Solid electrolyte, preparation method thereof and lithium ion battery

A solid electrolyte, lithium ion battery technology, applied in the field of lithium ion batteries, can solve the problems of poor mechanical strength and poor formability, and achieve the effects of excellent electrical conductivity and mechanical strength, excellent cycle performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The second aspect of the present invention is to provide a method for preparing a solid electrolyte in the first aspect, comprising the following steps:

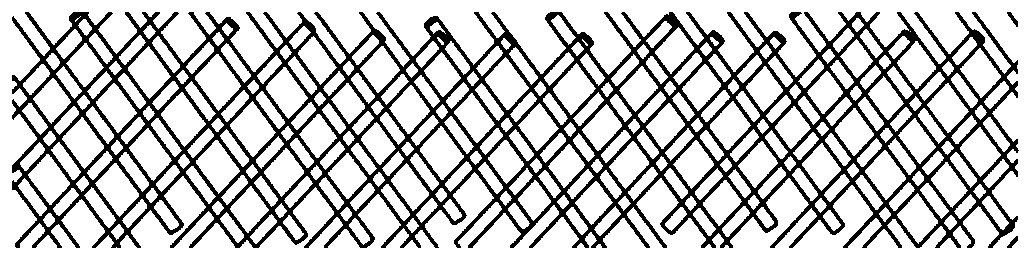

[0061] After volatilizing the solvent in the solution containing at least the polymer and the lithium salt, spinning the obtained solid to obtain a filament;

[0062] 3D printing using the filament as a raw material to obtain the polymer electrolyte skeleton;

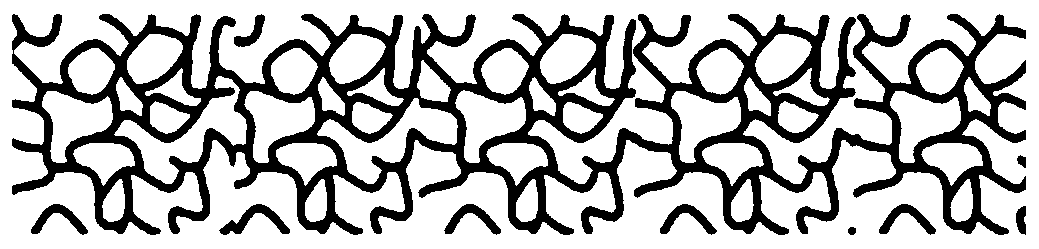

[0063] The polymer electrolyte framework is soaked in the precursor solution of plastic crystal electrolyte and heated to obtain a solid electrolyte; wherein, the precursor solution includes monomer, electrolyte and initiator.

[0064] The types of raw materials and the composition of raw materials in the preparation method are the same as those described above, and will not be repeated here.

[0065] Before 3D printing, the raw materials used to form the polymer electrolyte framework, including at least lithium salt and polymer, are mixed and stirred with org...

Embodiment 1

[0080] The preparation method of the lithium ion battery of the present embodiment comprises the following steps:

[0081]1. Mix 23.6g polylactic acid (PLA, Mw is about 60000), 7.3g lithium bistrifluoromethanesulfonimide (LiTFSI) and 2.8g silicon dioxide (SiO 2 ) were mixed evenly, placed in a beaker, and dissolved in a certain amount of chloroform, and stirred at a speed of 500rpm at 35°C for 3h to form a homogeneous solution;

[0082] 2. Heating the homogeneous solution to fully volatilize the solvent to obtain a block solid, vacuum-drying at 50°C for 12 hours, and shearing and grinding the block solid;

[0083] Send the ground particles into the screw extruder for blending and spinning. The spinning temperature is 161°C, and the pulling machine is pulled at a speed of 10cm / min. The diameter of the extruded filament is 0.40mm, and the size is uniform. the wire, and coiled the wire;

[0084] 3. Use 3DMax software to carry out three-dimensional modeling to obtain printing da...

Embodiment 2

[0089] The preparation method of the lithium ion battery of the present embodiment comprises the following steps:

[0090] 1. 18g polycaprolactone (PCL, Mw is about 80000), 7.8g polyethylene oxide (PEO, Mw is about 100W), 8.5g lithium difluorooxalate borate (LiDFOB) and 0.2g epoxy toughening phase After the solvent is mixed evenly, put it in a beaker, then dissolve it in a certain amount of ACN, and stir evenly at 50°C at a speed of 1000rpm for 3h until a homogeneous solution is formed;

[0091] 2. Heating the homogeneous solution to fully volatilize the solvent to obtain a block solid, vacuum-drying at 59°C for 18 hours, and shearing and grinding the block solid;

[0092] Send the ground particles into the screw extruder for blending and spinning. The spinning temperature is 78°C, and the pulling machine is pulled at a speed of 22cm / min. The diameter of the extruded filament is 0.80mm, and the size is uniform. the wire, and coiled the wire;

[0093] 3. Use 3DMax software to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com