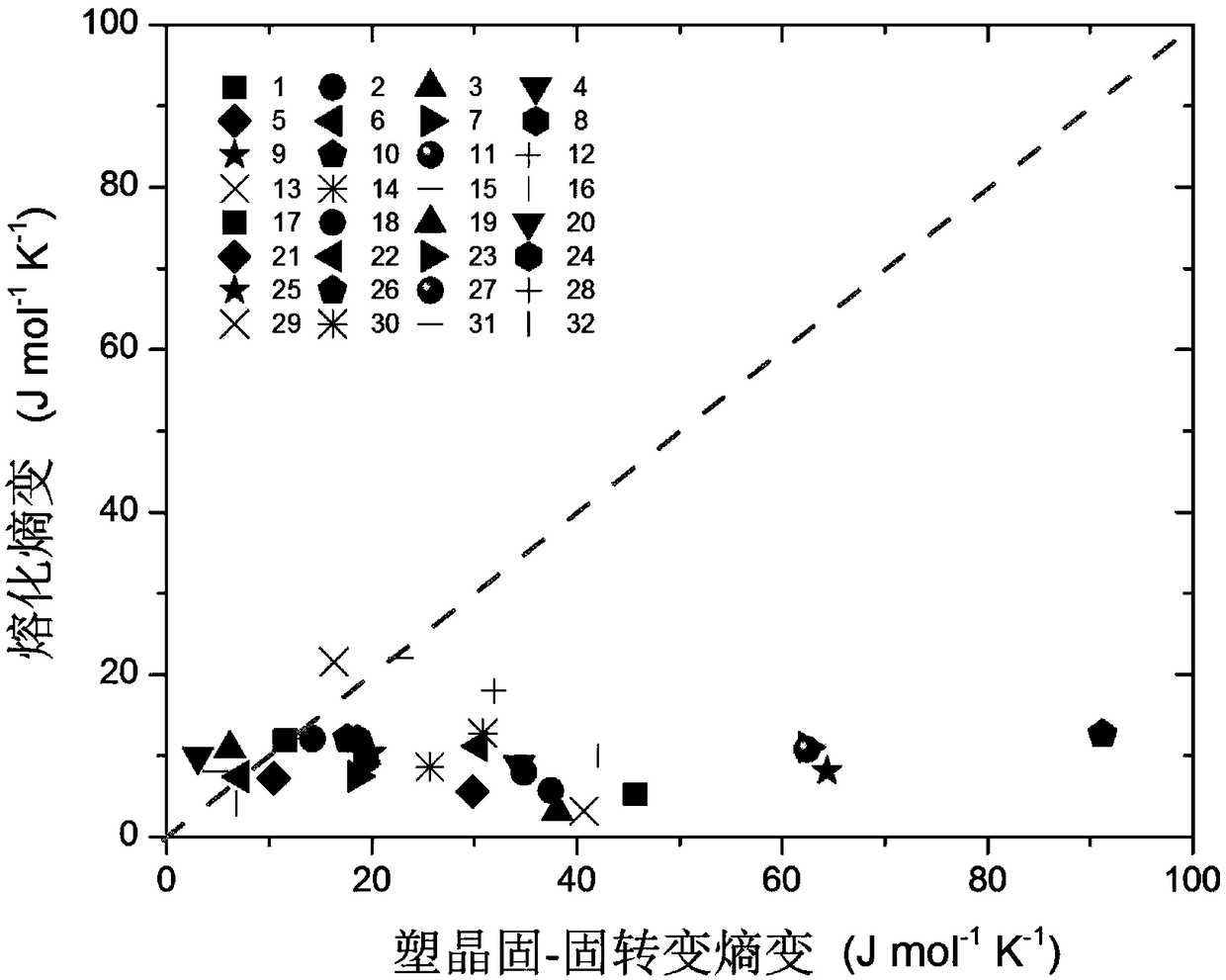

Solid-state refrigeration method based on static-pressure driving of plastic crystal materials

A solid-state refrigeration and drive technology, applied in the field of materials, to achieve high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

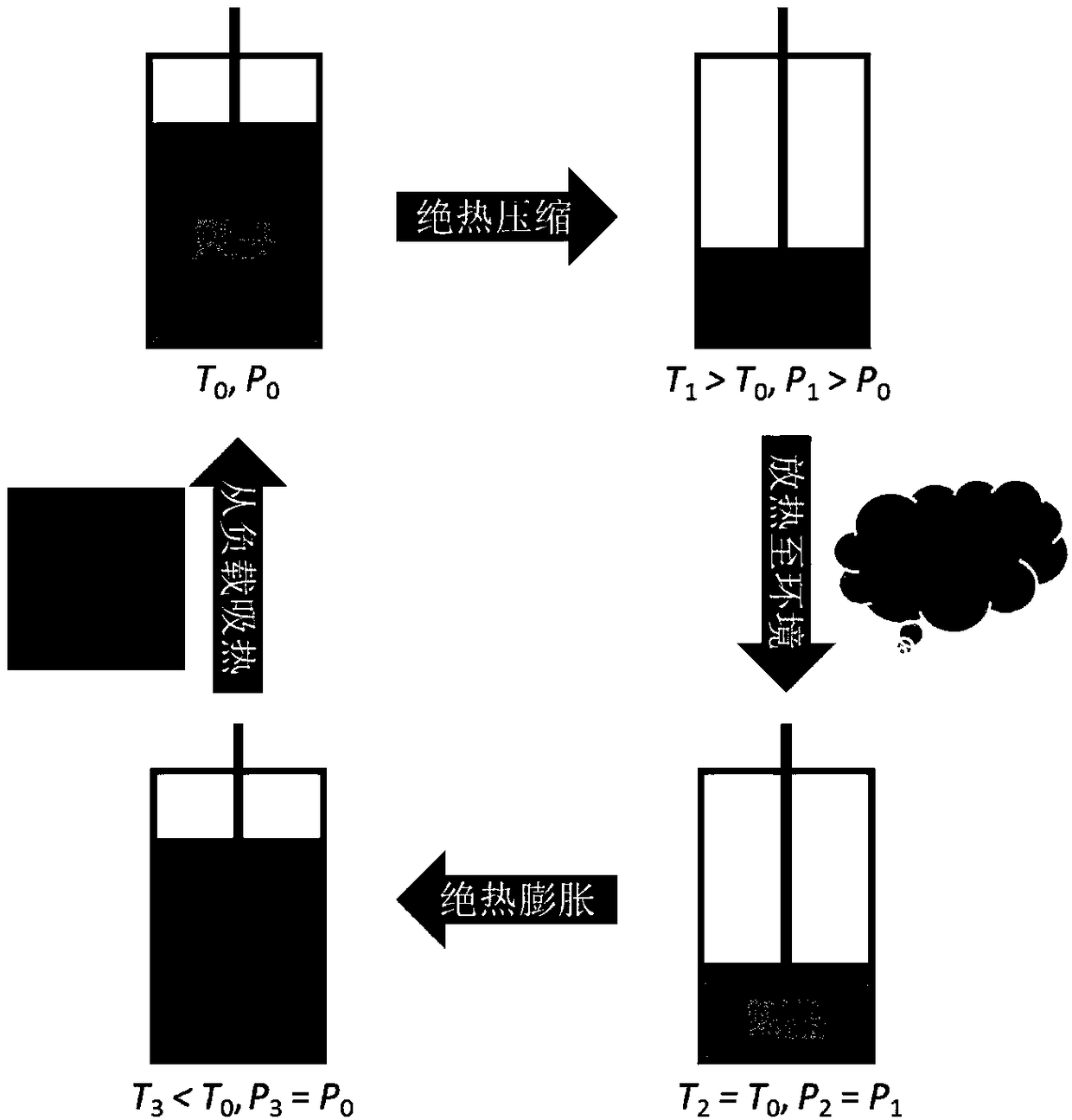

Method used

Image

Examples

Embodiment 1

[0038] 20MPa refrigeration effect:

[0039] Put the refrigerant neopentyl glycol into the airtight high-pressure sample cell, and put the reference sample cell together into the sample cavity of the μDSC7 (produced by Setaram, France) microcalorimeter. Utilize the high-pressure gas control panel, feed nitrogen, keep the gas pressure constant at 1 atmospheric pressure (0.1MPa), heat from 293K to 335K with a heating rate of 1K / min, and record the heat flow data of the sample, such as Figure 7 shown in the first curve on the left. Next, increase the pressure of the gas to 20MPa, repeat the above process, and obtain data such as Figure 7 shown in the second curve. Convert heat flow data to entropy change data, such as Figure 8 shown. Subtract the two lines to get the entropy change when the pressure increases from 1 to 20MPa, and its maximum value is 150J kg -1 K -1 , the maximum adiabatic temperature change is 9K.

Embodiment 2

[0041] Saturation trend of cooling effect:

[0042] Put the refrigerant neopentyl glycol into the airtight high-pressure sample cell, and put the reference sample cell together into the sample cavity of the μDSC7 microcalorimeter. Use the high-pressure gas control panel to feed pure nitrogen, keep the gas pressure constant at 1 atmosphere (0.1MPa), heat from 293K to 335K at a heating rate of 1K / min, and record the heat flow data of the sample, such as Figure 7 shown in the first curve. Next, raise the pressure of the gas to 40MPa, 60MPa, 80MPa, and 100MPa, repeat the above measurement process, and obtain the data as follows: Figure 7 Shown in the third to sixth curves. Convert heat flow data to entropy change data, such as Figure 8 shown. Subtract the two lines to get the entropy change when the pressure increases from 0.1MPa to 40MPa, 60MPa, 80MPa, and 100MPa, and use the specific heat data to get the corresponding adiabatic temperature change. The maximum entropy cha...

Embodiment 3

[0046] Thermal Hysteresis:

[0047] Put the refrigerant neopentyl glycol into the airtight high-pressure sample cell, and put the reference sample cell together into the sample cavity of the μDSC7 microcalorimeter. Use the high-pressure gas control panel to feed pure nitrogen, keep the gas pressure constant at 1 atmosphere (0.1MPa), heat from 293K to 335K at a heating rate of 1K / min, and record the heat flow data of the sample, such as Figure 7 The first line (positive values) is shown. Then, lower the temperature to 293K at the same rate, and record the data as Figure 7 The first line (negative value) is shown. The extreme values of the two are 317K and 302K respectively, with a thermal hysteresis effect of 15K. The thermal hysteresis at pressures of 40MPa, 60MPa, 80MPa, and 100MPa is also approximately 15K, such as Figure 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com