Electrolyte for an electrochemical device, method for manufacturing same, and electrochemical device including same

An electrochemical and electrolyte technology, applied in the direction of non-aqueous electrolyte batteries, electrochemical generators, circuits, etc., can solve the problems of not having mechanical properties and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

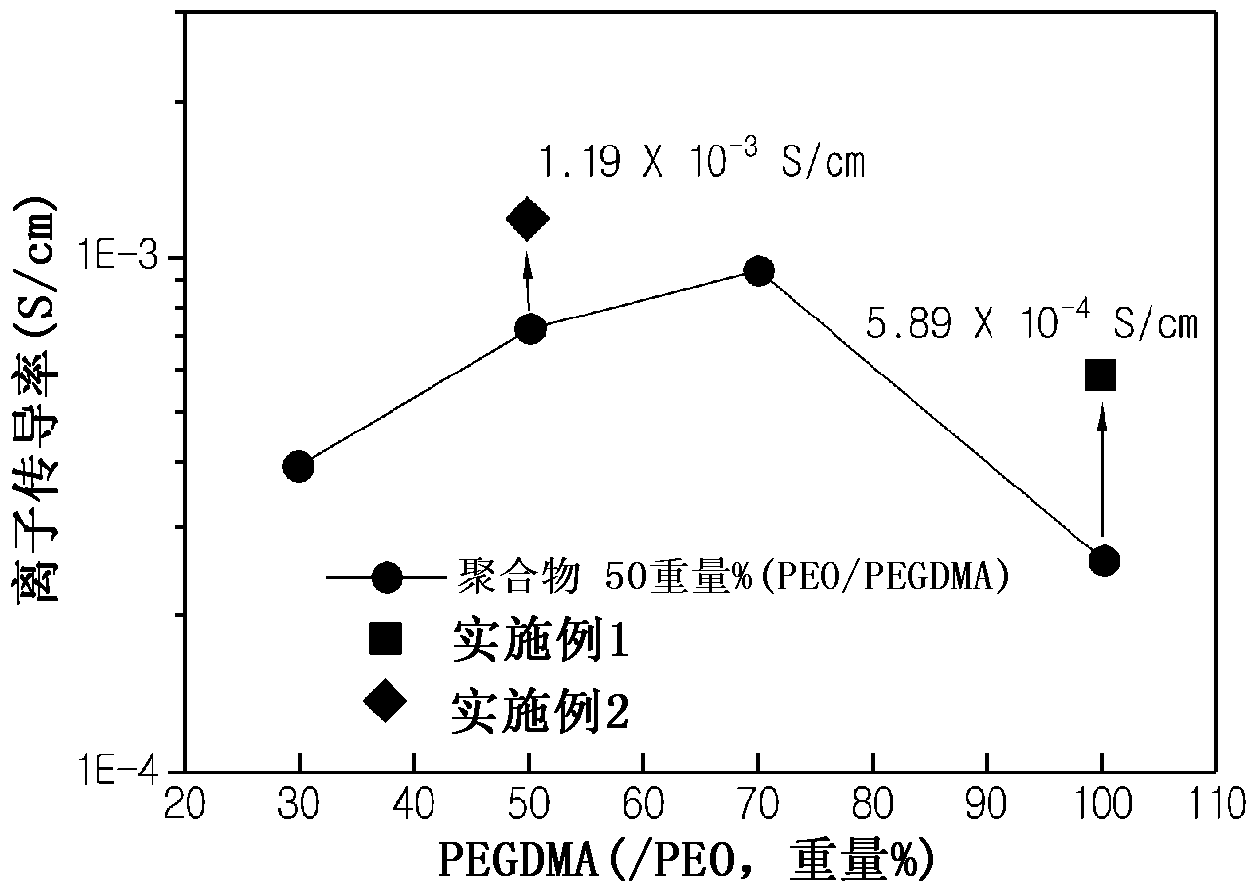

Embodiment 1

[0058] Embodiment 1: Preparation of PCE / PEGDMA / PEGMA solid electrolyte

[0059] For 50 parts by weight of succinonitrile as a plastic crystal electrolyte (PCE), 25 parts by weight of polyethylene glycol dimethacrylate (PEGDMA) with a weight average molecular weight of 400, and 25 parts by weight of polyethylene glycol dimethacrylate (PEGDMA) with a weight average molecular weight of 400 Alcohol methacrylate for mixing. Lithium bis(trifluoromethanesulfonyl)imide was added to the mixture in a molar ratio of lithium salt to PEGDMA and ethylene oxide units of PEGMA of 1:8. After homogenizing the mixture, benzoin as UV initiator was added to the mixture in an amount of 3% by weight, based on the total weight of PEGDMA and PEGMA.

[0060] Thereafter, the prepared mixture was cast on a glass plate and irradiated with UV light for 1 minute. As a result of the polymerization, an electrolyte is produced in the form of a membrane.

Embodiment 2

[0061] Embodiment 2: Preparation of PCE / PEO / PEGDMA / PEGMA solid electrolyte

[0062] For 50 parts by weight of succinonitrile, 25 parts by weight of polyethylene oxide, 12.5 parts by weight of polyethylene glycol dimethacrylate (PEGDMA) with a weight average molecular weight of 400 and 12.5 parts by weight of polyethylene glycol dimethacrylate (PEGDMA) with a weight average molecular weight of 400 Polyethylene glycol methacrylate for mixing. Lithium bis(trifluoromethanesulfonyl)imide was added to the mixture in a molar ratio of lithium salt to ethylene oxide units of PEO, PEGDMA and PEGMA of 1:8. After homogenizing the mixture, benzoin as UV initiator was added to the mixture in an amount of 3% by weight, based on the total weight of PEGDMA and PEGMA.

[0063] Thereafter, the prepared mixture was cast on a glass plate and irradiated with UV light for 1 minute. As a result of the polymerization, an electrolyte is produced in the form of a membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com