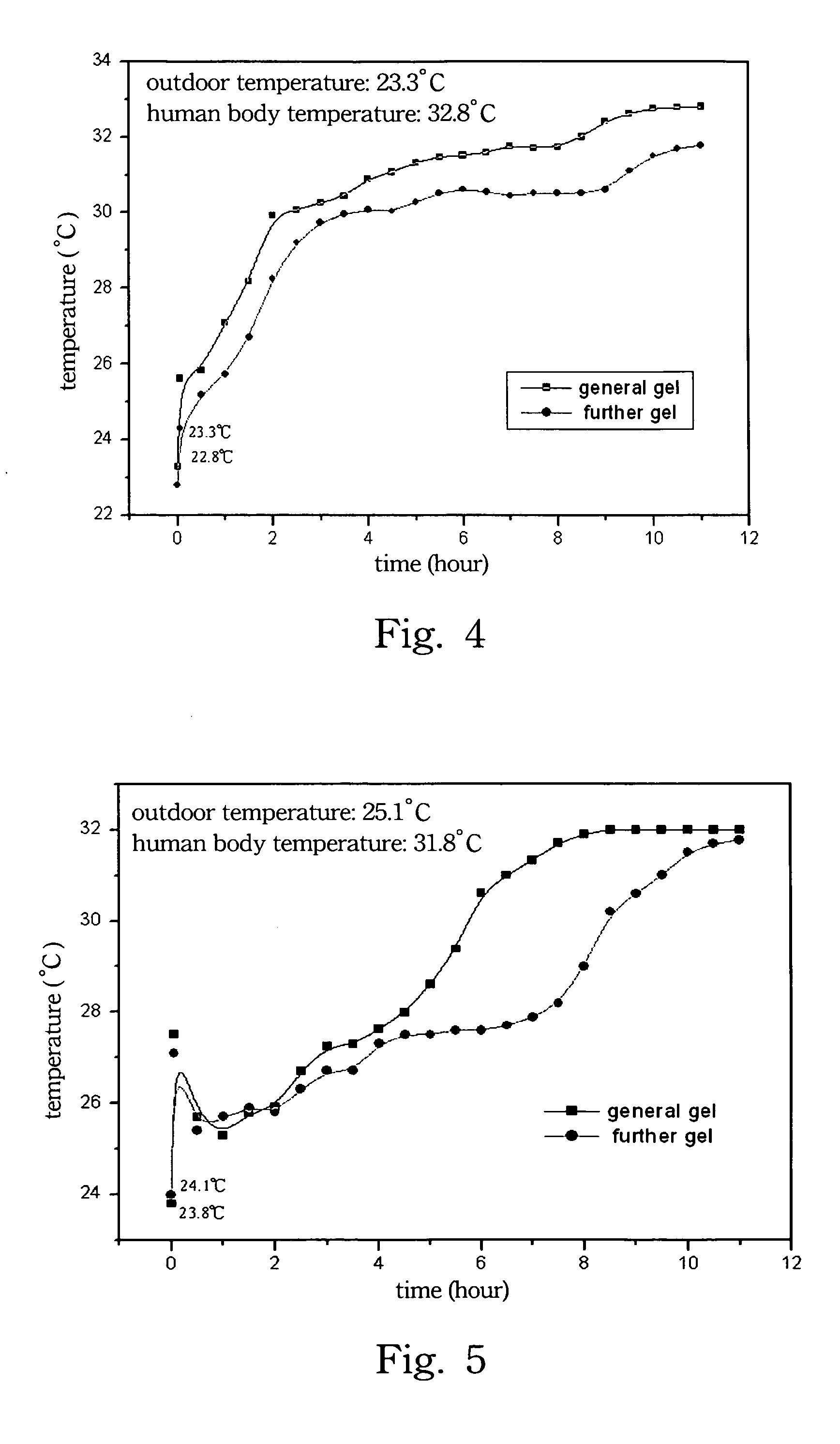

Temperature regulating gel and article comprising the same

InactiveUS20070088104A1Increased durabilityPromote environmental protectionCosmetic preparationsPeptide/protein ingredientsPlastic crystalPhase-change material

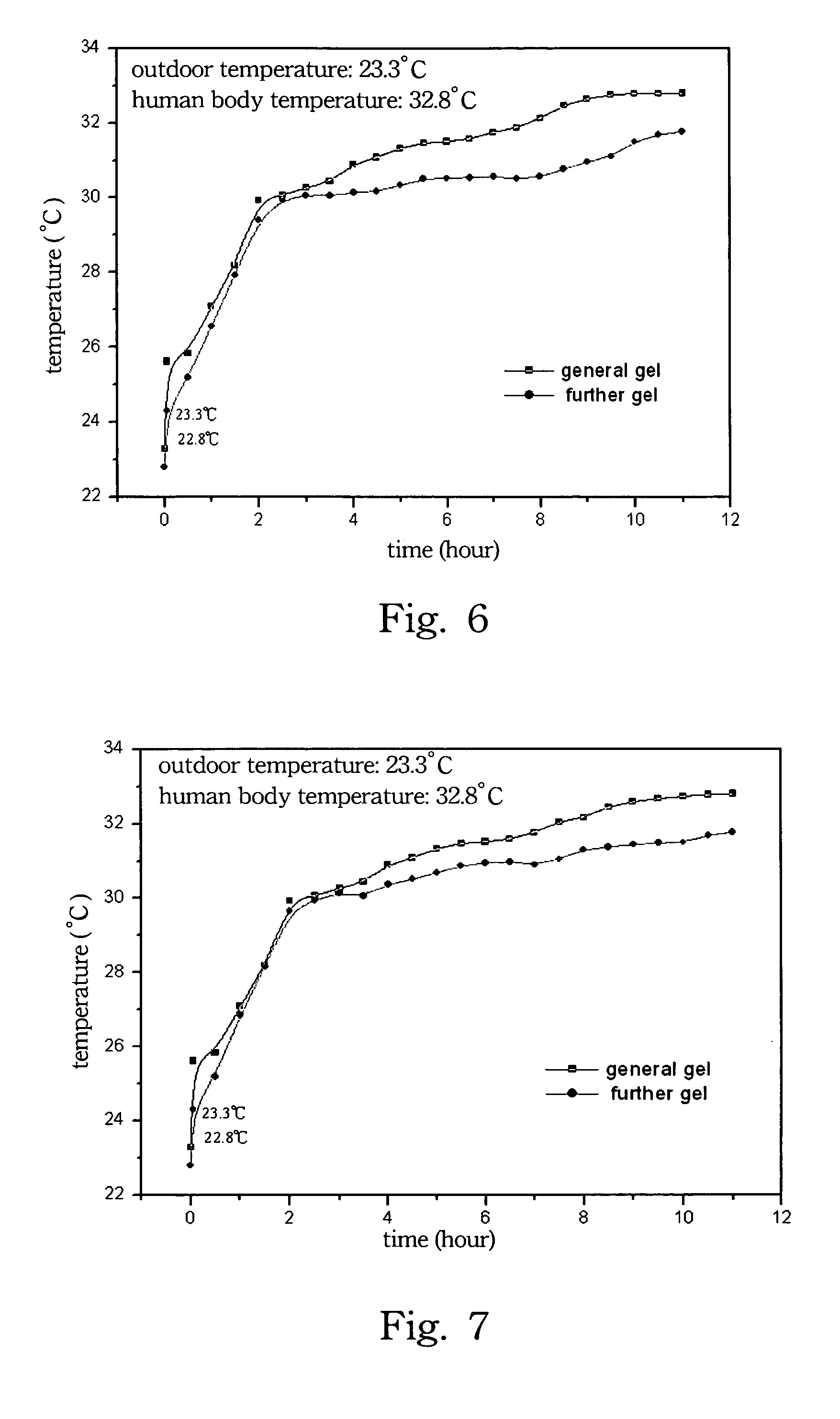

A temperature regulating gel includes a hydrophilic polymeric substrate and a heat-storing material. The hydrophilic polymeric substrate may include a natural hydrogel, a synthetic hydrogel, or any combination thereof. The heat-storing material may include a phase change material, a plastic crystal, or any combination thereof. The present invention also discloses a temperature regulating article including the temperature regulating gel.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

InactiveUS6863976B2High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingYarnThermoplastic

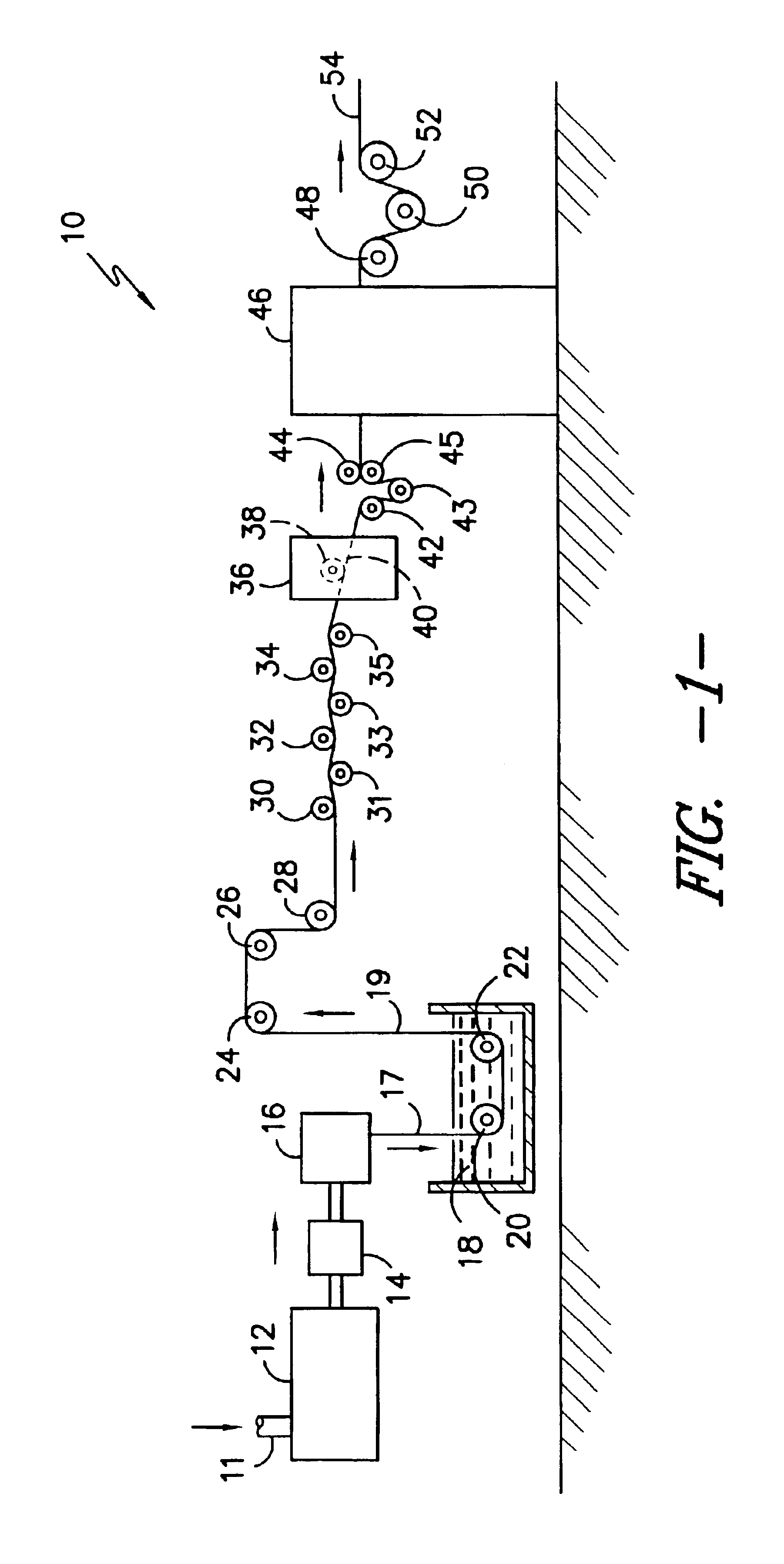

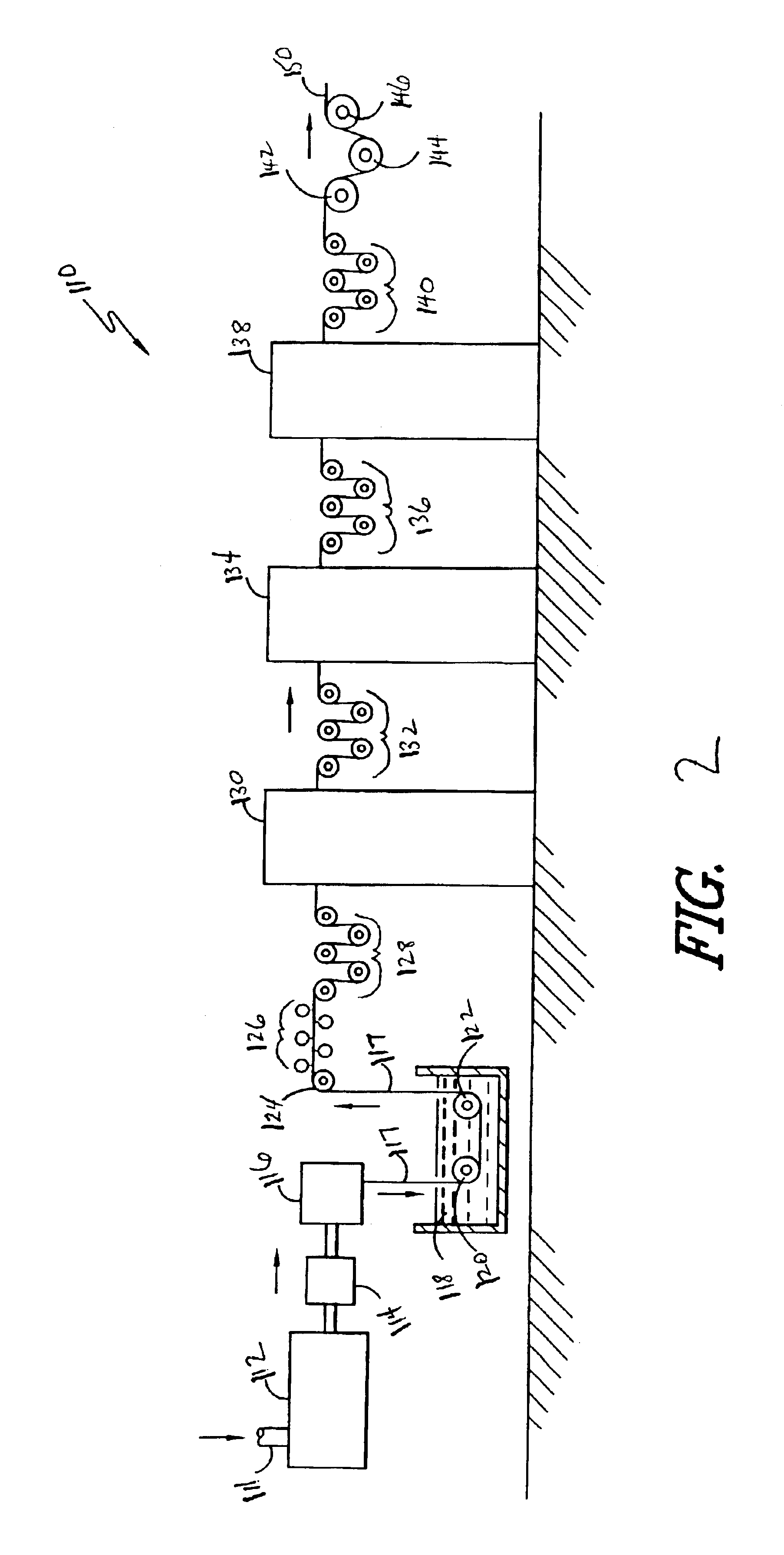

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the “rigidifying” nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred “rigidifying” compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2′-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

Electrolyte For Electrochemical Device, Method For Preparing The Electrolyte And Electrochemical Device Including The Electrolyte

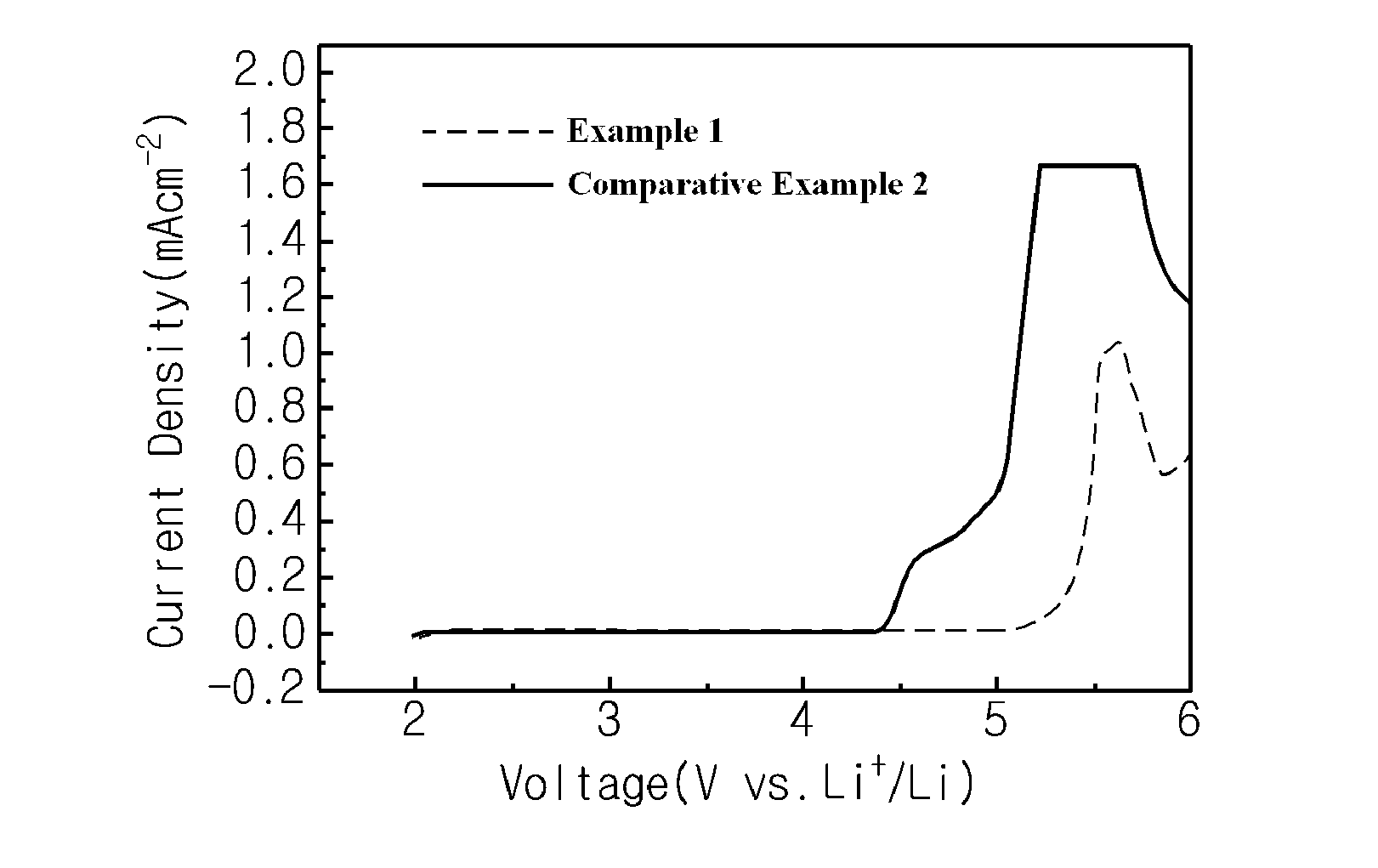

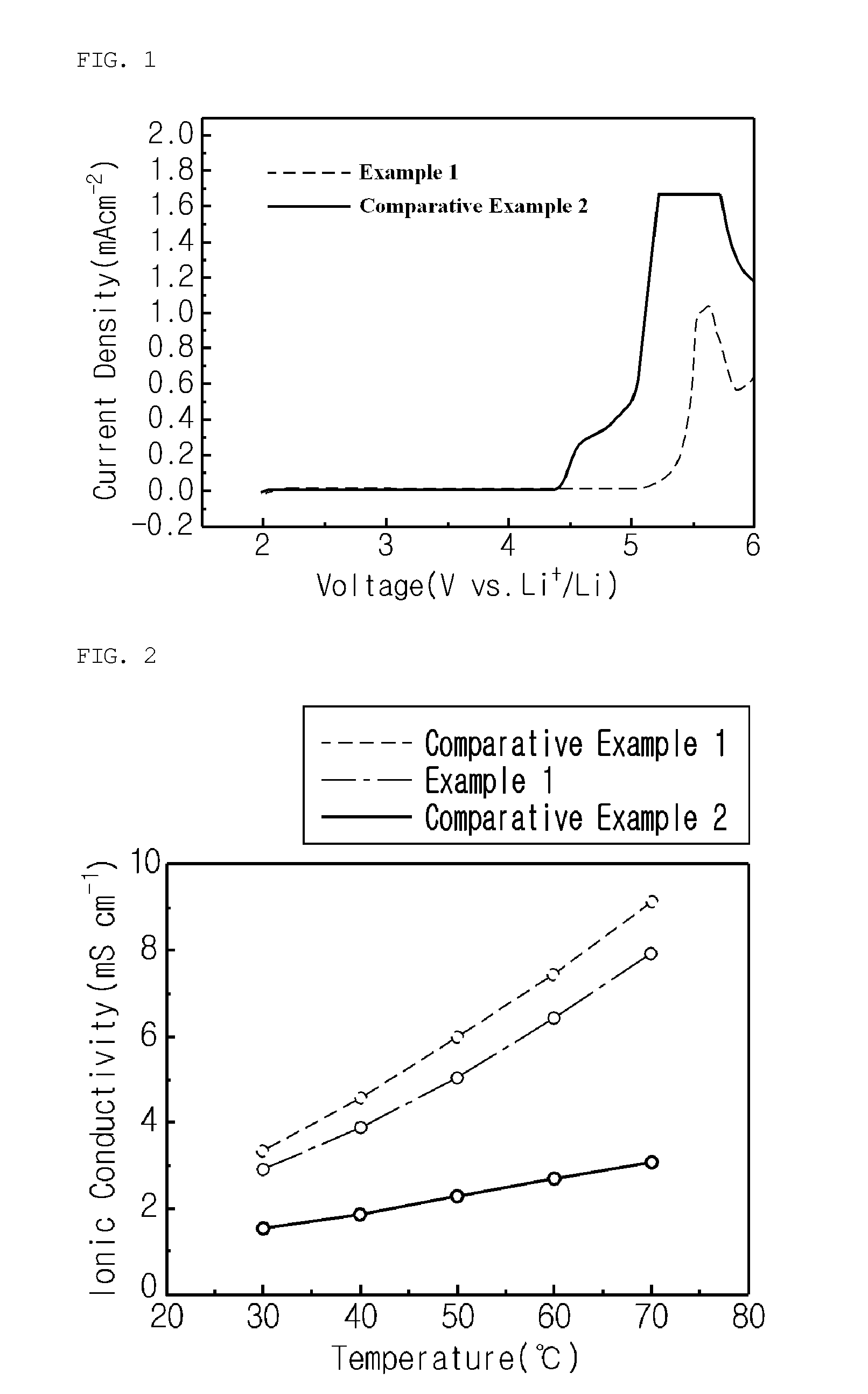

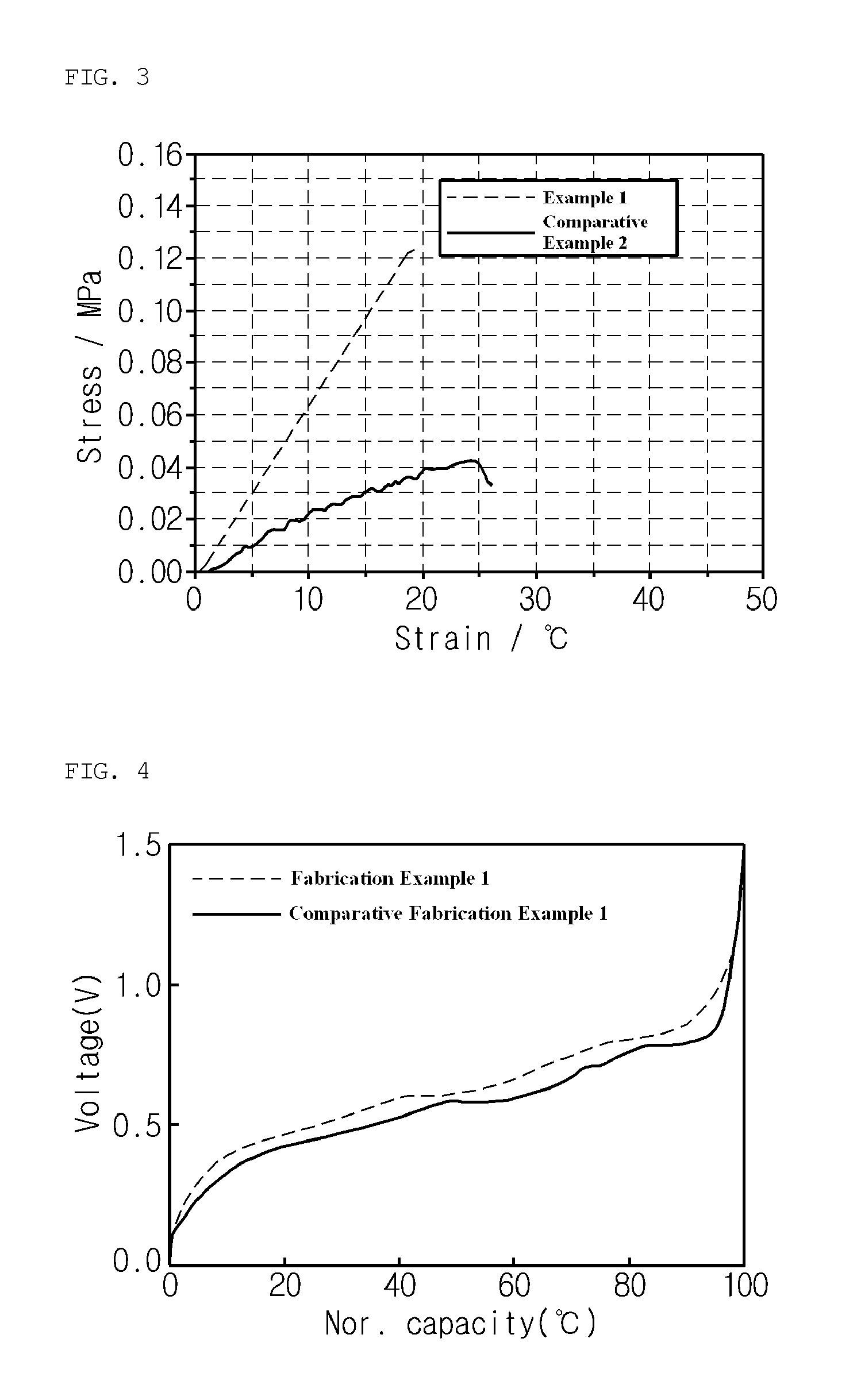

ActiveUS20120115040A1High mechanical strengthEasy to changeSolid electrolytesFinal product manufacturePlastic crystalPhysical chemistry

Owner:LG ENERGY SOLUTION LTD

Plastic crystal electrolyte for lithium batteries

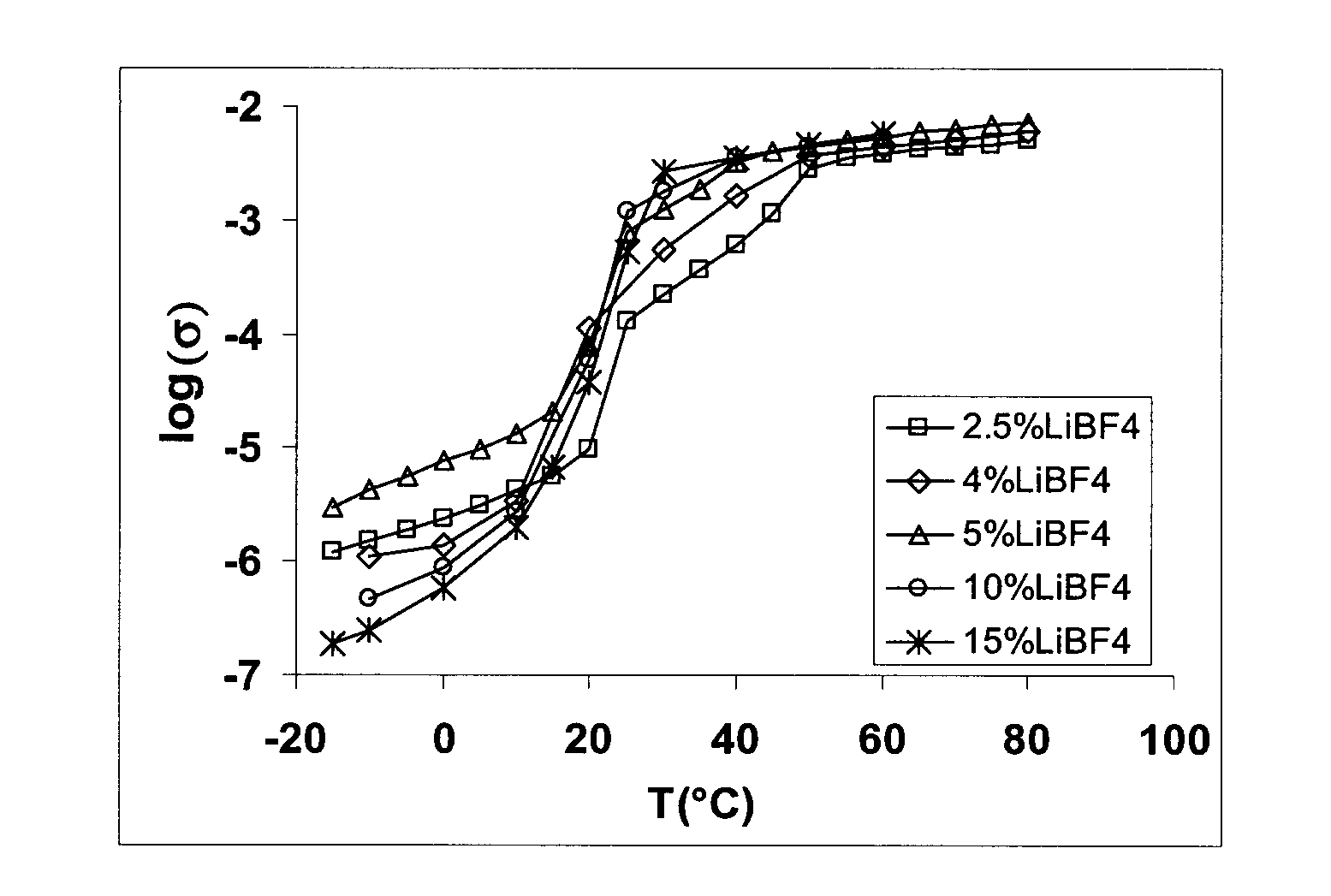

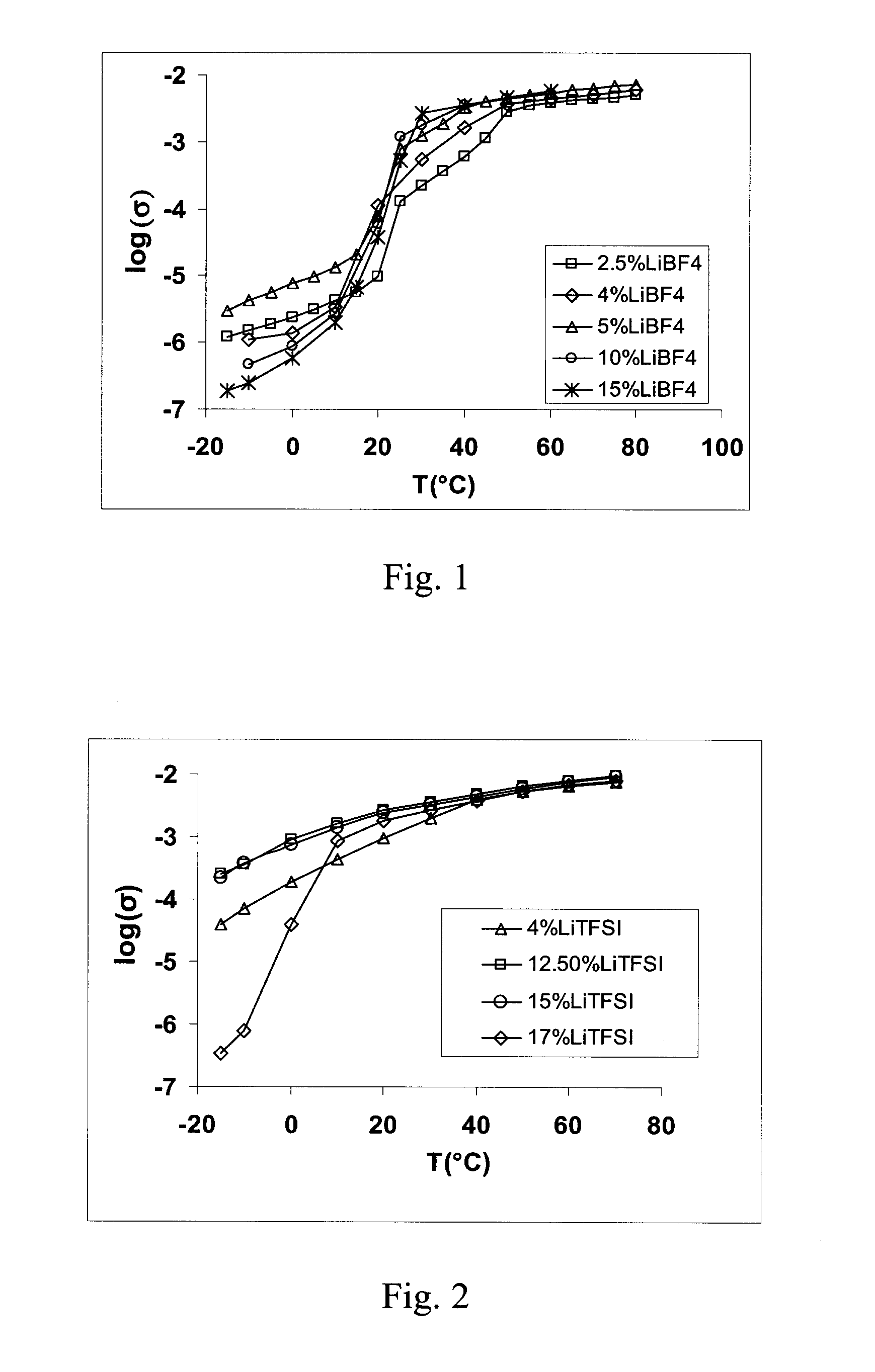

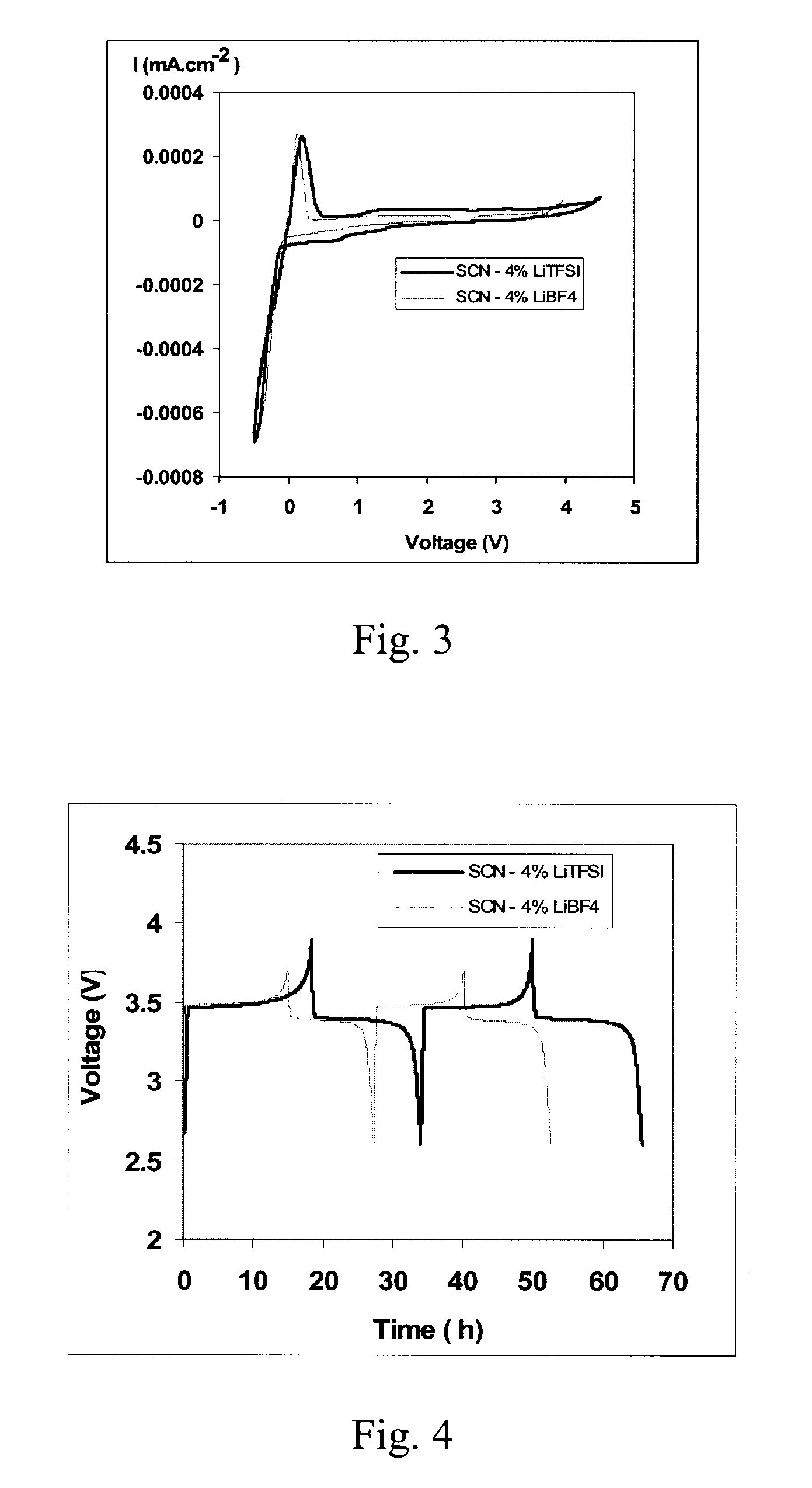

ActiveUS20090092902A1Increase polarityImprove solubilitySolid electrolytesSolid electrolyte cellsPlastic crystalLithium metal

A solid ionic electrolyte having a neutral organic plastic crystal matrix doped with an ionic salt may be used in an electrochemical device having an anode comprising a Li-containing material having an electrochemical potential within about 1.3 V of lithium metal. Electrochemical devices are disclosed having a cathode, an anode of a Li-containing material having an electrochemical potential within about 1.3 V of lithium metal, and a solid ionic electrolyte having a neutral organic plastic crystal matrix doped with an ionic salt. Such devices have high energy density delivery capacity combined with the favourable properties of a neutral organic plastic crystal matrix such as succinonitrile.

Owner:NAT RES COUNCIL OF CANADA

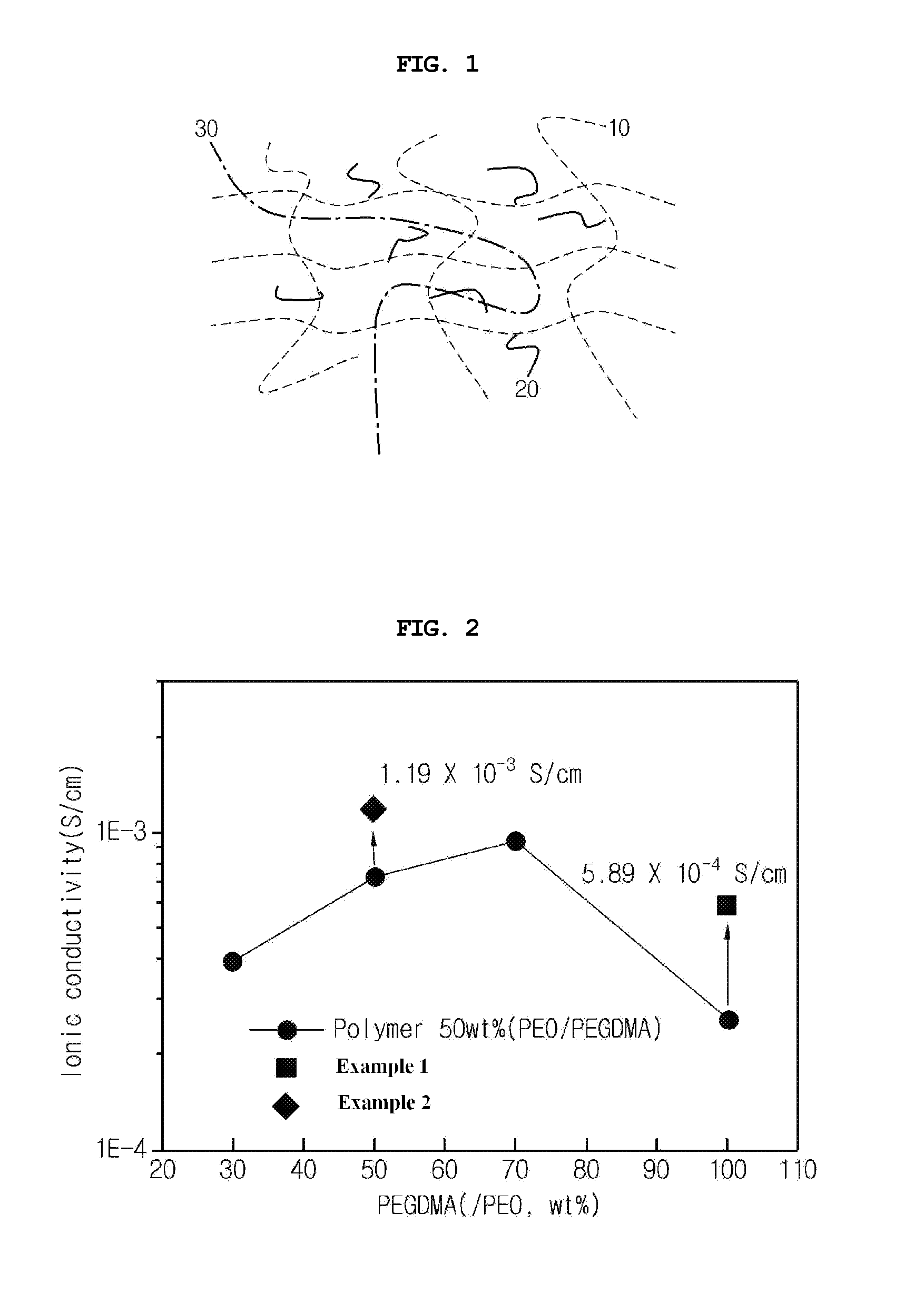

Electrolyte for an electrochemical device, method for manufacturing same, and electrochemical device including same

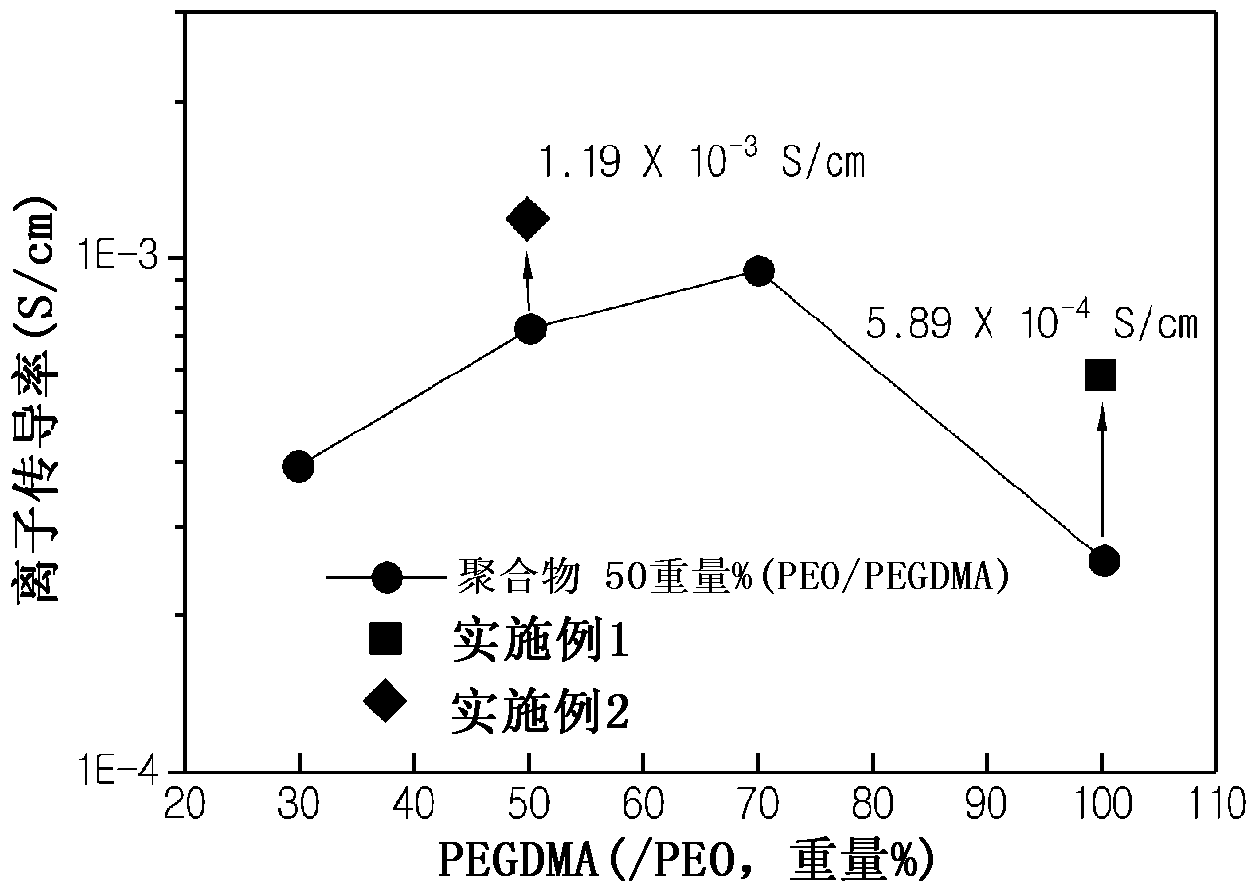

ActiveCN103329332AImprove ionic conductivityHigh mechanical strengthLi-accumulatorsCross-linkPlastic crystal

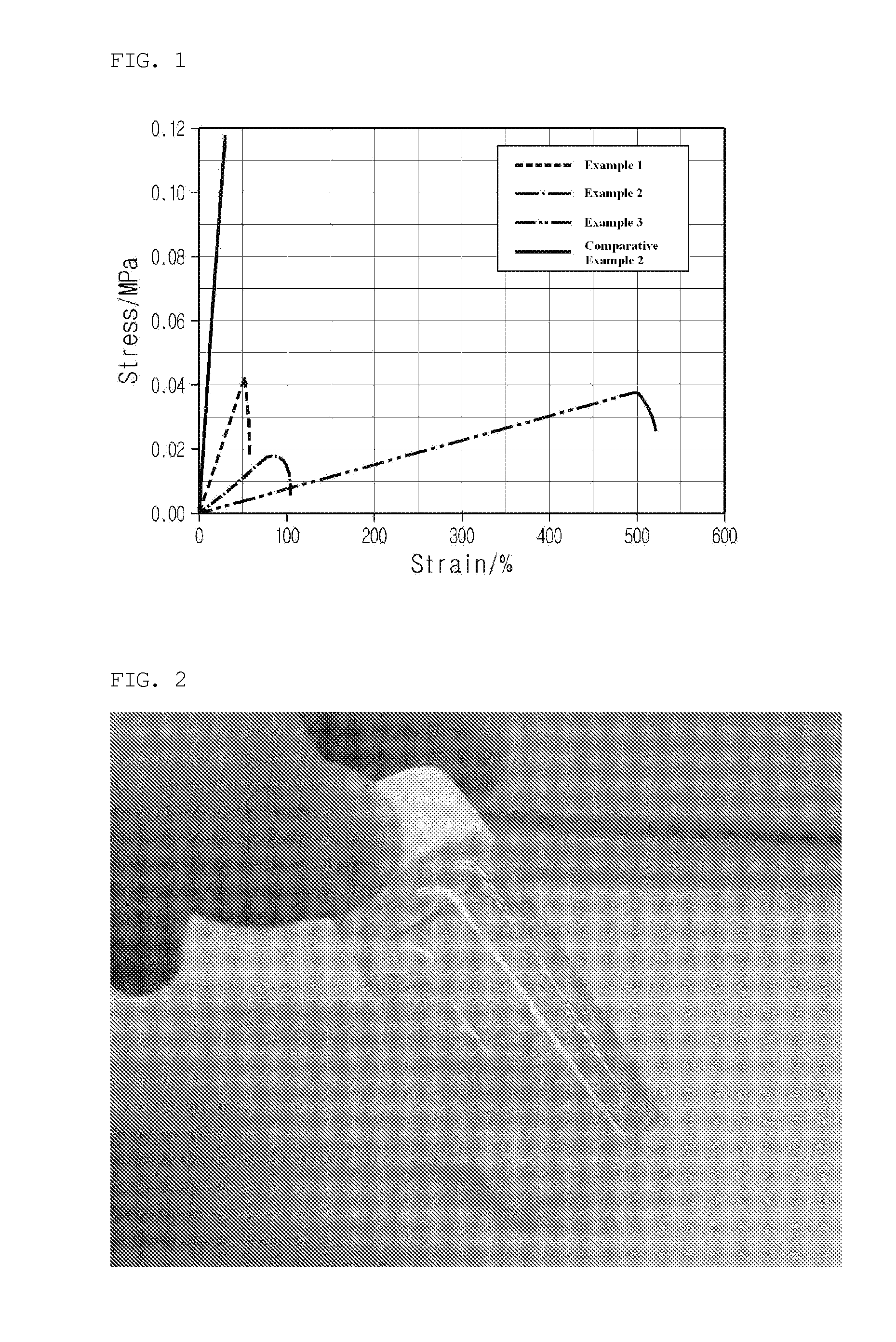

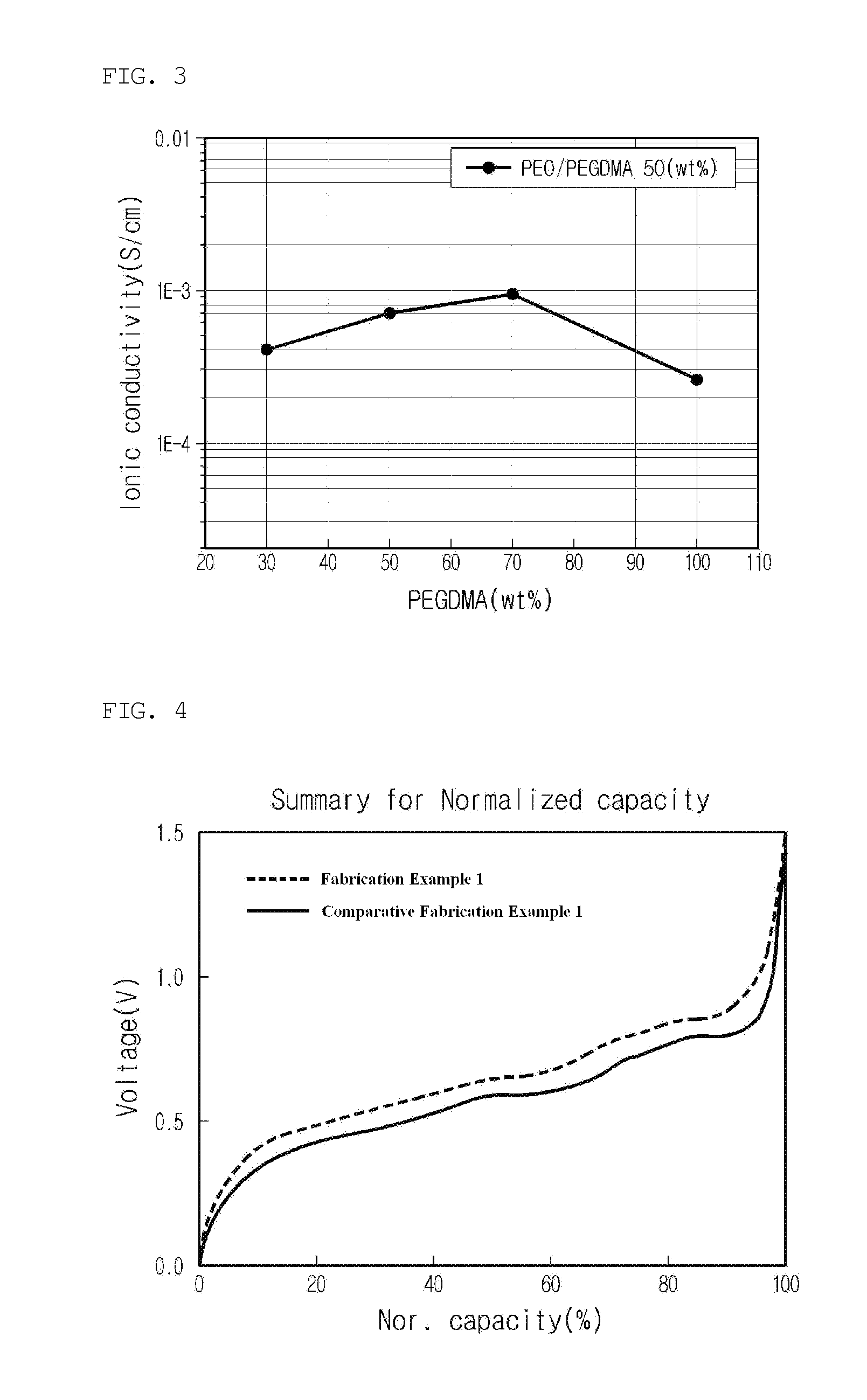

The present invention relates to a solid electrolyte for an electrochemical device comprising a plastic crystal matrix electrolyte doped with ionic salt, and a complex of a polymer having a cross-linking structure including a chemically bonded linear polymer having a weight average molecular weight of 100 to 5,000 and one functional group, and to a method for manufacturing same. Since the electrolyte is obtained using the plastic crystal, the electrolyte has good ion conductivity which is a feature of a liquid electrolyte. Since the electrolyte includes the polymer having the cross-linking structure, the electrolyte has good mechanical strength which is a feature of a solid electrolyte. In addition, a solvent is not necessarily required while manufacturing the electrolyte, and therefore a drying process can be omitted to simplify the manufacturing process. The electrolyte has high ion conductivity and the mechanical strength of a solid electrolyte, and therefore the electrolyte can be used in a cable-type battery, the form of which is easily modified.

Owner:LG ENERGY SOLUTION LTD

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

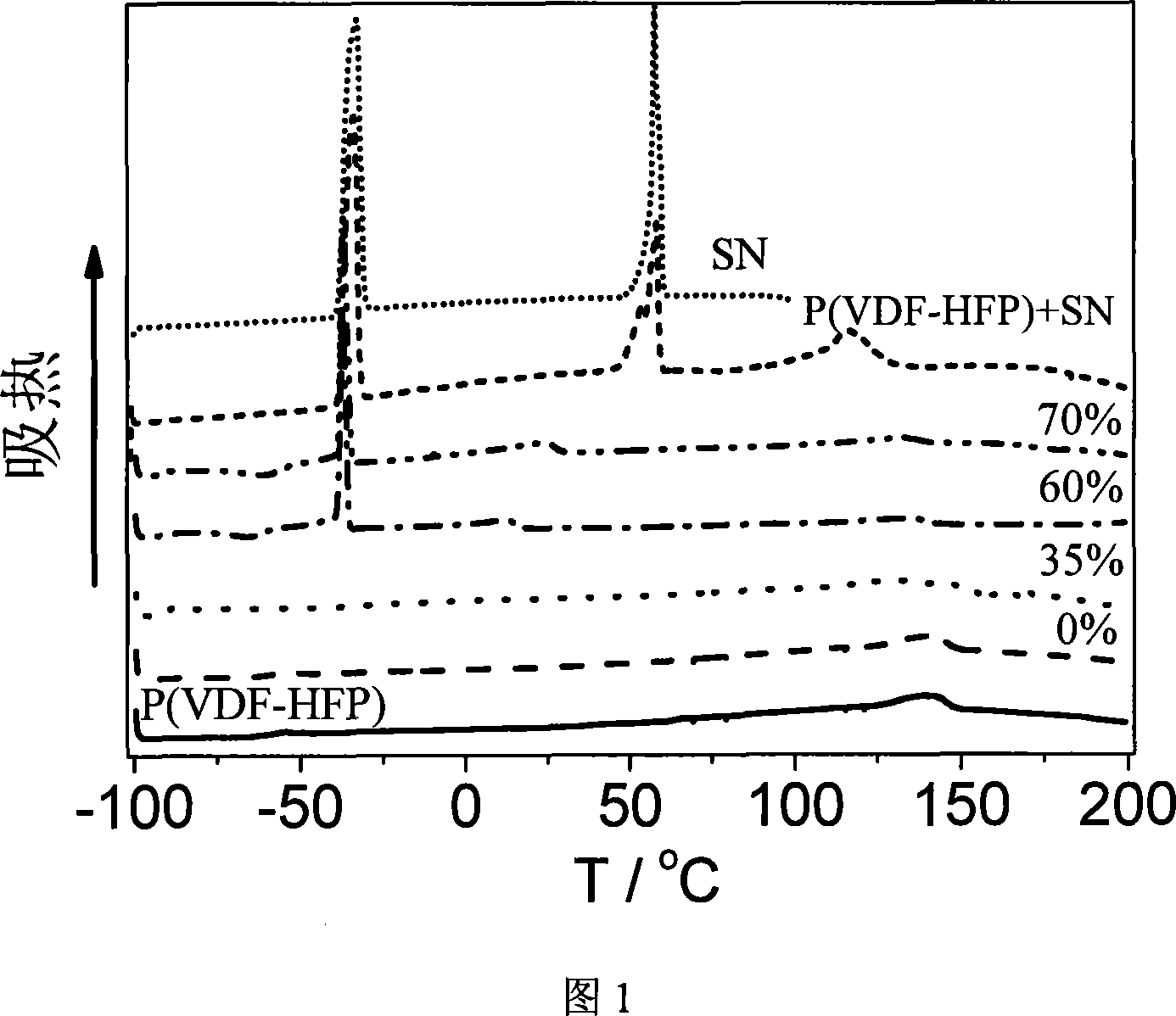

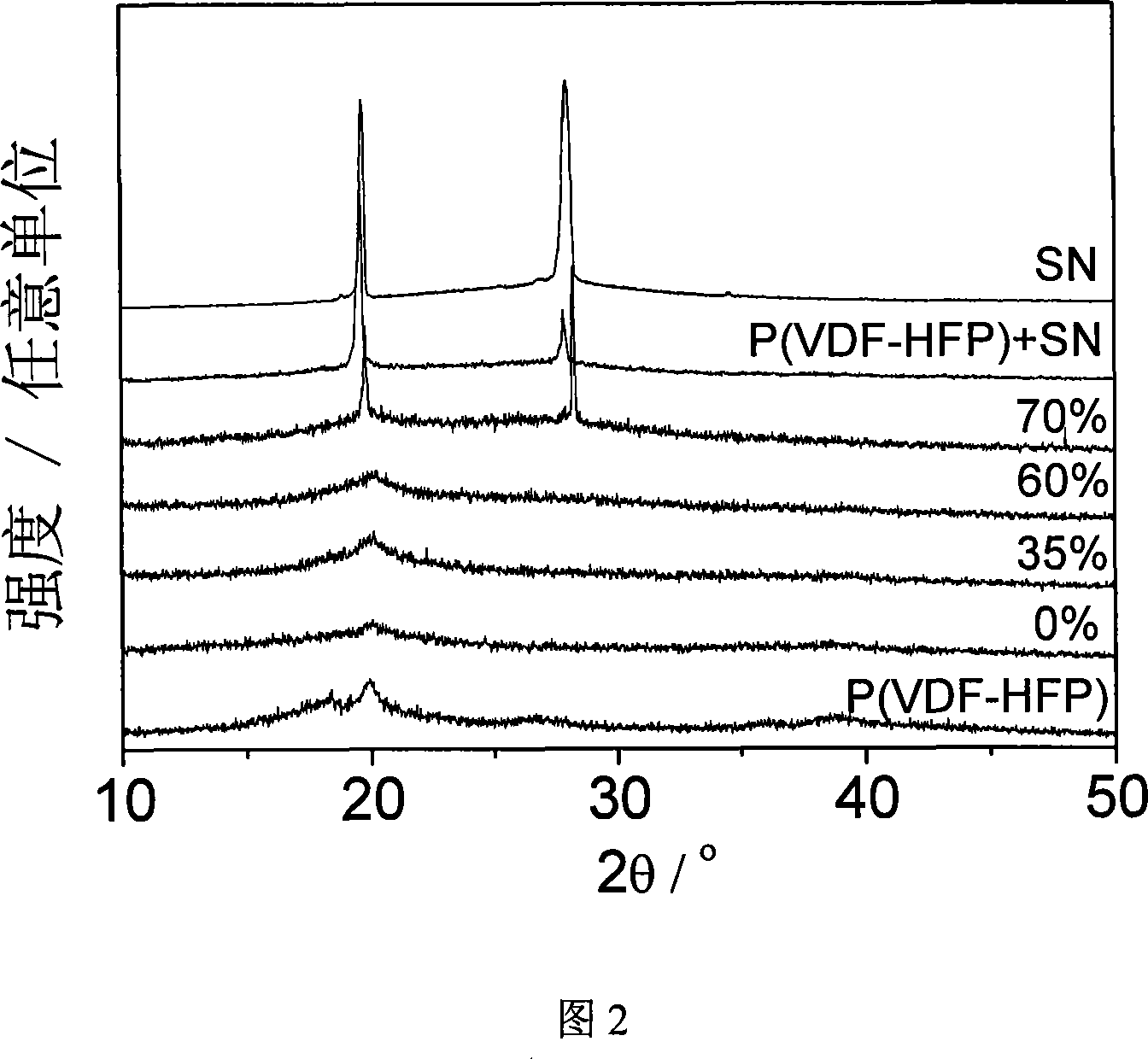

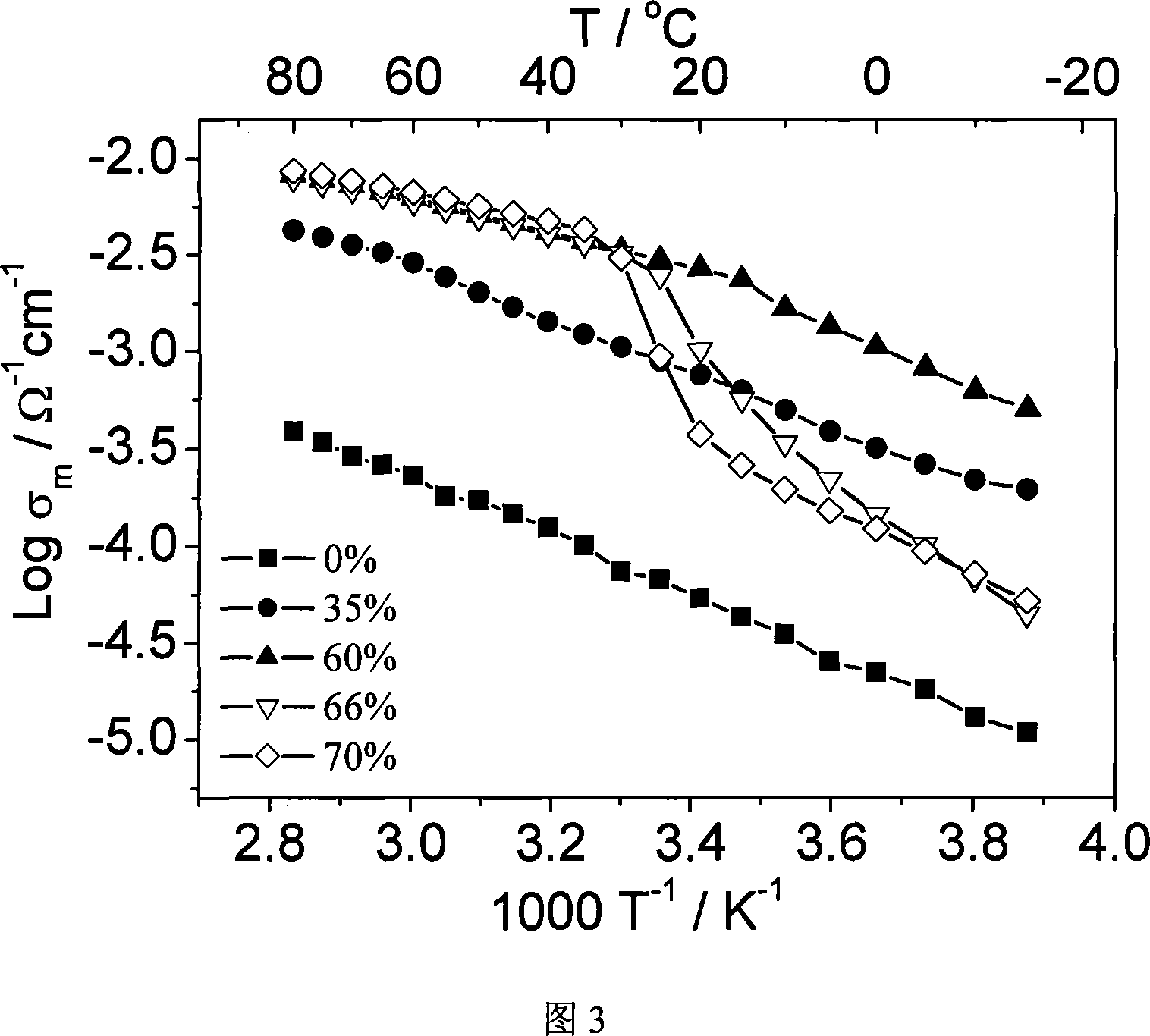

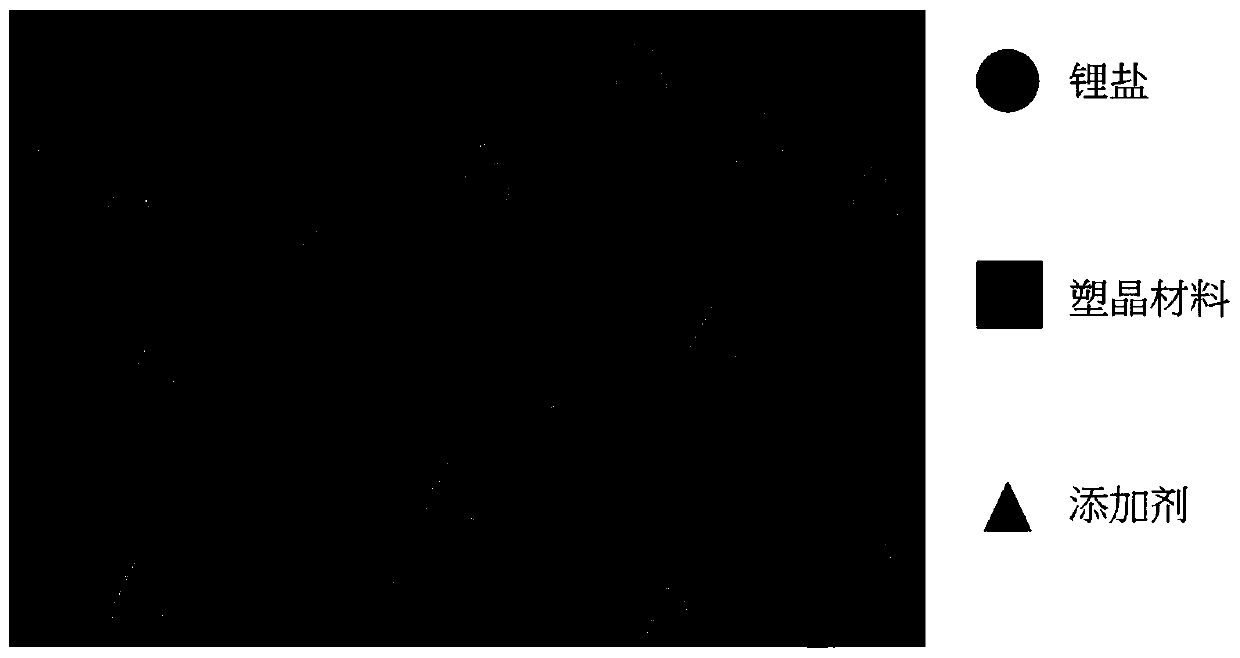

Compound polymer electrolytic material and preparation method thereof

This invention relates to a compound type polymer dielectric stuff and its preparation method, belong to electrochemistry and new energy stuff region. It composed by copolymer of fluoro ethylene and hexafluoro-propylene, lithium salts and plastic crystal stuff. Processing steps: take copolymer, lithium salts and plastic crystal stuff, use solvent to dissolve, whip go as far as uniformity, then pour above solution to teflon tooting, evaporate solvent, finally vacuum drying. While this compound type electrolyte stuff in rather wide temperature range and all components are solid-state, the ionic conductivity can reach using standard of lithium Secondary Battery. It overcomes shortcoming of traditional gel-type polymer dielectric that liquid electrolyte easily leak as well as plastic crystal electrolyte unease form film, and also combine the merit that polymer dielectric easily form film as well as plastic crystal electrolyte has high room temperature ionic conductivity.

Owner:UNIV OF SCI & TECH BEIJING

Polypropylene monofilament fibers exhibiting low-shrink, high tenacity, and extremely high modulus levels

InactiveUS20040096661A1Reduced shrinkage performanceLow shrinkageSynthetic resin layered productsMonocomponent polypropylene artificial filamentThermoplasticYarn

Unique thermoplastic monofilament fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than any other previously produced thermoplastic fibers, particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:ROYER JOSEPH R +2

Plastic crystal polymer electrolyte material prepared by in-situ polymerization and preparation method therefor

InactiveCN106654366AImprove conductivityImprove thermal stabilityFinal product manufactureSecondary cells servicing/maintenanceCross-linkPolymer science

The invention relates to a plastic crystal polymer electrolyte material prepared by in-situ polymerization and a preparation method therefor, and belongs to the technical field of an electrolyte material. The plastic crystal polymer electrolyte material prepared by the in-situ polymerization comprises a monomer, an initiator, a cross-linking agent, a lithium salt, and plastic crystals; a mixed solution of the monomer, the initiator, the cross-linking agent, the lithium salt and the plastic crystals is heated to be subjected to the in-situ polymerization to obtain the plastic crystal polymer electrolyte material; the preparation method for the plastic crystal polymer electrolyte material prepared by the in-situ polymerization comprises the steps of mixing and dissolving the monomer, the initiator, the cross-linking agent, the lithium salt and the plastic crystals; and pouring the solution into a polytetrafluoroethylene die, and heating and performing the in-situ polymerization to obtain the plastic crystal polymer electrolyte material. By adoption of a one-step method for synthesis, the preparation process is simple and industrial production can be realized favorably; and in addition, the plastic crystal polymer electrolyte material is high in conductivity at room temperature, high in thermal stability and interface stability, high in mechanical property, excellent in electrochemical performance, and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Electrolyte for electrochemical device, method for preparing the electrolyte and electrochemical device including the electrolyte

ActiveUS20120094187A1High mechanical strengthEasy to changeSolid electrolytesFinal product manufacturePlastic crystalPhysical chemistry

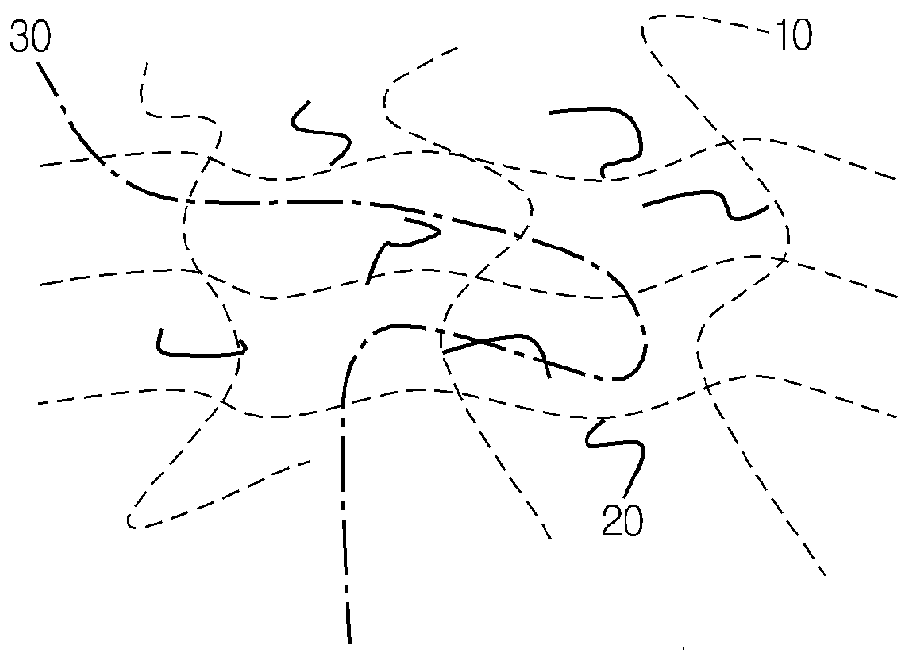

Disclosed is a solid electrolyte for an electrochemical device. The solid electrolyte includes a composite consisting of: a plastic crystal matrix electrolyte doped with an ionic salt; and a network of a non-crosslinked polymer and a crosslinked polymer structure. The electrolyte has high ionic conductivity comparable to that of a liquid electrolyte due to the use of the plastic crystal, and high mechanical strength comparable to that of a solid electrolyte due to the introduction of the non-crosslinked polymer / crosslinked polymer structure network. Particularly, the electrolyte is highly flexible. Further disclosed is a method for preparing the electrolyte. The method does not essentially require the use of a solvent. Therefore, the electrolyte can be prepared in a simple manner. The electrolyte is suitable for use in a cable-type battery whose shape is easy to change due to its high ionic conductivity and high mechanical strength in terms of flexibility.

Owner:LG ENERGY SOLUTION LTD

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

InactiveUS20050019565A1High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingYarnThermoplastic

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the “rigidifying” nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred “rigidifying” compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2′-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

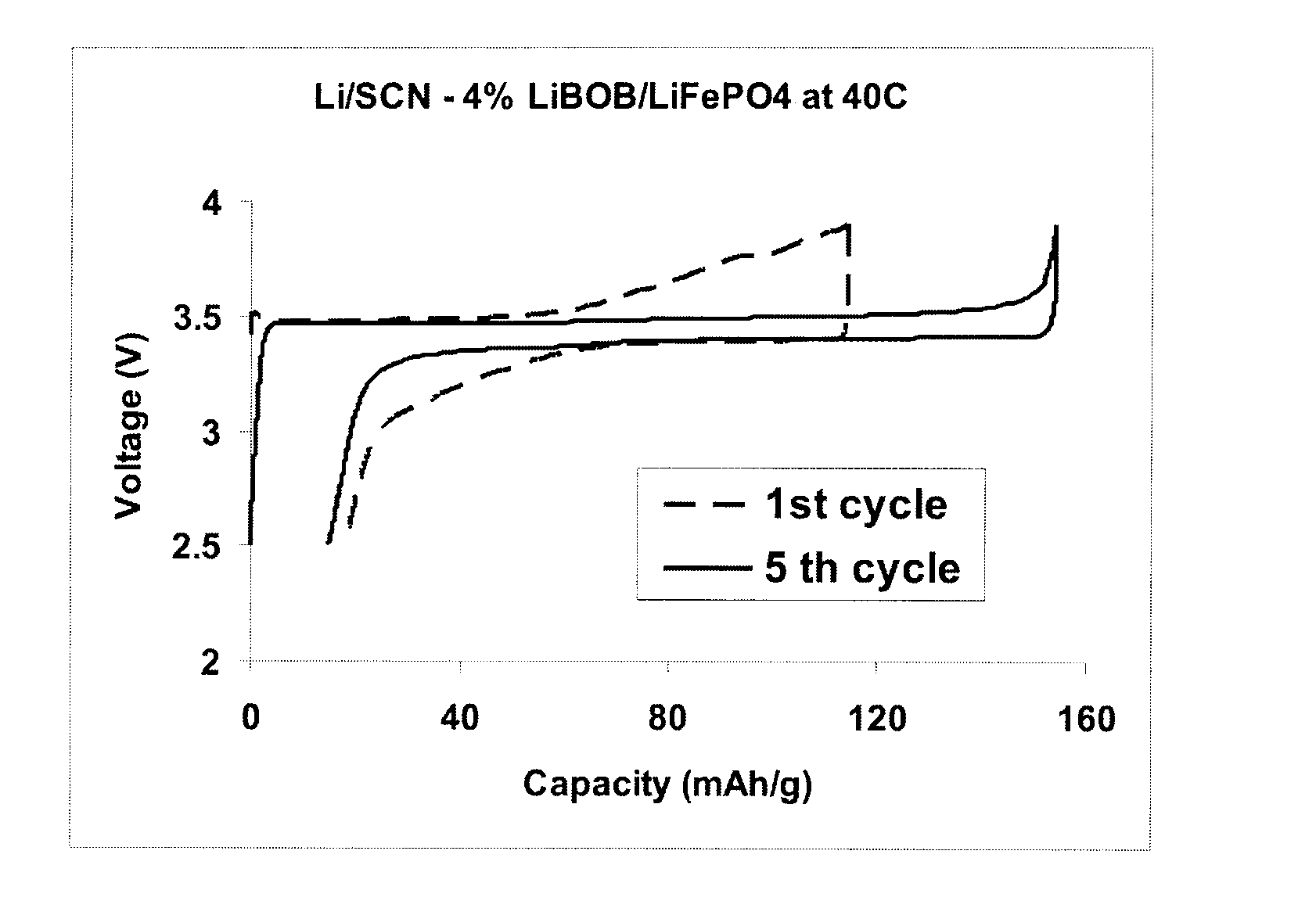

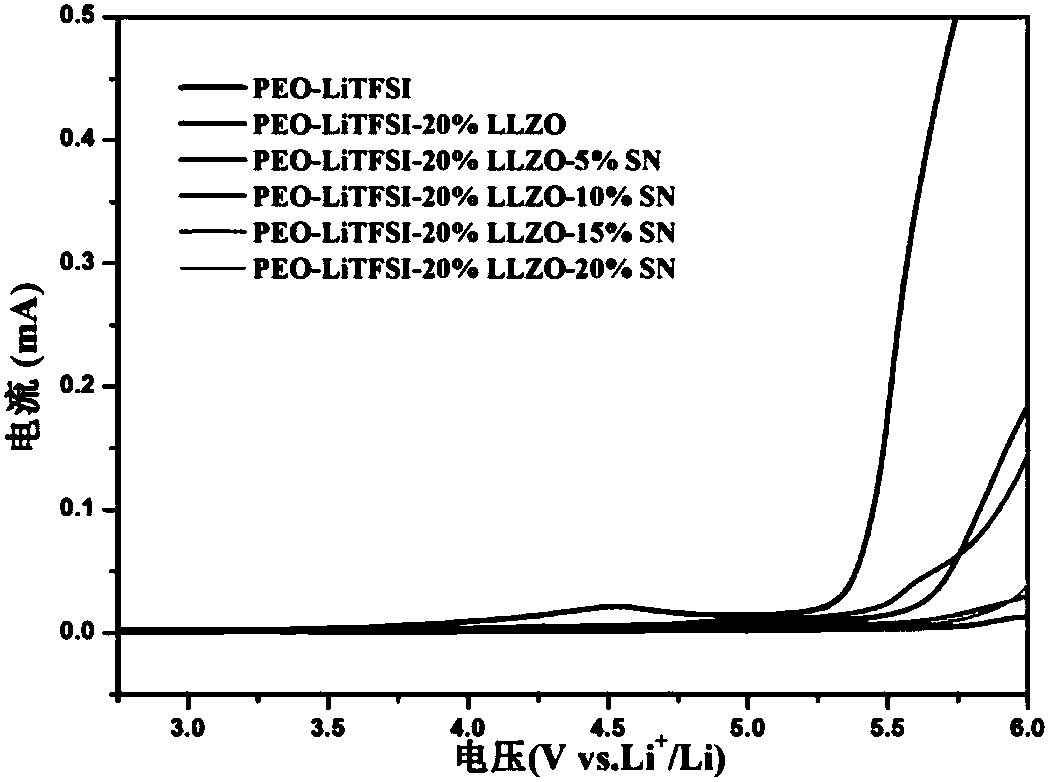

Plastic Crystal Electrolyte with a Broad Potential Window

ActiveUS20100119951A1Limit amount can be usedSolid electrolytesAlkaline accumulatorsLithiumPlastic crystal

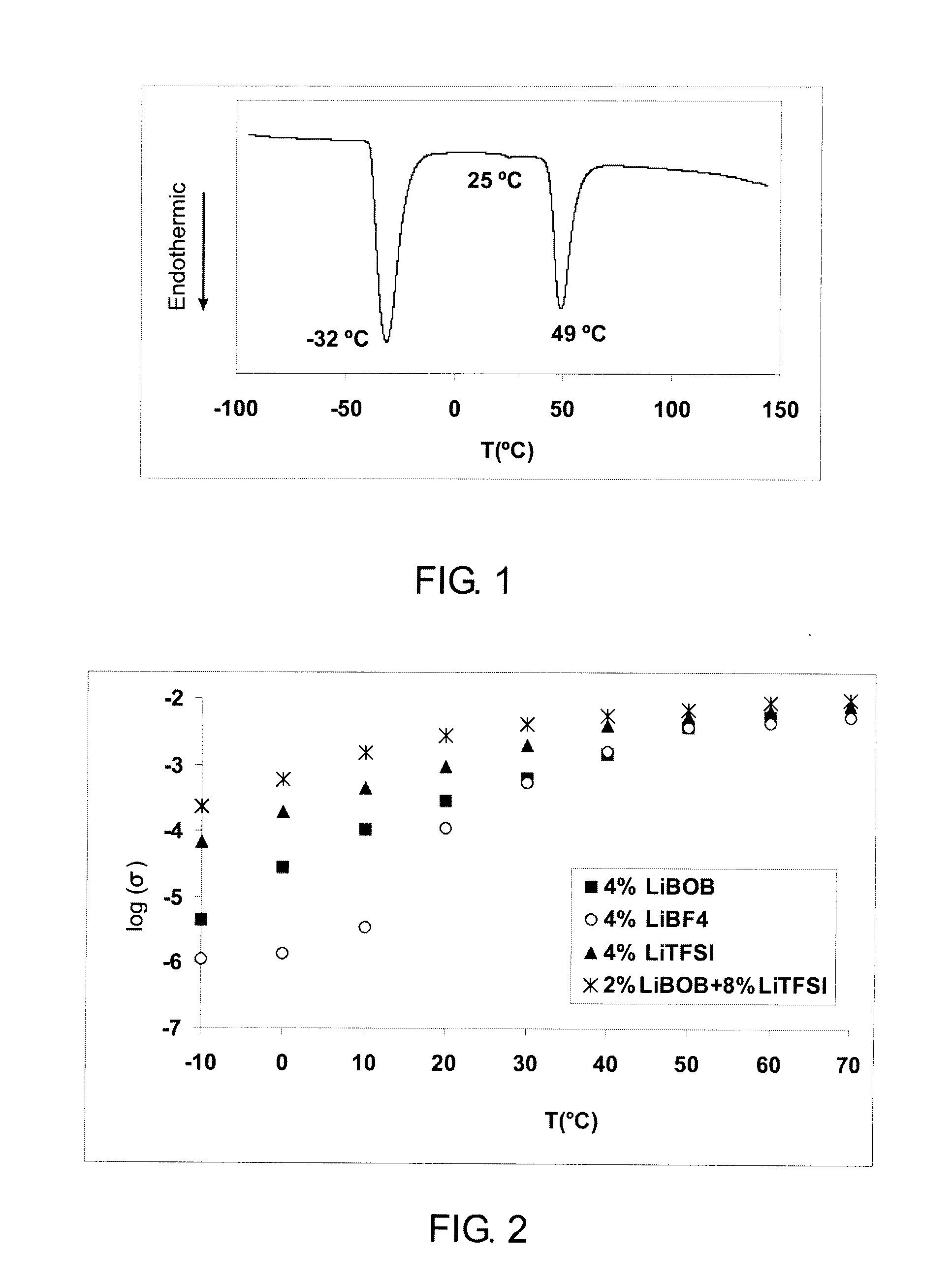

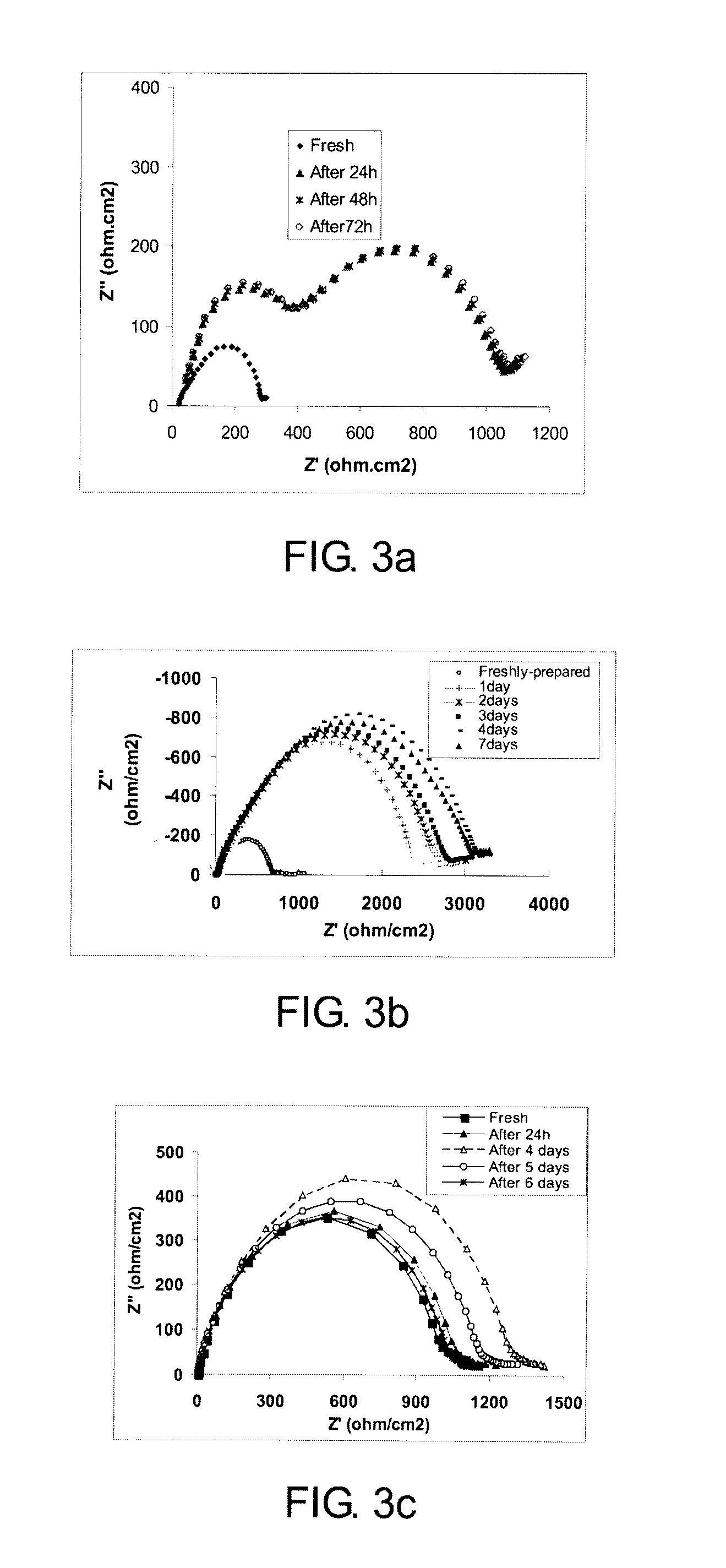

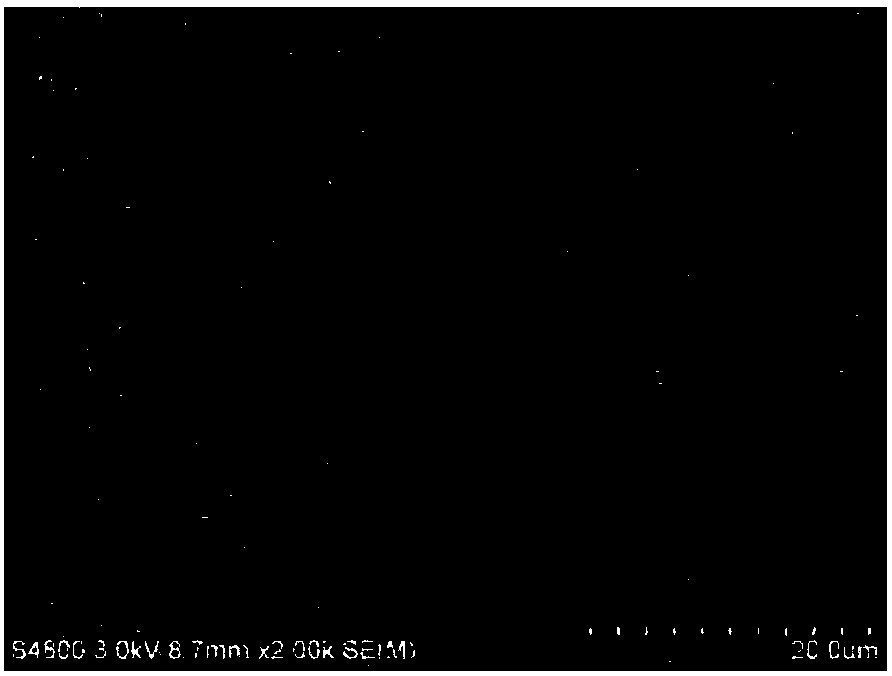

A solid ionic electrolyte having an organic plastic crystal solvent (e.g. succinonitrile) doped with lithium bioxalato borate salt (LiBOB) may be used in an electrochemical device. Electrochemical devices are disclosed having a cathode, an anode, and a solid ionic electrolyte having a neutral organic plastic crystal solvent doped with LiBOB alone or in combination with another lithium salt. Such devices have a stable electrolyte interface over a broad potential window combined with high energy density delivery capacity and, in one example, the favourable properties of a neutral organic plastic crystal matrix such as succinonitrile.

Owner:NAT RES COUNCIL OF CANADA

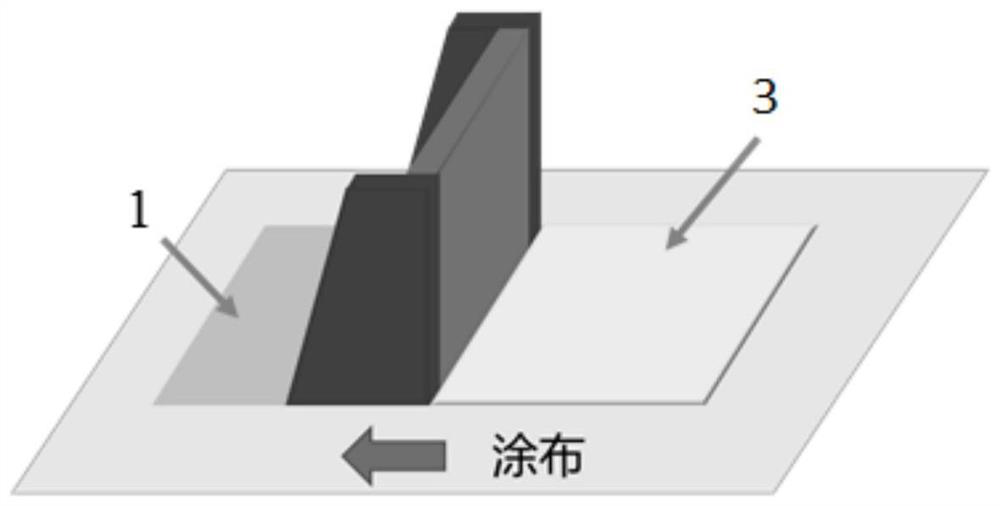

Porous membrane reinforced polymer-plastic solid electrolyte membrane, preparation method thereof and application thereof

ActiveCN110010964AImprove mechanical propertiesImprove low temperature conductivitySolid electrolytesSecondary cellsPlastic crystalPorous membrane

The invention discloses a porous membrane reinforced polymer-plastic solid electrolyte membrane, a preparation method thereof and application thereof. The polymer-plastic solid electrolyte membrane includes a support layer including a porous membrane and a polymer-plastic solid electrolyte layer covering at least one side of the surface of the porous membrane, wherein the porous membrane plays therole of a support frame and has a continuous three-dimensional network structure, the mechanical properties of the solid electrolyte membrane can be improved, and at the same time, the preparation ofa thinner solid electrolyte membrane is facilitated by the porous membrane support frame. The polymer-plastic solid electrolyte layer contains a polymer, lithium salt and a plastic crystal compound,and a porous membrane reinforced flexible polymer-plastic solid electrolyte membrane with high voltage resistance and high low-temperature conductivity can be obtained by optimizing the proportions ofthe polymer, the lithium salt and the plastic crystal. The polymer-plastic solid electrolyte membrane can be applied to an all-solid lithium-ion battery, the preparation process is simple, and the polymer-plastic solid electrolyte membrane is suitable for industrial production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

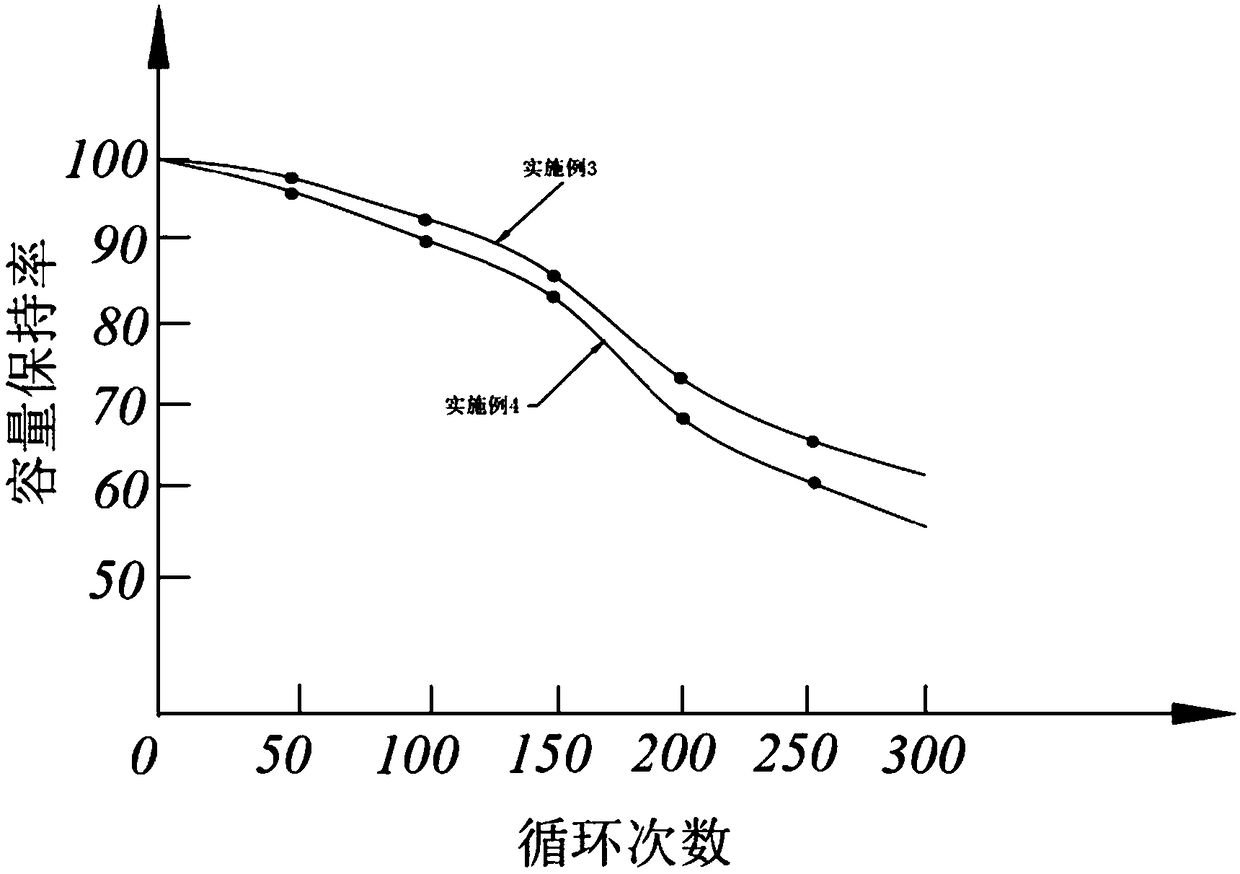

Composite solid electrolyte material, preparation method thereof, and all-solid-state battery

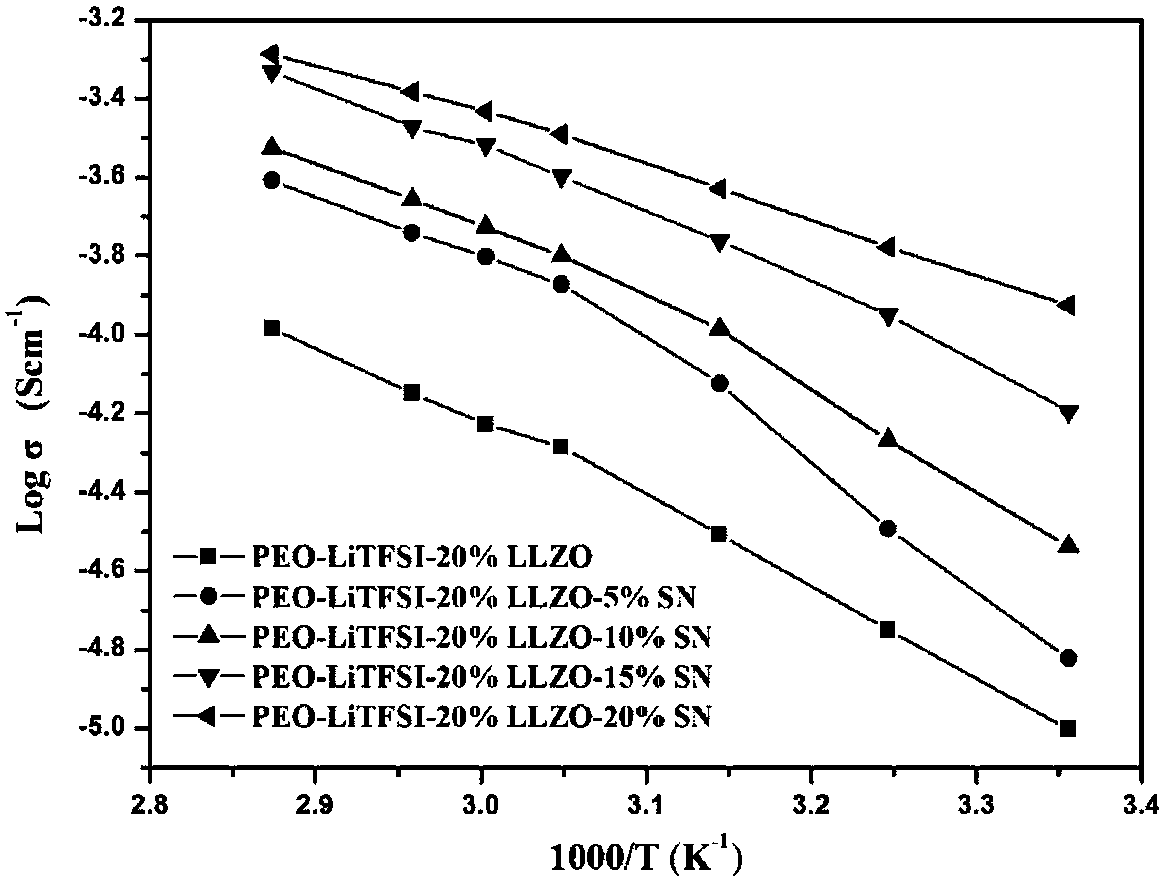

InactiveCN108963332AHigh room temperature ionic conductivityImprove electrochemical stabilitySolid electrolytesSecondary cellsAll solid stateUltrasound attenuation

The invention discloses a composite solid electrolyte material, a preparation method thereof, and an all-solid-state battery. The all-solid-state battery includes a positive electrode layer, a negative electrode layer, and the composite solid electrolyte material positioned between the positive electrode layer and the negative electrode layer. The composite solid electrolyte material includes polyoxyethylene, an inorganic powder having a high ionic conductivity, a plastic crystal compound and a lithium salt. The preparation method comprises the following steps: weighing the polyoxyethylene andthe lithium salt in proportion, adding the weighed substances to an organic solution, and performing stirring to obtain a solution A; weighing the inorganic powder and the plastic crystal compound inproportion, adding the weighed substances to the solution A, and performing stirring to obtain a uniformly mixed suspension B; and pouring the suspension B into a mold, and drying the suspension B inthe mold to obtain the organic / inorganic composite solid electrolyte material. The composite solid electrolyte material has an obviously improved room-temperature ionic conductivity and an enhanced electrochemical stability, and has a stable interface contact with a positive electrode and a negative electrode, and the capacity attenuation problem of the all-solid-state battery formed by assembling the composite solid electrolyte material is significantly improved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS +1

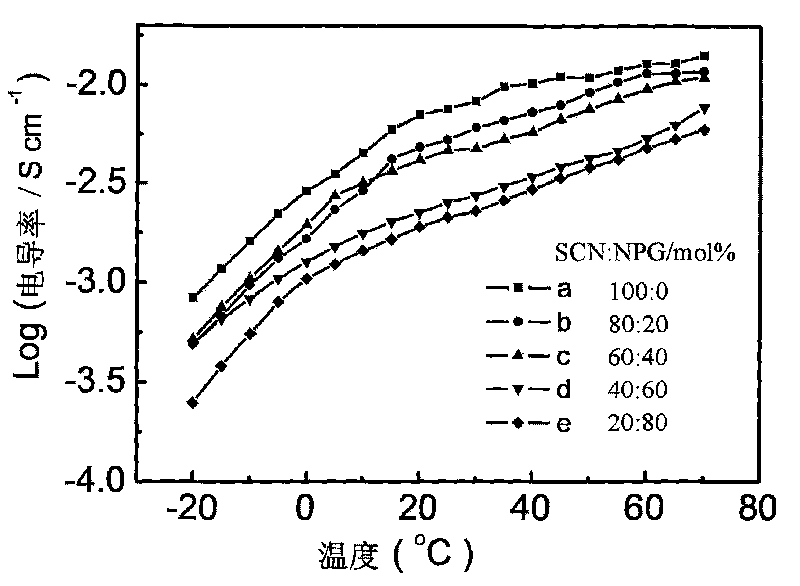

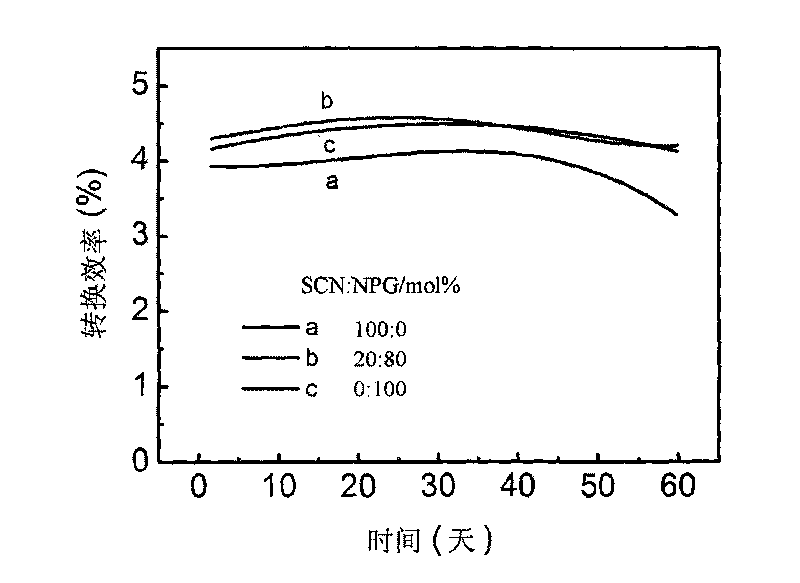

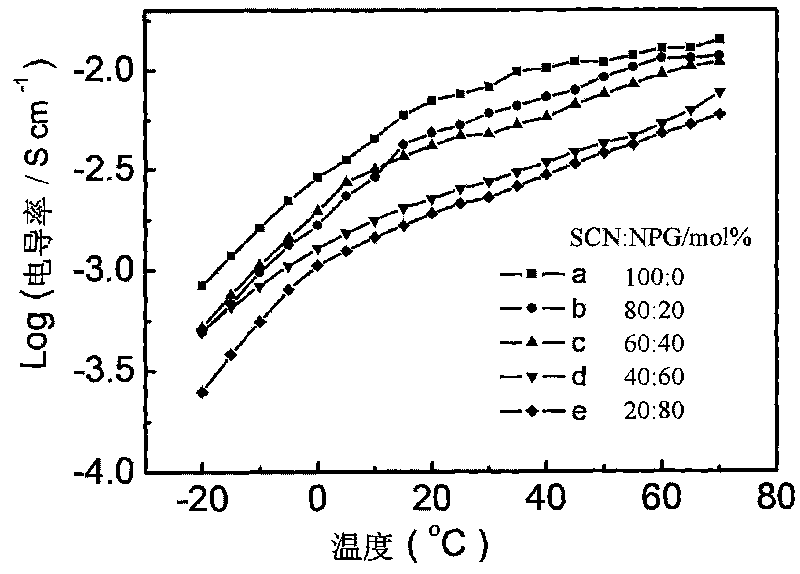

All-solid-state organic alloy electrolyte for dye-sensitized solar battery

ActiveCN101719427AWell mixedImprove photoelectric conversion efficiencyLight-sensitive devicesSolid-state devicesPlastic crystalQuaternary ammonium cation

The invention discloses an all-solid-state organic alloy electrolyte for a dye-sensitized solar battery and a preparation method thereof. The electrolyte comprises an organic alloy material prepared from more than two or three plastic crystals selected from succinonitrite, neopentyl glycol, trimethylolethane, pentaerythritol, camphor, imidazole and the derivative quaternary ammonium salt thereof and pyridine and the derivative quaternary ammonium salt thereof, iodine accounting for 1-5 percent of the amount of substance of the organic alloy, lithium iodide or potassium iodide or sodium iodide accounting for 1- 10 percent of the amount of substance of the organic alloy and one or more of methyl ethyl imidazole iodine, tert-butyl pyridine, LiTFSI and LiBF4 conducting salt, which account for 1- 10 percent of the amount of substance of the organic alloy. The prepared electrolyte has a high melting point (more than 80 DEG C) and equivalent electrical conductivity with a liquid electrolyte, and the dye-sensitized solar battery (DSSCs) prepared from the electrolyte has high photoelectric transformation efficiency and stability.

Owner:常熟紫金知识产权服务有限公司

Electrolyte for electrochemical device, method for preparing the same and electrochemical device including the same

ActiveUS20130295466A1High mechanical strengthEasy to changeSolid electrolyte cellsLi-accumulatorsPolymer sciencePlastic crystal

A solid electrolyte for an electrochemical device includes a composite of a plastic crystal matrix electrolyte doped with an ionic salt and a crosslinked polymer structure having a linear polymer as a side chain chemically bonded thereto. The linear polymer has a weight average molecular weight of 100 to 5,000 and one functional group. The electrolyte has high ionic conductivity comparable to that of a liquid electrolyte due to the use of the plastic crystal, and high mechanical strength comparable to that of a solid electrolyte due to the introduction of the crosslinked polymer structure. A method for preparing the solid electrolyte does not essentially require the use of a solvent, eliminating the need for drying. The electrolyte is suitable for use in a cable-type battery whose shape is easy to change due to its high ionic conductivity and high mechanical strength comparable to that of a solid electrolyte.

Owner:LG ENERGY SOLUTION LTD

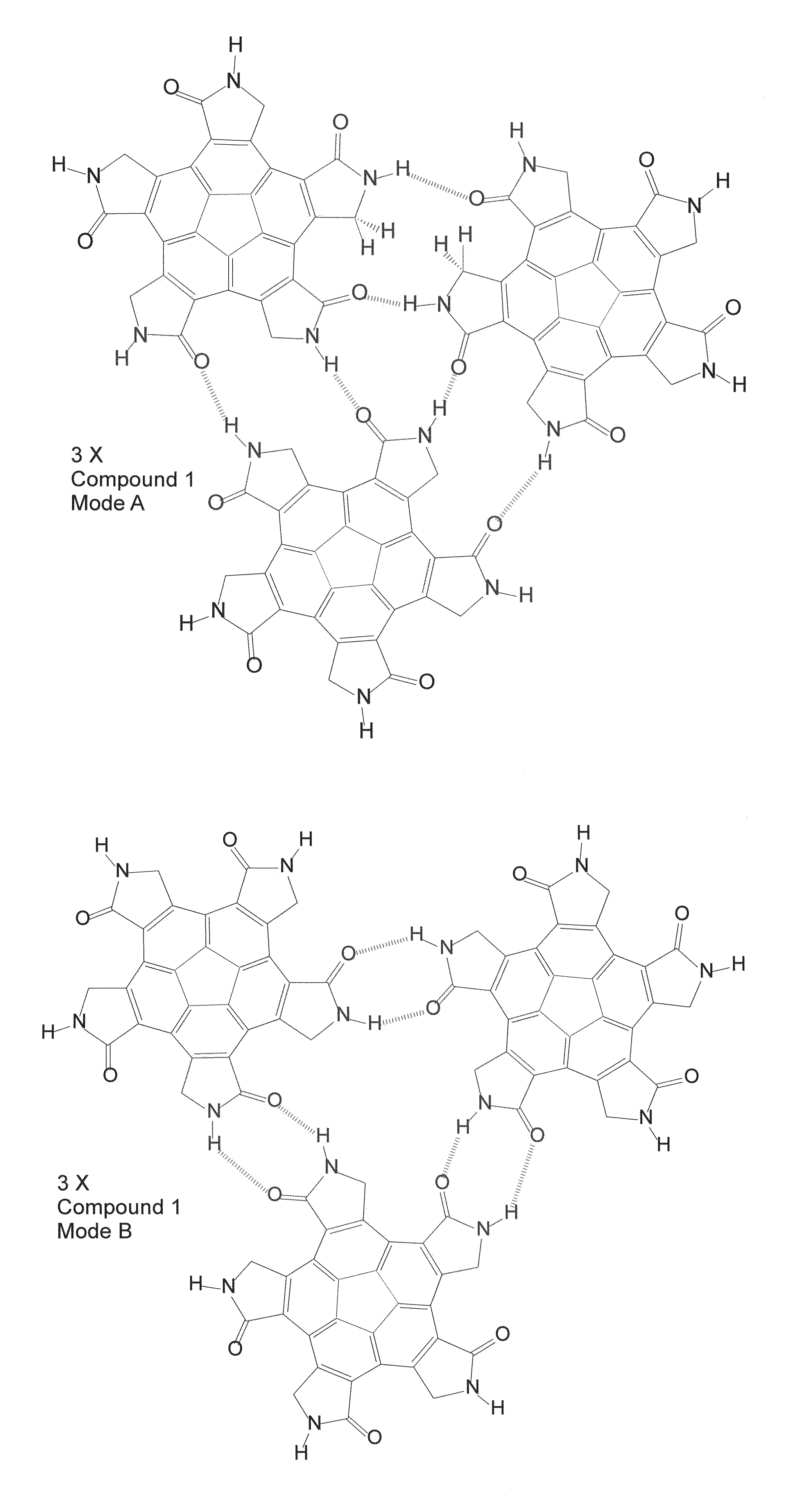

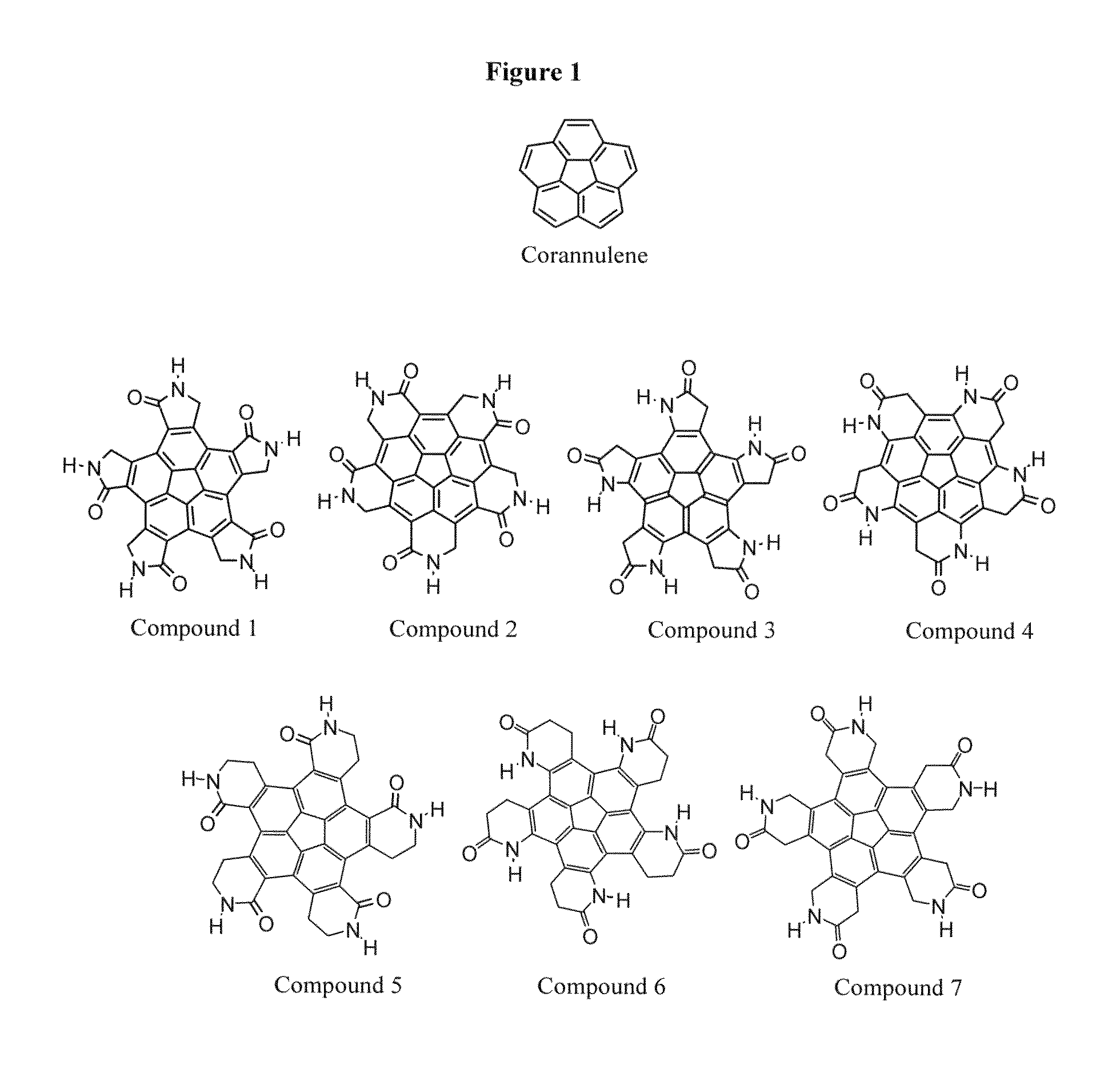

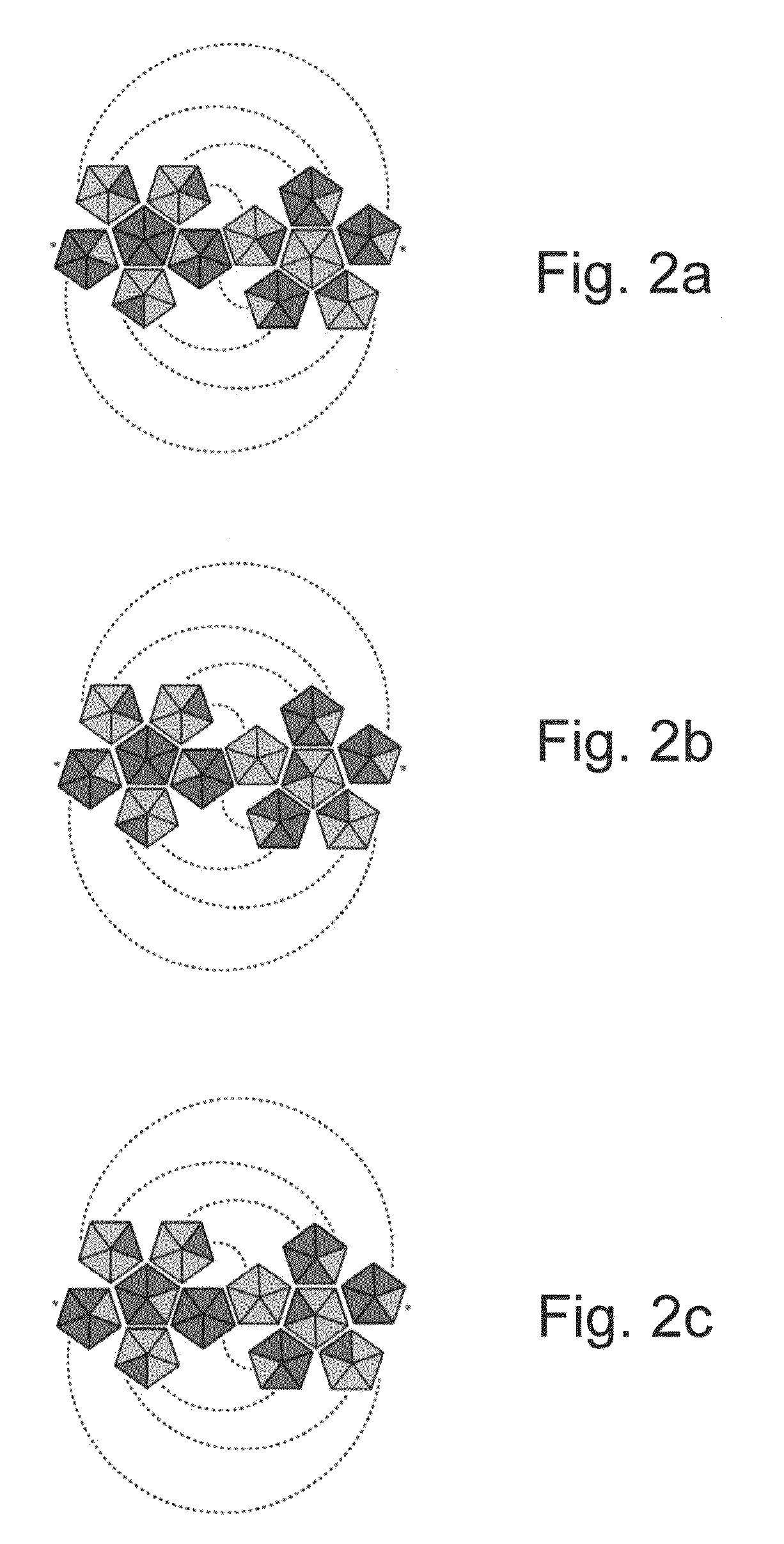

Self-assembled polyhedral multimeric chemical structures

Self-assembled, closed and hollow chemical multimer structures having a dodecahedral morphology, composed of chemical monomers having a structurally symmetric core which possess a 5-fold rotational symmetry, are provided. Also provided are methods of creating such chemical monomers, methods of creating such chemical multimer structures and compositions comprising these chemical multimer structures. Also provided are uses of these chemical multimer structures in applications such as drug delivery, imaging, immunization, formation of plastic crystals and nanoparticle matrices and other medical and material science applications.

Owner:TECHNION RES & DEV FOUND LTD

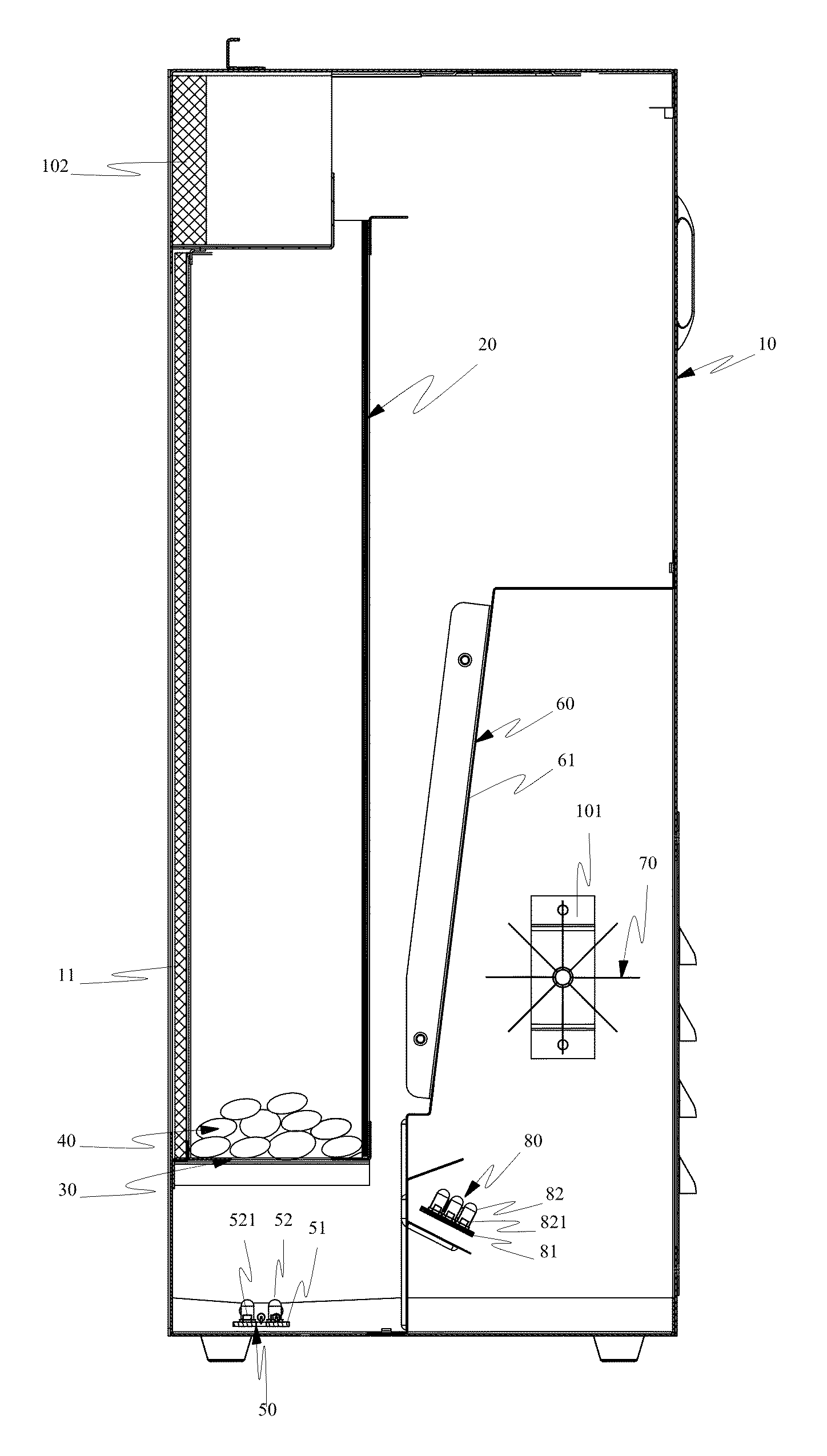

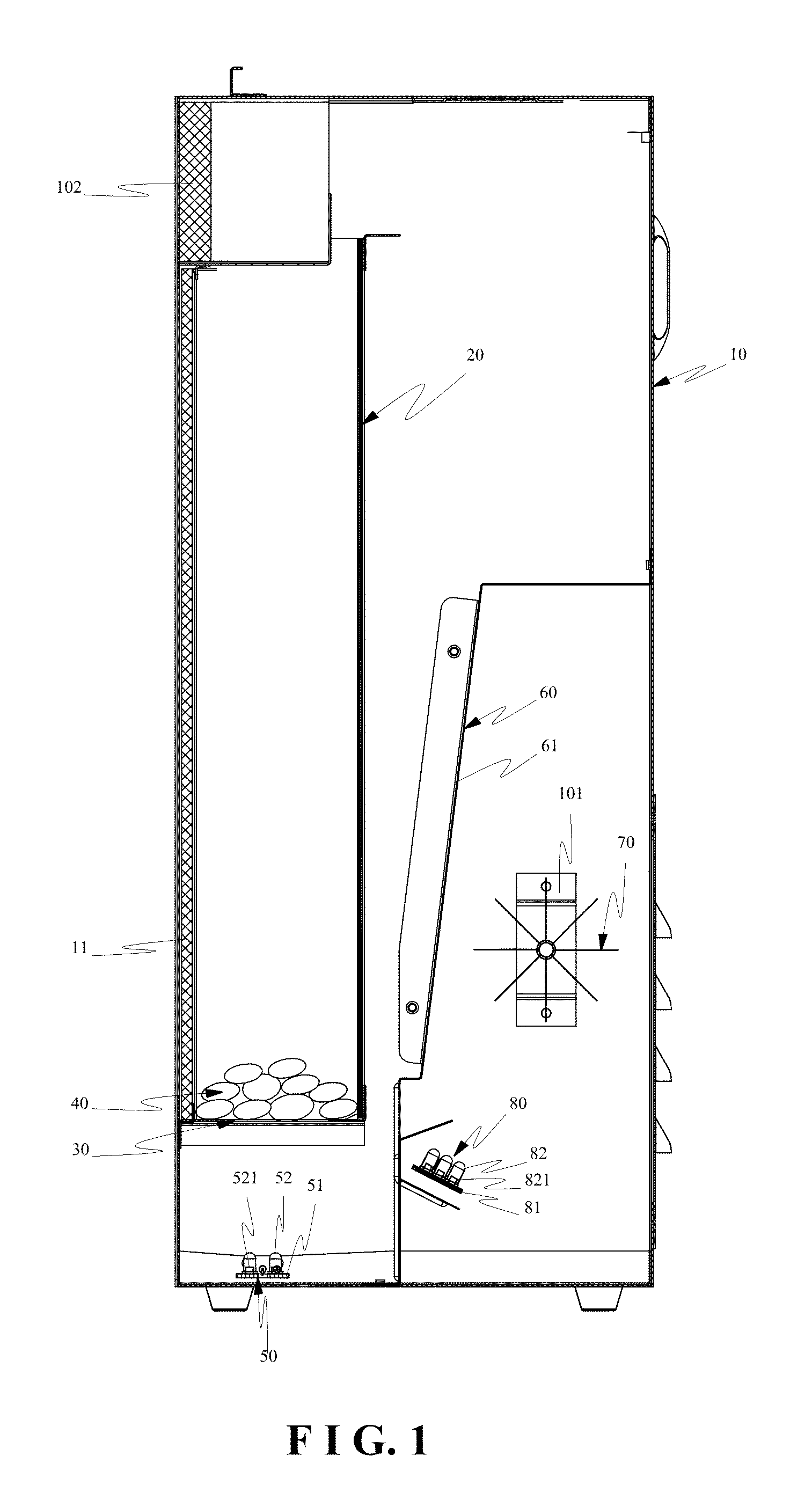

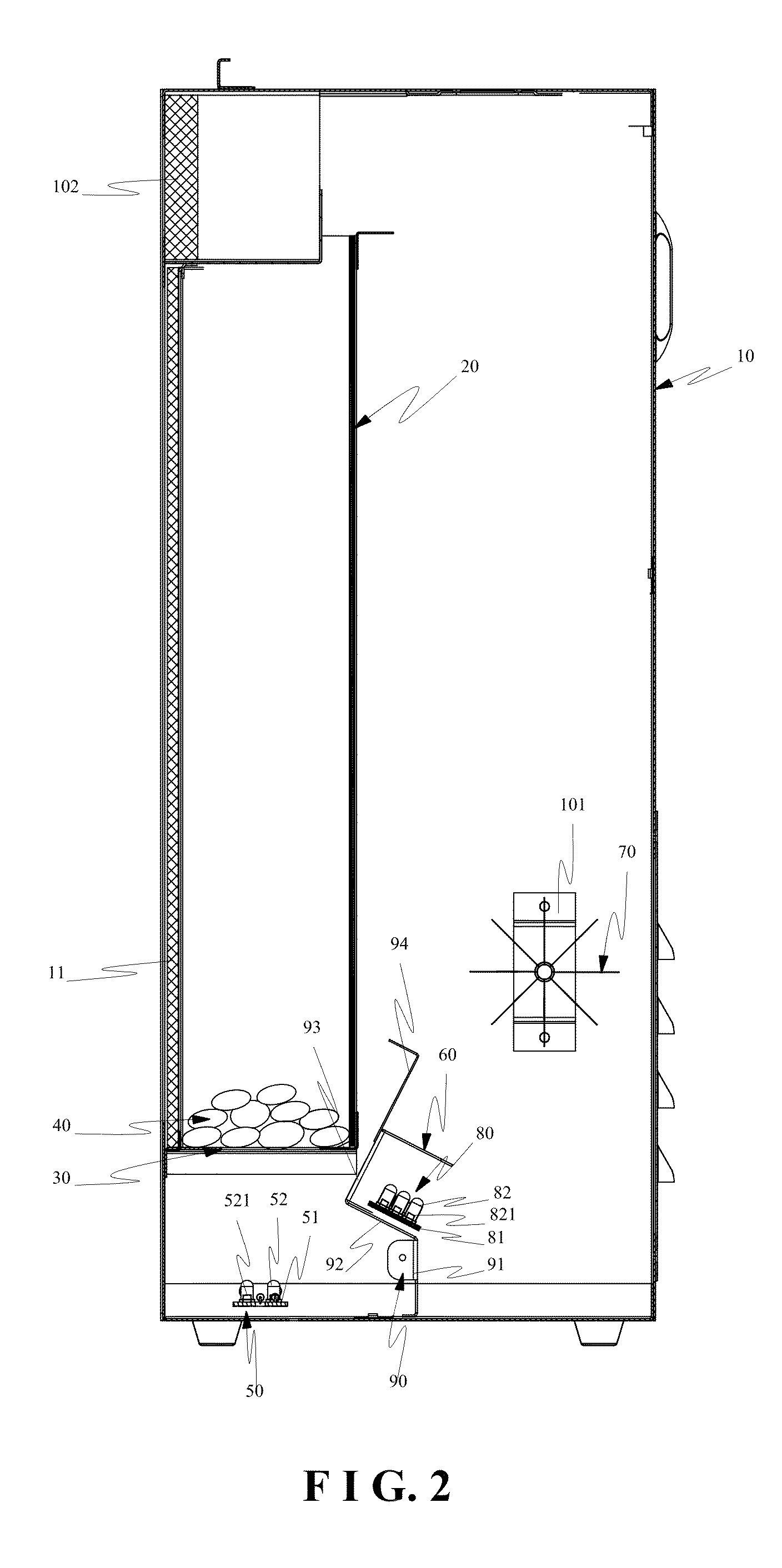

Electric fireplace having multi-function flame

ActiveUS20150338105A1Improve the quality of lifeSignificant comprehensive benefitsDomestic stoves or rangesElectrical heating fuelElectricityPlastic crystal

An electric fireplace having multi-function flame includes a housing, a projection screen, a plastic screen, plastic crystals, a first illuminating device, a flame image plate, a reflection assembly, and a second illuminating device. The first illuminating device can shoot a single color or two colors or a combination of more than two colors of light. The second illuminating device includes a plurality of second lights disposed on a second circuit board. Each of the second lights includes at least two different chips. The second illuminating device can shoot a single color or two colors or a combination of more than two colors of light. The present invention can generate single or multi-color flame to achieve a multi-function purpose. The change effect of the movement and color of the flame can be more perfect and realistic and appreciation.

Owner:LU MIN HSUN

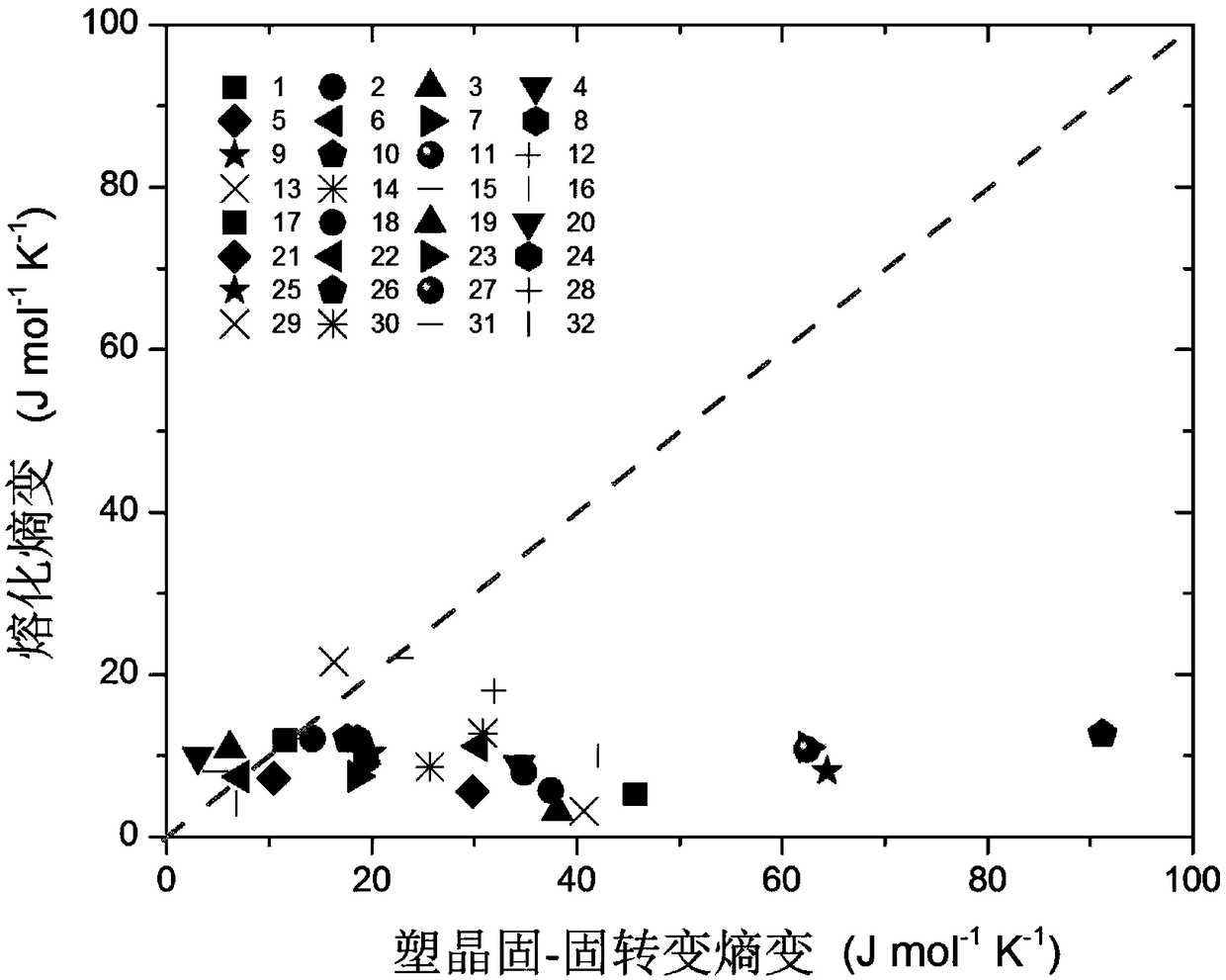

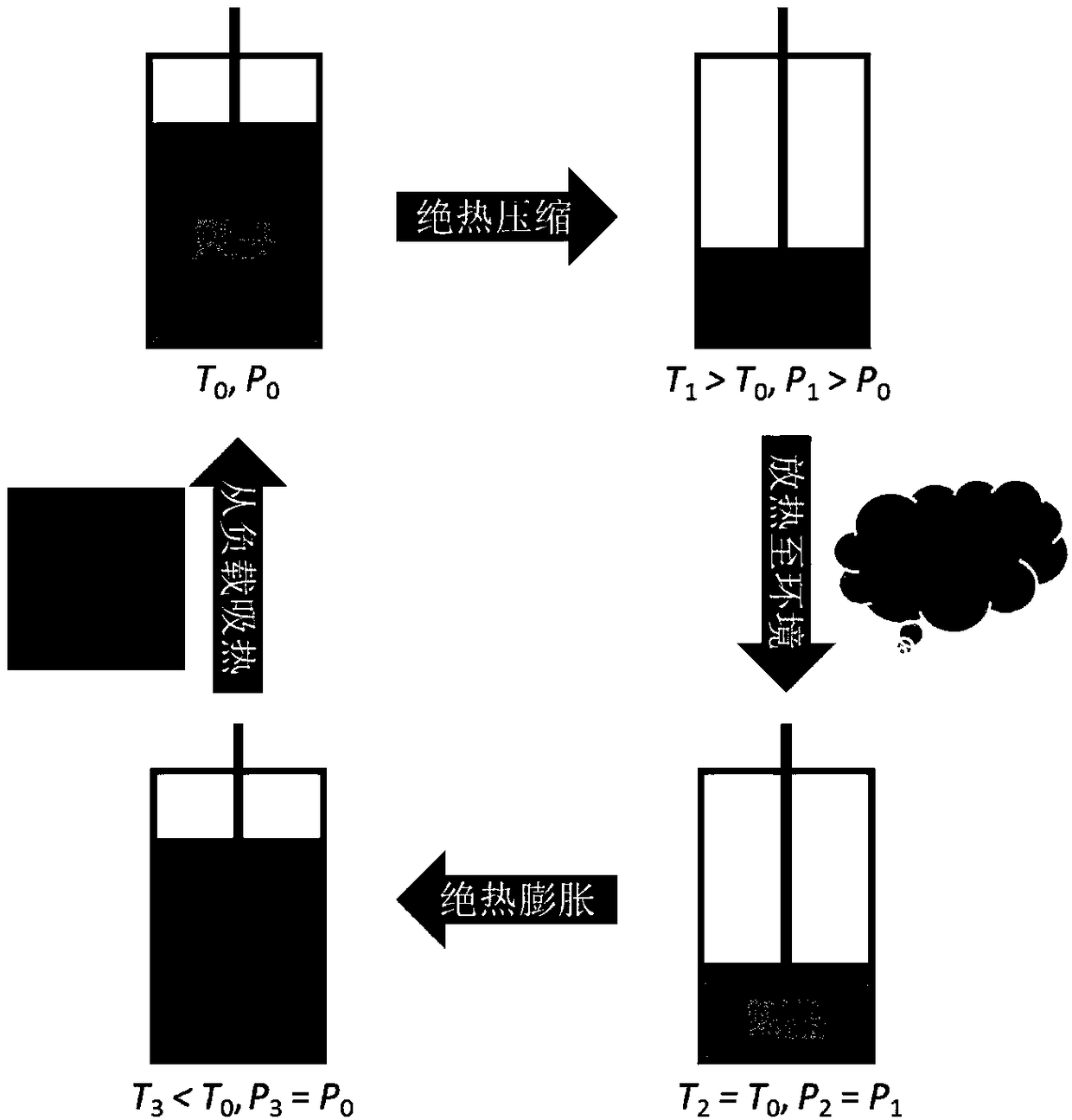

Solid-state refrigeration method based on static-pressure driving of plastic crystal materials

InactiveCN109140821AReduce driving pressureImprove compatibilityRefrigeration machinesPlastic crystalThermal insulation

The invention provides a novel efficient solid-state refrigeration method driven by pressure of plastic crystal materials. Plastic crystals are orientation ordered-unordered transformed organic molecular crystals or inorganical crystals with molecules or structural units. The plastic crystals are transformed in a solid state by a two-step melting process along with entropy change and enthalpy change comparable to the melting process. The phase change can be induced by lower pressure to generate huge pressure clamping effect. Taking the plastic crystal materials-neopentyl glycol as an example,the thermal insulation temperature change of 9 K is generated under the pressure of 20 MPa to achieve higher advantage compared with other pressure clamping effect material systems.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Thermoplastic monofilament fibers exhibiting low-shrink, high tenacity, and extrimely high modulus levels

Unique thermoplastic monofilament fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than any other previously produced thermoplastic fibers, particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

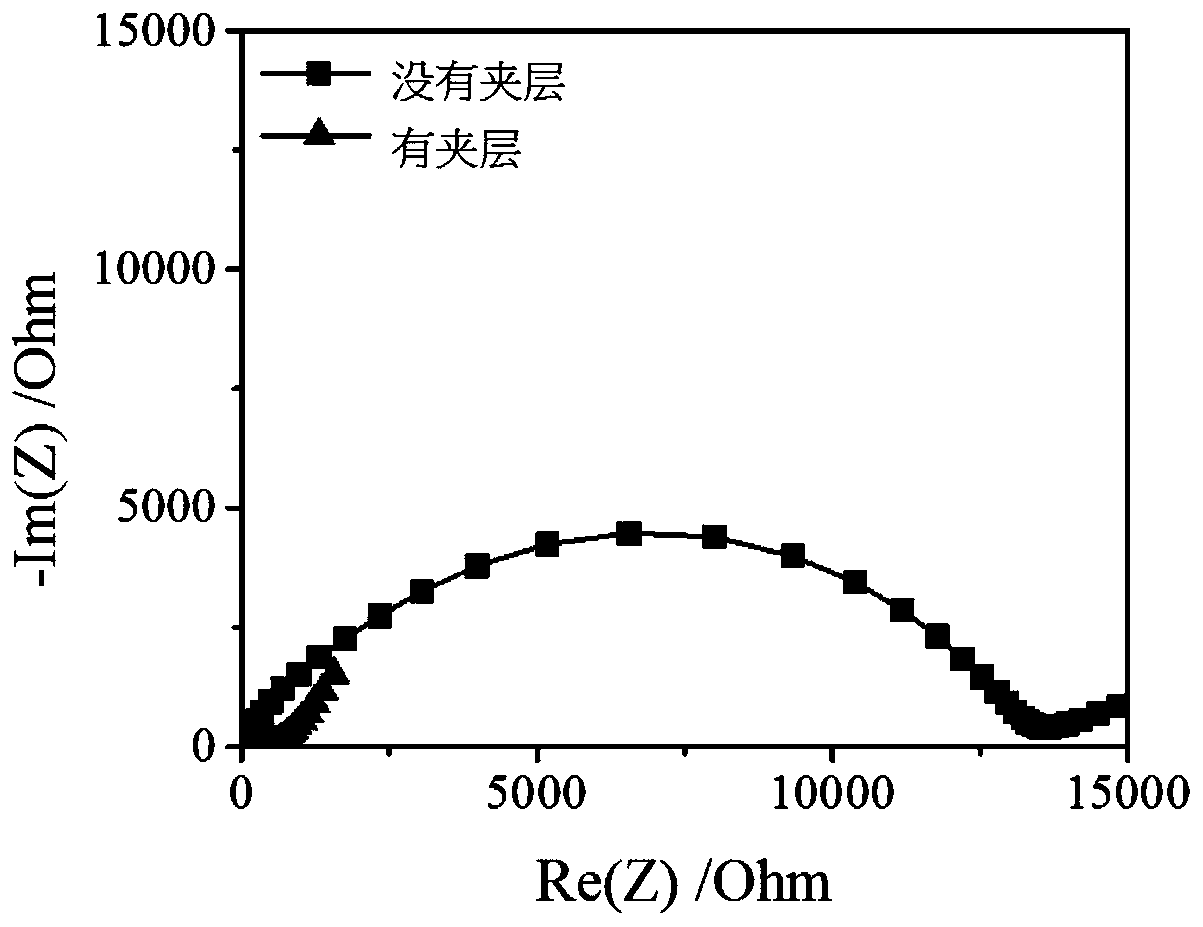

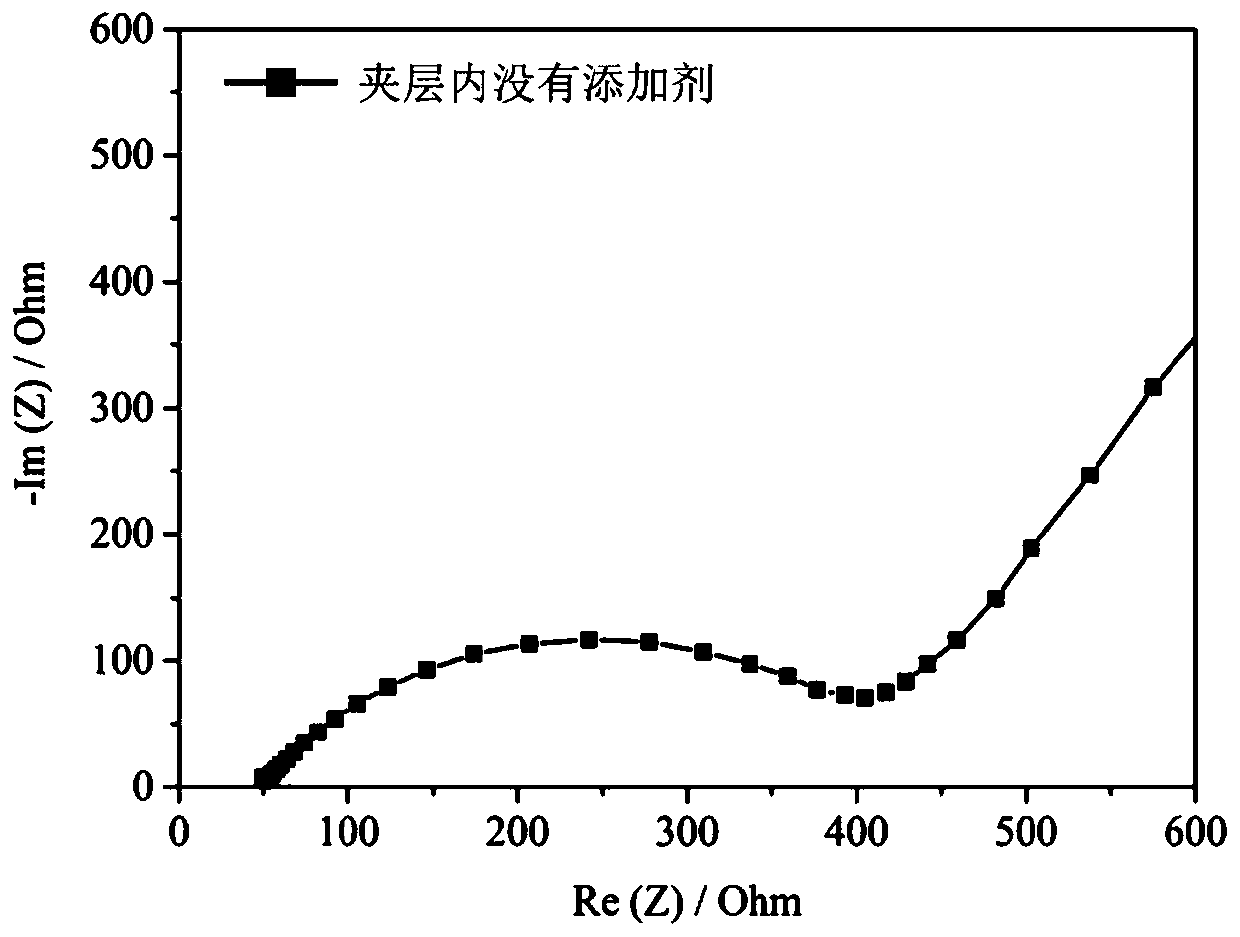

Solid-state electrochemical component, solid-state electrochemical device and preparation method of solid-state electrochemical component

ActiveCN110581303ASolid electrolytesHybrid capacitor electrolytesSolid state electrolytePlastic crystal

The invention provides a solid-state electrochemical component, a solid-state electrochemical device and a preparation method of the solid-state electrochemical component. The solid-state electrochemical assembly includes a solid-state electrochemical functional layer and a plastic crystal interlayer in physical contact with the solid-state electrochemical functional layer, the plastic crystal interlayer including a plastic crystal matrix and an ion conductive compound and an additive dispersed in the plastic crystal matrix. The assembly, the solid-state electrochemical device, and the methodof preparing the same of the present invention improve interface resistance between an electrode and a solid-state electrolyte.

Owner:THE HONG KONG UNIV OF SCI & TECH

Solid-state electrolyte applied to lithium battery and preparation method of solid-state electrolyte

InactiveCN108199081AImprove ionic conductivityImprove stabilitySecondary cellsSolid state electrolytePlastic crystal

The invention discloses a solid-state electrolyte applied to a lithium battery and a preparation method of the solid-state electrolyte. The solid-state electrolyte at least comprises trihydroxymethylpropane trimethyl acrylate (TMPTMA), a plastic crystal and a lithium salt. The plastic crystal is used as the solid-state electrolyte of a substrate, the lithium salt can be dissociated by high polarity and high diffusion performance of a plastic crystal phase, and the prepared solid-state electrolyte is enabled to have relatively high ion conductivity and electrochemical window stability; and bycombination of a polymer and the plastic crystal, the film formation performance and the mechanical strength of the solid-state electrolyte can be improved, the plastic crystal also have an effect ofa plasticizer, and the solid-state electrolyte is enabled to have relatively high ion conductivity when the plastic crystal is wrapped in holes of the polymer.

Owner:SUZHOU FLUOLYTE

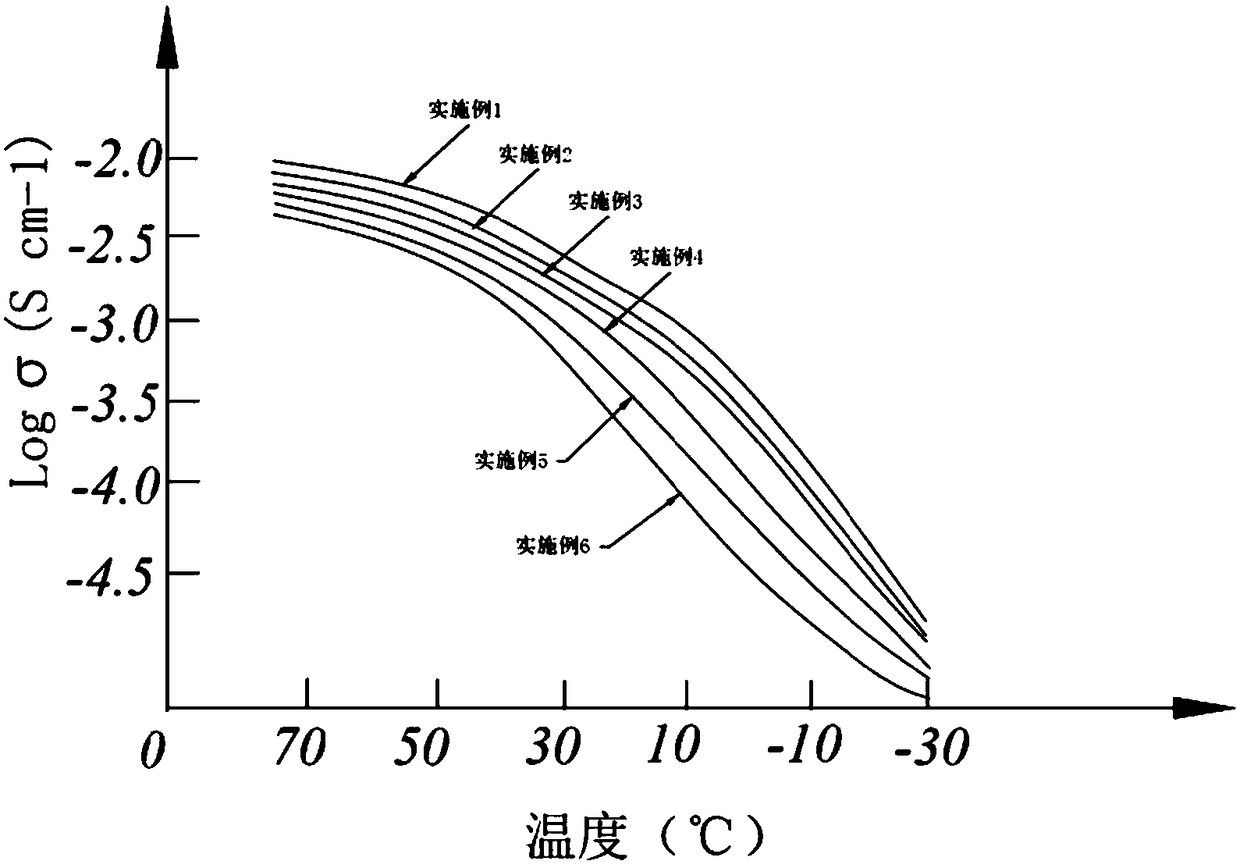

Polymer film electrolyte of all-solid-state lithium metal battery, preparation method of polymer film electrolyte, and application of polymer film electrolyte in wide temperature range

InactiveCN110165296AImprove ionic conductivitySimple preparation processSecondary cellsElectrolytesPolymer sciencePlastic crystal

The invention discloses a polymer film electrolyte of an all-solid-state lithium metal battery, a preparation method of the polymer film electrolyte, and an application of the polymer film electrolytein a wide temperature range, and belongs to the technical field of all-solid-state electrolytes. The polymer film is composed of polyethylene oxide, a plastic crystal material and lithium salt. The polymer film has the characteristics of high ionic conductivity and wide electrochemical stability window. The all-solid-state lithium metal battery using the polymer film as the electrolyte has high capacity in a wide temperature range (-5 DEG C to 100 DEG C). The method is simple in technological process and compatible with an existing technology, the production and matching processes of the solid-state lithium metal battery can be effectively simplified, the battery performance is improved, and therefore, the method has great application prospects.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

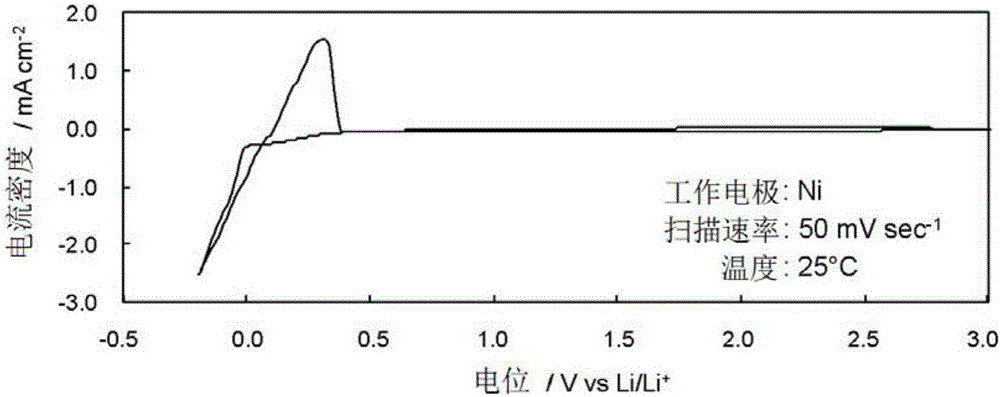

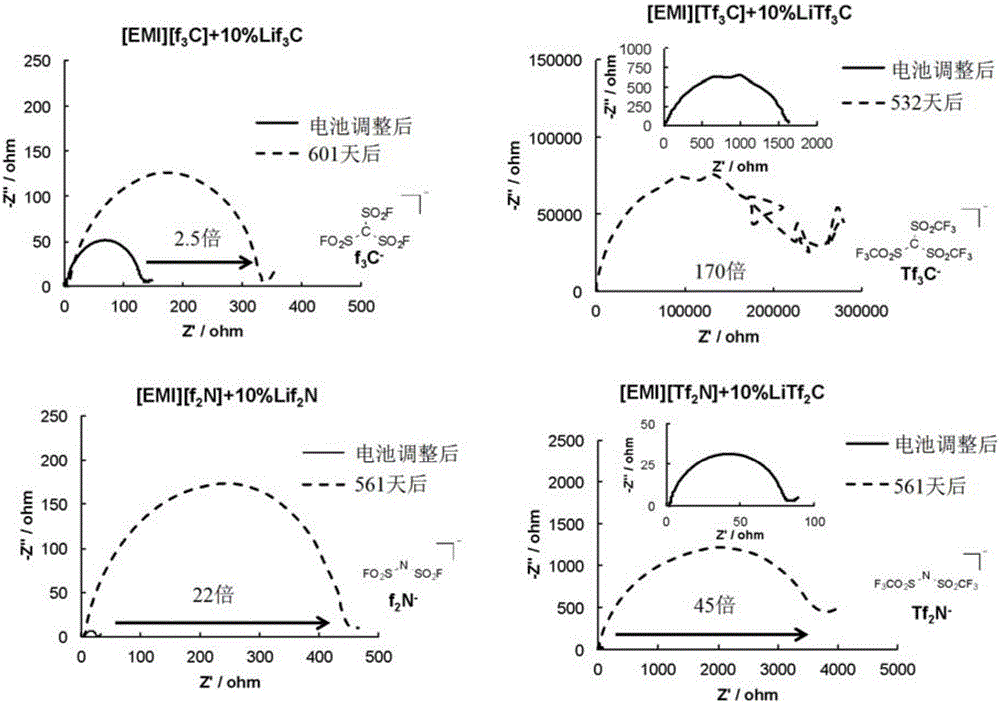

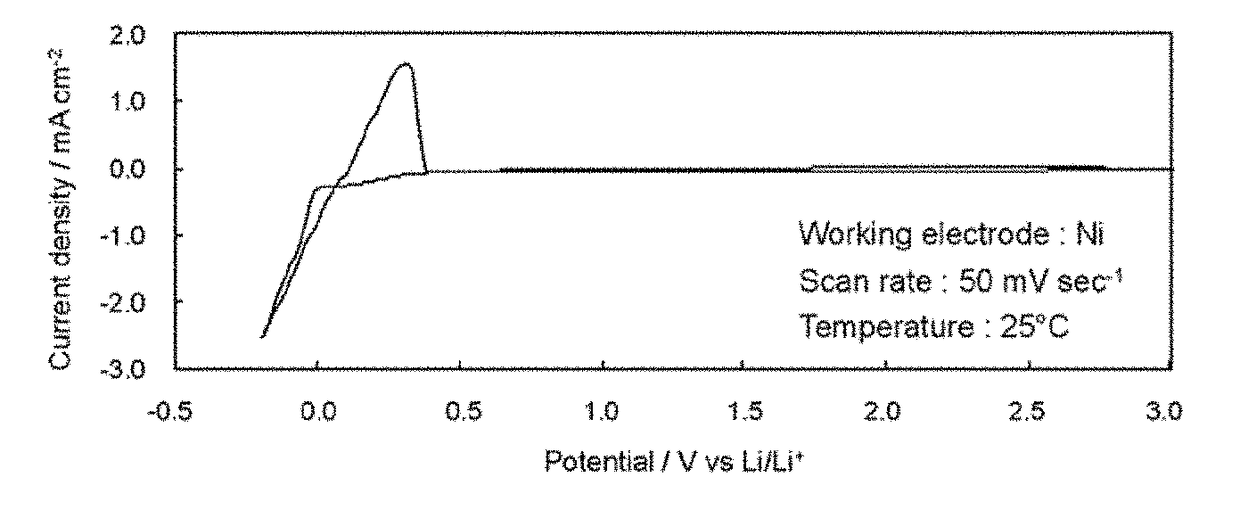

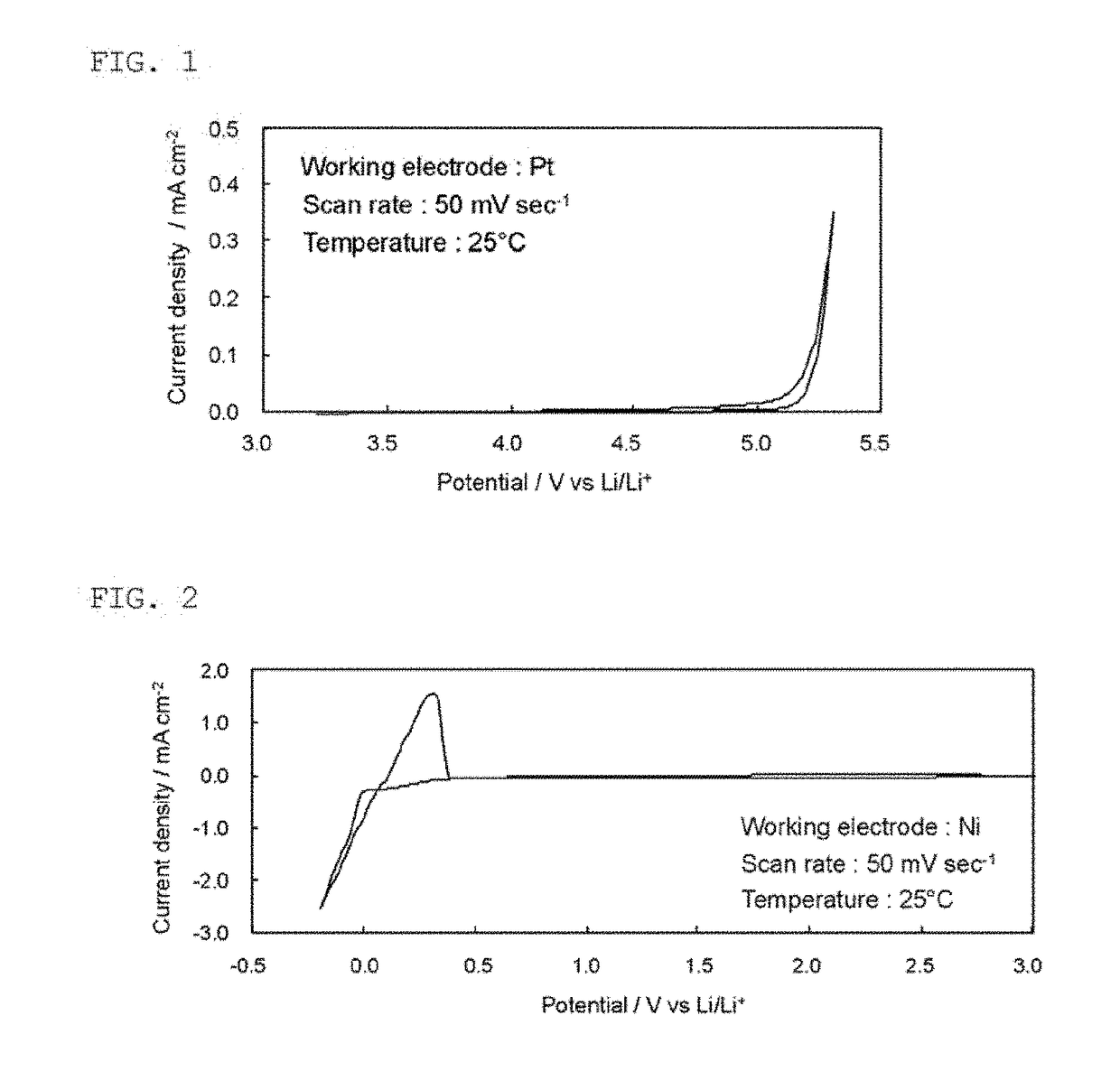

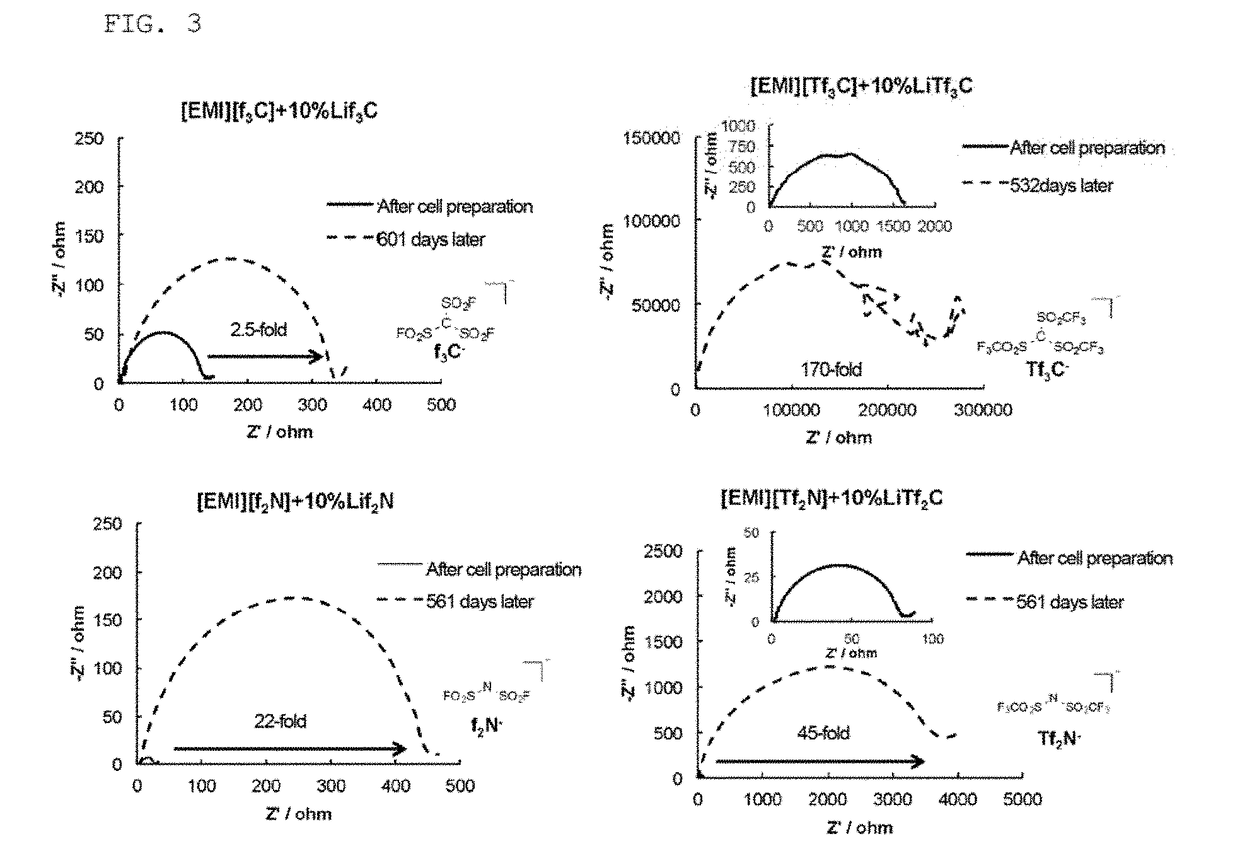

Ionic liquid and plastic crystal

ActiveCN106715389AInhibit the need for coolingGood storage efficiencyOrganic chemistryNegative electrodes1-hexyl-3-methylimidazoliumPlastic crystal

The present invention provides an ionic liquid or plastic crystal comprising anions and cations, said anions including [C(SO2F)3]- and said cations including at least one type selected from the group consisting of 1-ethyl-3-methylimidazolium ([EMI]+), N,N-diethyl-N-methyl-(2-methoxyethyl ) ammonium ([DEME]+), N-methyl-N-propylpyrrolidinium ([Py13]+), N-methyl-N-propylpiperidinium ([PP13]+), tetramethylammonium ([N1111]+), tetraethylammonium ([N2222]+), triimethyl hexyl ammonium ([N6111]+), triethylhexylammonium ([N6222]+), N-methyl-N-ethylpyrrolidinium ([Py12]+), 1-butyl-3-methylimidazolium ([C4mim]+), and 1-hexyl-3-methylimidazolium ([C6mim]+).

Owner:NAT INST OF ADVANCED IND SCI & TECH

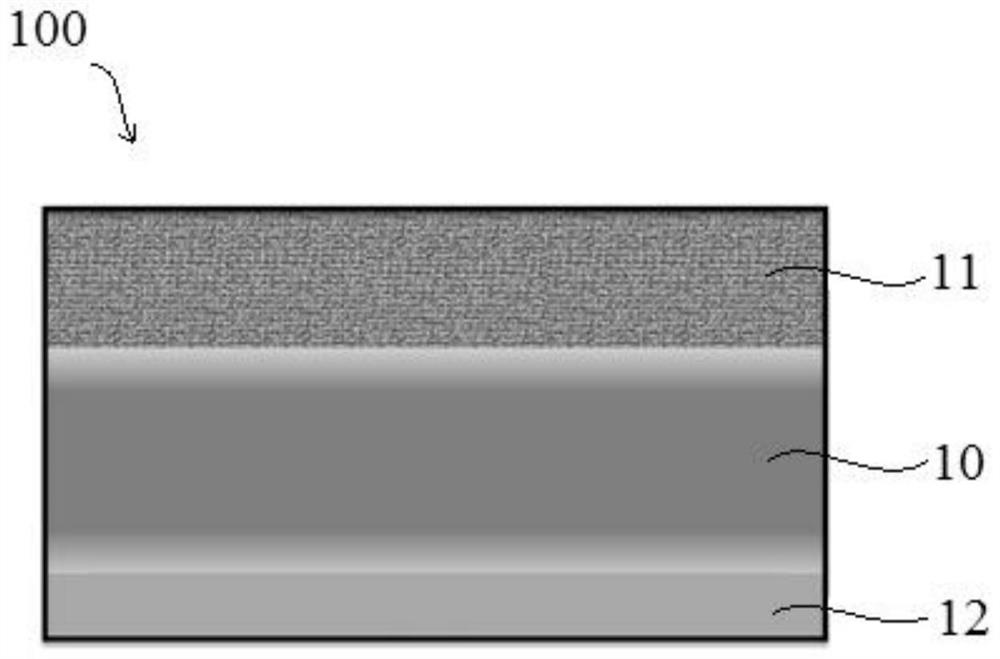

Solid composite electrolyte membrane, manufacturing method thereof and polymer secondary battery

PendingCN111864258AImprove conductivityIncrease contactSecondary cells servicing/maintenanceElectrolyte immobilisation/gelificationPolymer electrolytesComposite electrolyte

The invention provides a solid composite electrolyte membrane, which is composed of a solid polymer electrolyte layer (1) serving as a main body and gel polymer electrolyte layers (2, 3) arranged on the surfaces of the two sides of the solid polymer electrolyte layer (1) respectively, wherein the solid polymer electrolyte layer (1) and the gel polymer electrolyte layers (2, 3) are prepared from apolymer electrolyte composition containing a polymer, a plastic crystal and an electrolyte salt, and the concentration of the electrolyte salt in the solid polymer electrolyte layer (1) is lower thanthe concentration of the electrolyte salt in the gel polymer electrolyte layers (2, 3). According to the solid-state composite electrolyte membrane, the conductivity of a polymer-electrolyte salt system can be improved by several orders of magnitudes, a battery containing the solid-state composite electrolyte membrane can normally operate at room temperature, the contact between a polymer electrolyte and an electrode can be effectively enhanced, and the interface impedance is reduced.

Owner:RESONAC CORP +1

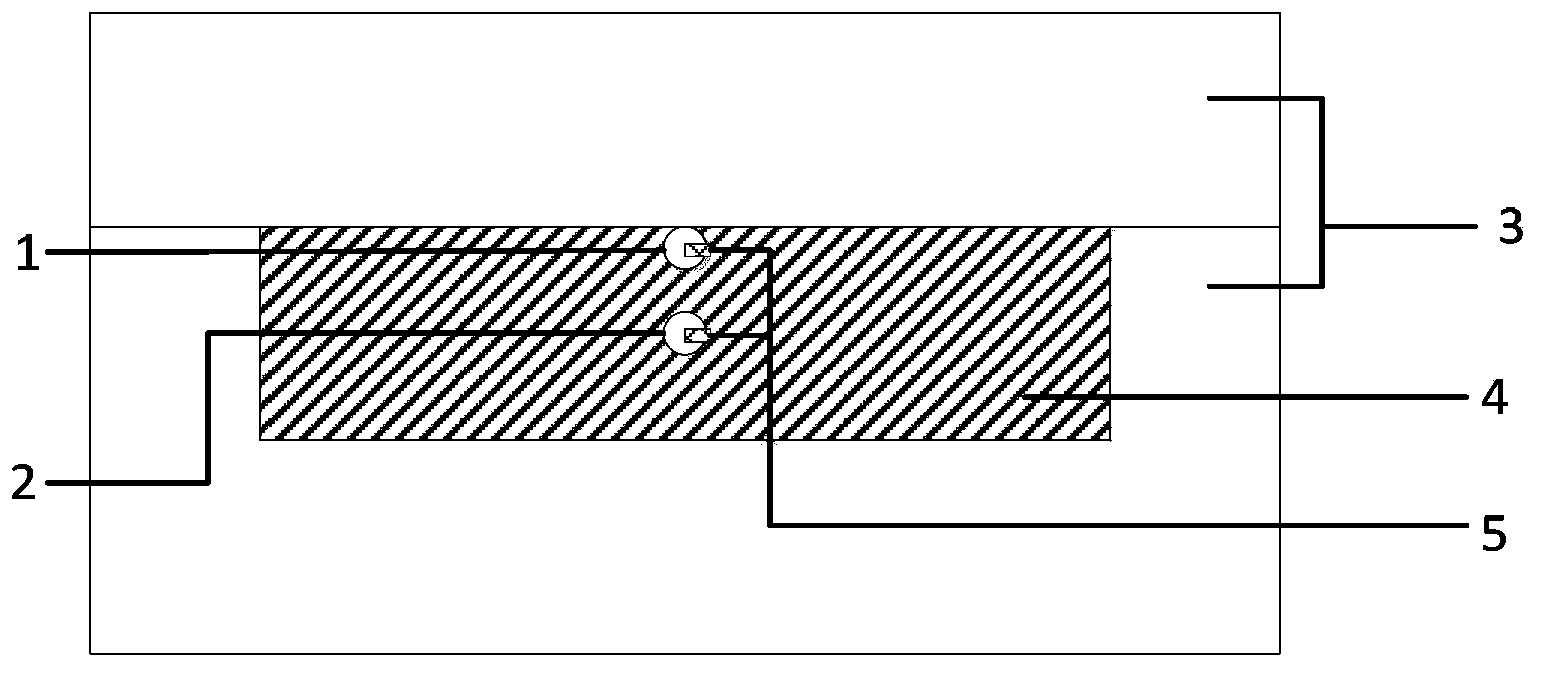

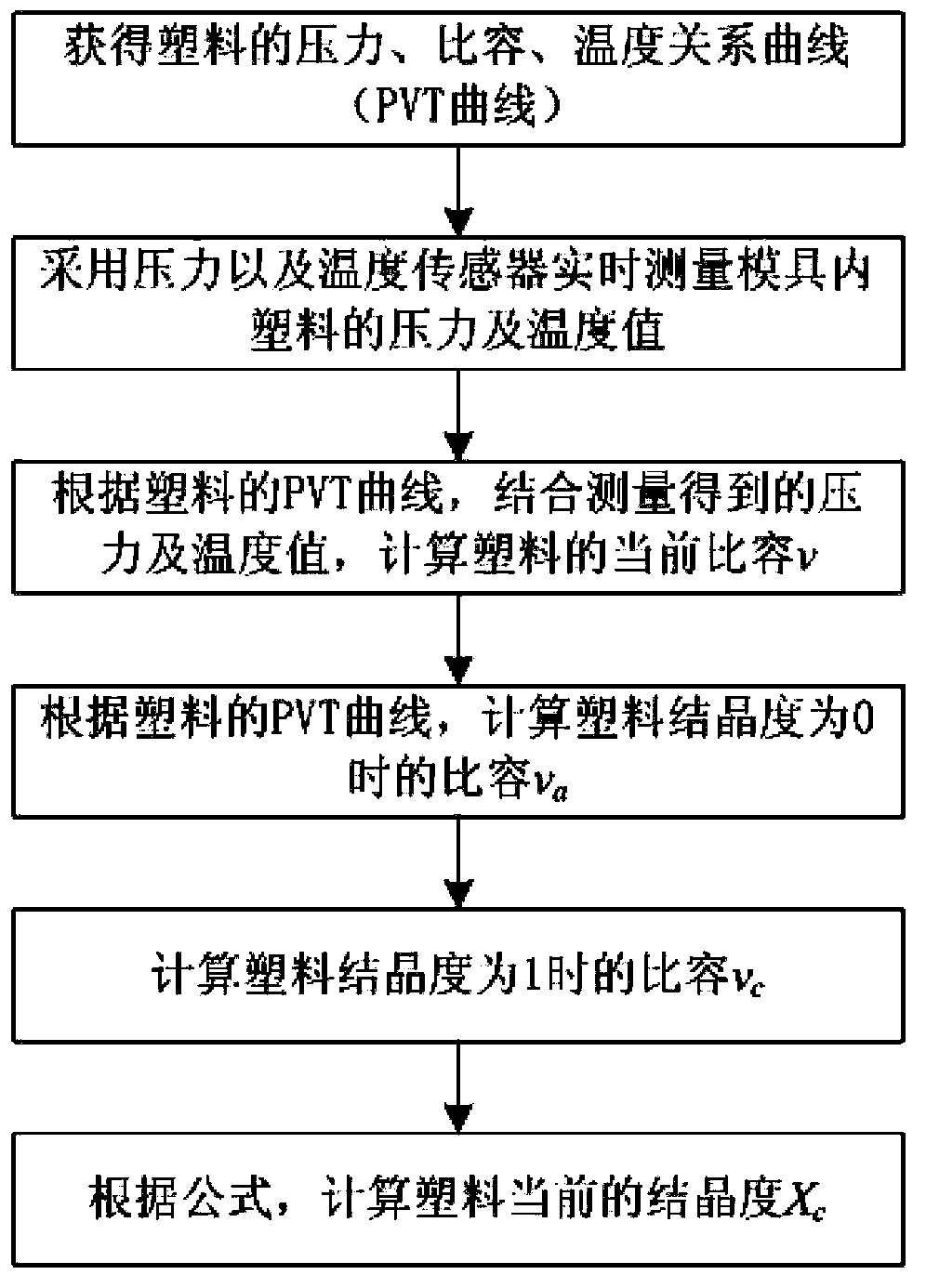

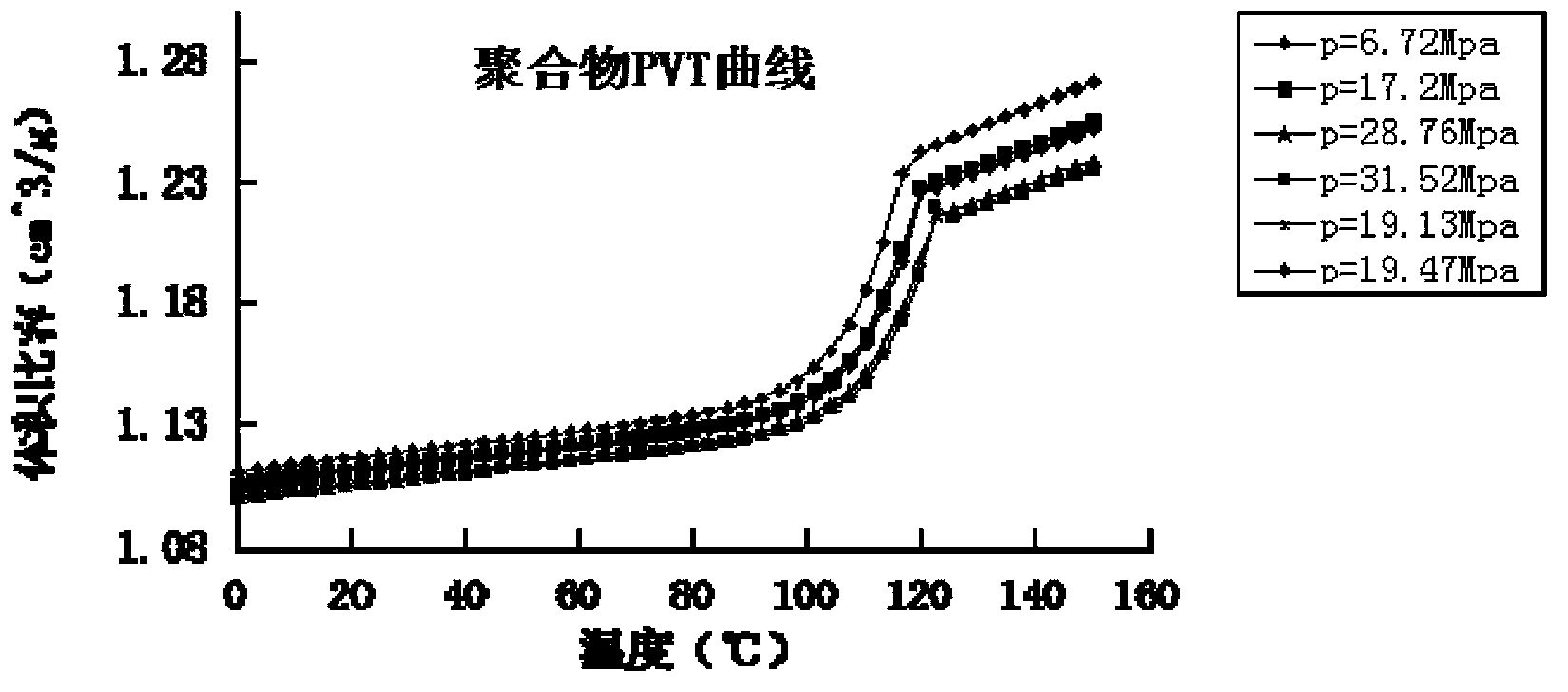

On-line plastic crystallinity measuring method based on pressure sensor and temperature sensor

ActiveCN103358511ALow priceSolving problems that can only be measured offlinePlastic crystalSpecific volume

The invention discloses an on-line plastic crystallinity measuring method based on a pressure sensor and a temperature sensor. The on-line measuring method comprises the following steps of: (1) constructing a relation curve of the pressure, specific volume and temperature of plastic, namely a PVT curve; (2) measuring pressure and temperature values of the plastic in a mould in real time by utilizing the pressure sensor and the temperature sensor; (3) calculating the current specific volume v of the plastic according to the PVT curve in combination with the pressure and temperature values measured in real time; (4) calculating the specific volume va when the plastic crystallinity is 0 and the specific volume vc when the plastic crystallinity is 1 according to the PVT curve; (5) calculating the current crystallinity Xc of the plastic. Through the on-line measurement of the crystallinity by using the temperature sensor and the pressure sensor, the invention provides a new universal method for on-line measurement on the plastic crystallinity which is low in price, easy to operate, high in precision and wide in application range, and can be used for solving the difficult problem that the plastic crystal morphology generally only can be measured off-line.

Owner:ZHEJIANG UNIV

Solid electrolyte, preparation method thereof and lithium ion battery

InactiveCN111554975AGuaranteed StrengthHigh mechanical strengthSecondary cellsElectrolyte immobilisation/gelificationPolymer electrolytesSolid state electrolyte

The invention provides a solid electrolyte, a preparation method thereof and a lithium ion battery. The solid electrolyte comprises a polymer electrolyte framework and a plastic crystal electrolyte atleast filled in the polymer electrolyte framework, wherein the composition of the polymer electrolyte framework comprises a polymer and a lithium salt. The solid electrolyte has excellent conductivity and mechanical strength, and after the solid electrolyte is applied to the lithium ion battery, the cycle life of the lithium ion battery can be remarkably prolonged.

Owner:ZHUHAI COSMX BATTERY CO LTD

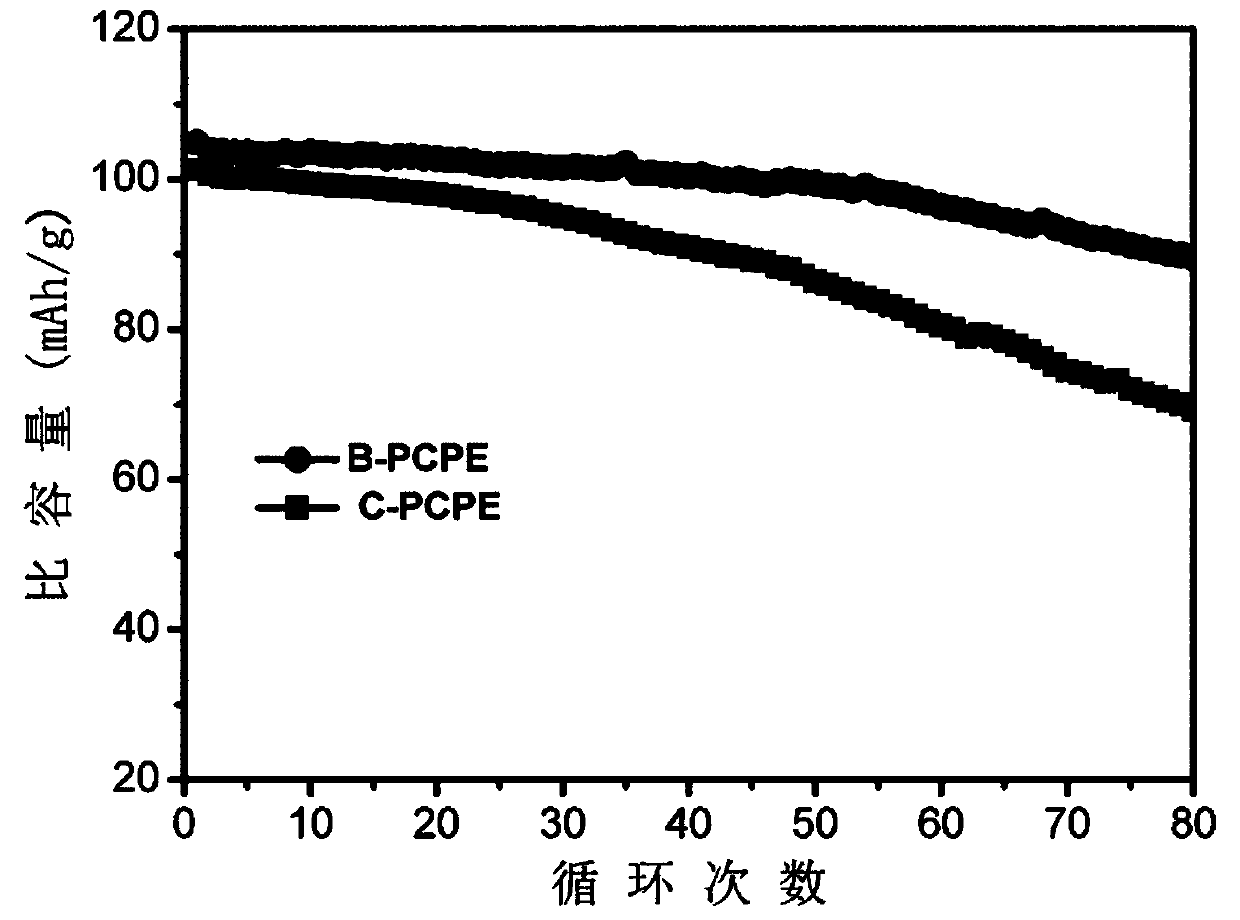

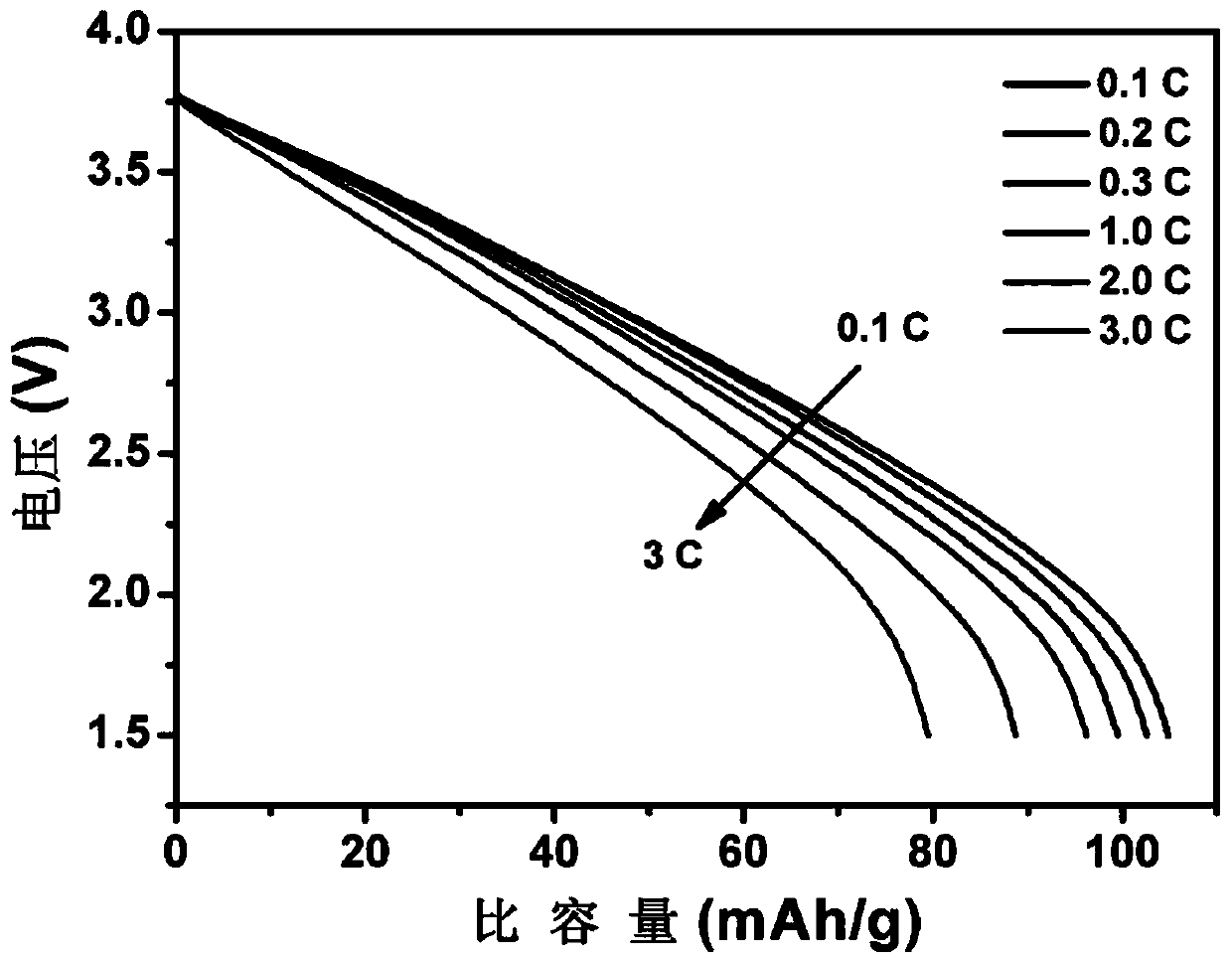

Boron-containing plastic crystal polymer and preparation method and application thereof

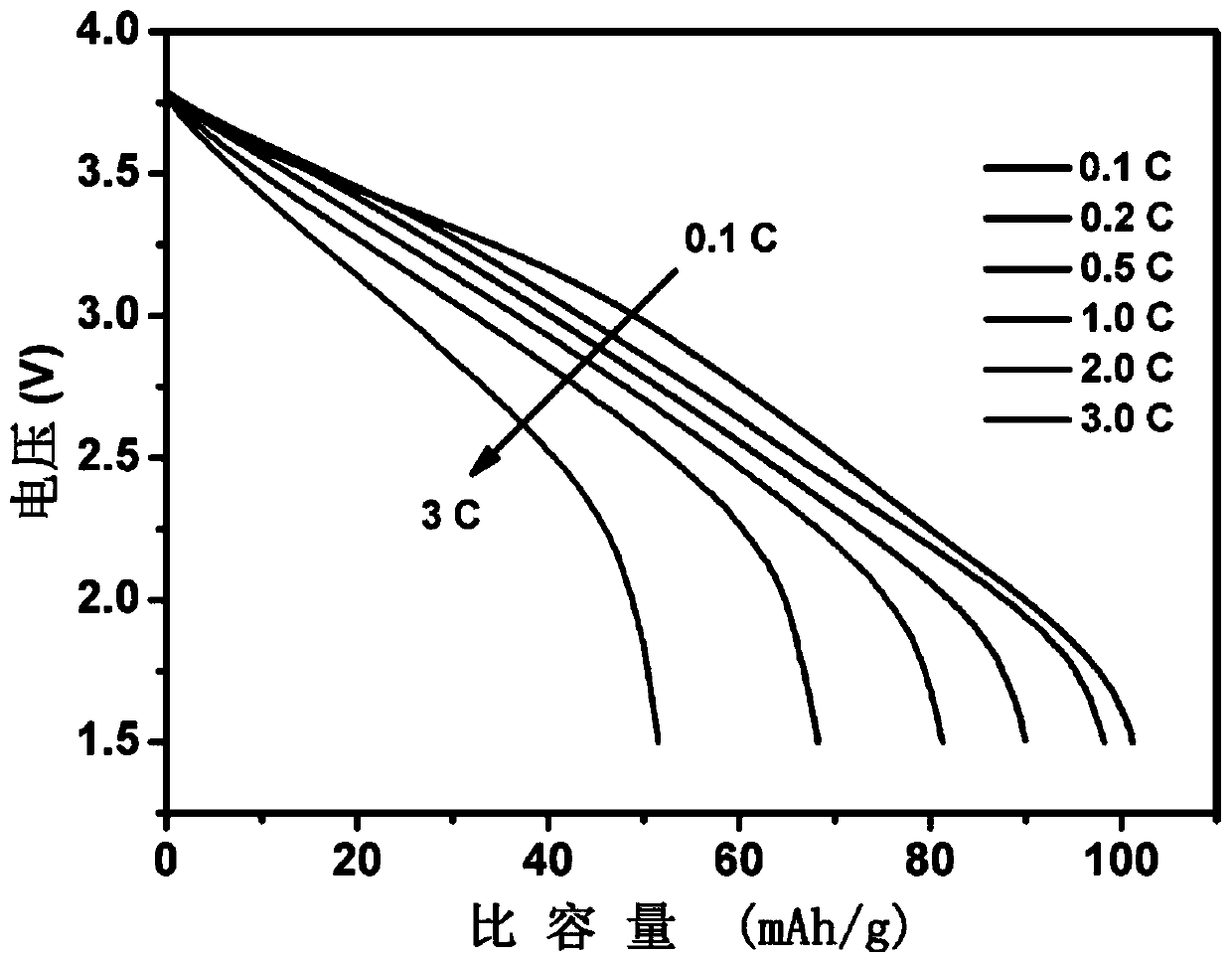

ActiveCN109786820AImprove conductivityExcellent rate performanceSecondary cellsImpregnation manufacturingHigh sodiumPlastic crystal

Owner:浙江钠创新能源有限公司

Ionic liquid and plastic crystal

InactiveUS20170256820A1Suppress needLow viscosityOrganic chemistryNegative electrodes1-hexyl-3-methylimidazoliumPlastic crystal

The present invention provides an ionic liquid or plastic crystal comprising an anion and a cation, the anion comprising [C(SO2F)3]−, and the cation comprising at least one member selected from the group consisting of 1-ethyl-3-methylimidazolium ([EMI]+), N,N-diethyl-N-methyl-(2-methoxyethyl)ammonium ([DEME]+), N-methyl-N-propylpyrrolidinium ([Py13]+), N-methyl-N-propylpiperidinium ([PP13]+), tetramethylammonium ([N1111]+), tetraethylammonium ([N2222]+), trimethylhexylammonium ([N6111]+), triethylhexylammonium ([N6222]+), N-methyl-ethylpyrrolidinium ([Py12]+), 1-butyl-3-methylimidazolium ([C4mim]+), and 1-hexyl-3-methylimidazolium ([C6mim]+).

Owner:NAT INST OF ADVANCED IND SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com