Electric commercial vehicle rear auxiliary box gear shifting executing mechanism

A shift actuator and a technology for commercial vehicles, applied in the field of vehicle shift, can solve the problems of large axial size of synchronizer, large shift impact, increased manufacturing cost, etc., achieve simple and efficient transmission structure, reduce motor power, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below, so that those skilled in the art can implement it with reference to the description.

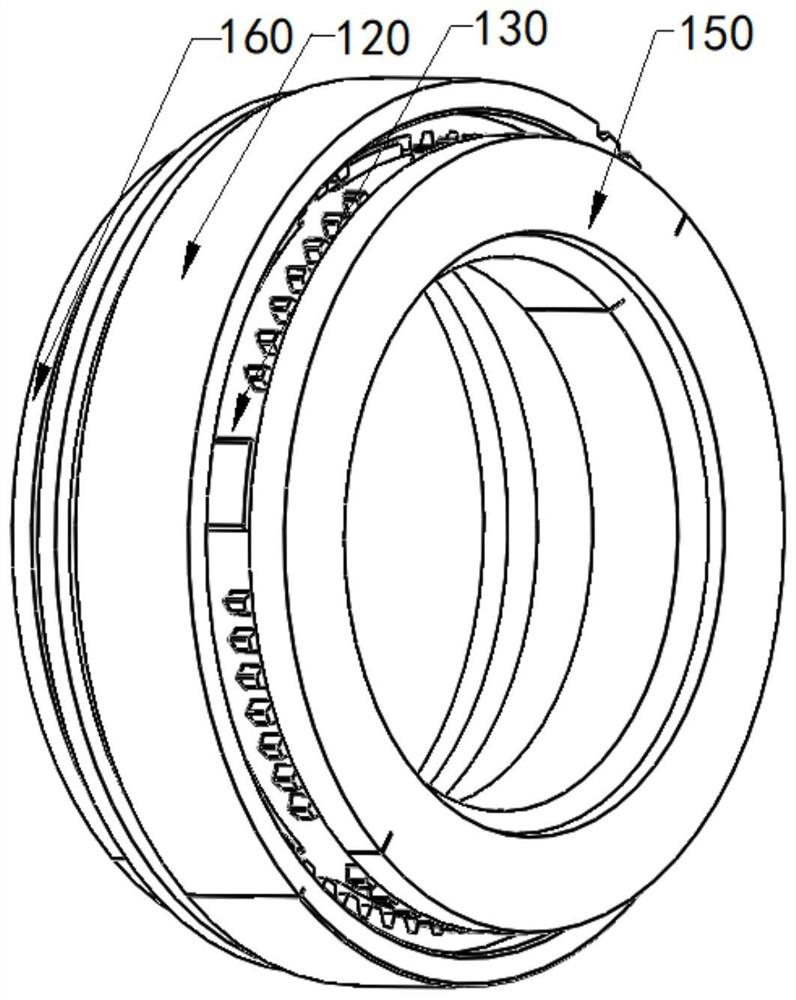

[0047] The invention provides a gear shift actuator of an electric rear auxiliary box of an electric commercial vehicle, which comprises a casing, a gear shift mechanism and a synchronizer.

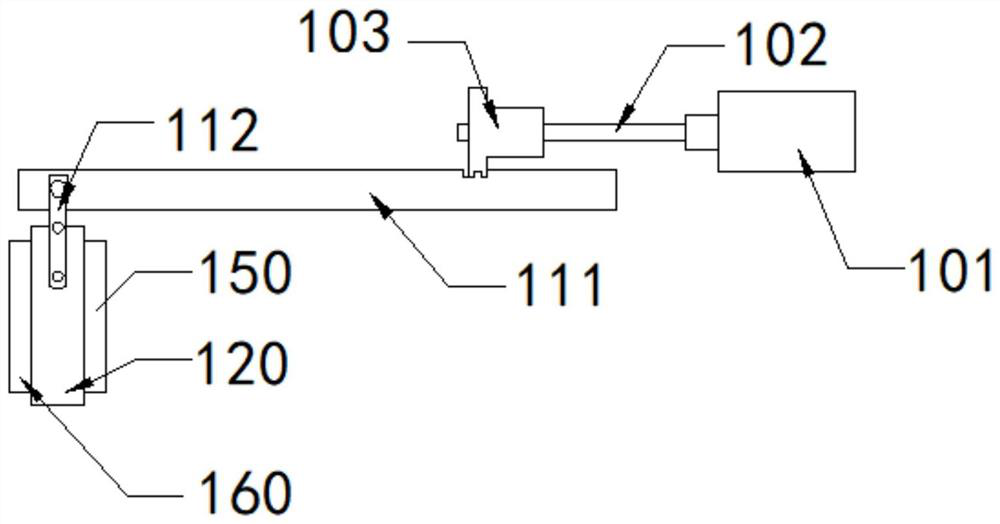

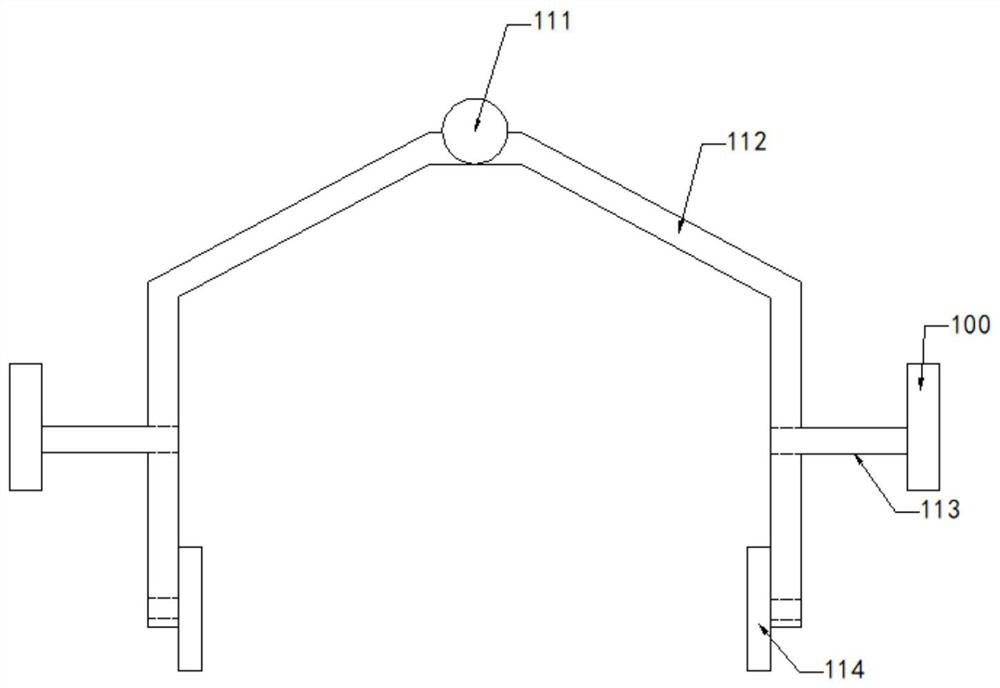

[0048] like figure 1 , figure 2 As shown, the shifting mechanism shown includes: a shifting motor 101, a lead screw 102, a nut 103, a shifting fork shaft 111 and a shifting fork 112, wherein the shifting motor 101 is fixed in the housing 100; The lead screw 102 is connected with the output end of the shifting motor 101 and can be rotated in the circumferential direction; one end of the nut 103 has an annular stepped flange, and the nut 103 is sheathed on the lead screw 102, and the two are connected as a lead screw Nut structure, the rotation of the lead screw 102 can drive the axial movement of the nut 103; the shift fork shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com