Patents

Literature

97 results about "Polymer crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

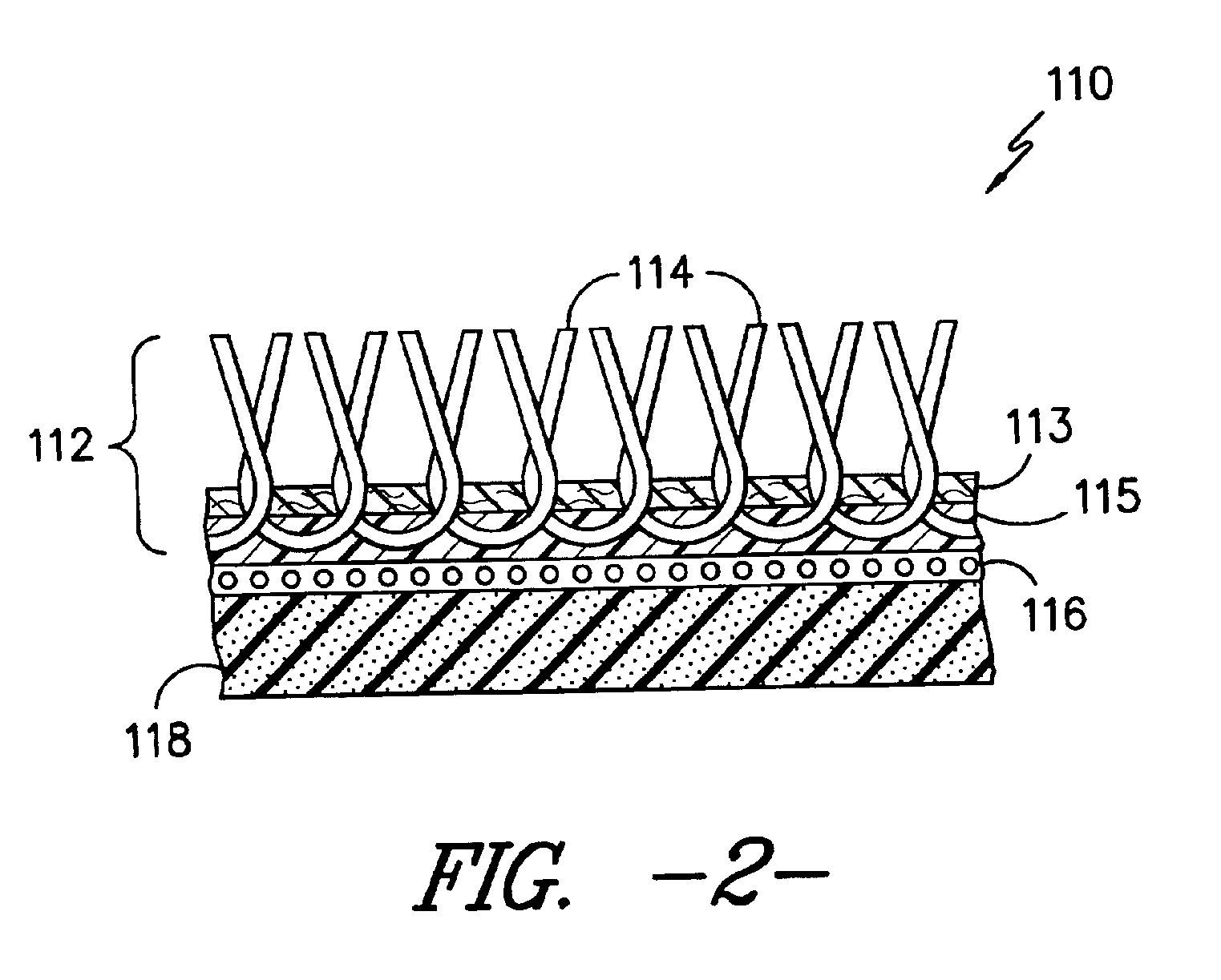

Thermoplastic monofilament fibers exhibiting low-shrink, high tenacity, and extremely high modulus levels

InactiveUS6759124B2High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingThermoplasticYarn

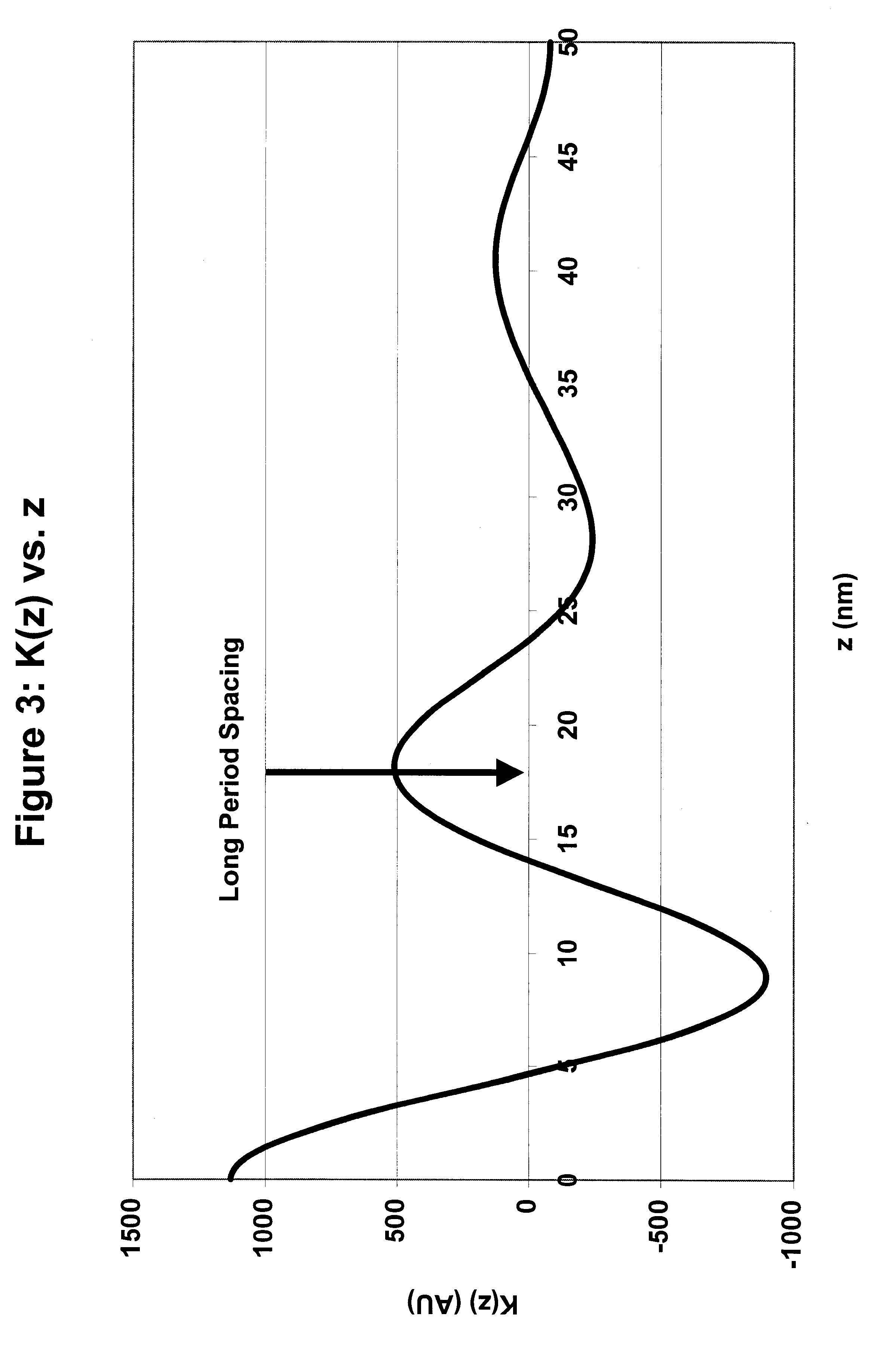

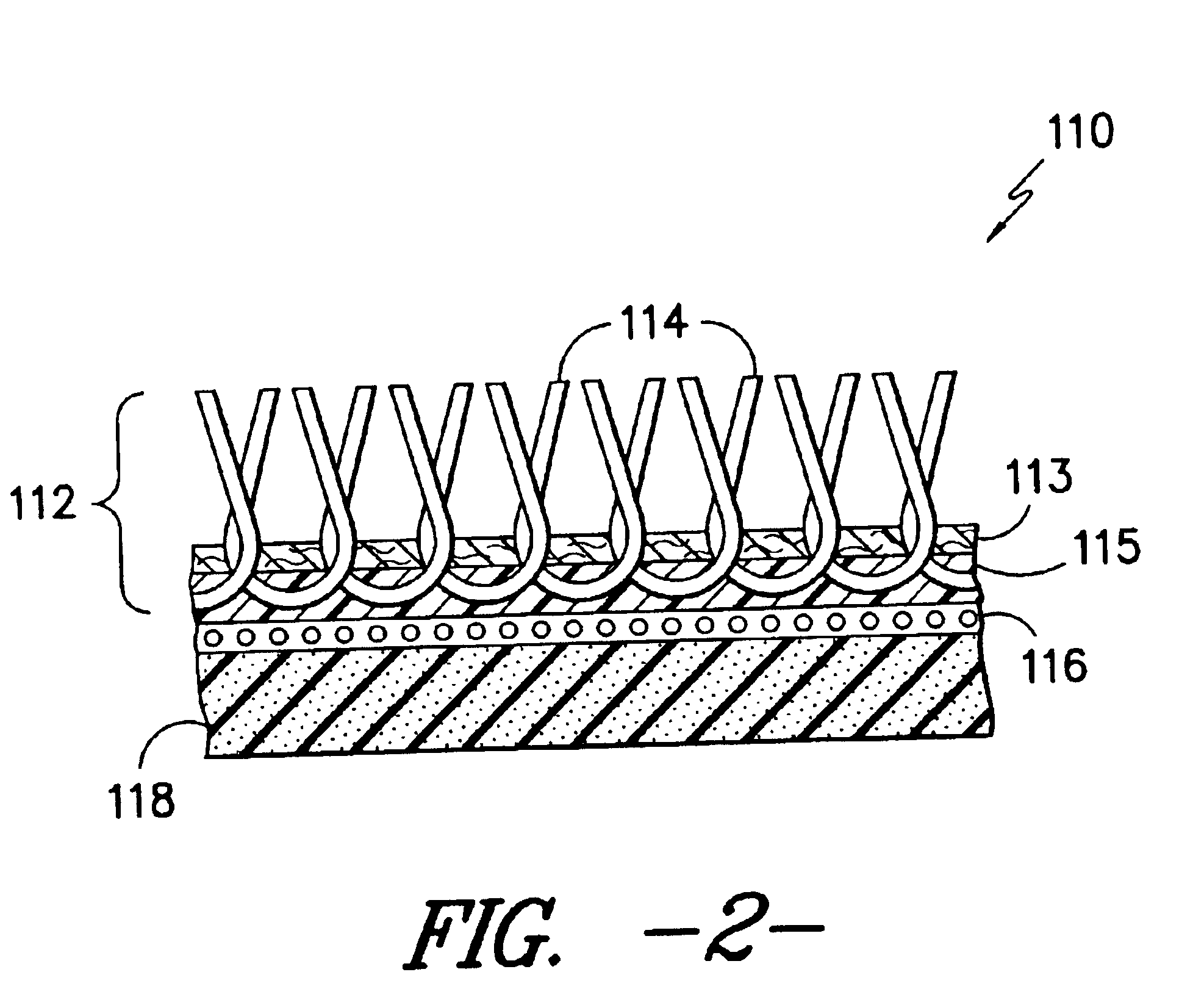

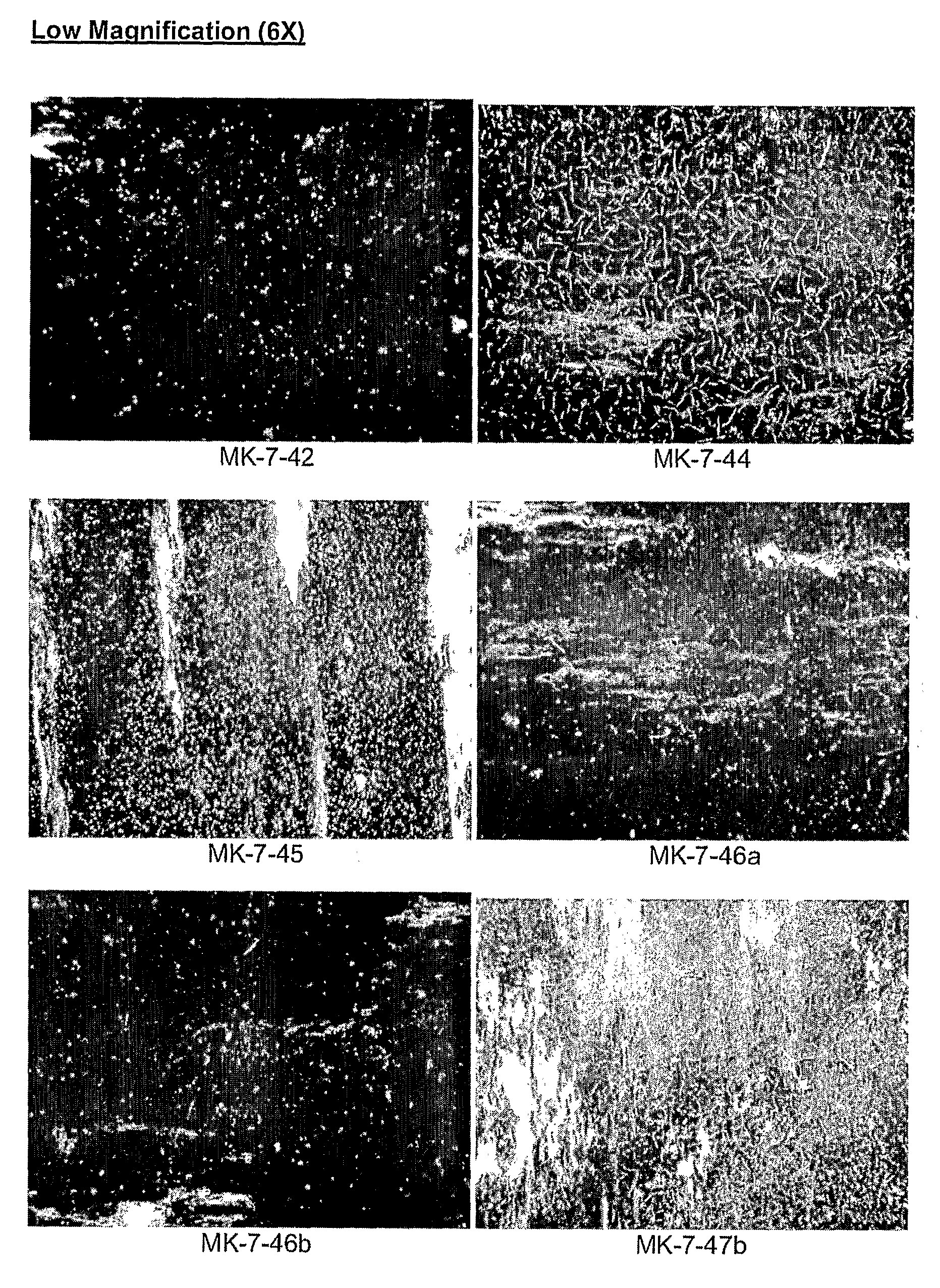

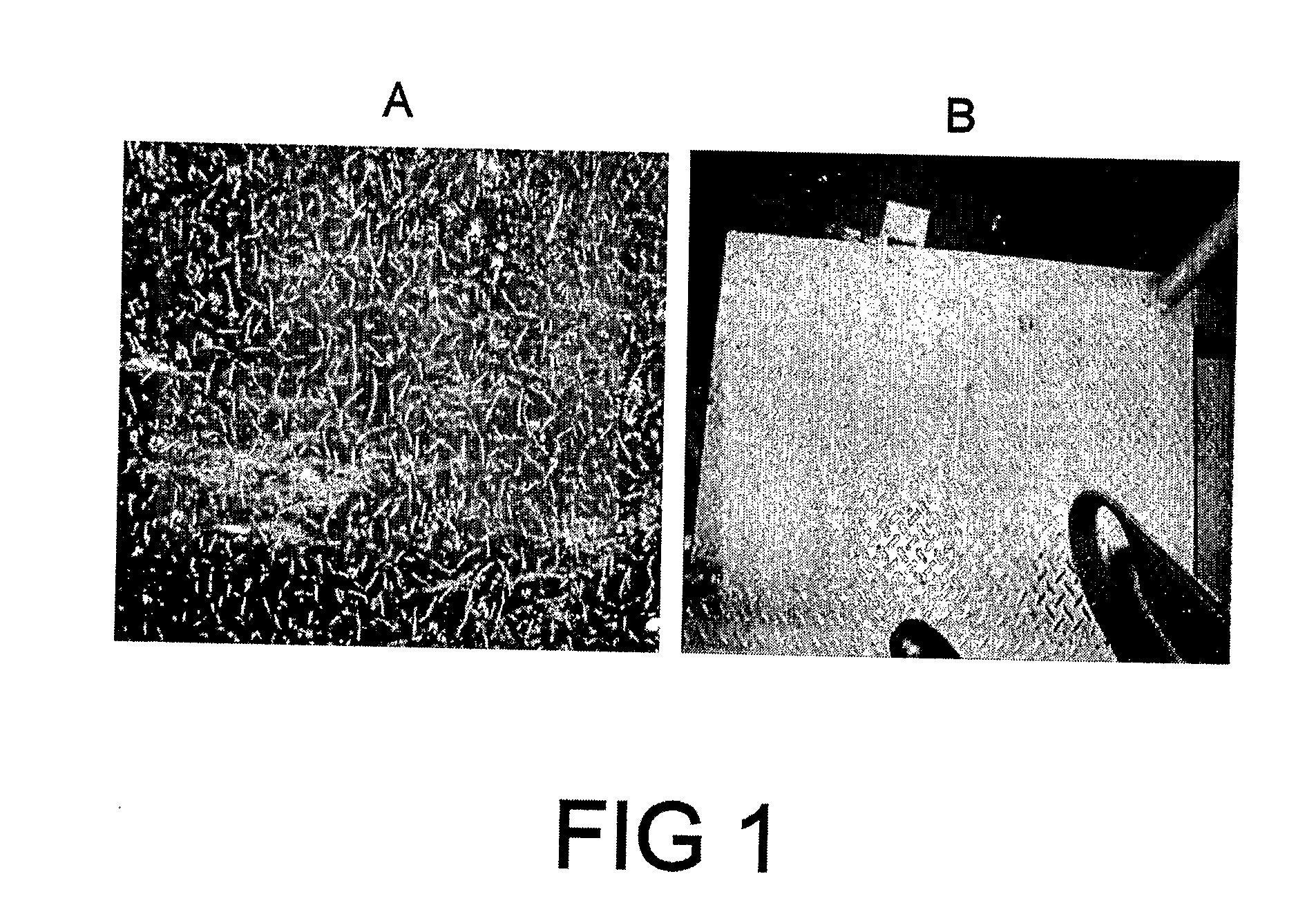

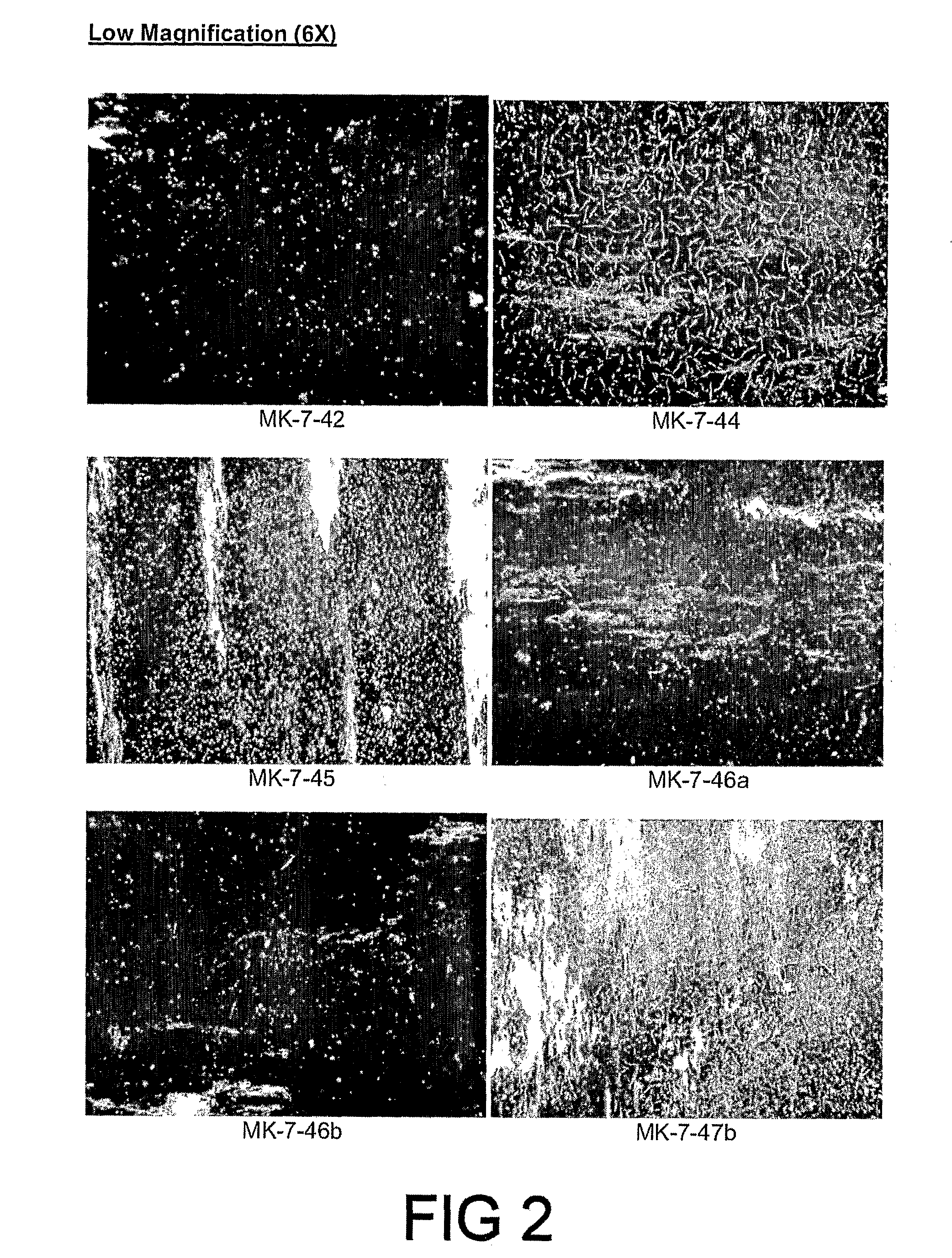

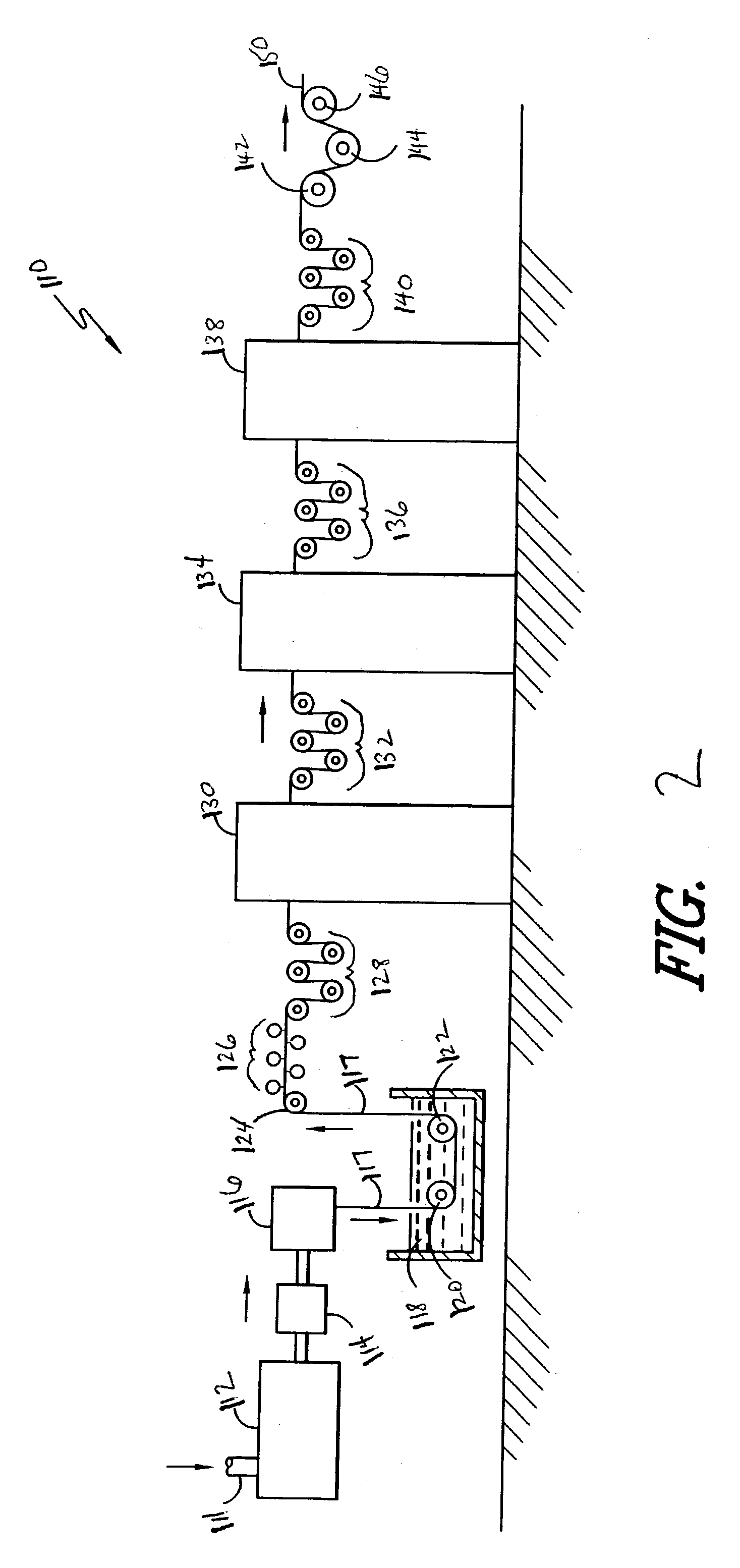

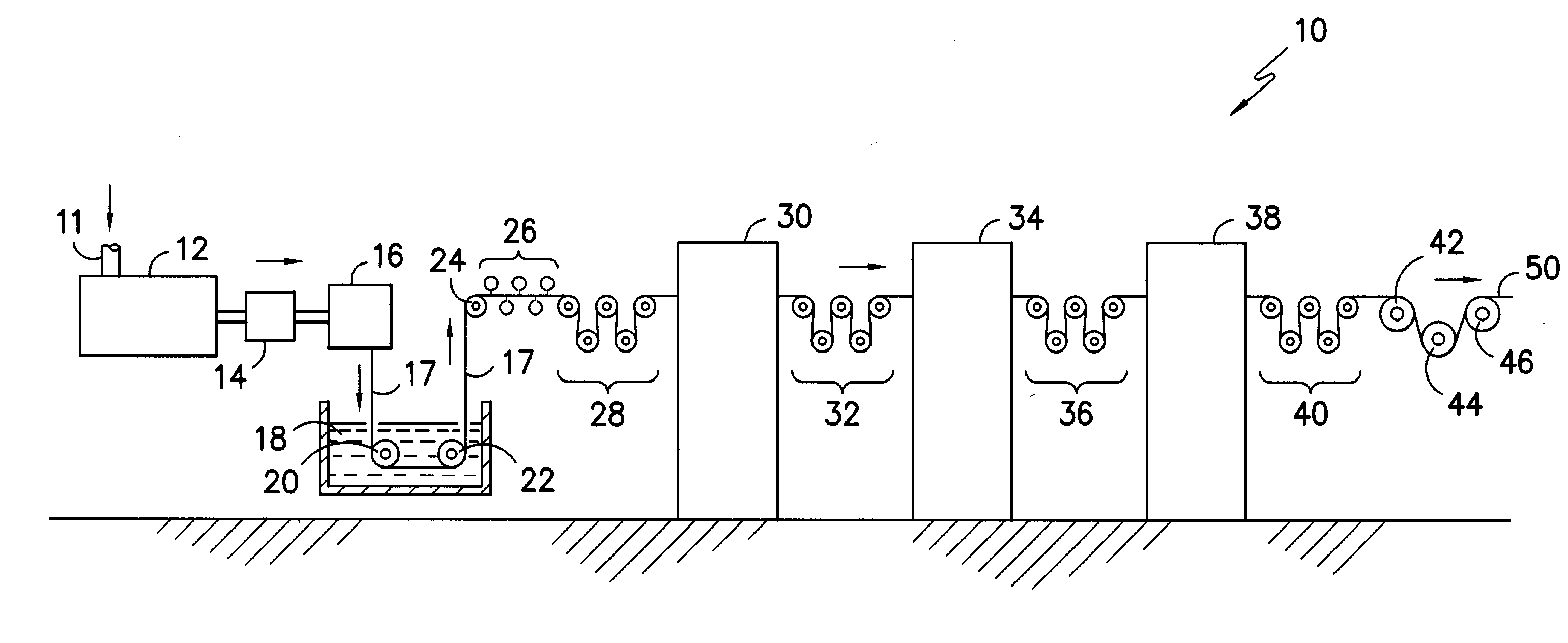

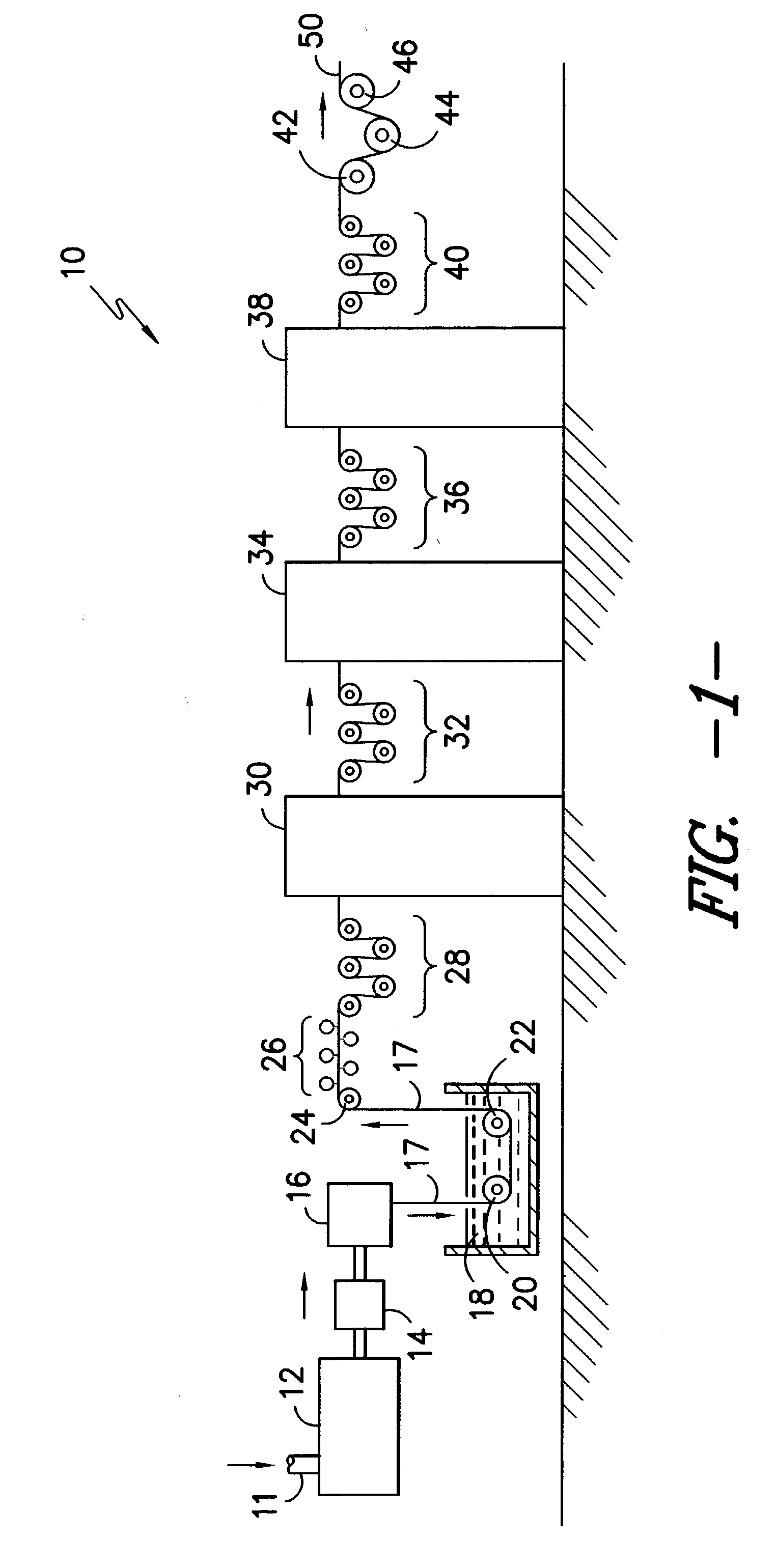

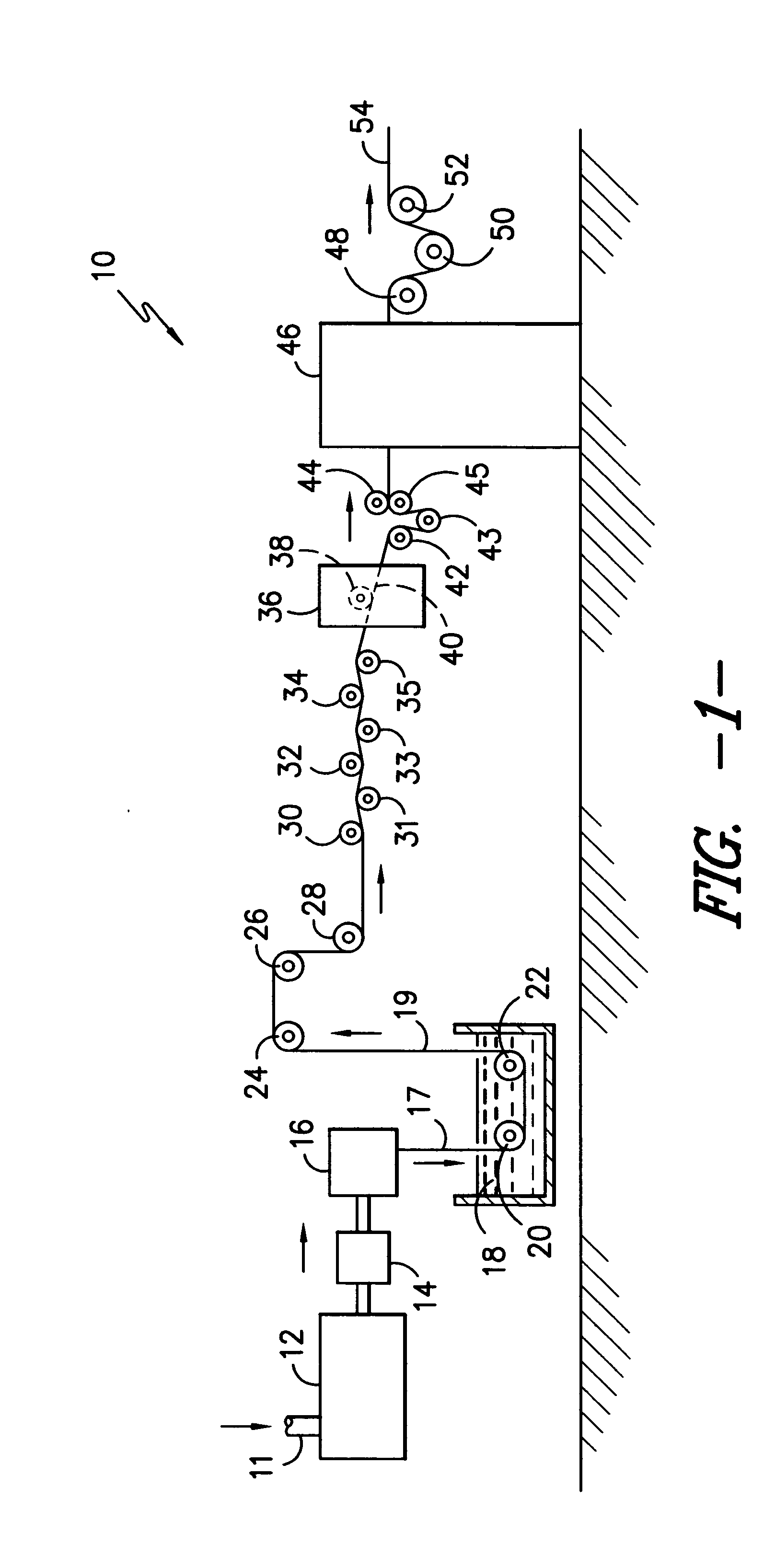

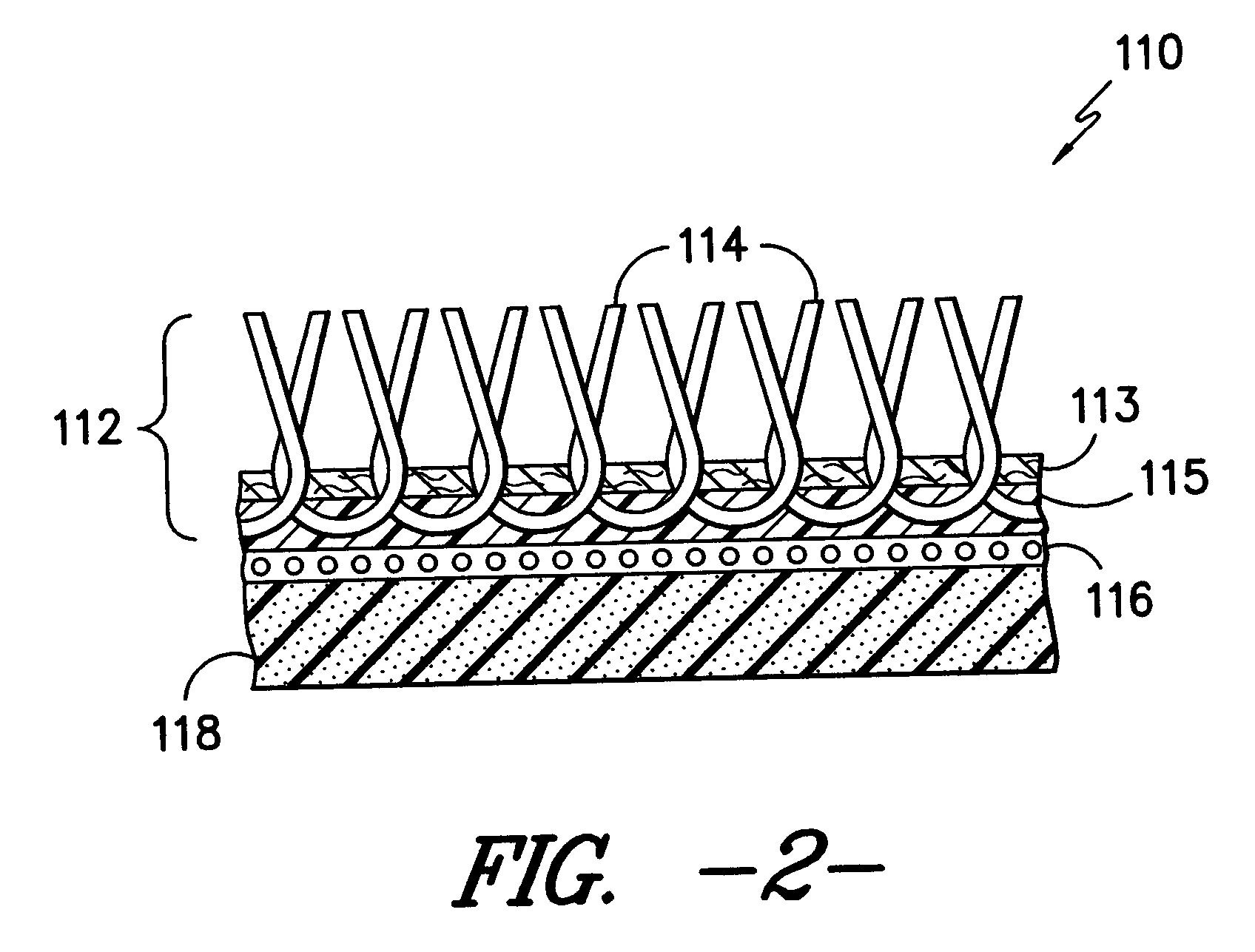

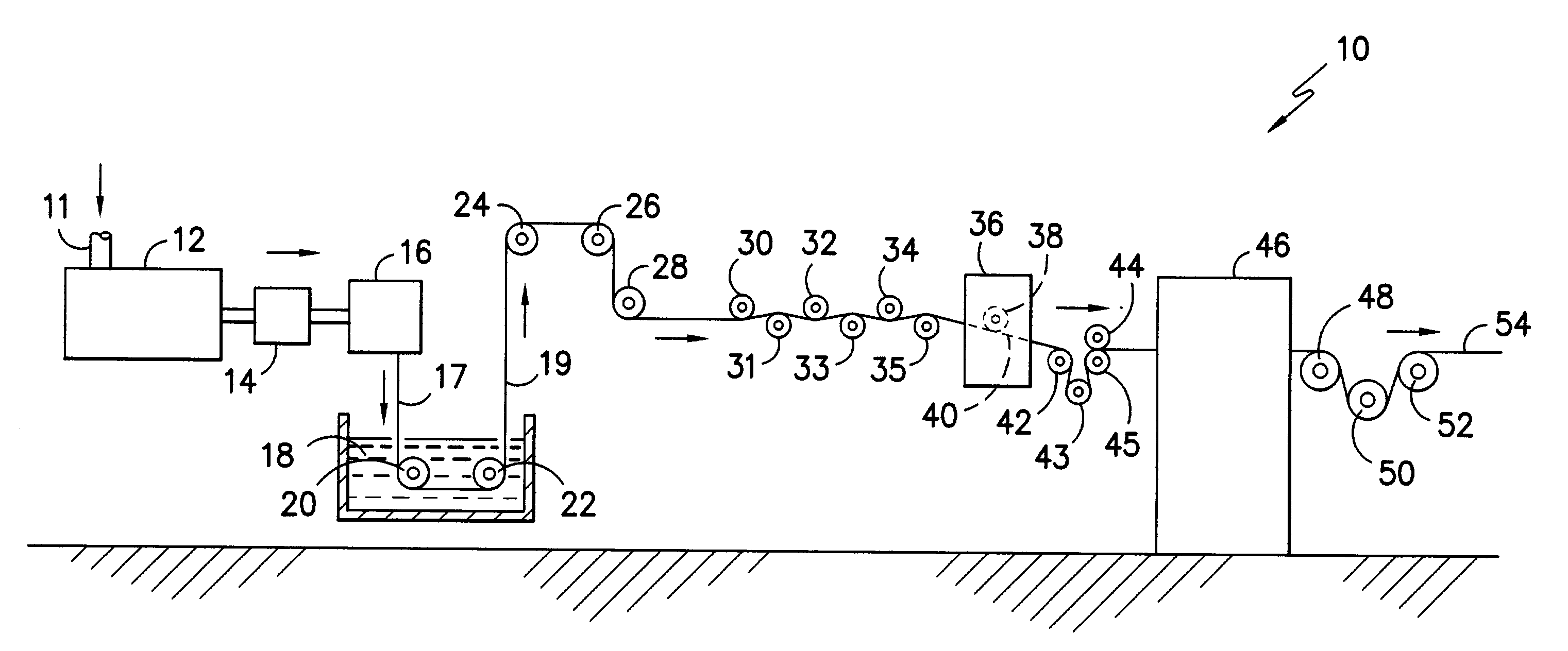

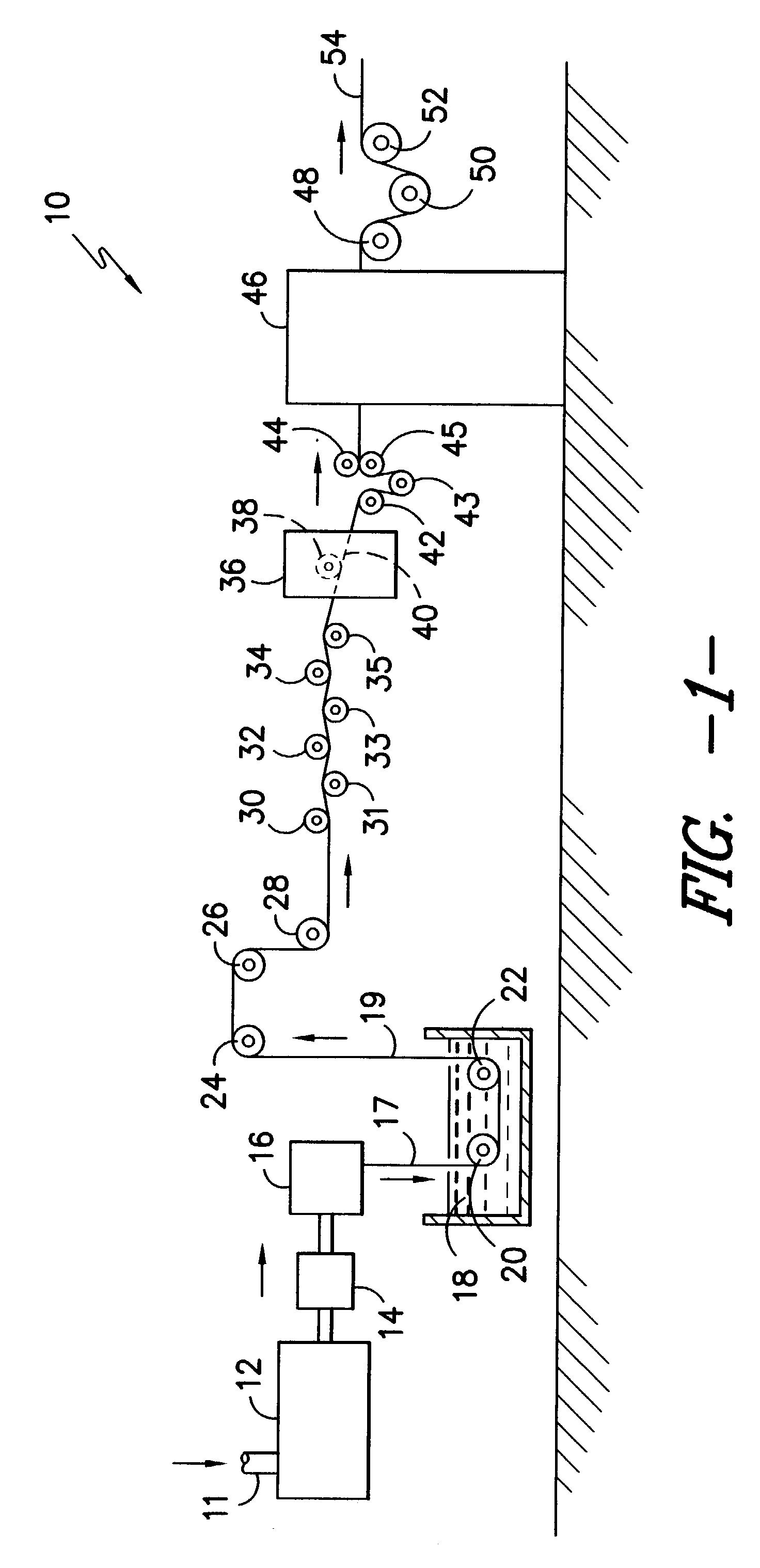

Unique thermoplastic monofilament fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present that the tenacity and modulus strength are much higher than any other previously produced thermoplastic fibers, particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

Low-shrink polypropylene fibers

This invention relates to improvements in preventing heat- and moisture-shrink problems in specific polypropylene fibers. Such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target polypropylene fiber after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target polypropylene after exposure to sufficient heat to melt the initial pelletized polymer and upon allowing such a melt to cool. The compounds must nucleate polymer crystals at a higher temperature than the target polypropylene without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for polypropylene crystal growth. After drawing the nucleated composition into fiber form, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as sodium benzoate, certain sodium and lithium phosphate salts (such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11). Specific methods of manufacture of such fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

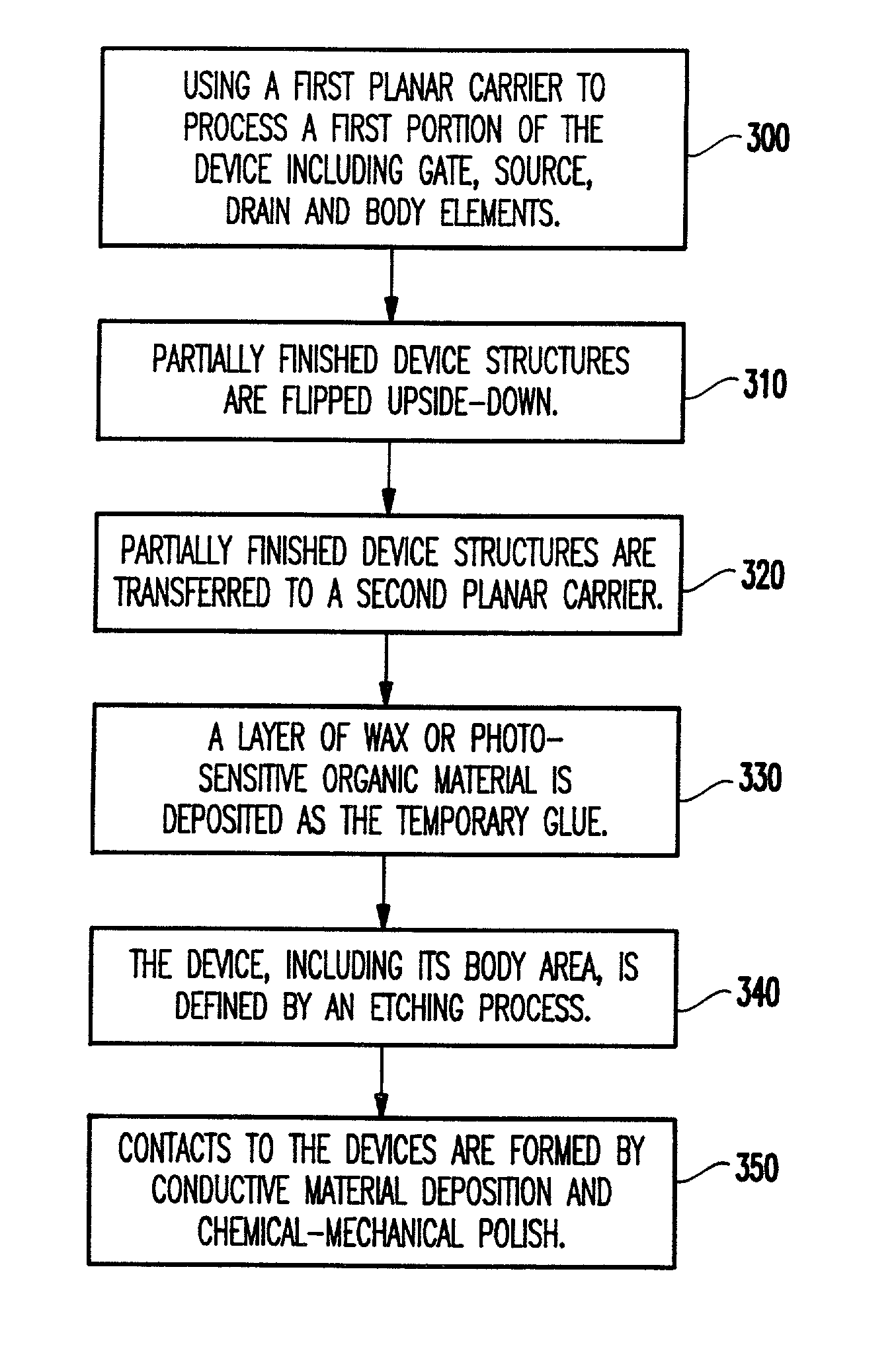

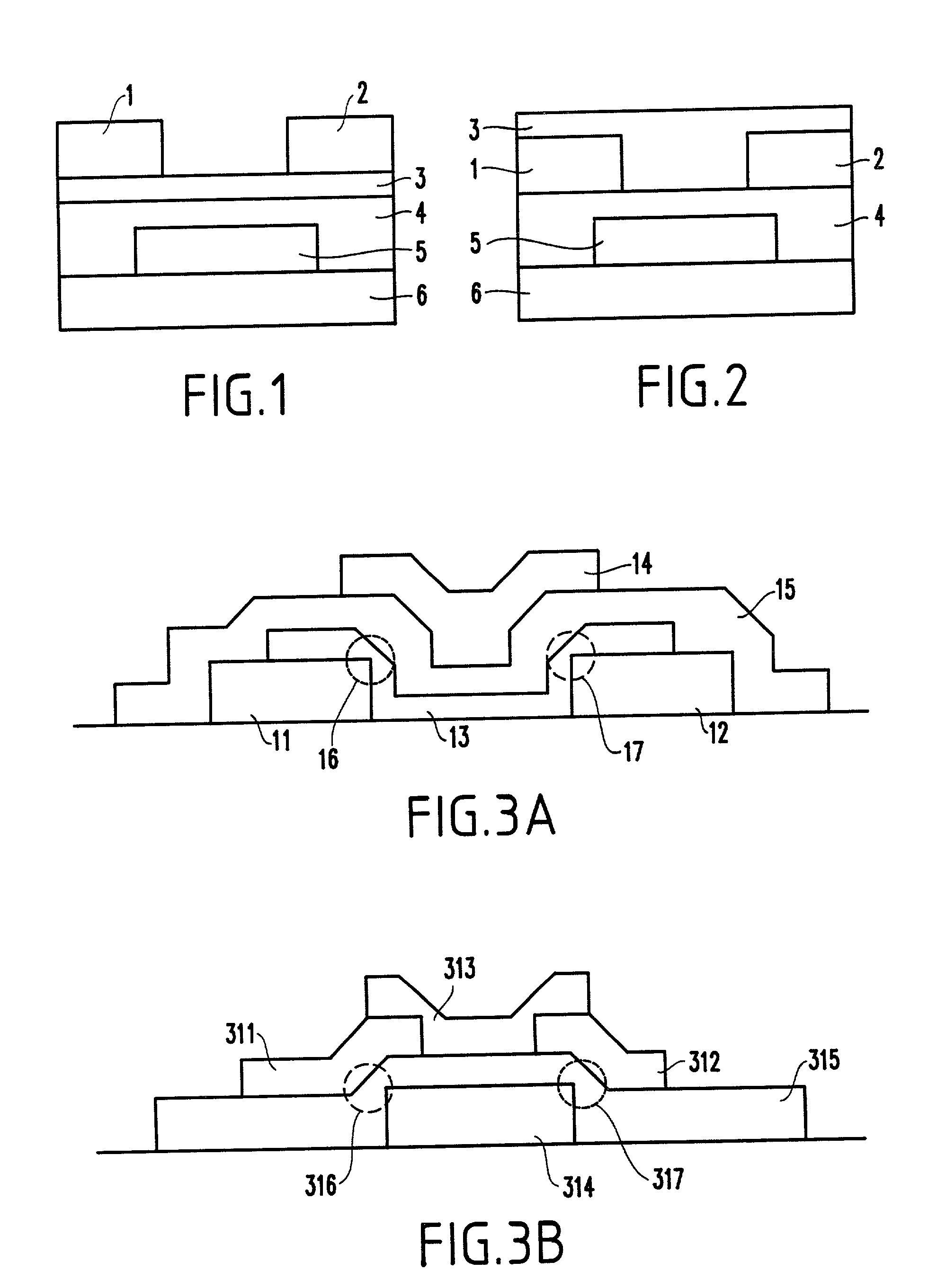

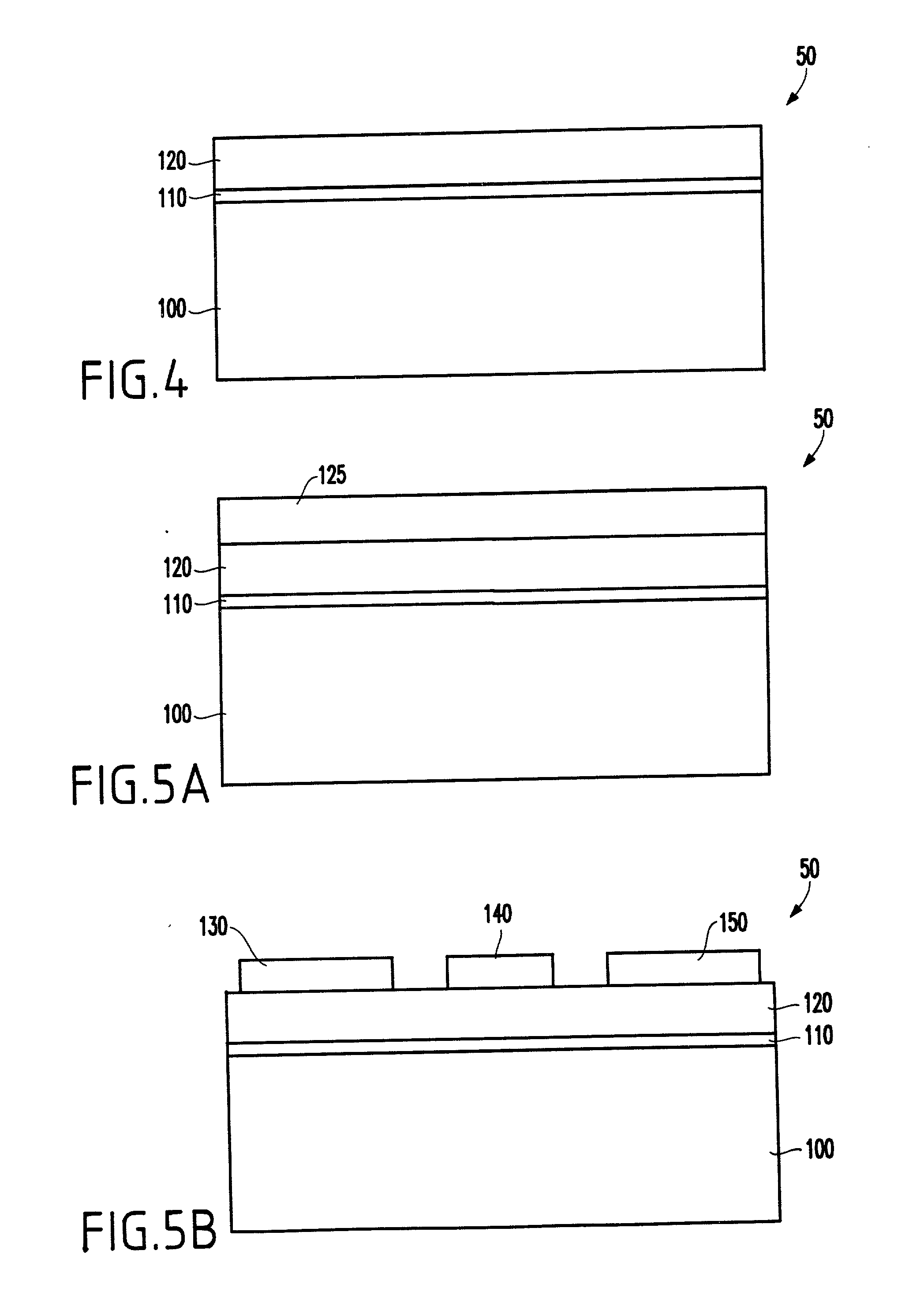

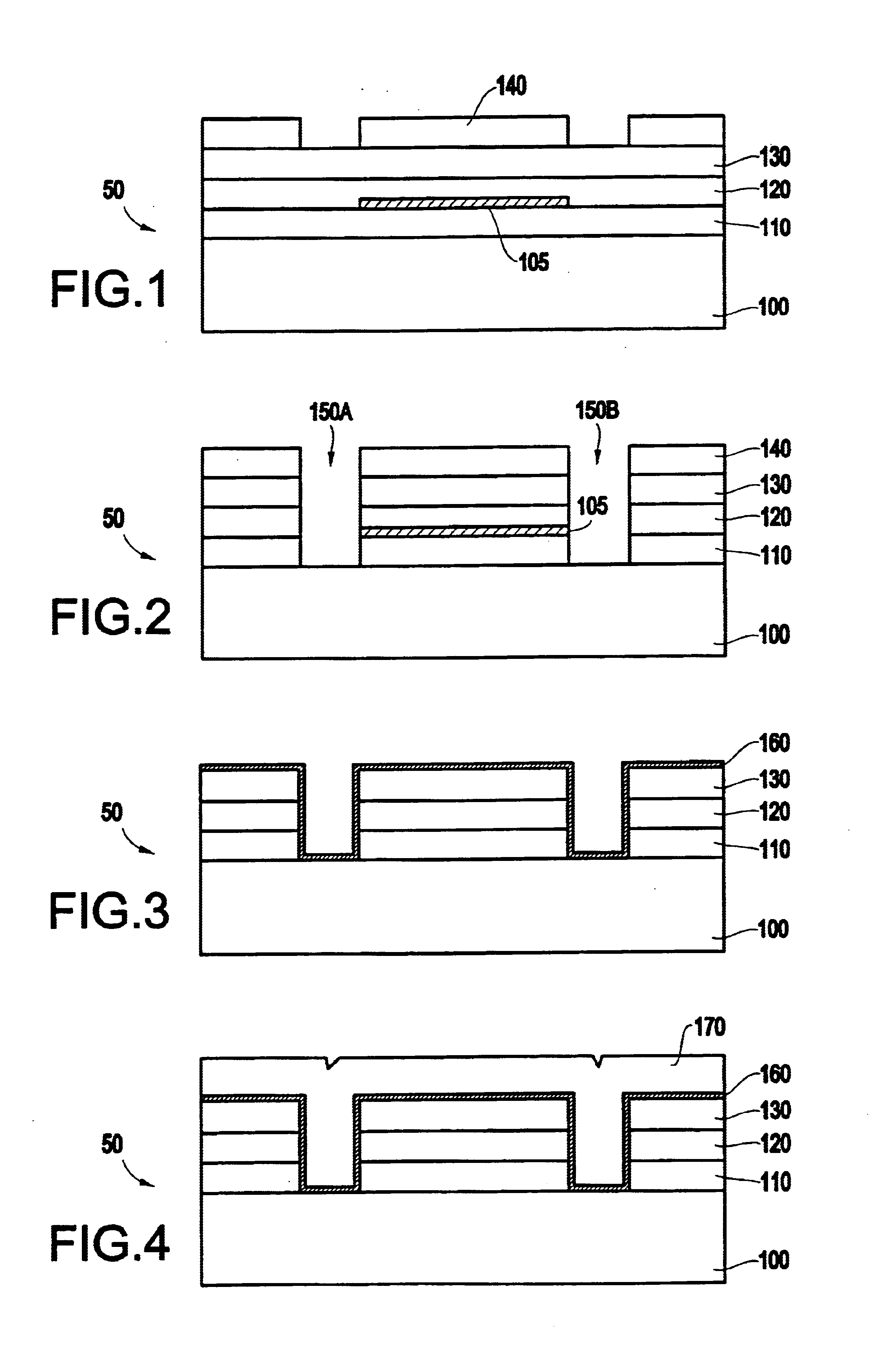

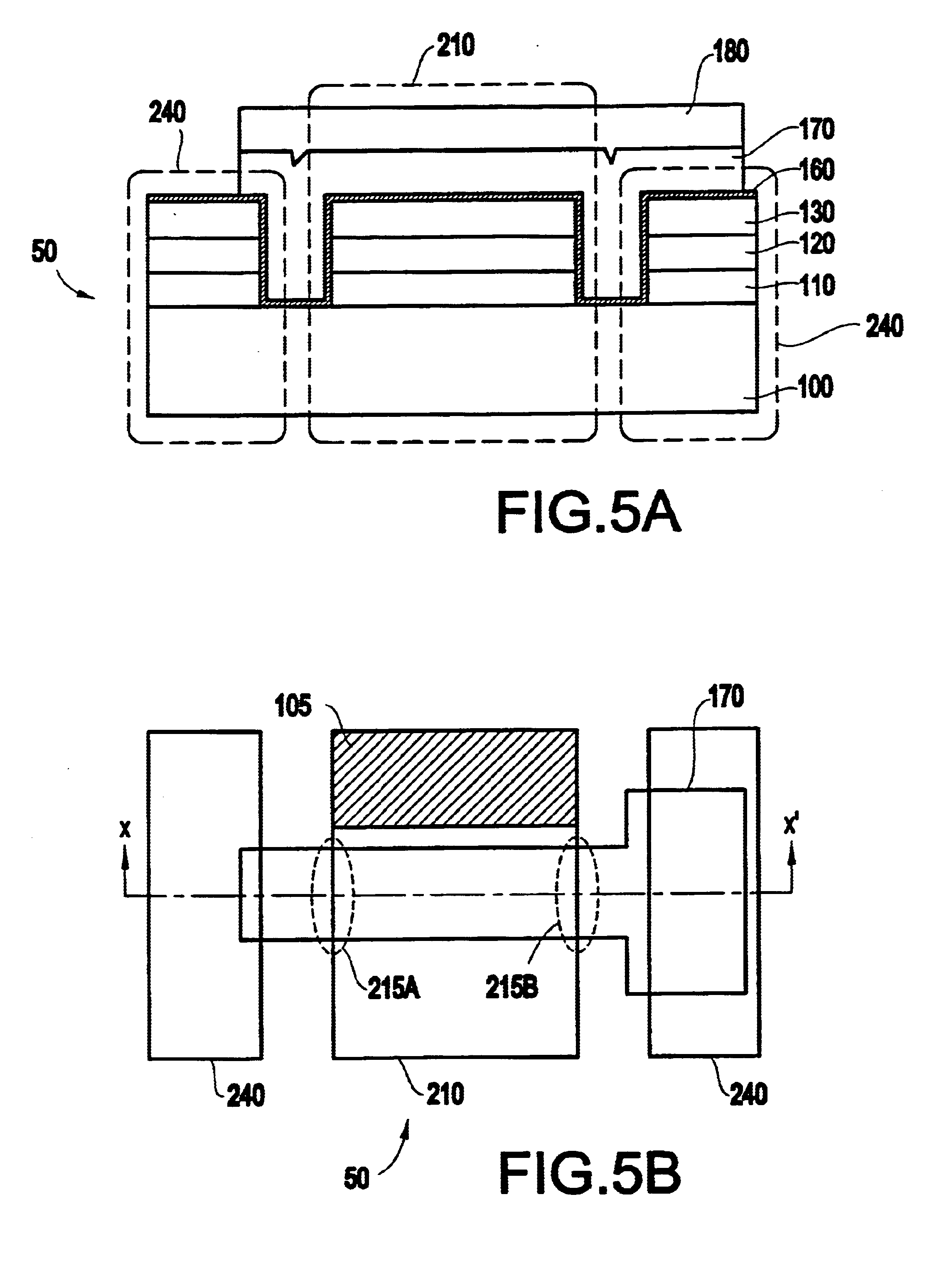

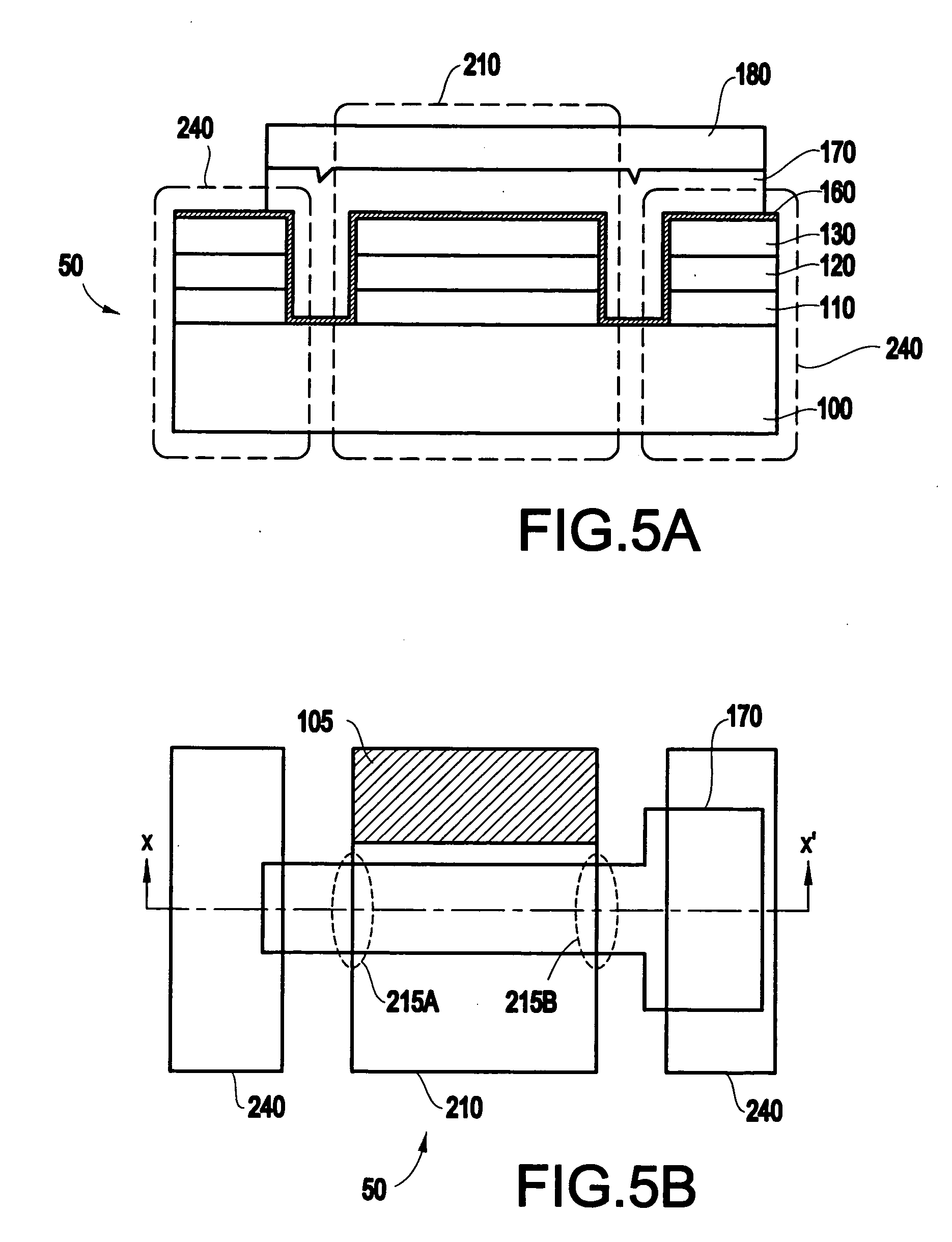

Method of forming a planar polymer transistor using substrate bonding techniques

A structure and method of forming a fully planarized polymer thin-film transistor by using a first planar carrier to process a first portion of the device including gate, source, drain and body elements. Preferably, the thin-film transistor is made with all organic materials. The gate dielectric can be a high-k polymer to boost the device performance. Then, the partially-finished device structures are flipped upside-down and transferred to a second planar carrier. A layer of wax or photo-sensitive organic material is then applied, and can be used as the temporary glue. The device, including its body area, is then defined by an etching process. Contacts to the devices are formed by conductive material deposition and chemical-mechanical polish.

Owner:IBM CORP

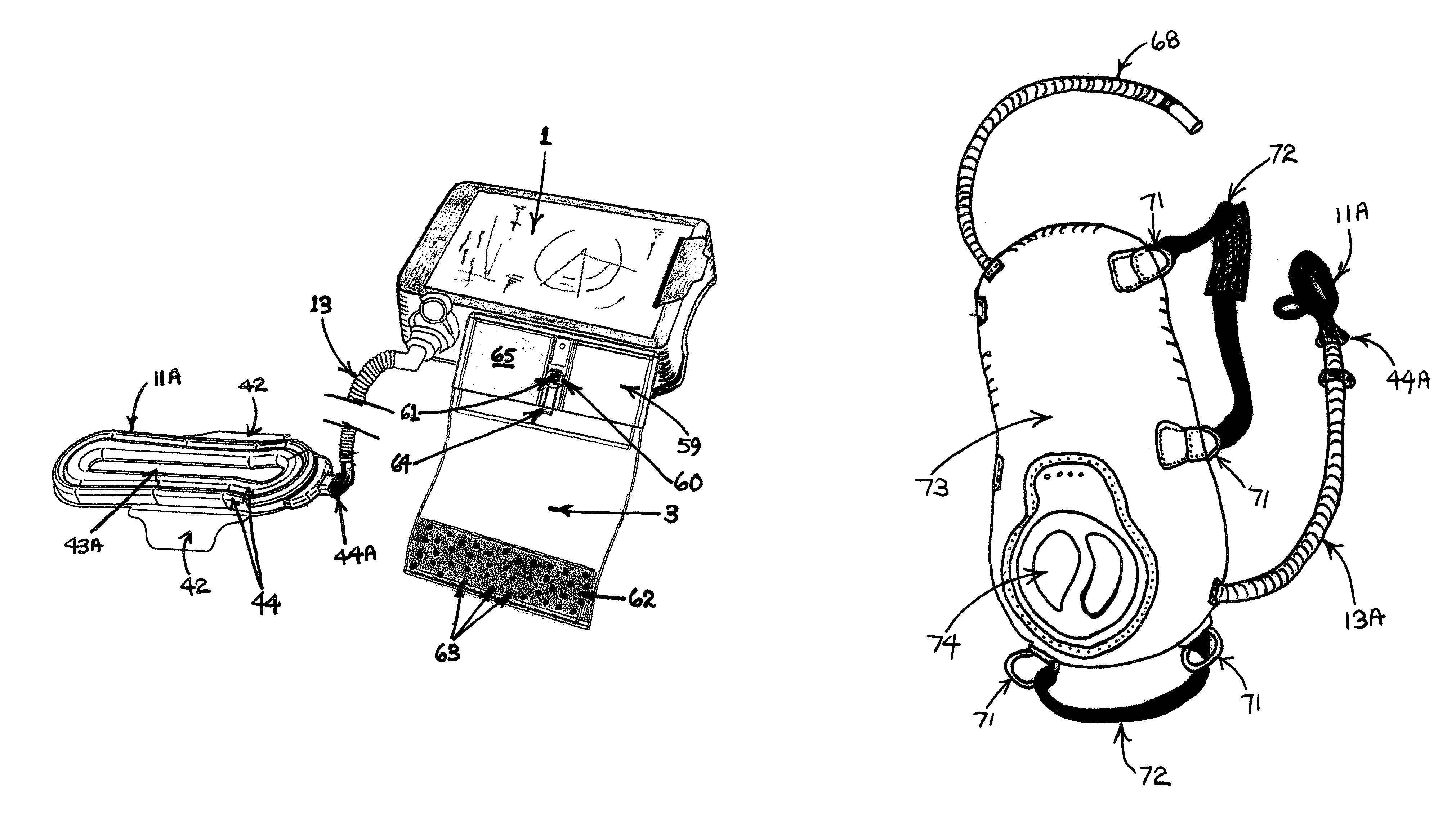

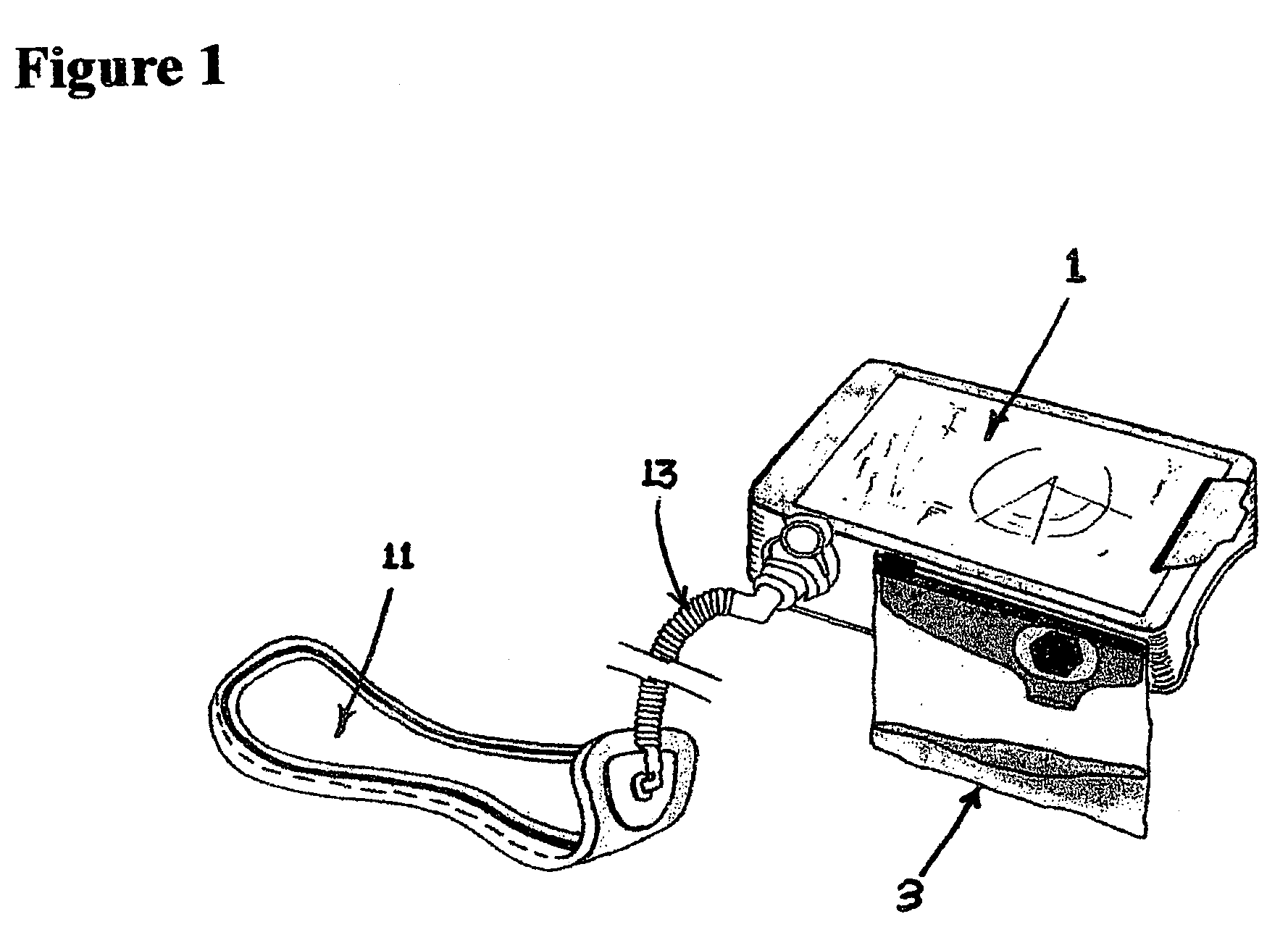

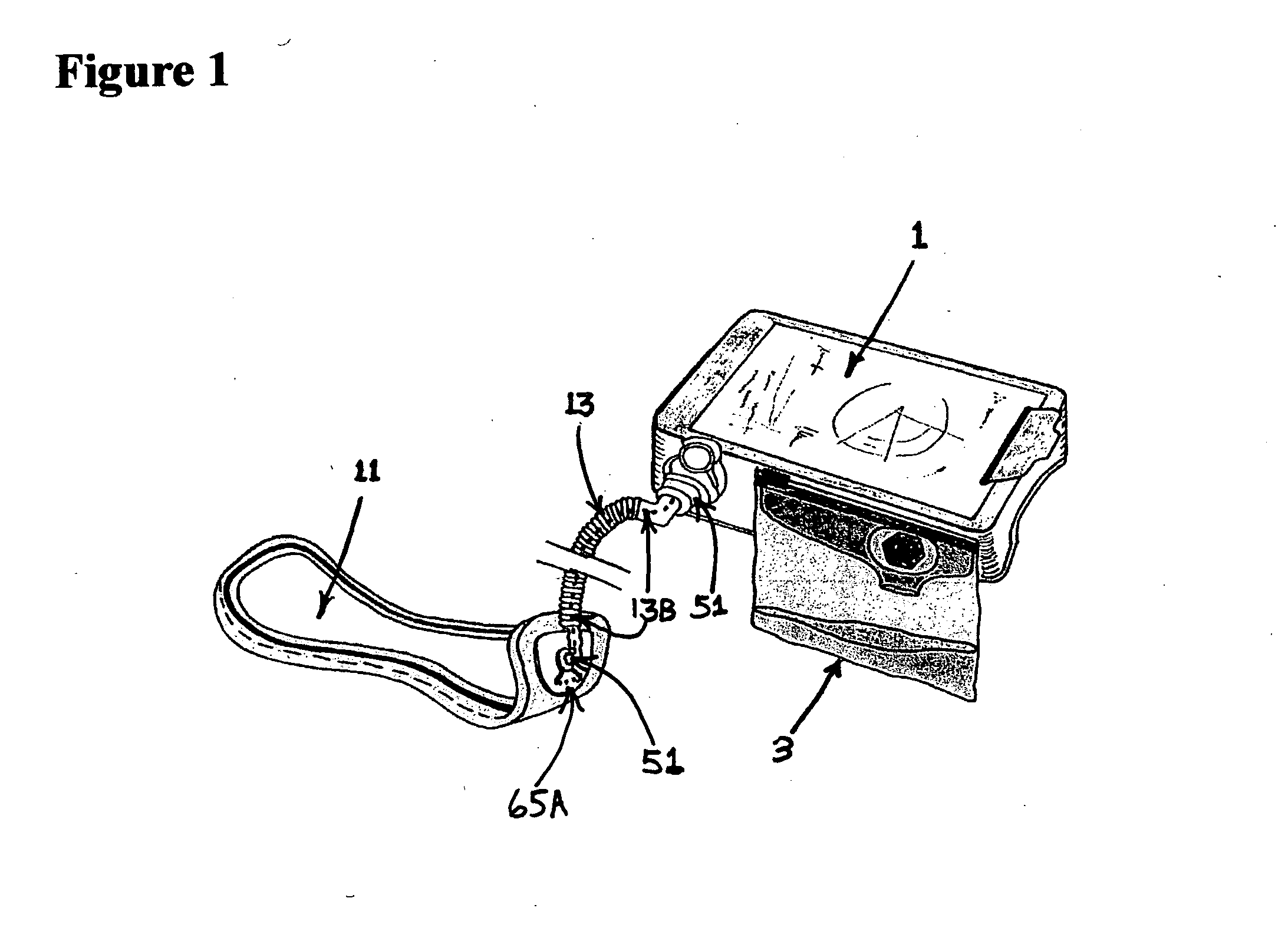

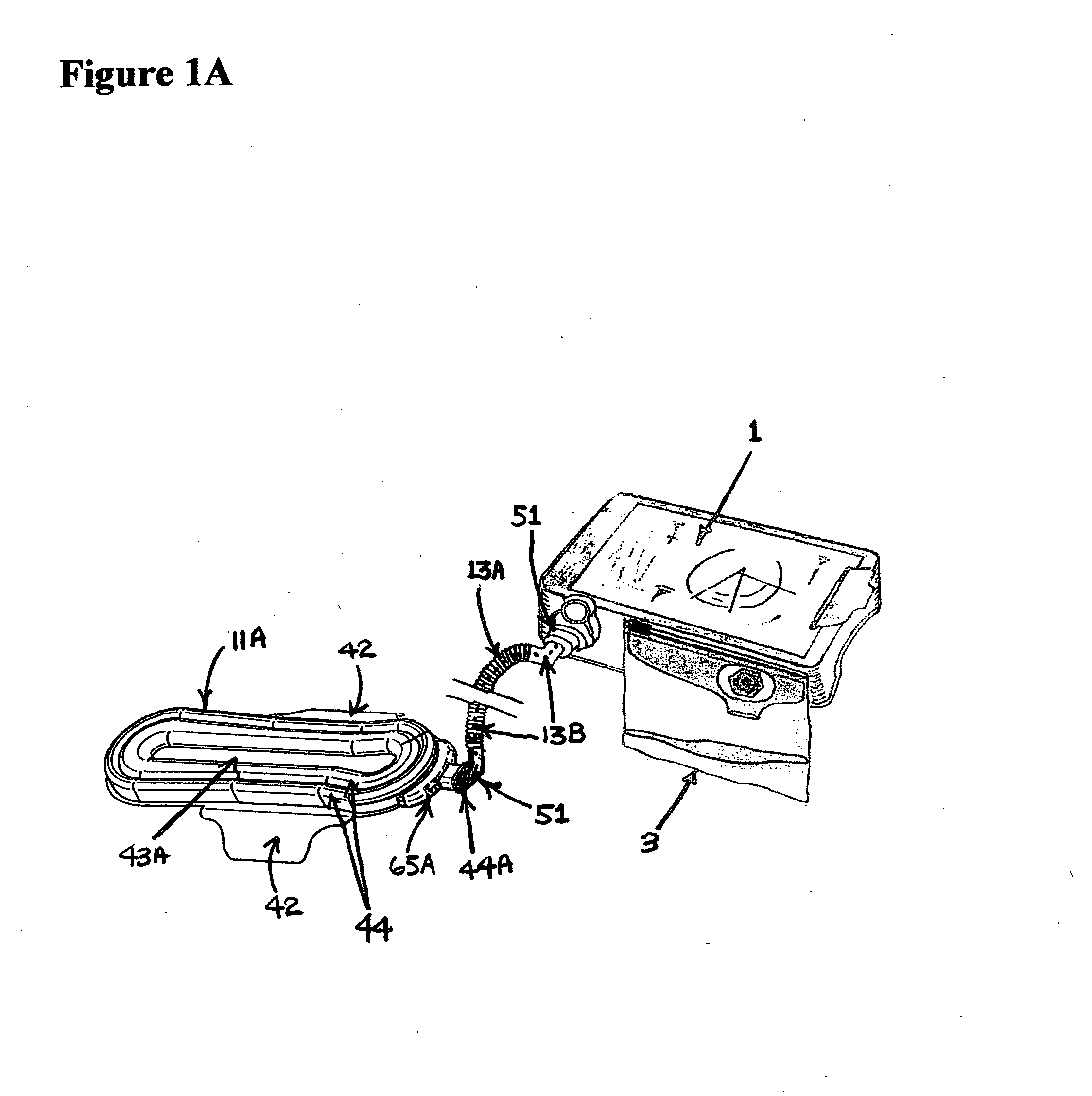

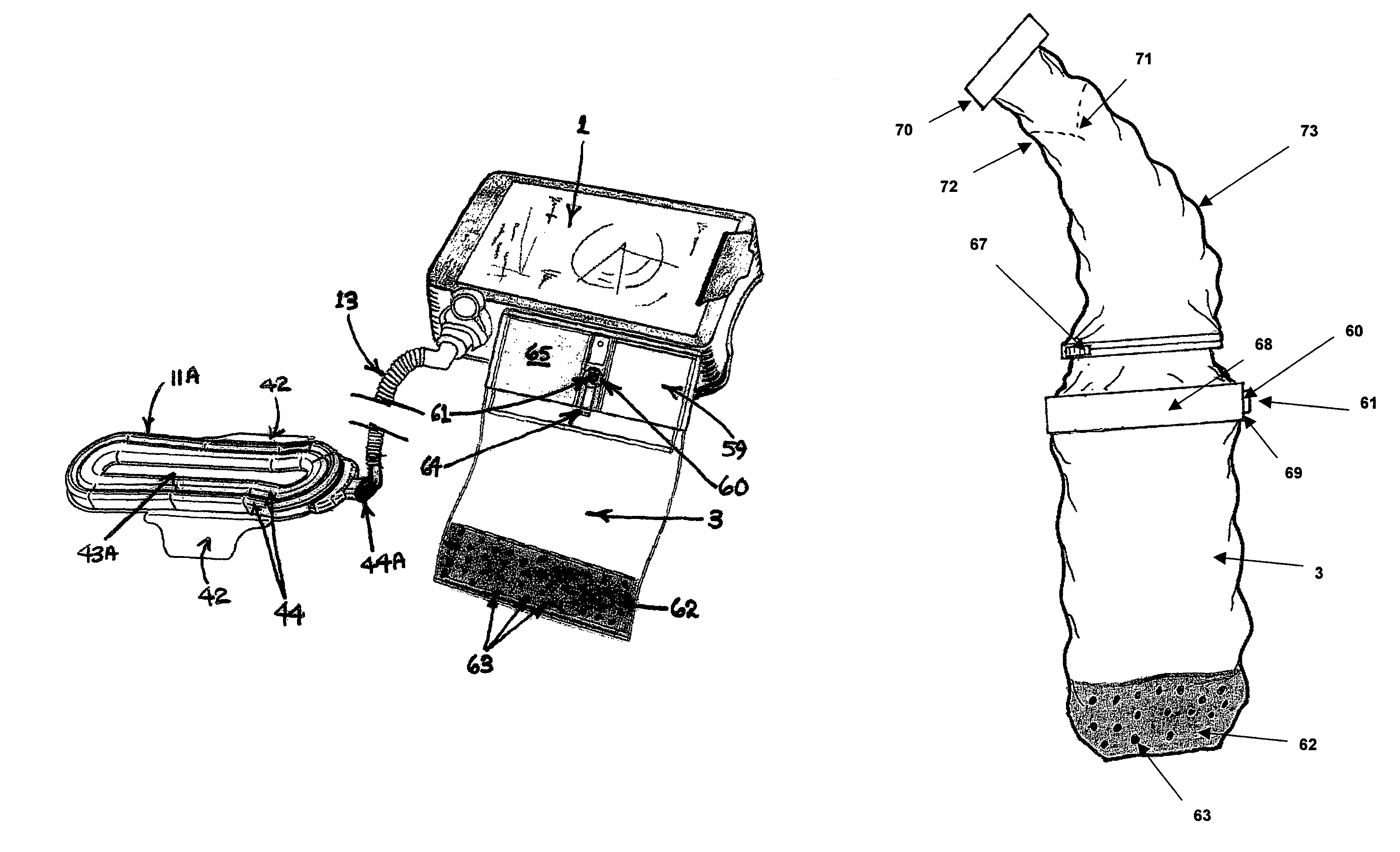

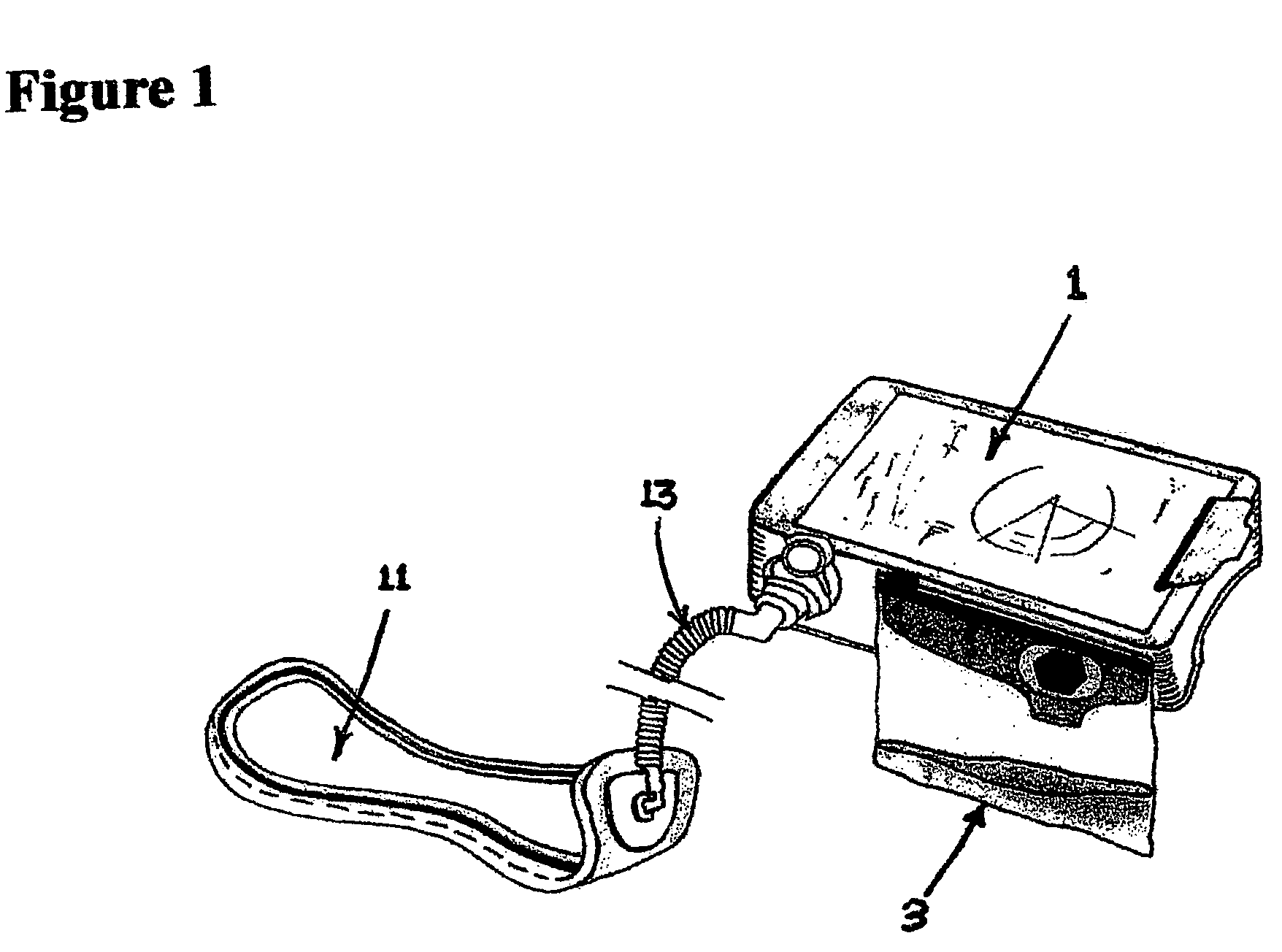

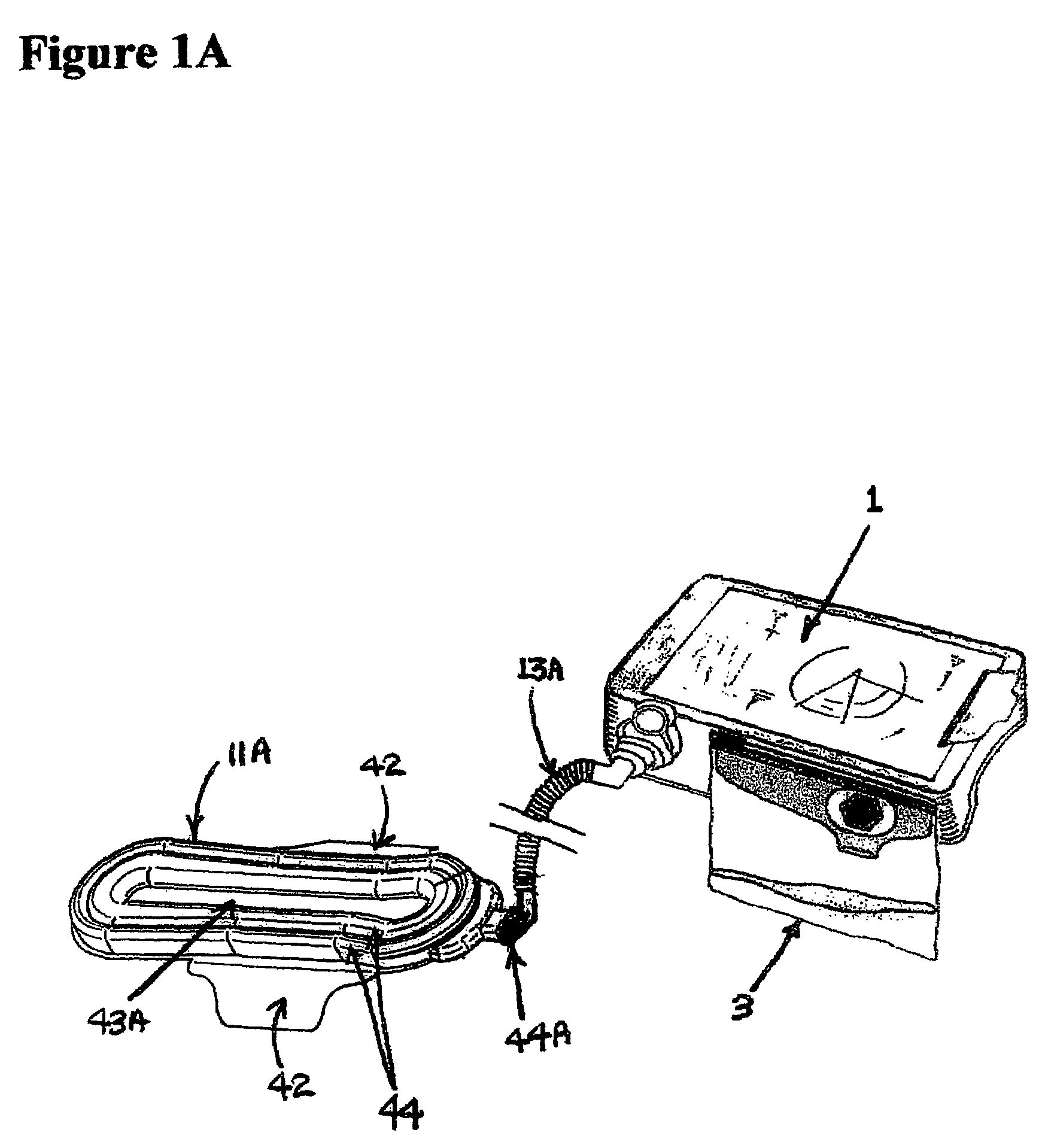

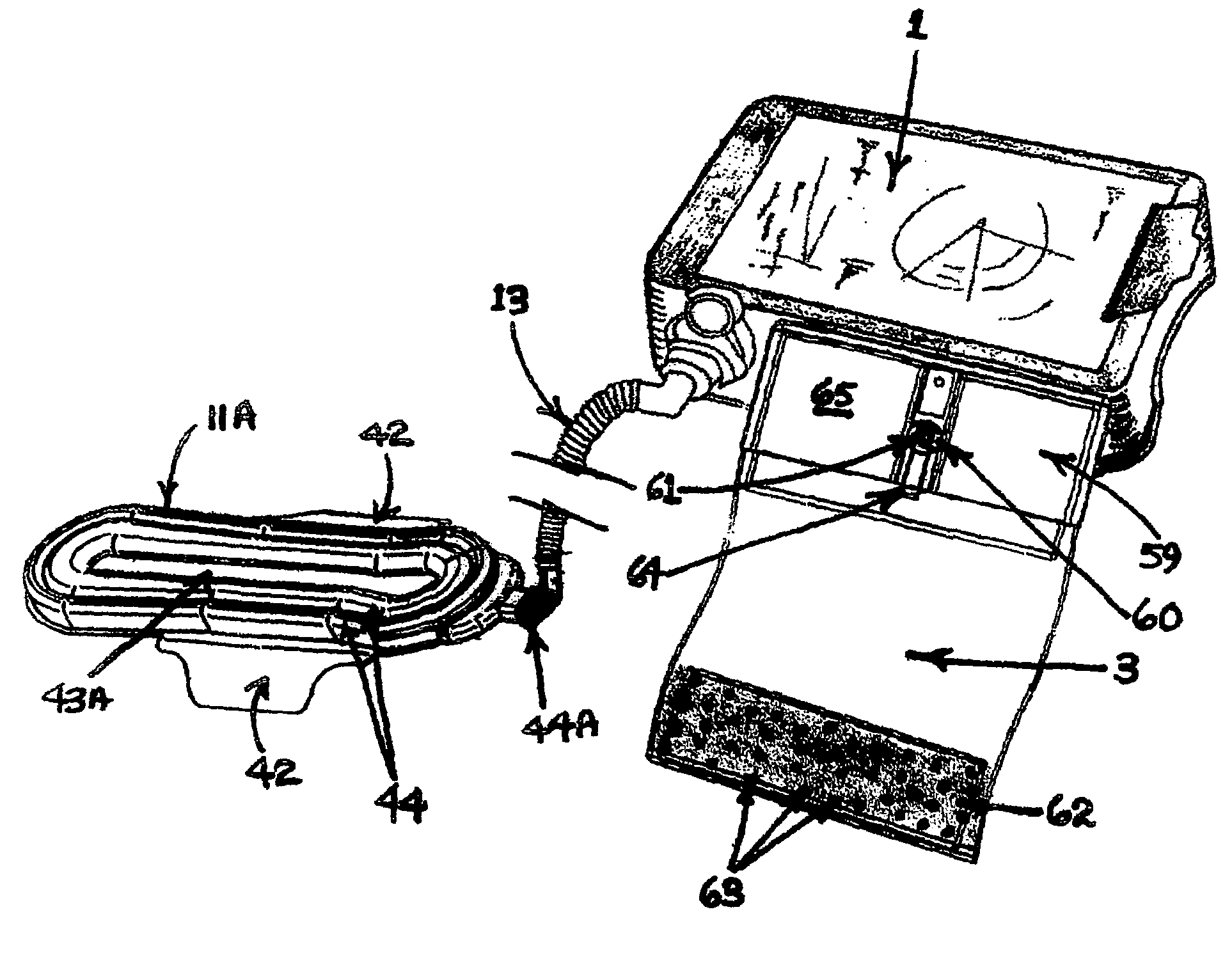

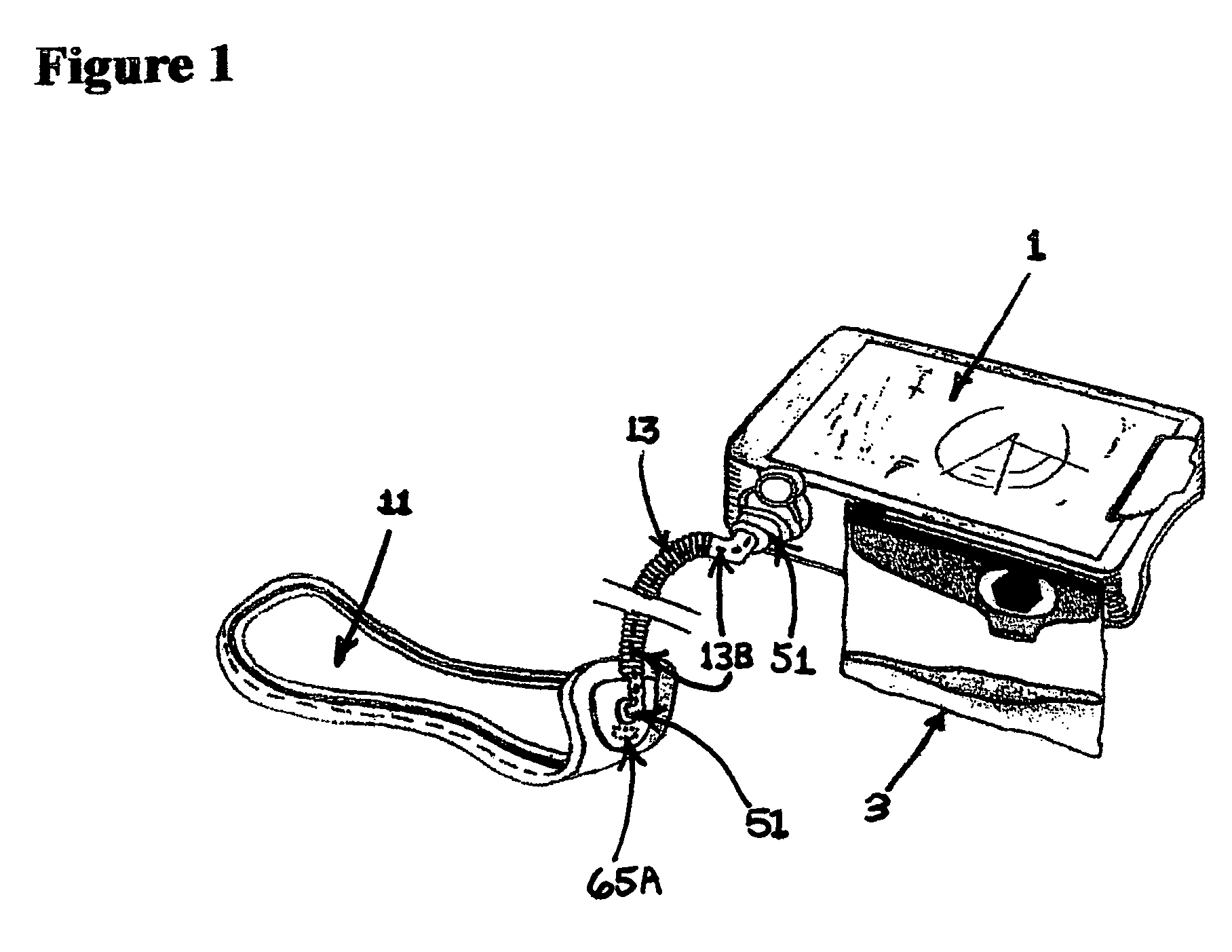

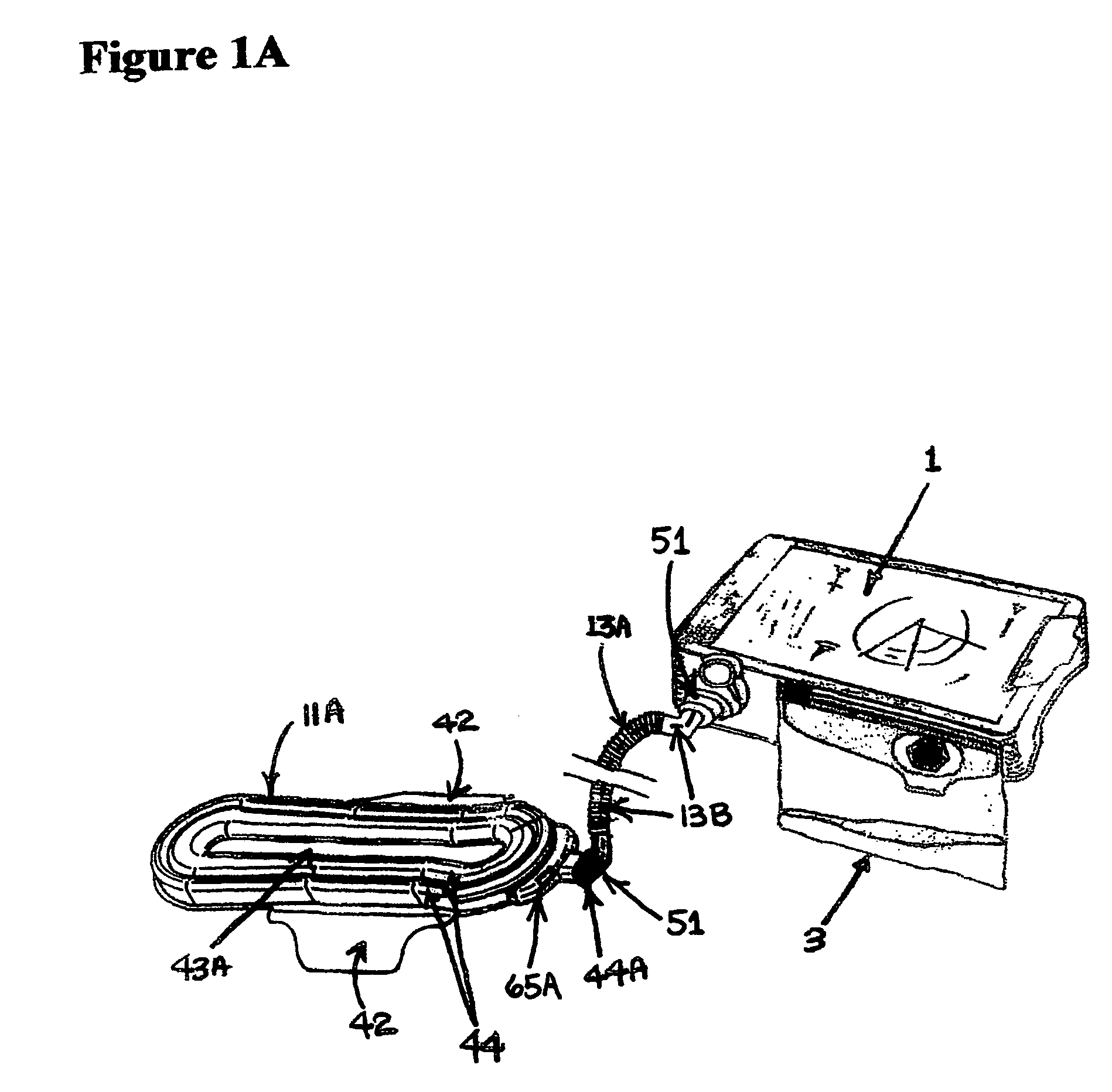

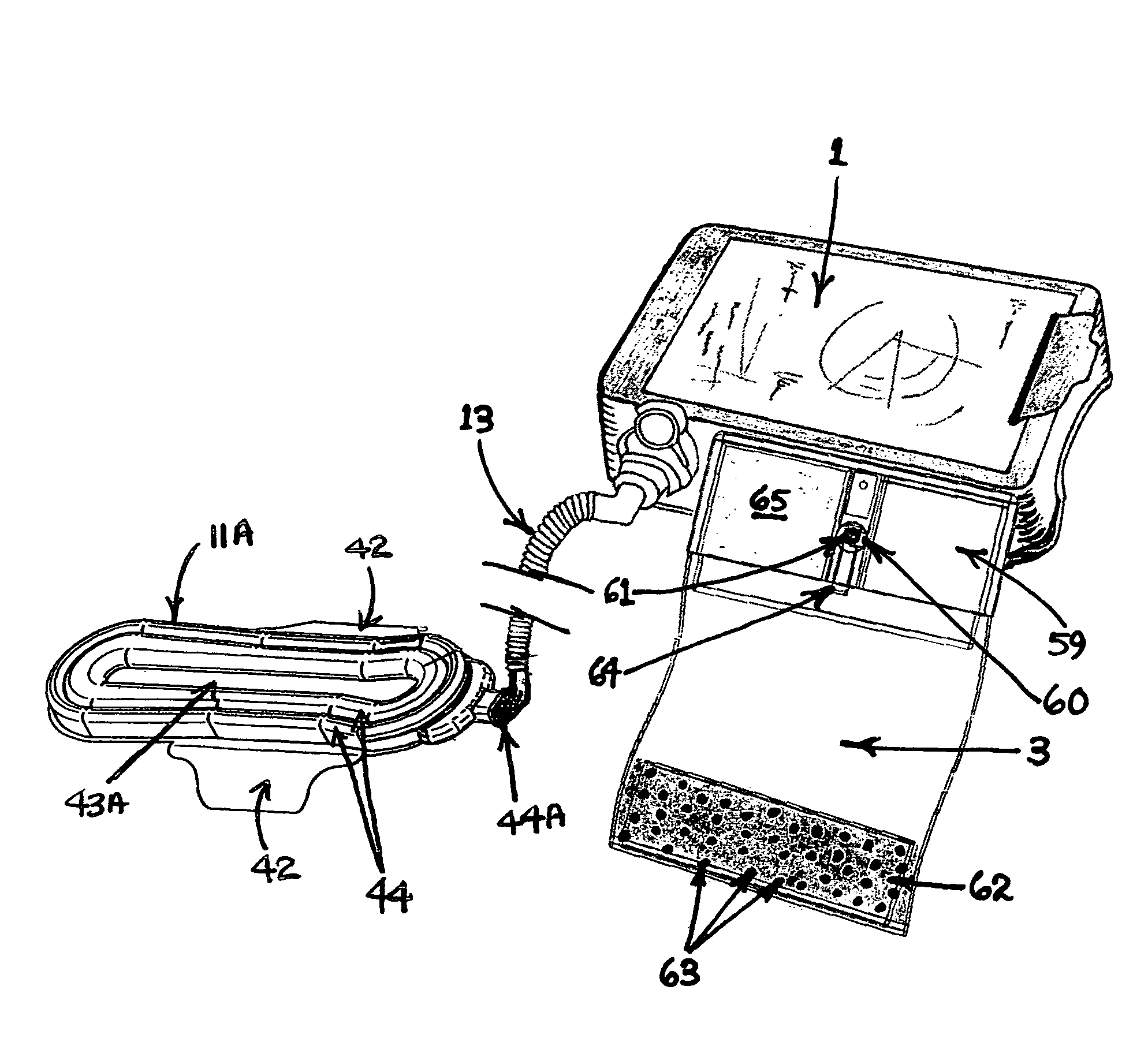

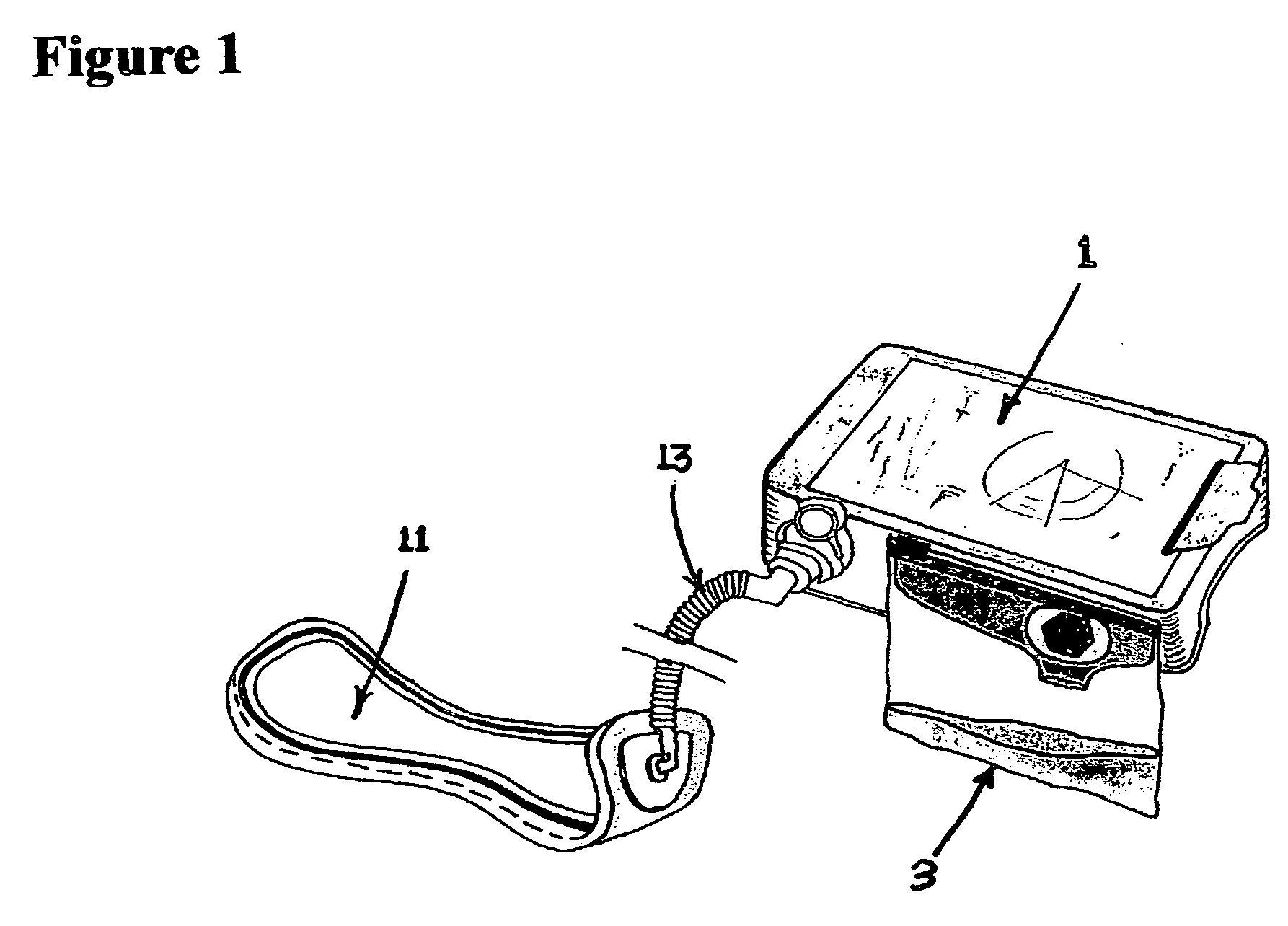

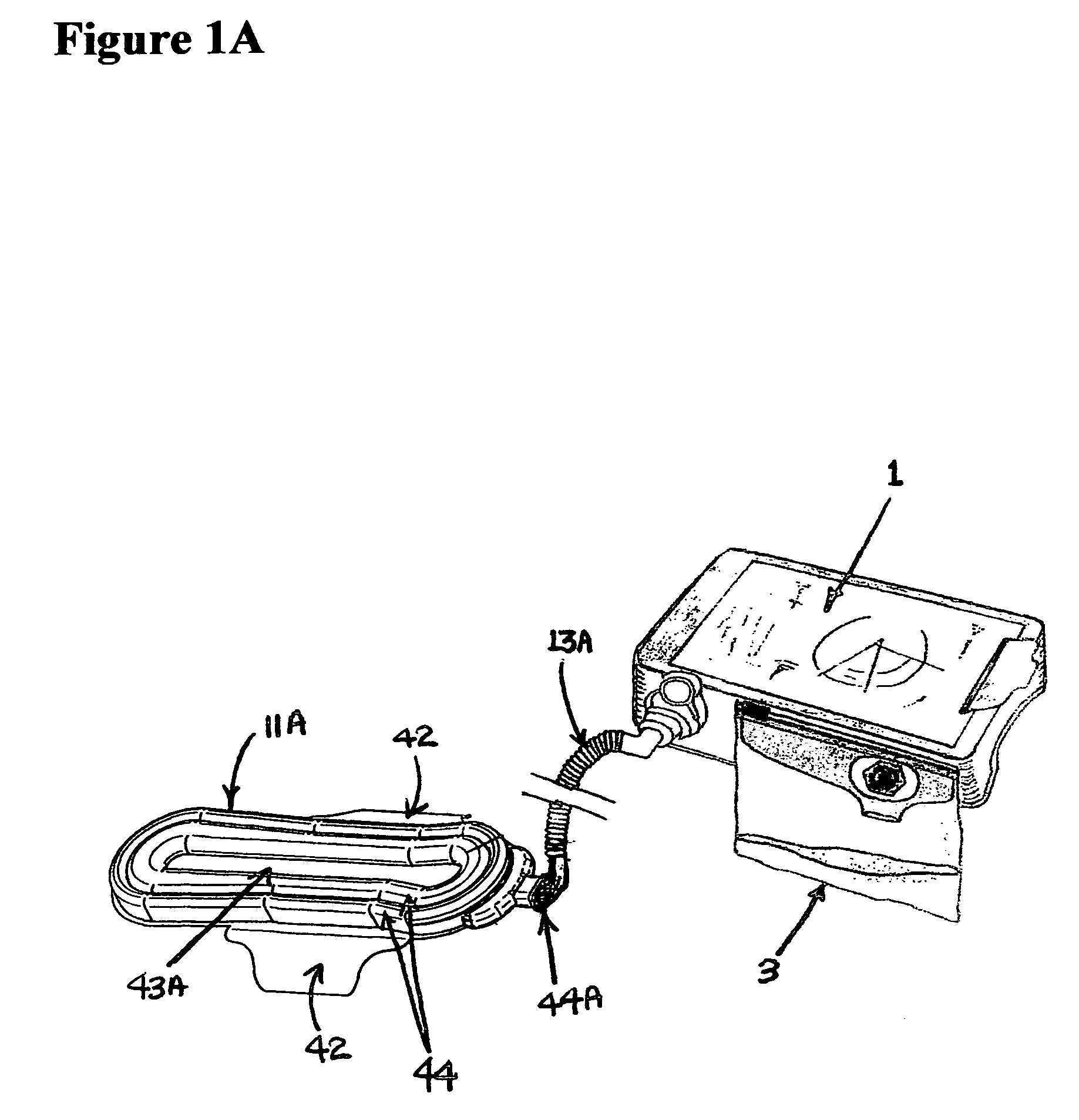

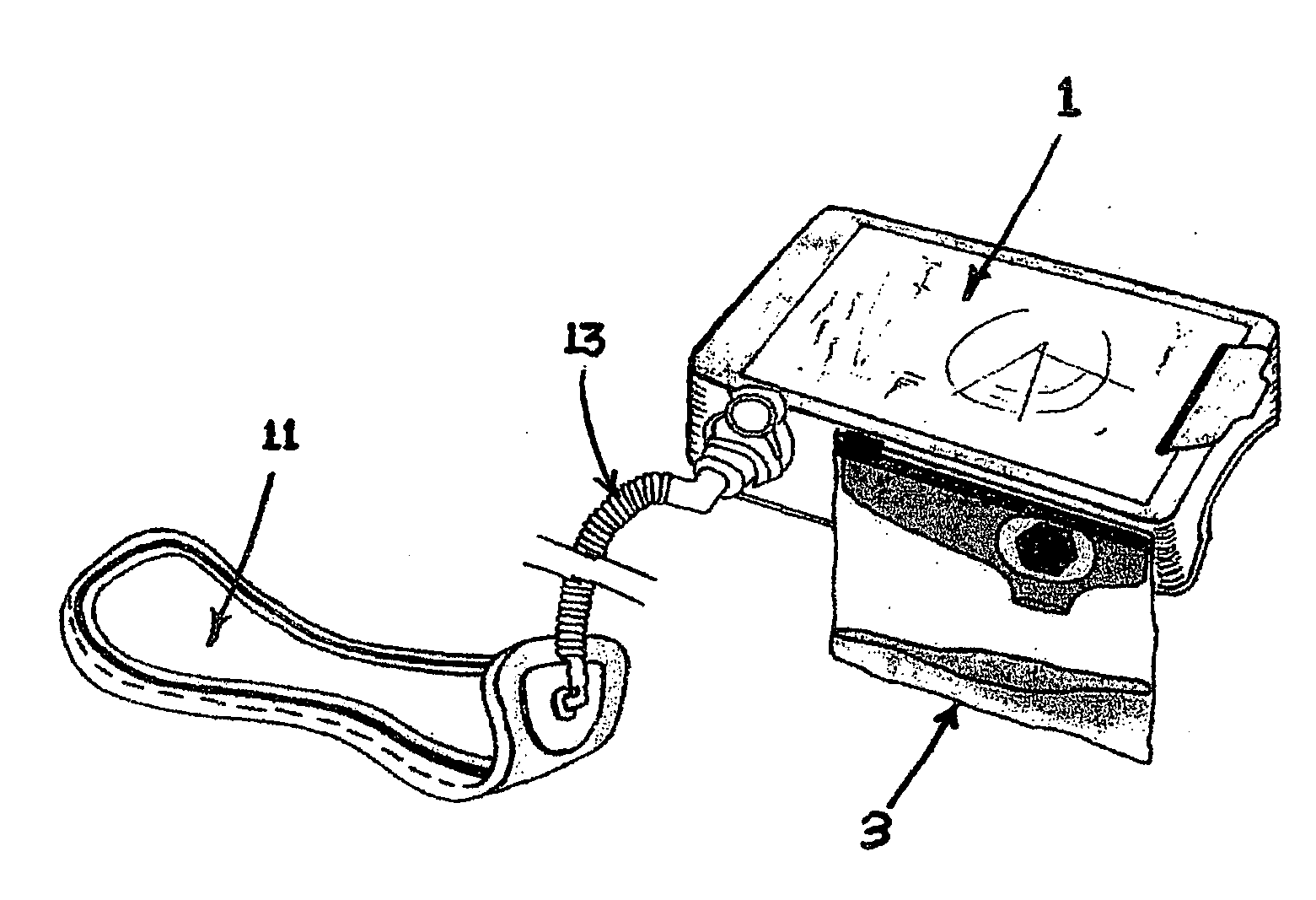

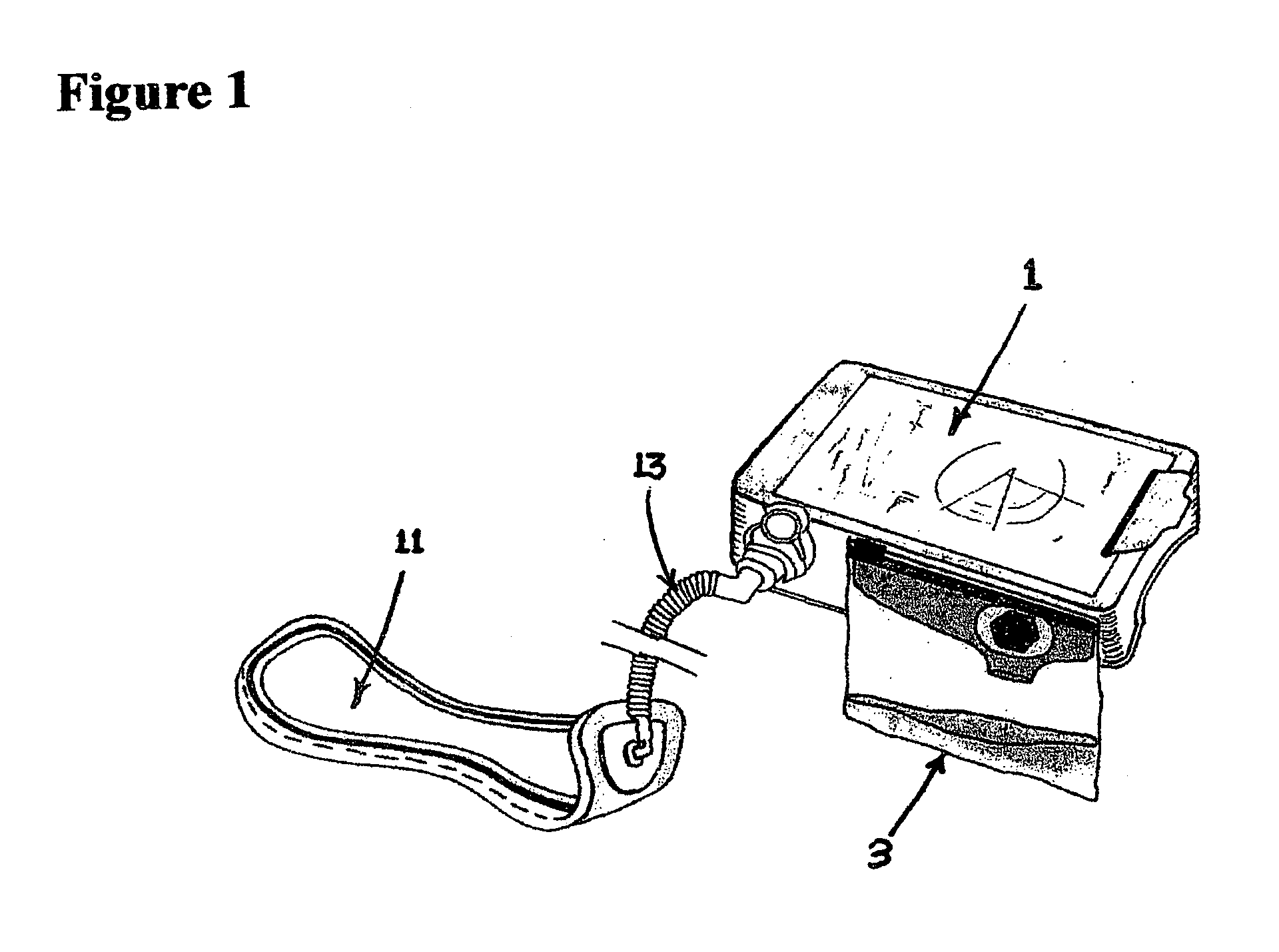

Automatic self cleaning bladder relief and hydration system

InactiveUS7141043B2Minimizing bulkMinimize discomfortNon-surgical orthopedic devicesSuction devicesSemi automaticUrine Collections

Owner:HARVIE MARK R

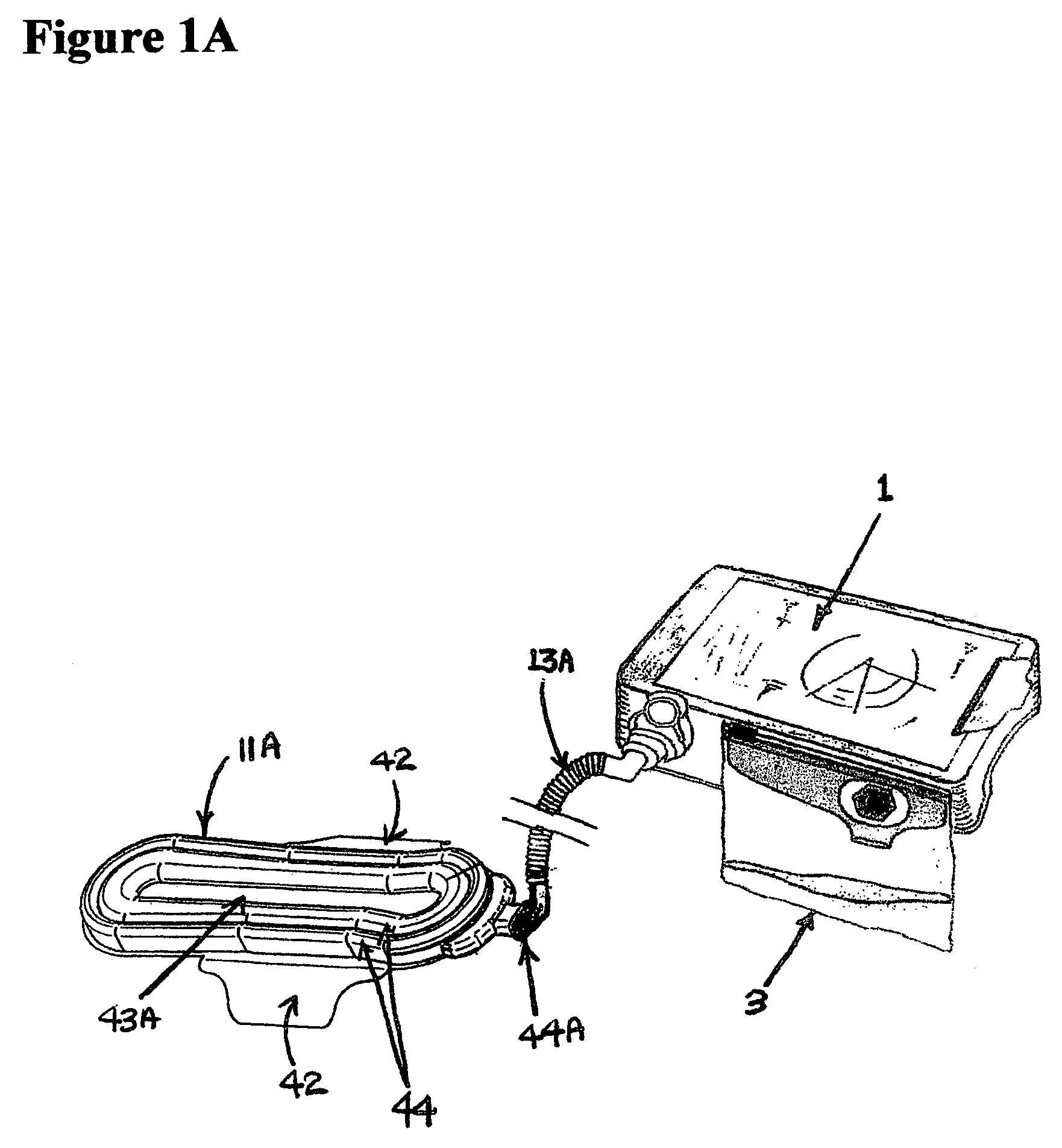

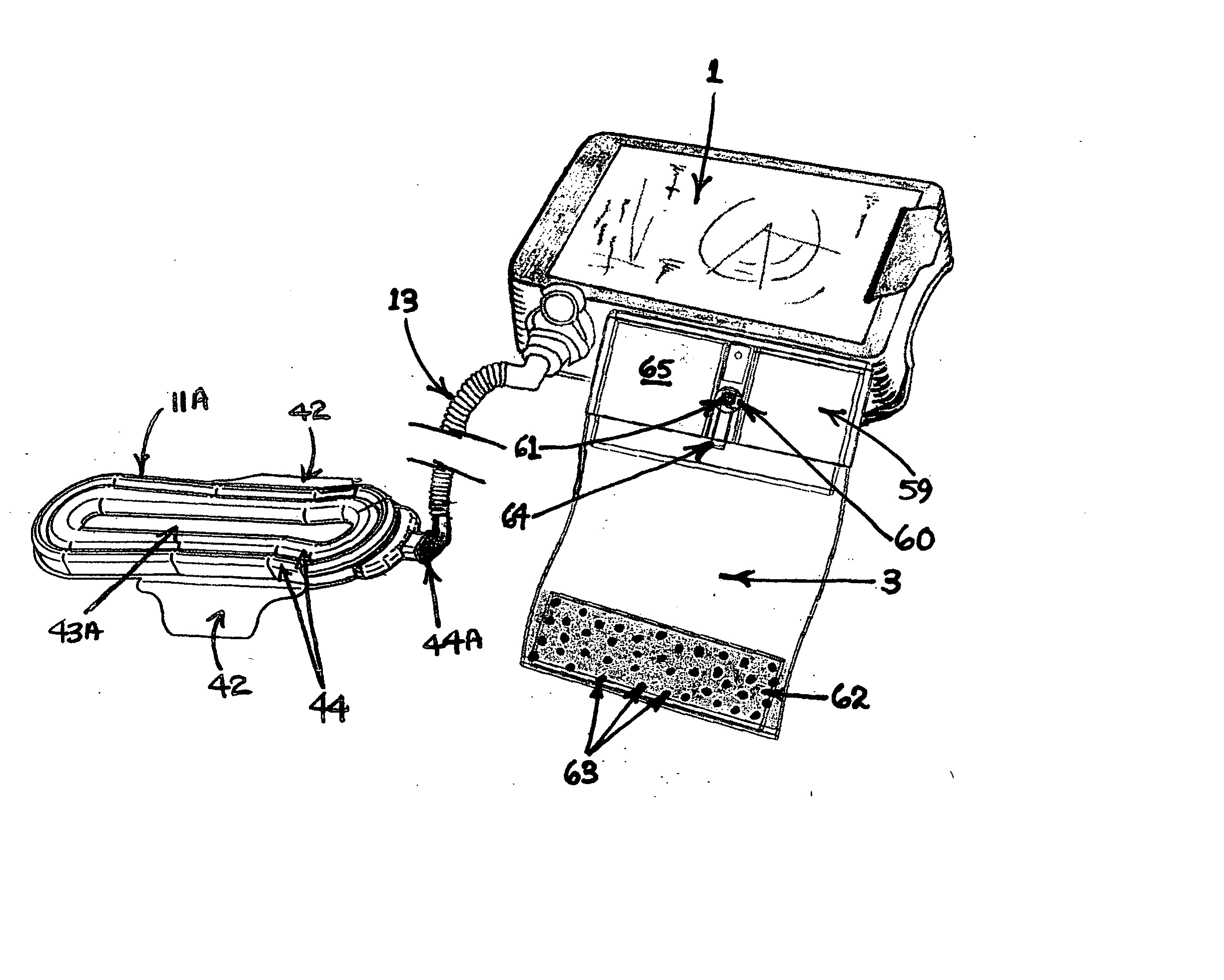

Automatic self cleaning bladder relief with diaper pad system

InactiveUS20080091153A1Minimizing bulkMinimize discomfortSuction devicesBodily discharge devicesUrine CollectionsSemi automatic

This invention is an automatic / semi-automatic bladder relief and fecal waste management system for use in the absence of sanitary facilities. The fecal collection bag is collapsed when not in use and is automatically expanded by the weight of feces upon defecation and is sealed after use. It incorporates an inflatable urine collection means that may be deflated after use. The power unit is powered by a battery that is integrated into a urine storage bag or female pad or male cup. It utilizes a disposable urine storage bag with an isolated cleaning fluid chamber with a directional valve and pump system automatically rinsing and sanitizing the pump, hoses, collection means and the user with a cleaning fluid stored in the cleaning fluid chamber of the urine storage bag. The disposable urine storage bag contains absorbent polymer crystals absorbing the urine as it is deposited in the bag during use.

Owner:HARVIE MARK

Low-shrink polypropylene tape fibers comprising high amounts of nucleating agents

InactiveUS6794033B2Low shrinkageLow heat shrinkageSynthetic resin layered productsFilament/thread formingFiberPolymer science

Owner:MILLIKEN & CO

Safety Coatings

InactiveUS20080249207A1Convenient coatingHigh glossAntifouling/underwater paintsPaints with biocidesPolymer crystalsCoating

The invention relates to coating compositions, in particular anti-slip floor coating compositions that contain a crystalline polymeric material in solution that crystallises as the coating cures leading to the formation of hard polymeric crystals within the cured coating composition. The invention also relates to methods of making these compositions and uses thereof.

Owner:WHITELEY

Automatic self cleaning bladder relief system and failsafe

InactiveUS7131964B2Maximum comfortMinimizing bulkNon-surgical orthopedic devicesSuction devicesDriver/operatorSemi automatic

This invention is an automatic or semi-automatic bladder relief system for users that require disposal of urine in the absence of sanitary facilities, like aircraft pilots and incontinent individuals. It incorporates an inflatable urine collector deflatable after use. It incorporates disposable batteries into a disposable urine storage bag with an isolated cleaning fluid chamber with directional valve and pump system that automatically rinses and sanitizes the pump, hoses, collection means and user with cleaning fluid stored in the cleaning fluid chamber. The urine storage bag has a failsafe device in the event of system failure, it being detachable from the pump with a stored extendable portion forming a seal with user's body allowing urination into the bag without urine splash-back and upon completion the user places the extended portion back into the unit closing it with a ziplock. The storage bag contains absorbent polymer crystals absorbing the deposited urine.

Owner:HARVIE MARK R

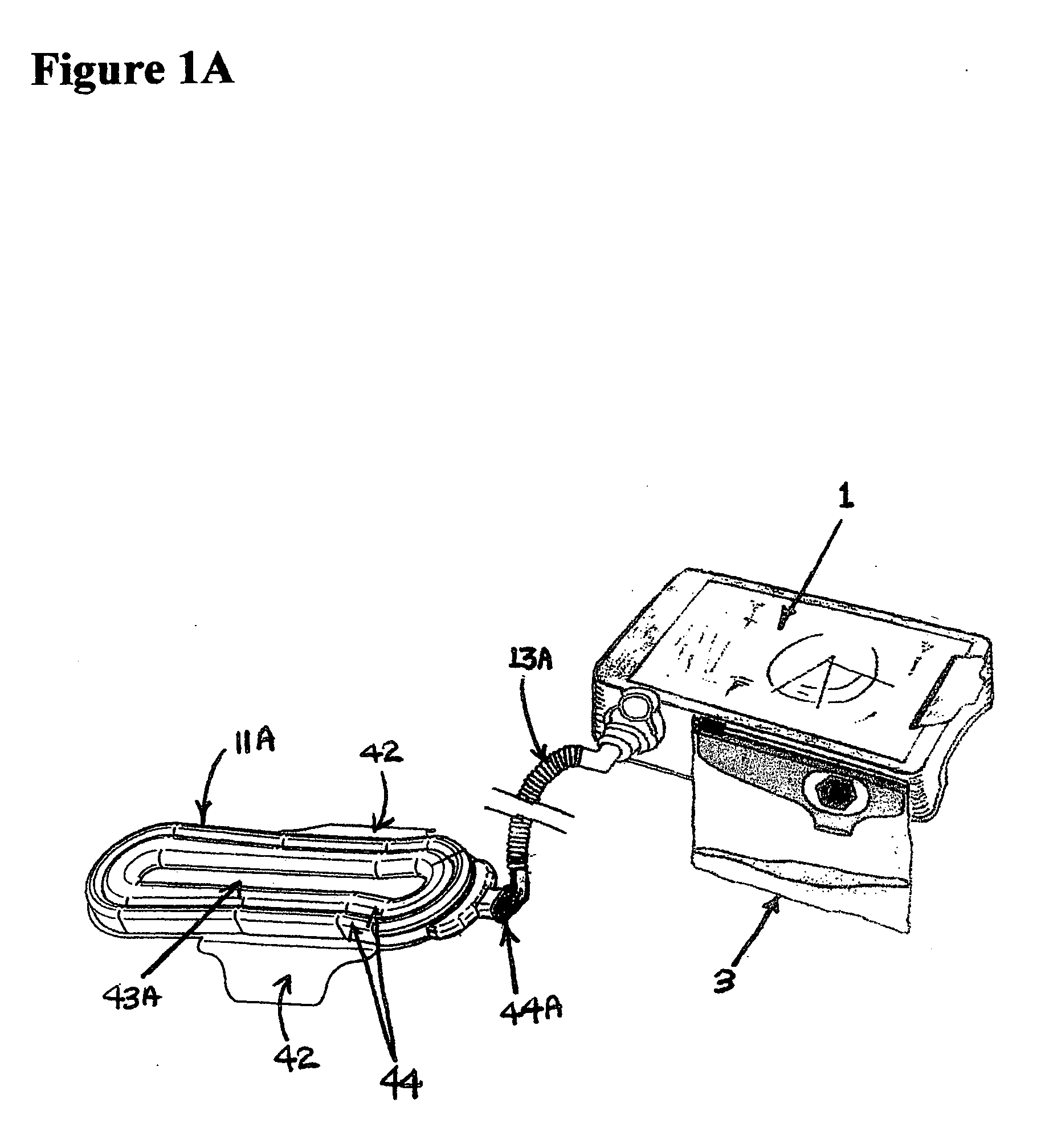

Automatic self cleaning bladder relief with battery pad system

InactiveUS7335189B2Minimizing bulkMinimize discomfortNon-surgical orthopedic devicesSuction devicesUrine collectionSemi automatic

This invention is an automatic or semi-automatic bladder relief system which increases sanitation and comfort for users requiring a means to dispose of urine in the absence of sanitary facilities, such as aircraft pilots and incontinent individuals. This invention incorporates an inflatable urine collection means that may be deflated after use. The power unit incorporates a battery that is integrated into a disposable urine storage bag or into a disposable female pad or male cup. This invention utilizes a disposable urine storage bag with an isolated cleaning fluid chamber with a directional valve and pump system automatically rinsing and sanitizing the pump, hoses, collection means and the user with a cleaning fluid stored in the cleaning fluid chamber of the disposable urine storage bag. The disposable urine storage bag contains absorbent polymer crystals absorbing the urine as it is deposited in the bag during use.

Owner:HARVIE MARK R

Automatic self cleaning bladder relief system

InactiveUS7135012B2Eliminate odorMinimizing bulkNon-surgical orthopedic devicesSuction devicesDriver/operatorUrine collection

This invention relates to an automatic or semi-automatic bladder relief system, specifically designed to increase the overall sanitation and comfort for users requiring a means to dispose of urine in the absence of sanitary facilities in situations such as aircraft pilots and incontinent individuals. This invention incorporates an inflatable urine collection means that may be deflated after use. The power unit incorporates a disposable battery that is integrated into a disposable urine storage bag. This invention also utilizes a disposable urine storage bag with an isolated cleaning fluid chamber with a directional valve and pump system automatically rinsing and sanitizing the pump, hoses, collection means and the user with a cleaning fluid stored in the cleaning fluid chamber of the disposable urine storage bag. The disposable urine storage bag contains absorbent polymer crystals absorbing the urine as it is deposited in the bag during use.

Owner:HARVIE MARK R

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

InactiveUS6863976B2High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingYarnThermoplastic

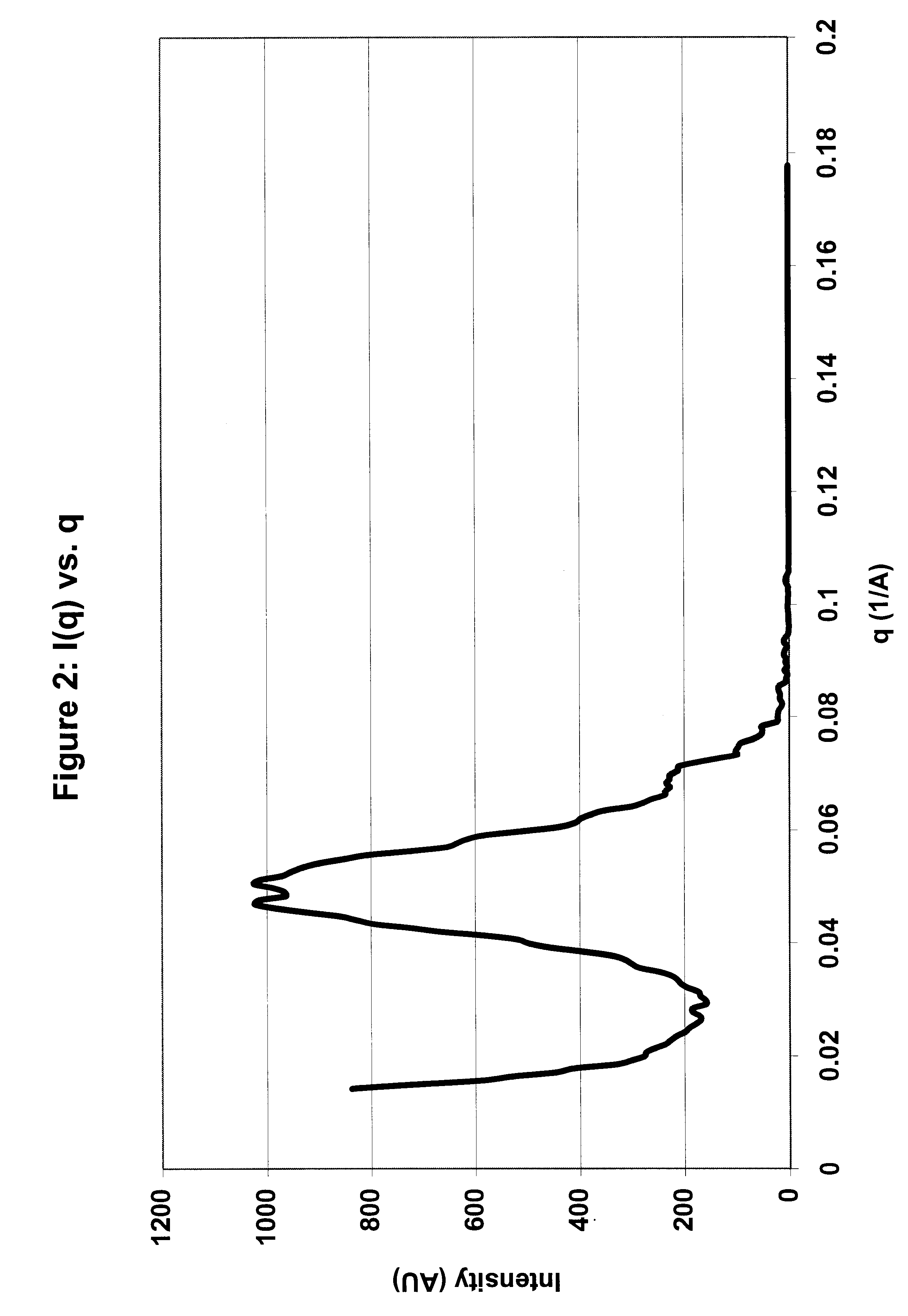

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the “rigidifying” nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred “rigidifying” compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2′-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

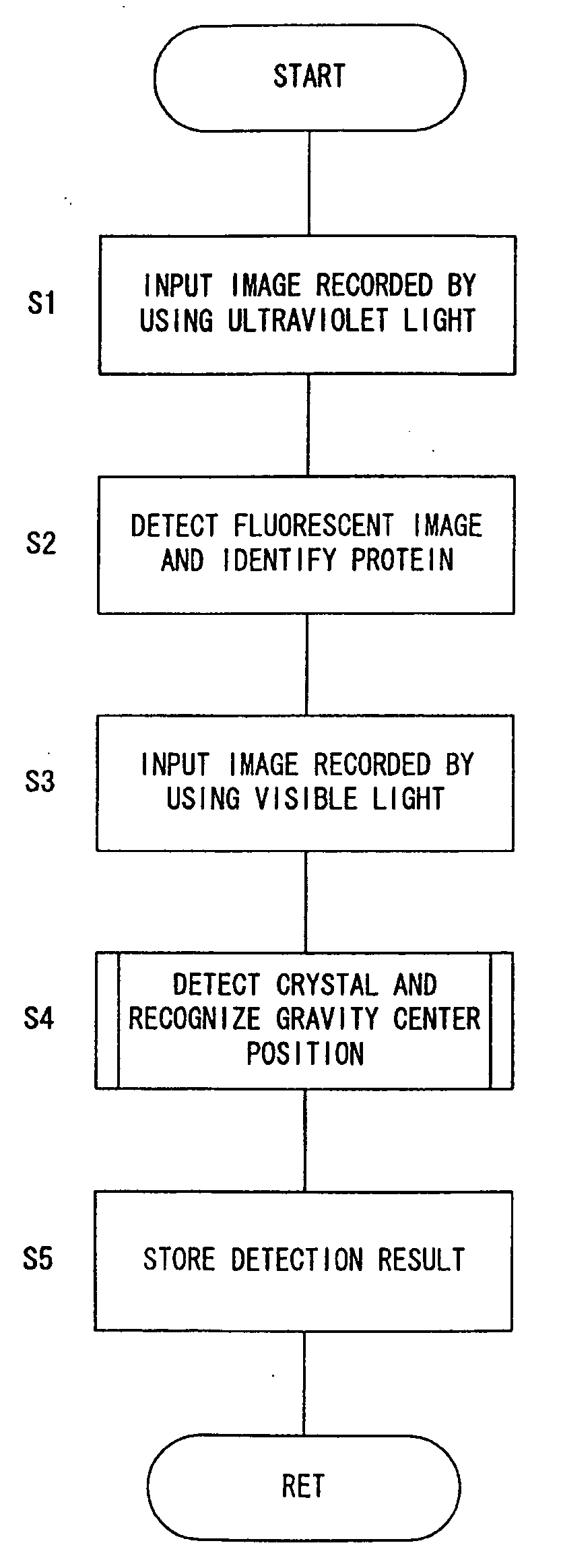

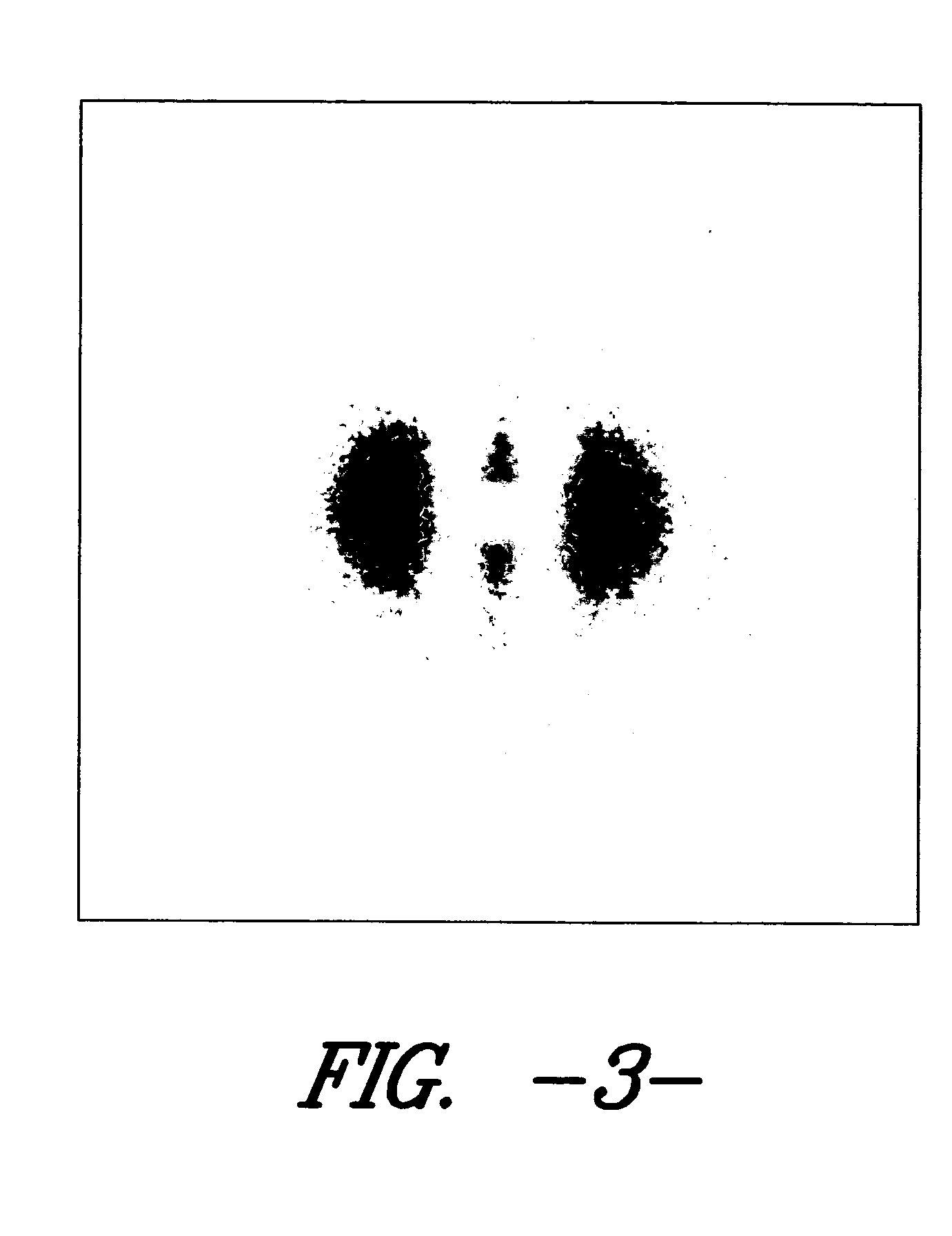

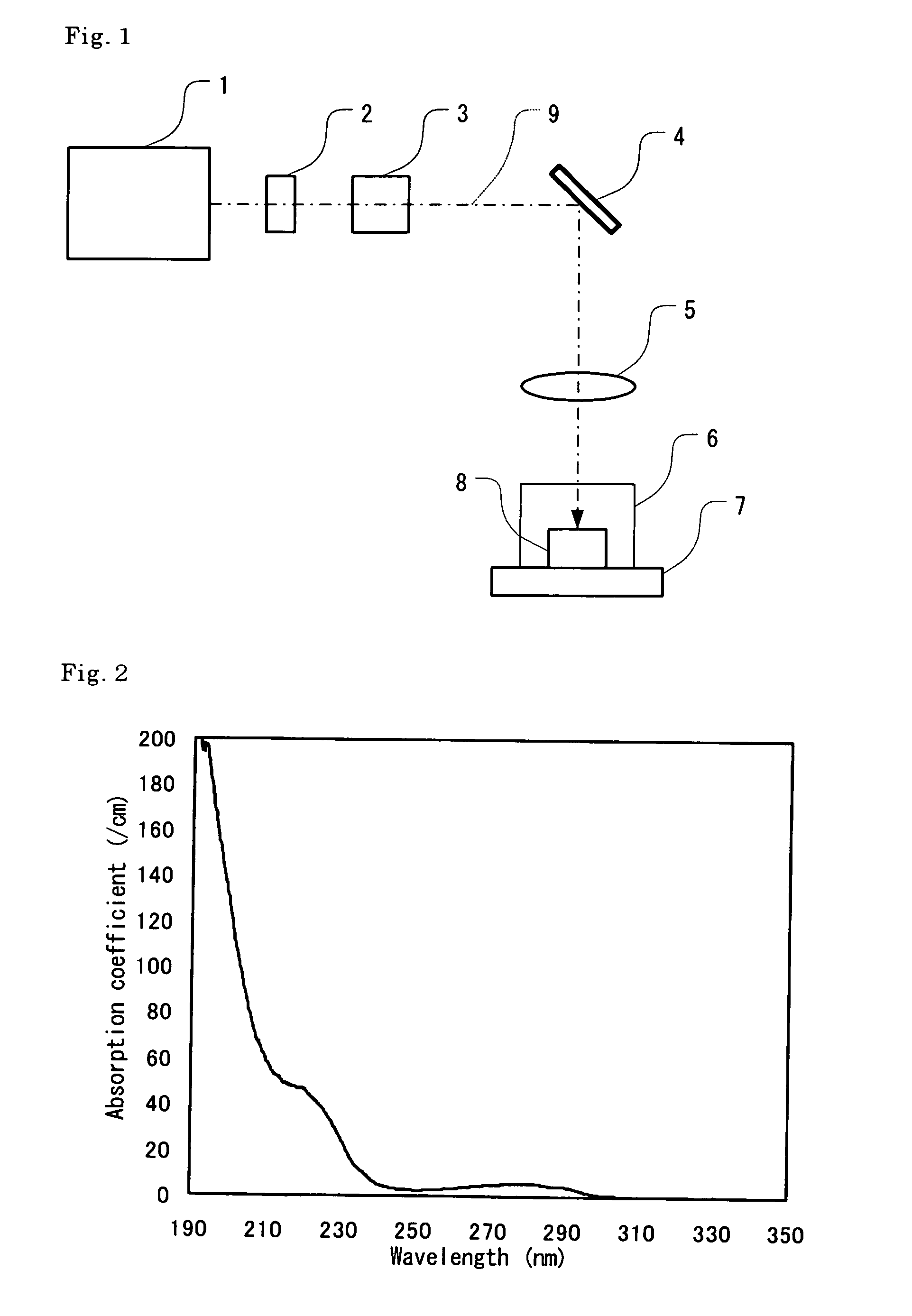

Method for detecting specified polymer crystal

InactiveUS20060222220A1Easy to handleCharacter and pattern recognitionFluorescence/phosphorescenceFluorescenceUltraviolet lights

In a specific macromolecule crystal detecting method according to the present invention, ultraviolet light is irradiated to sample solution, and a fluorescent image emitted from a sample in the sample solution is detected to detect specific macromolecules in the sample solution. Furthermore, by detecting the outline of the sample from the visible light image of the sample contained in the sample solution, the crystal is discriminated from other materials on the basis of the outline. By integrating the detection results of the fluorescent image and the visible light image, the specific macromolecule crystal is detected from the sample solution.

Owner:RIGAKU CORP

Chiral metal organic framework polymer sensor as well as preparation and application thereof

InactiveCN106442686AEasy to prepareReduce energy consumptionMaterial electrochemical variablesEnantiomerMetal-organic framework

The invention discloses a chiral metal organic framework polymer {[CuL] 2(H2O)} n sensor based on a chiral metal organic framework polymer, and a preparation and application thereof. An ultrasonic method is adopted for preparation; the method comprises the following steps: preparing chiral metal organic framework polymer crystal {[CuL] 2(H2O)} n, and carrying out thermal dehydration on the chiral metal organic framework polymer crystal {[CuL] 2(H2O)} n to obtain a chiral metal organic framework polymer {[CuL] 2} n; modifying an electrochemical chiral working electrode by using the {[CuL] 2} n to obtain the chiral metal organic framework polymer sensor; the sensor is used for detecting the content of enantiomers of D-(+)-tryptophan and L-(-) tryptophan. The chiral sensor prepared based on the material is simple in preparation method and easy to operate, and has a remarkable technical effect.

Owner:UNIV OF JINAN

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

Polypropylene monofilament fibers exhibiting low-shrink, high tenacity, and extremely high modulus levels

InactiveUS20040096661A1Reduced shrinkage performanceLow shrinkageSynthetic resin layered productsMonocomponent polypropylene artificial filamentThermoplasticYarn

Unique thermoplastic monofilament fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than any other previously produced thermoplastic fibers, particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:ROYER JOSEPH R +2

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

InactiveUS20050019565A1High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingYarnThermoplastic

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the “rigidifying” nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred “rigidifying” compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2′-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

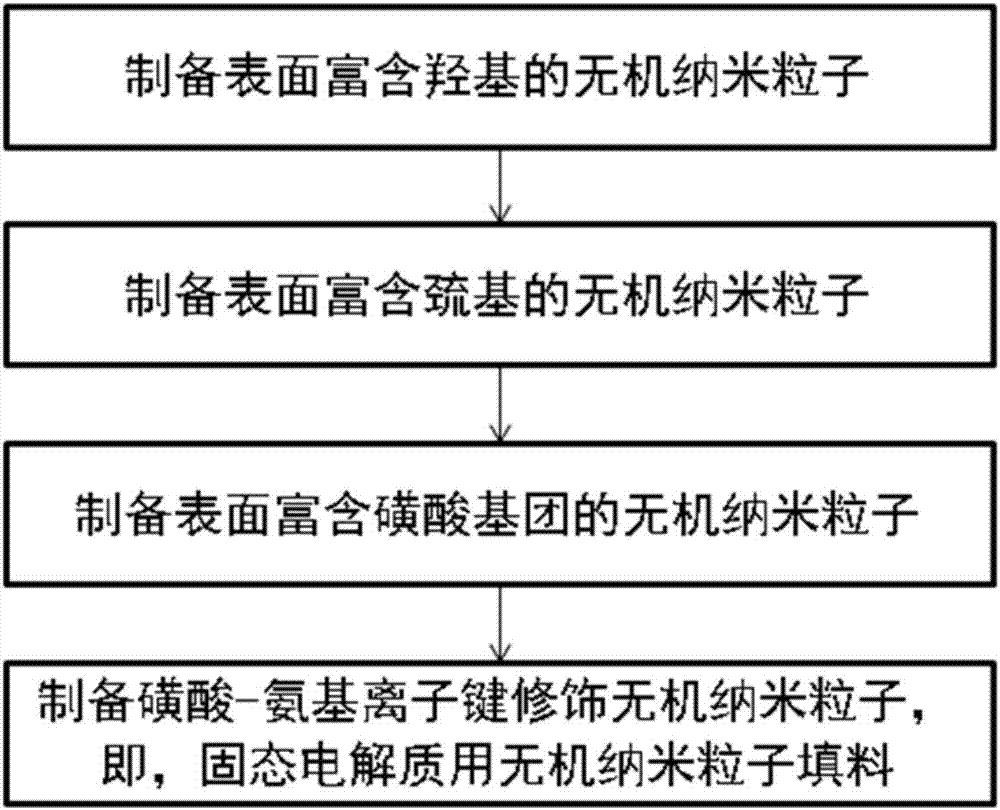

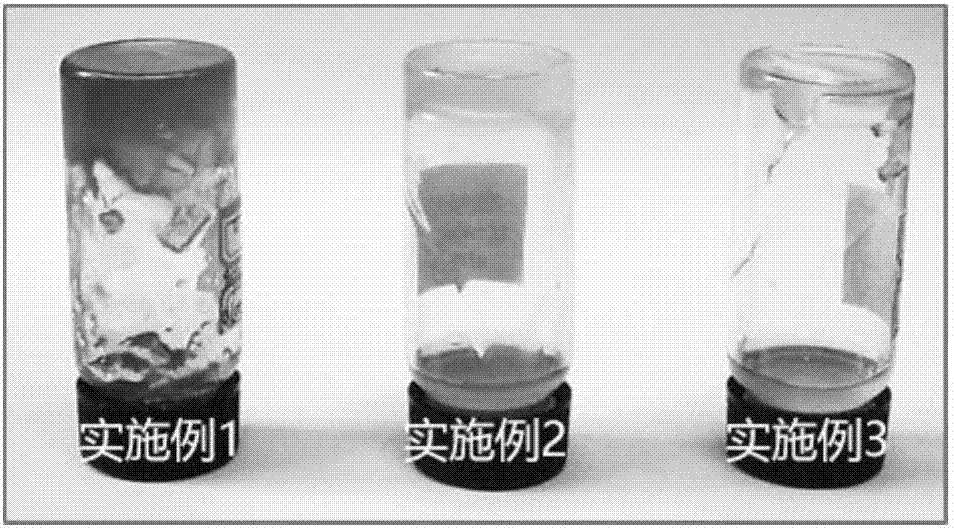

Inorganic nano particle filler for solid state electrolyte and preparation method of inorganic nano particle filler

ActiveCN107134587AEasy to manufactureReduce manufacturing costSolid electrolytesChemical industrySolid state electrolytePolymer crystals

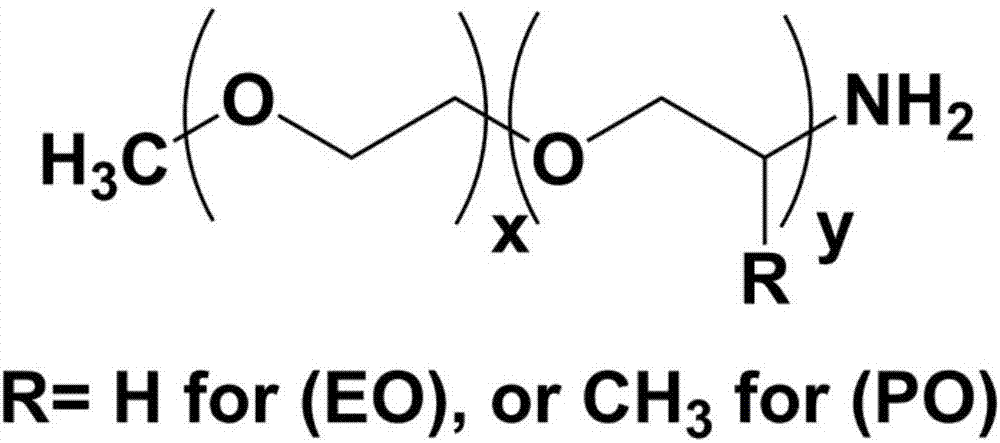

The invention discloses an inorganic nano particle filler for a solid state electrolyte and a preparation method of the inorganic nano particle filler. The inorganic nano particle filler for the solid state electrolyte is mainly formed by linking sulfonic acid group-modified inorganic nano particles and amino-terminated polyether by virtue of sulfonic acid-amino ionic bonds; and the mass ratio of the sulfonic acid group-modified inorganic nano particles to the amino-terminated polyether is 10 / 1-1 / 10. By adjusting the key components and shell components of the filler as well as the proportion between the key components and the shell components and improving the integrated process flow design and parameter conditions of each reaction step of the preparation method, the obtained inorganic nano particle filler for the solid state electrolyte has the advantages that on the one hand the surface of the filler is grafted with charges of the same polarity, and the mutual repulsion effect of the charges ensures the uniform dispersion of nano particles in the system; and on the other hand, the uniformly distributed filler can effectively inhibit the growth of polymer crystals so as to improve the ionic conductivity of the electrolyte.

Owner:HUAZHONG UNIV OF SCI & TECH

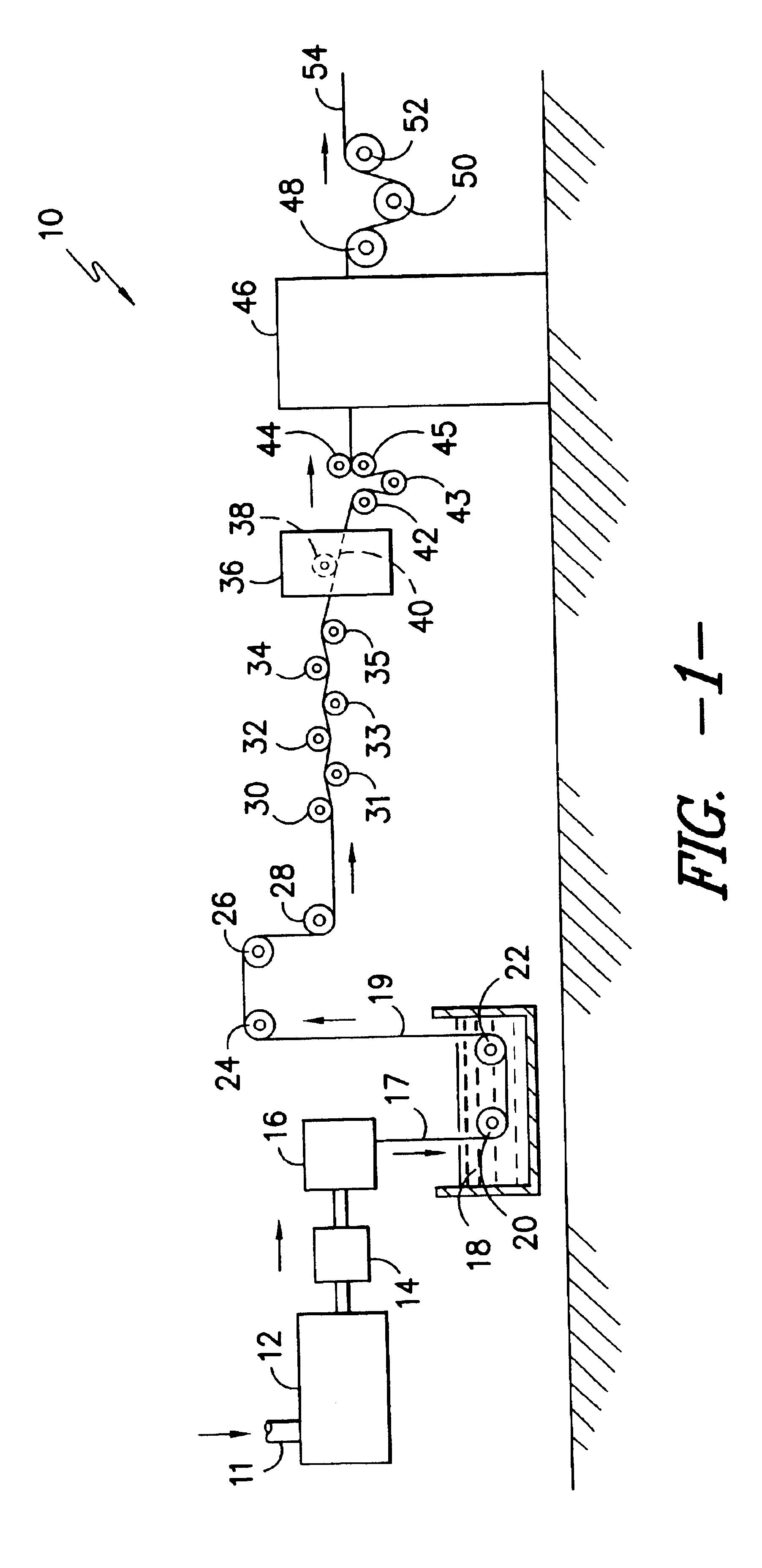

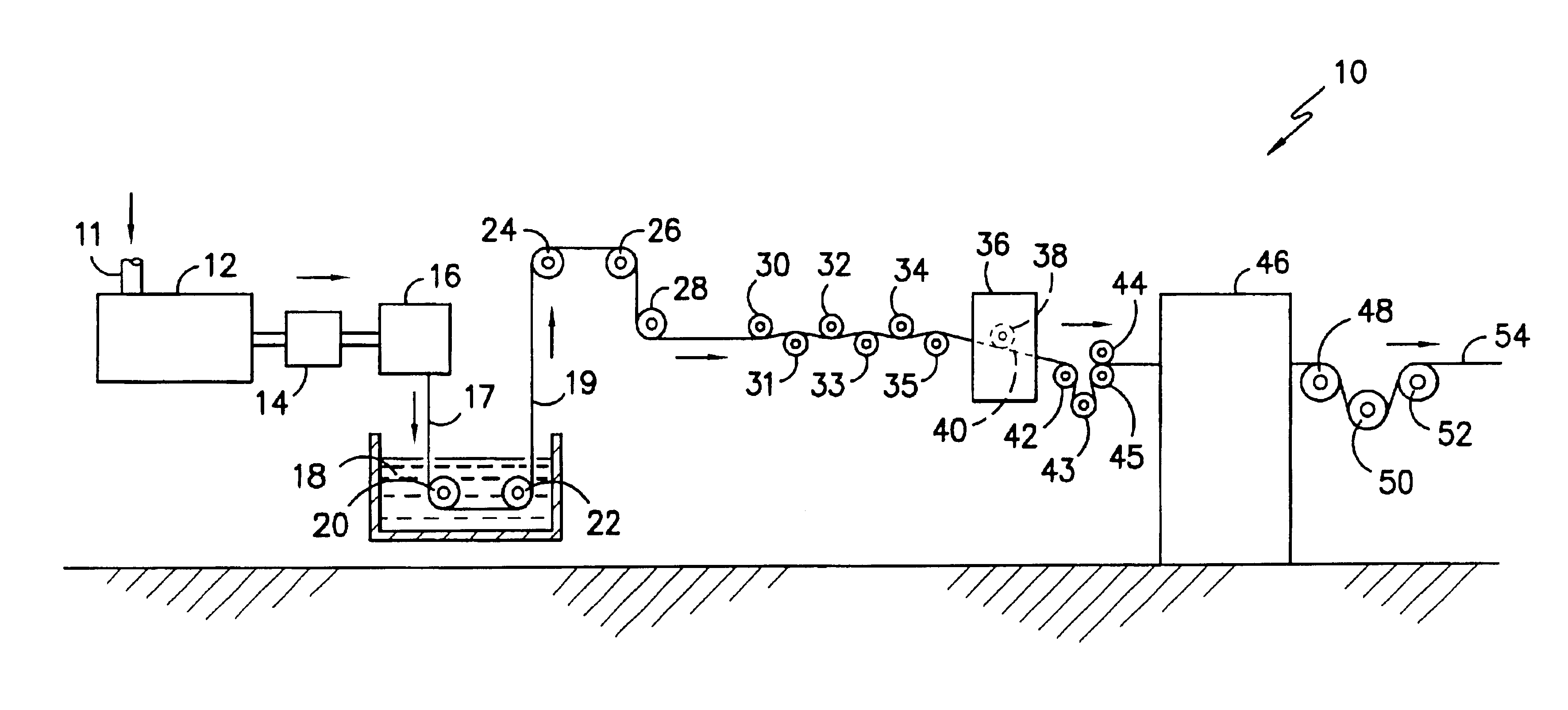

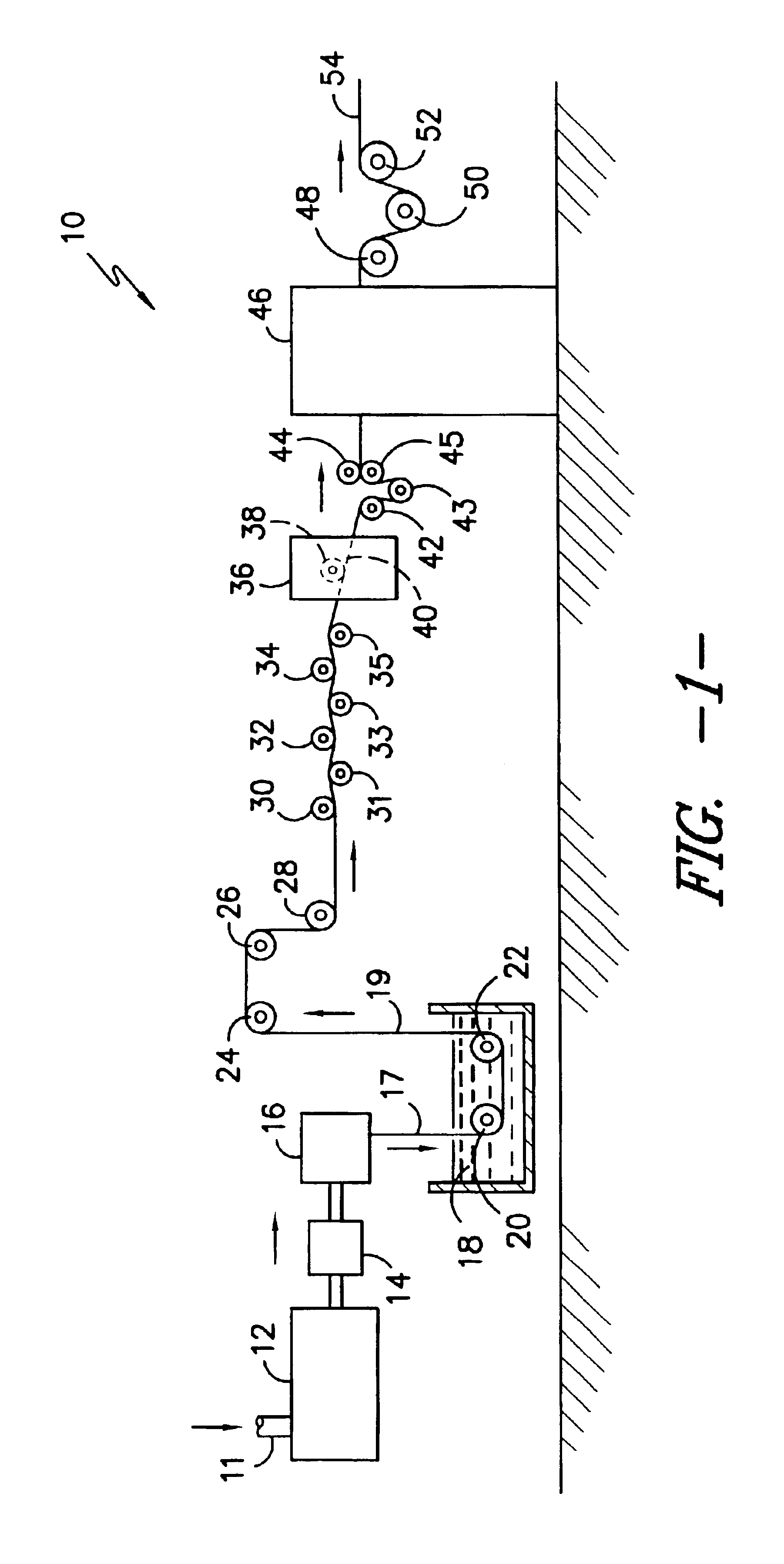

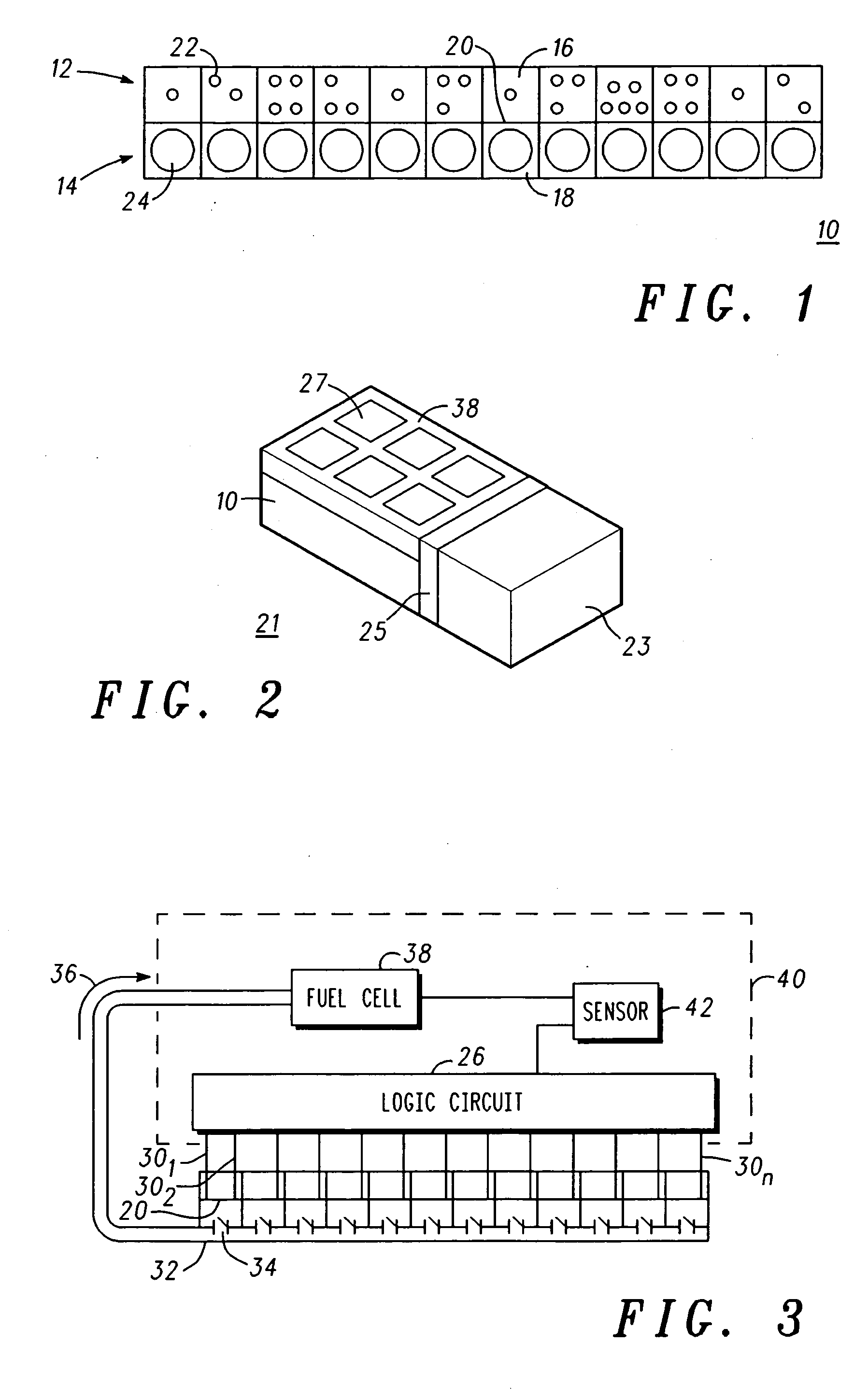

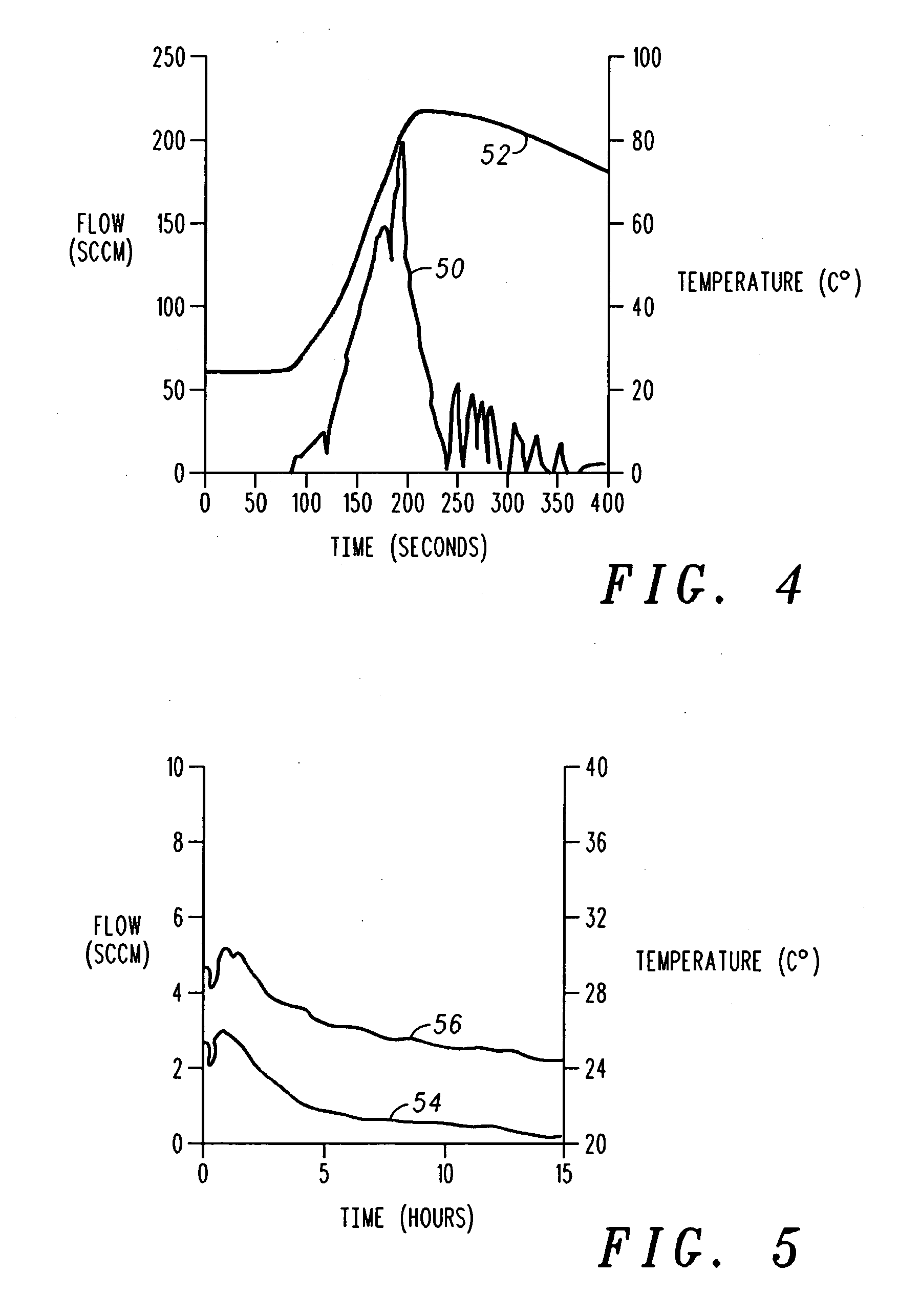

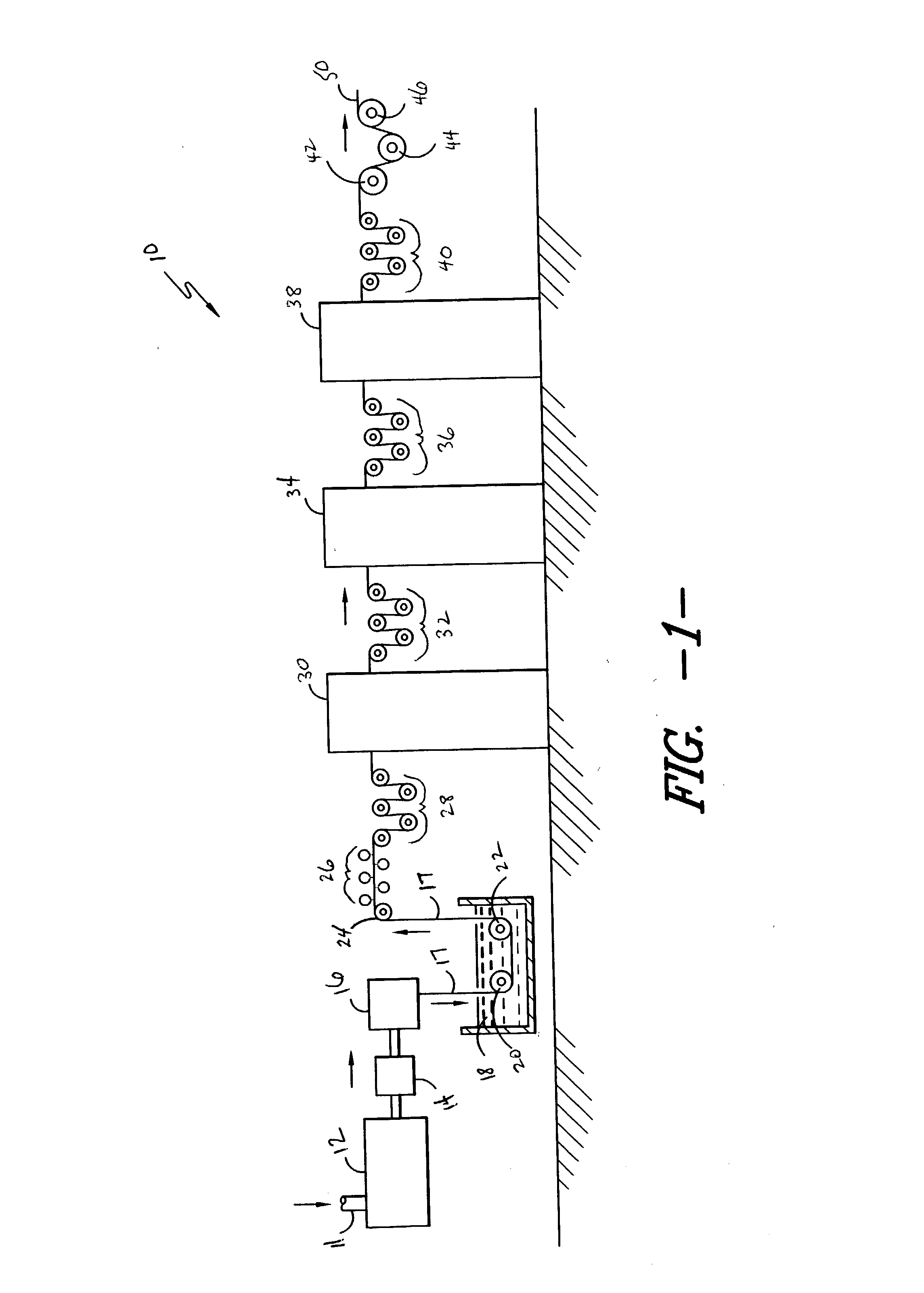

Hydrogen supply for micro fuel cells

InactiveUS20070253875A1The process is compact and efficientReactant parameters controlChemical/physical processesNuclear engineeringSolid fuel

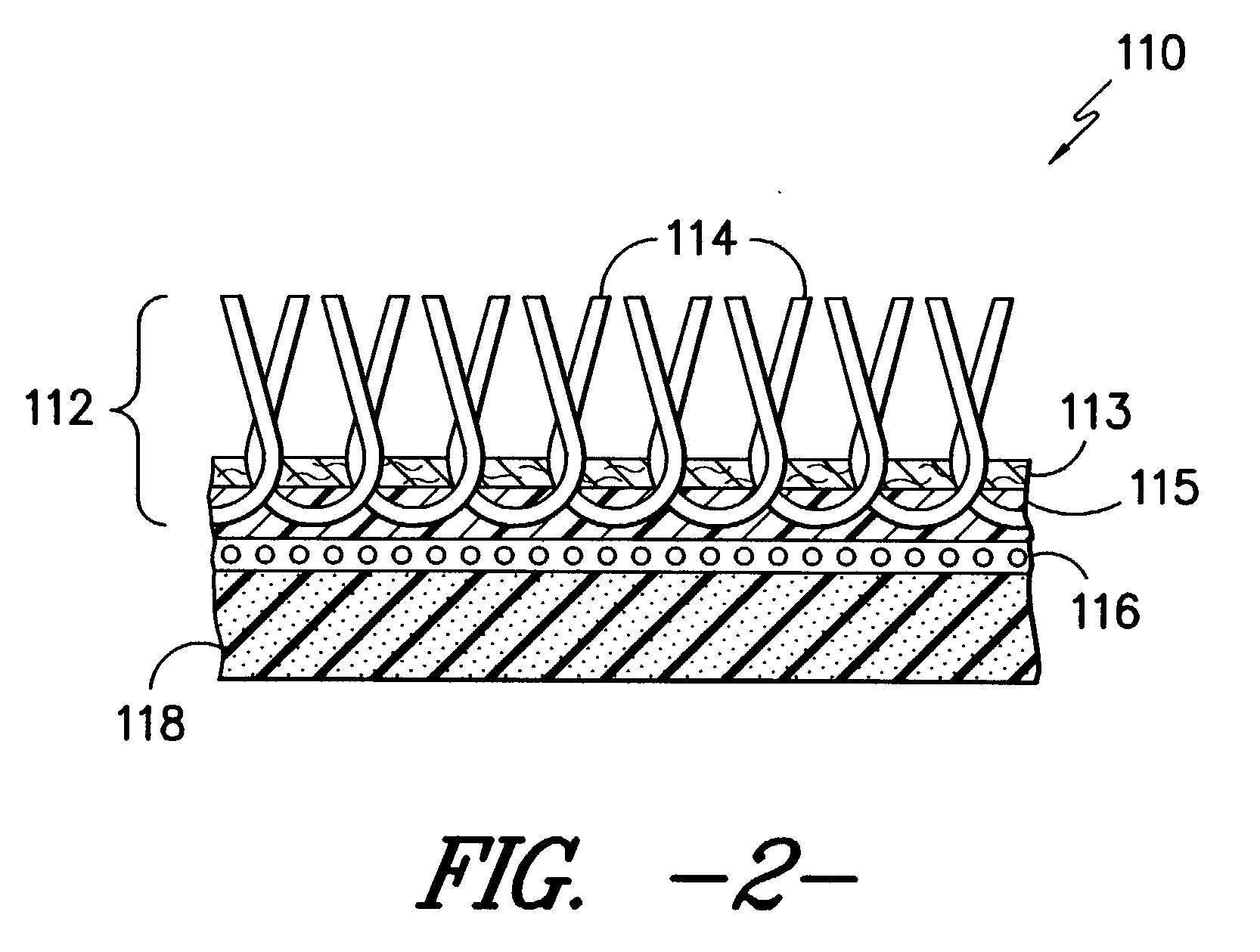

A disposable, compact, and efficient storage apparatus (10) contains a fuel source (24) and water for supplying hydrogen fuel (36) to a micro-fuel cell. The storage apparatus comprises a housing defining a fuel source chamber (14) and a plurality of water chambers (12), and one or more polymer crystals (22) containing water positioned within each of the water chambers (12). The fuel source (24), such as a chemical hydride mixed with a catalyst, is positioned within the fuel source chamber (14), wherein the water in each of the water chambers (12) is selectively allowed to migrate to the fuel source chamber (14) to contact the solid fuel, thereby producing the hydrogen fuel (36) at a desired flow rate and temperature. A conduit (32) supplies the hydrogen fuel (36) produced within the housing to the fuel cell (38).

Owner:MOTOROLA INC

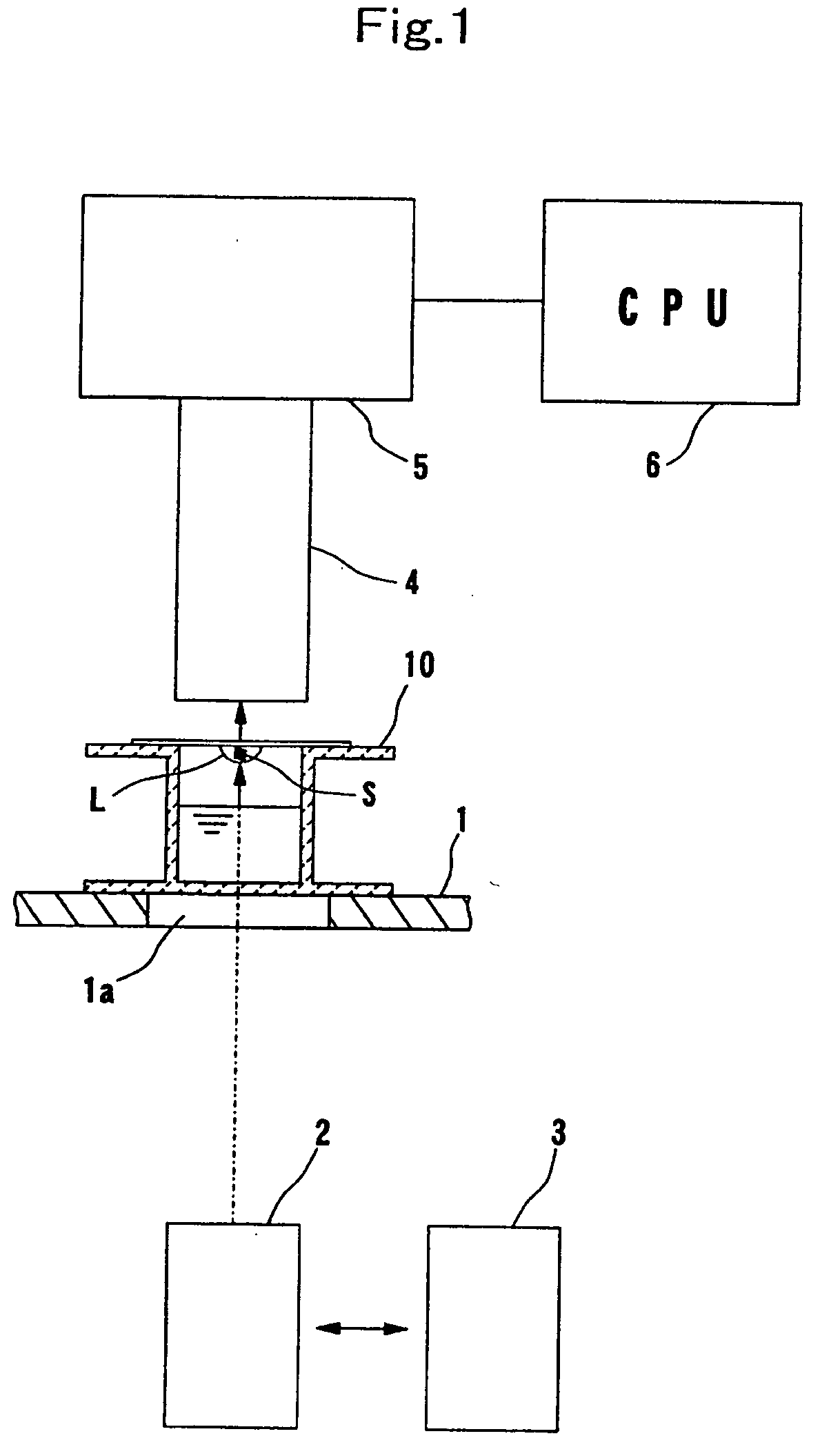

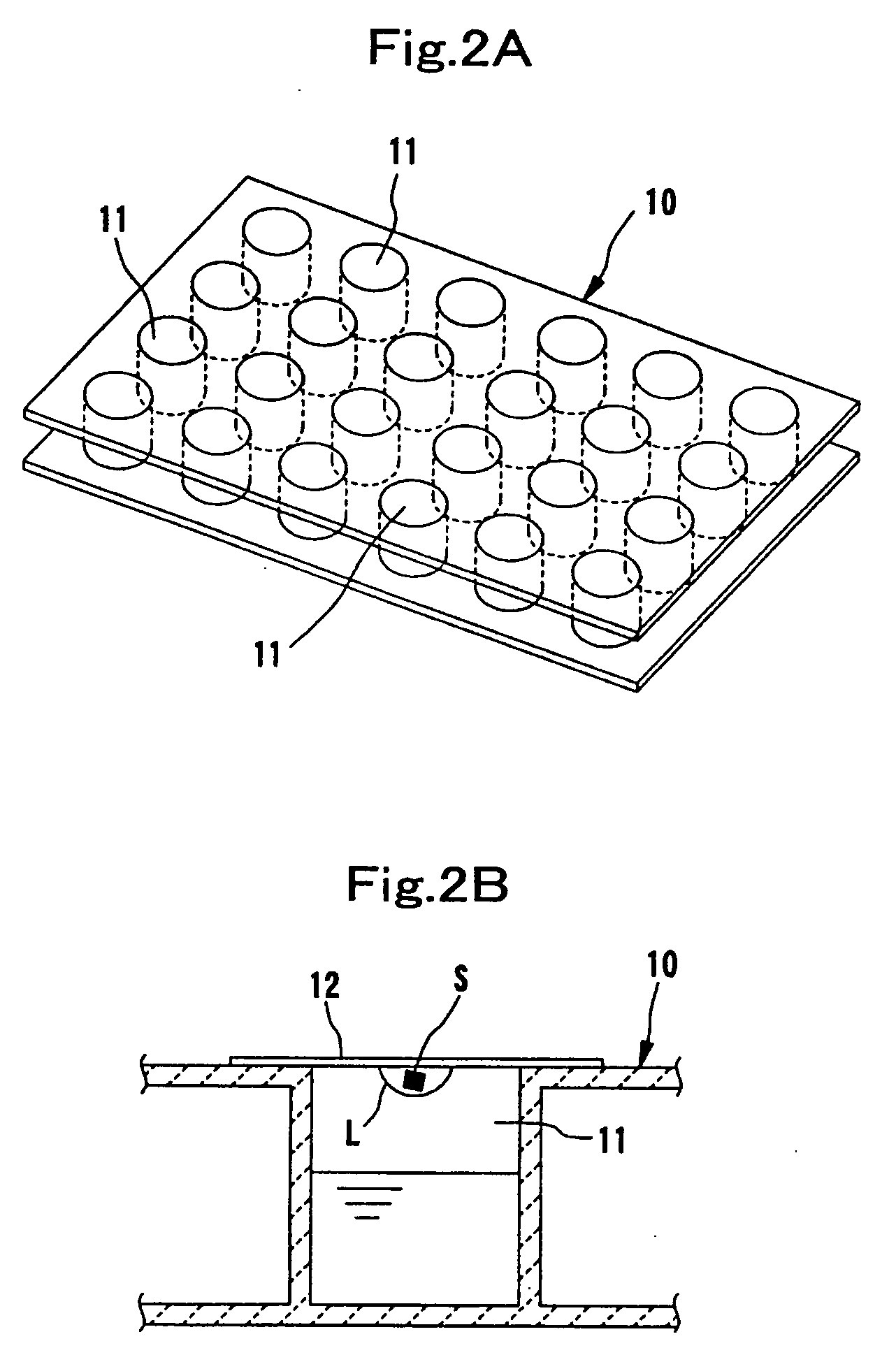

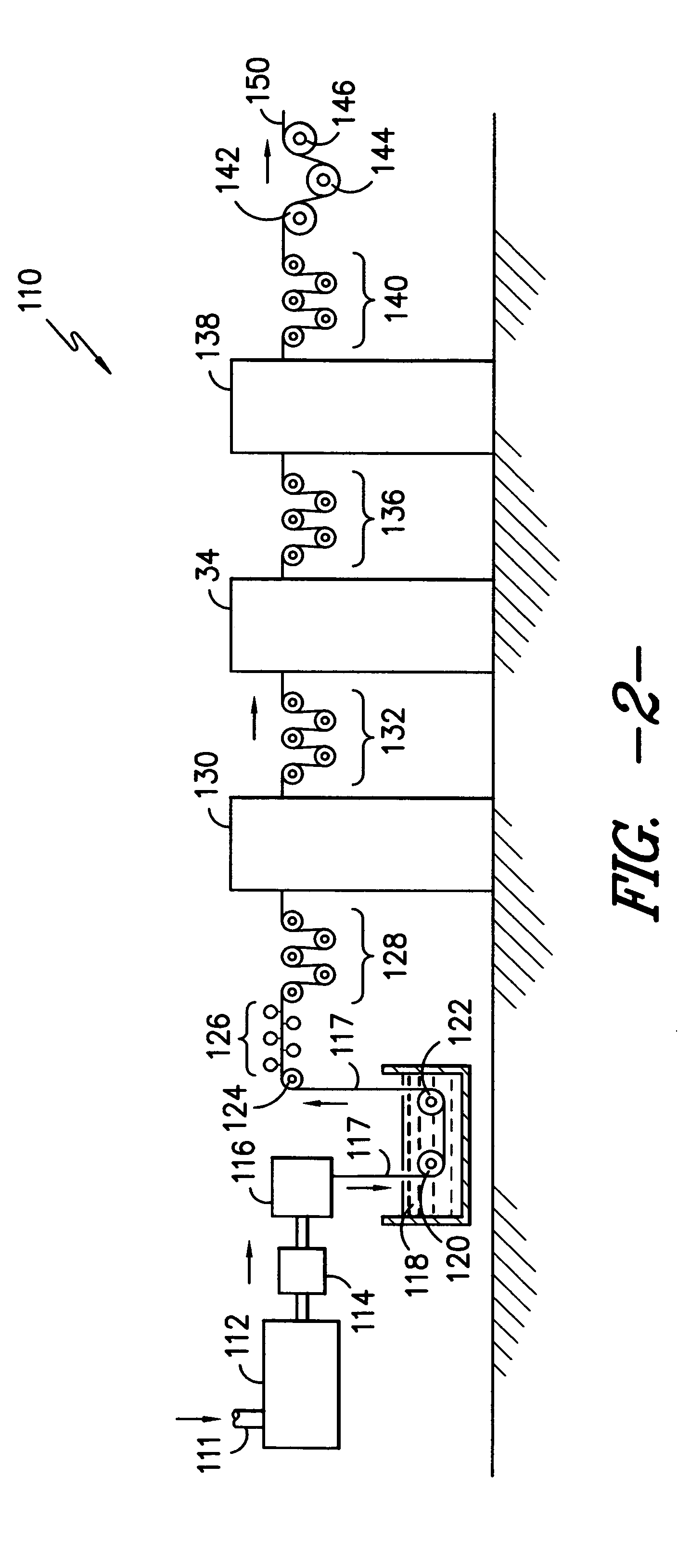

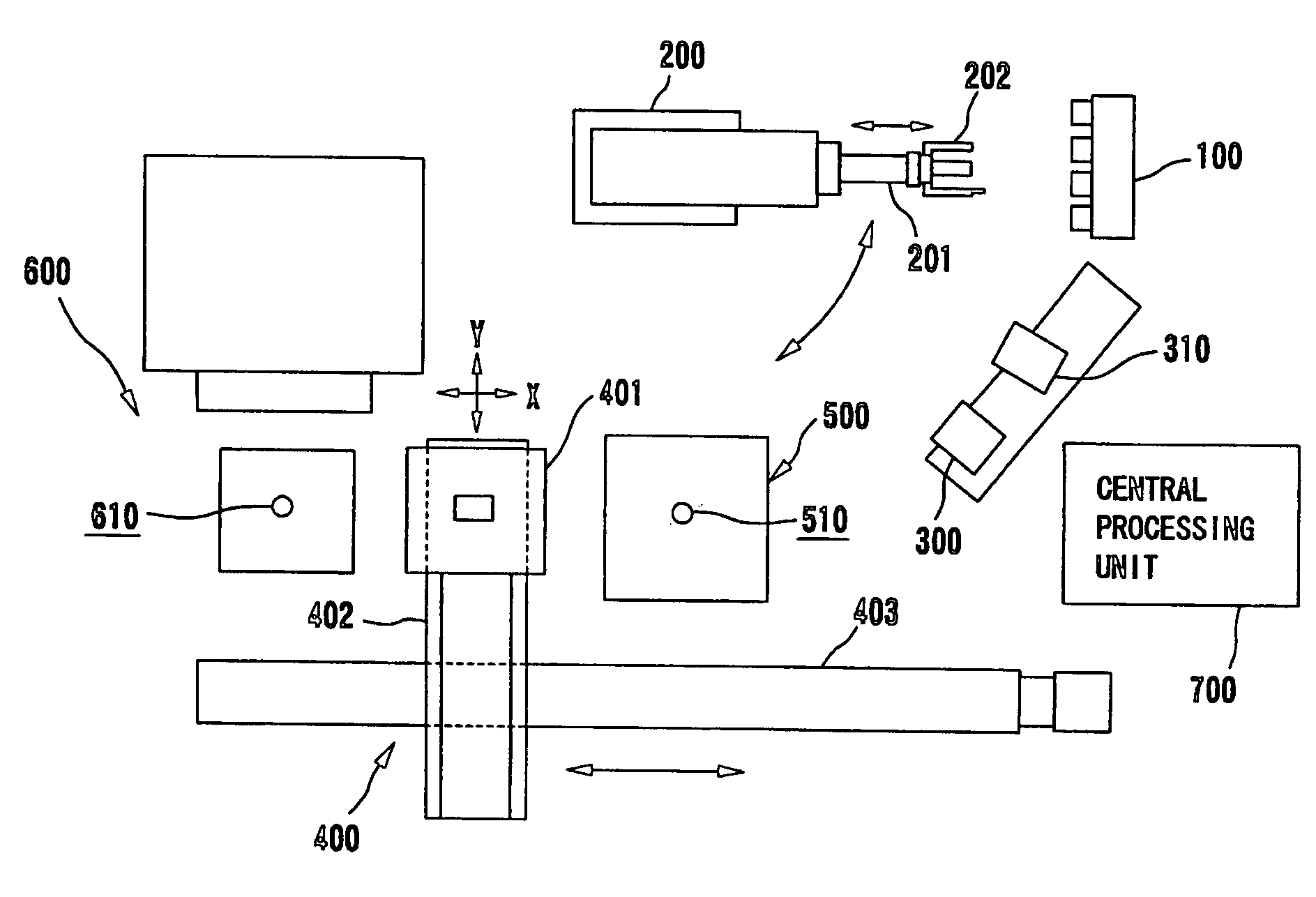

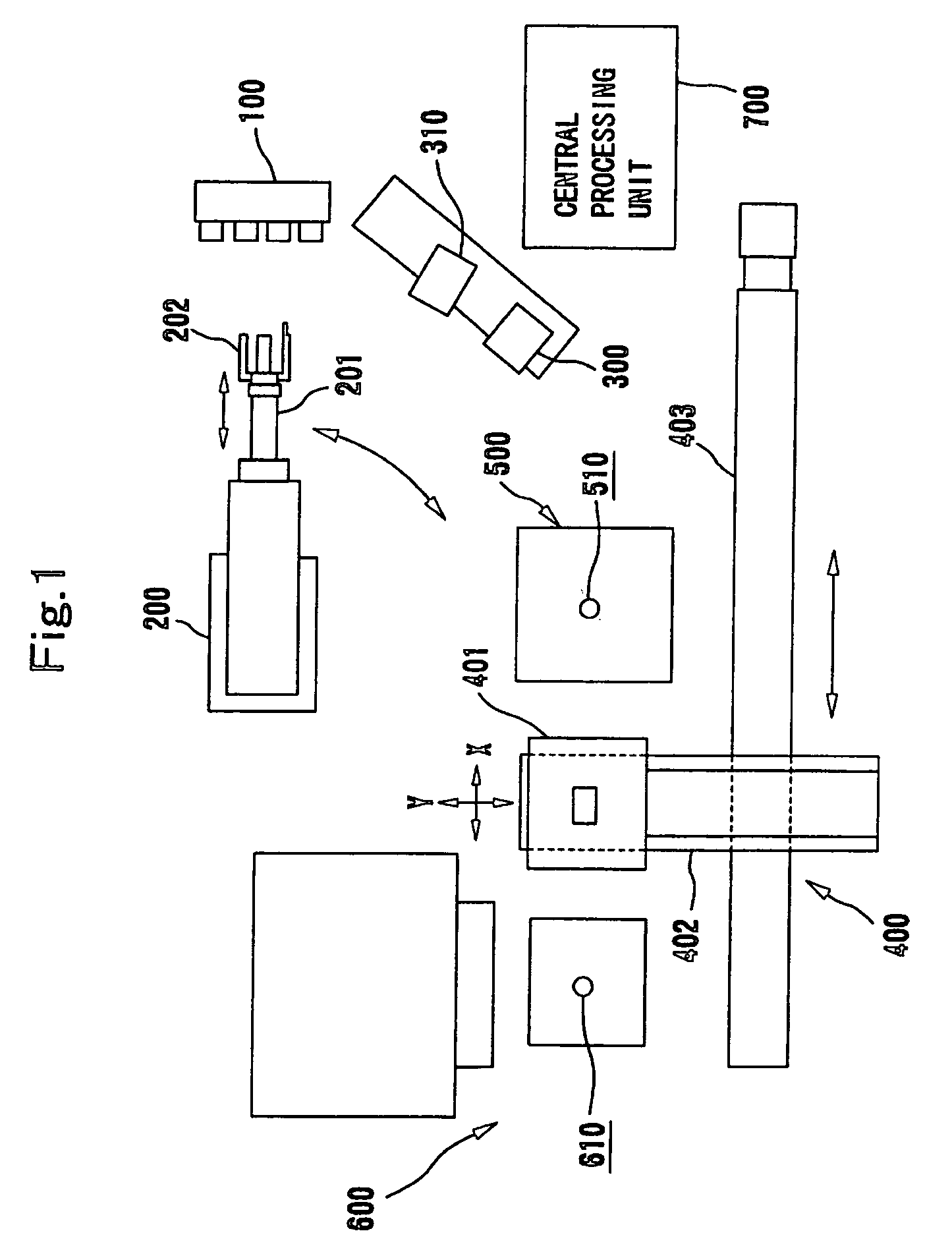

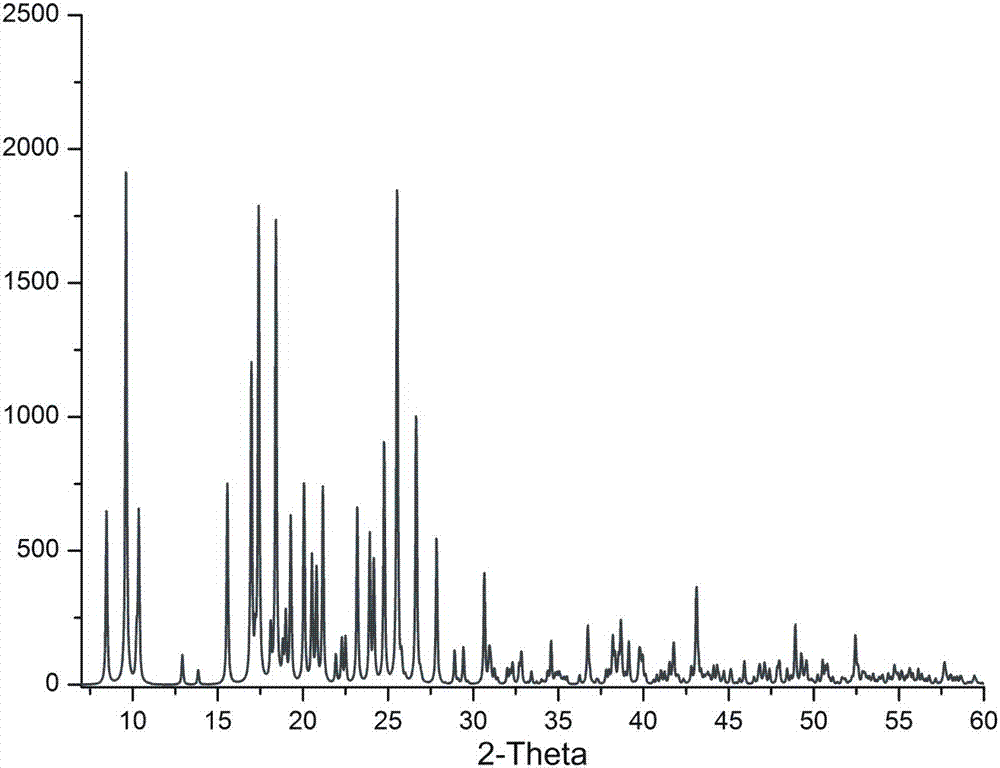

Apparatus for estimating specific polymer crystal

InactiveUS7342995B2SpeedShort working hoursX-ray/infra-red processesX-ray spectral distribution measurementX-rayPolymer crystals

A specific macromolecule crystal evaluating device according to the present invention is equipped with a sample detecting stage for detecting a protein crystal in a sample container, an X-ray measuring stage that is spaced from the sample detecting stage and carries out X-ray diffraction measurement of the protein crystal, a feeding unit for feeding the sample container from the sample detecting stage to the X-ray measuring stage, and a central processing unit for recognizing the position of the protein crystal on the basis of the information achieved in the sample detecting stage and controlling the feeding unit on the basis of the position information to position the protein crystal to a sample disposing portion of the X-ray measuring stage.

Owner:RIGAKU CORP

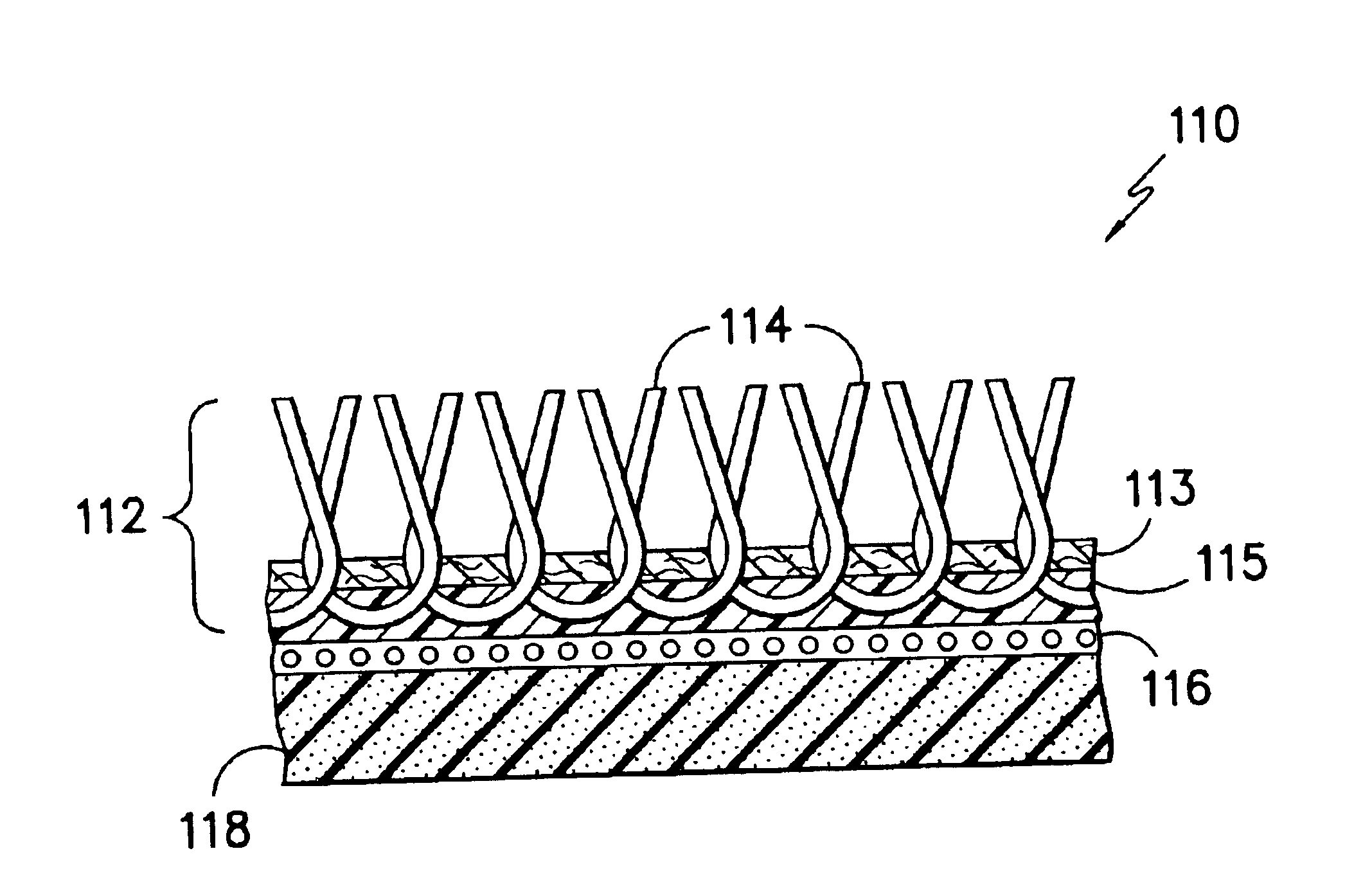

Low-shrink polypropylene tape fibers comprising high amounts of nucleating agents

InactiveUS20040086713A1Low shrinkageAcceptable low-shrink characteristicSynthetic resin layered productsFilament/thread formingFiberPolymer science

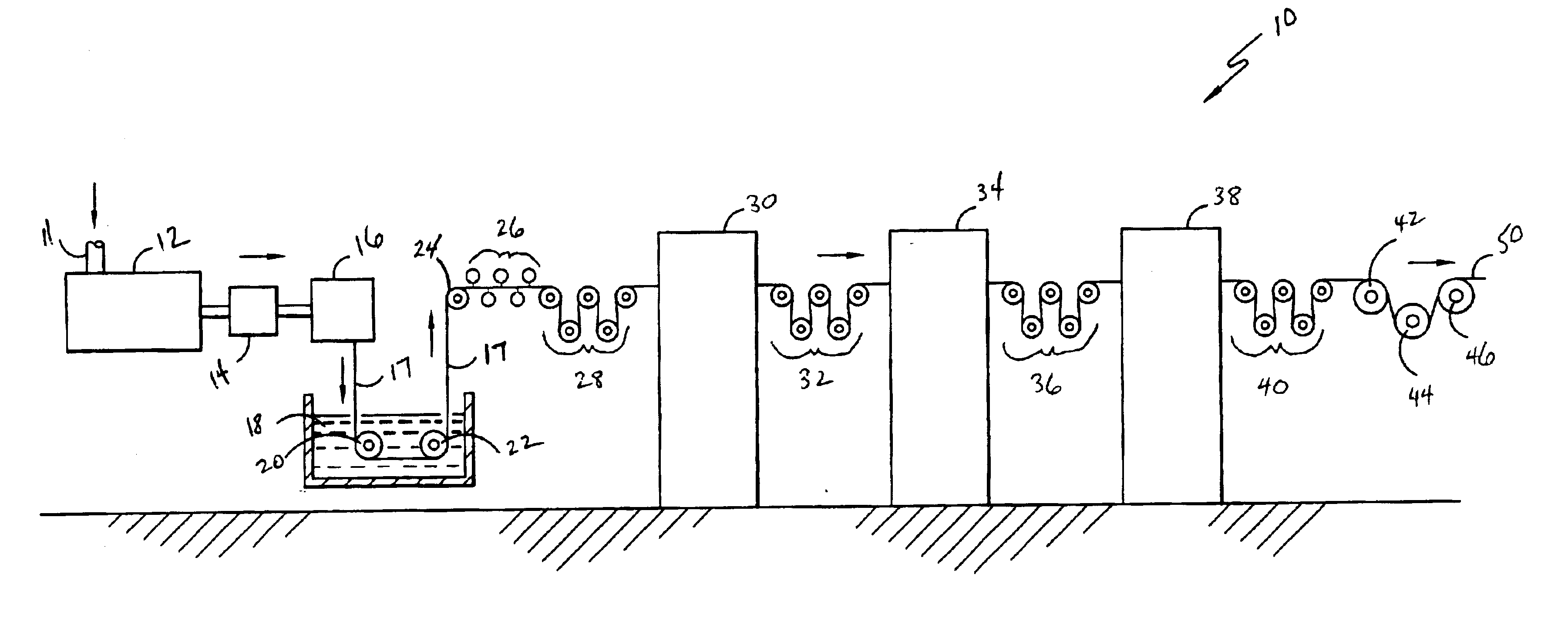

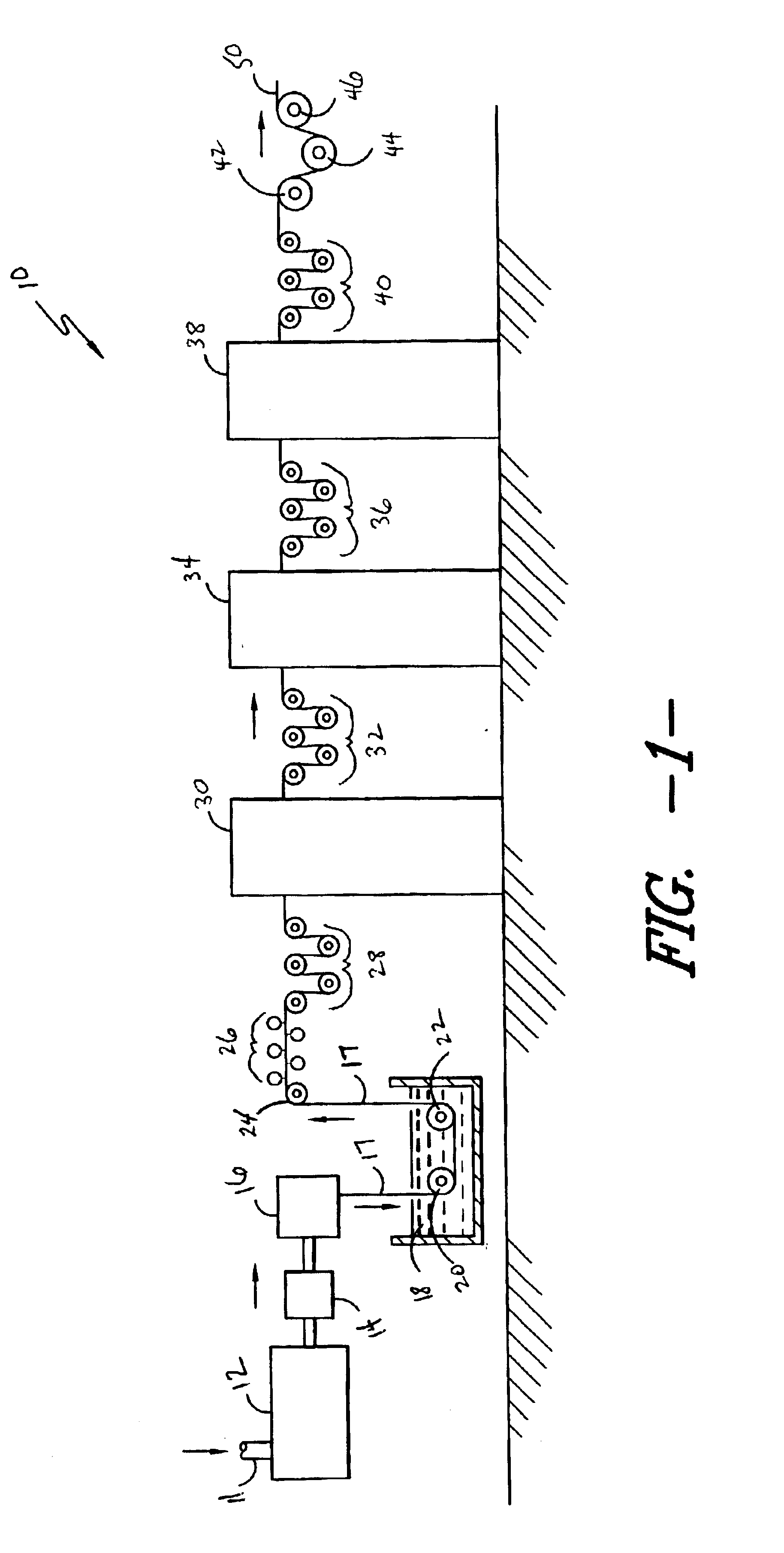

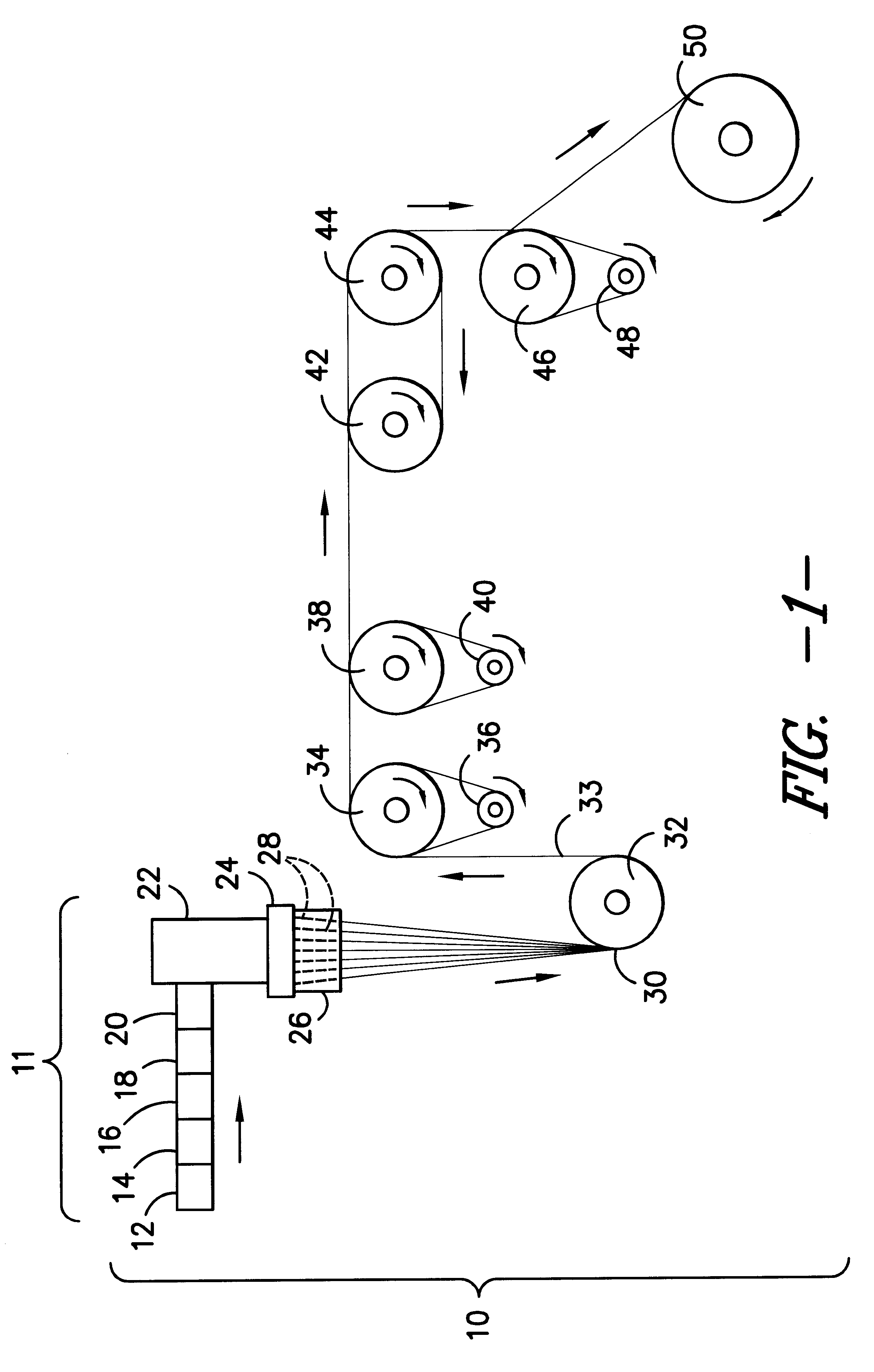

Improvements in preventing heat- and moisture-shrink problems in specific polypropylene tape fibers are provided. Such tape fibers are basically manufactured through the initial production of polypropylene films or tubes which are then slit into very thin, though flat (and having very high cross sectional aspect ratios) tape fibers thereafter. These inventive tape fibers (and thus the initial films and / or tubes) require the presence of relatively high amounts of certain compounds that quickly and effectively provide rigidity to the target polypropylene tape fiber. Generally, these compounds include any structure that nucleates polymer crystals within the target polypropylene after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target polypropylene without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for polypropylene crystal growth. Subsequent to slitting the initial film and / or tube, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive tape fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

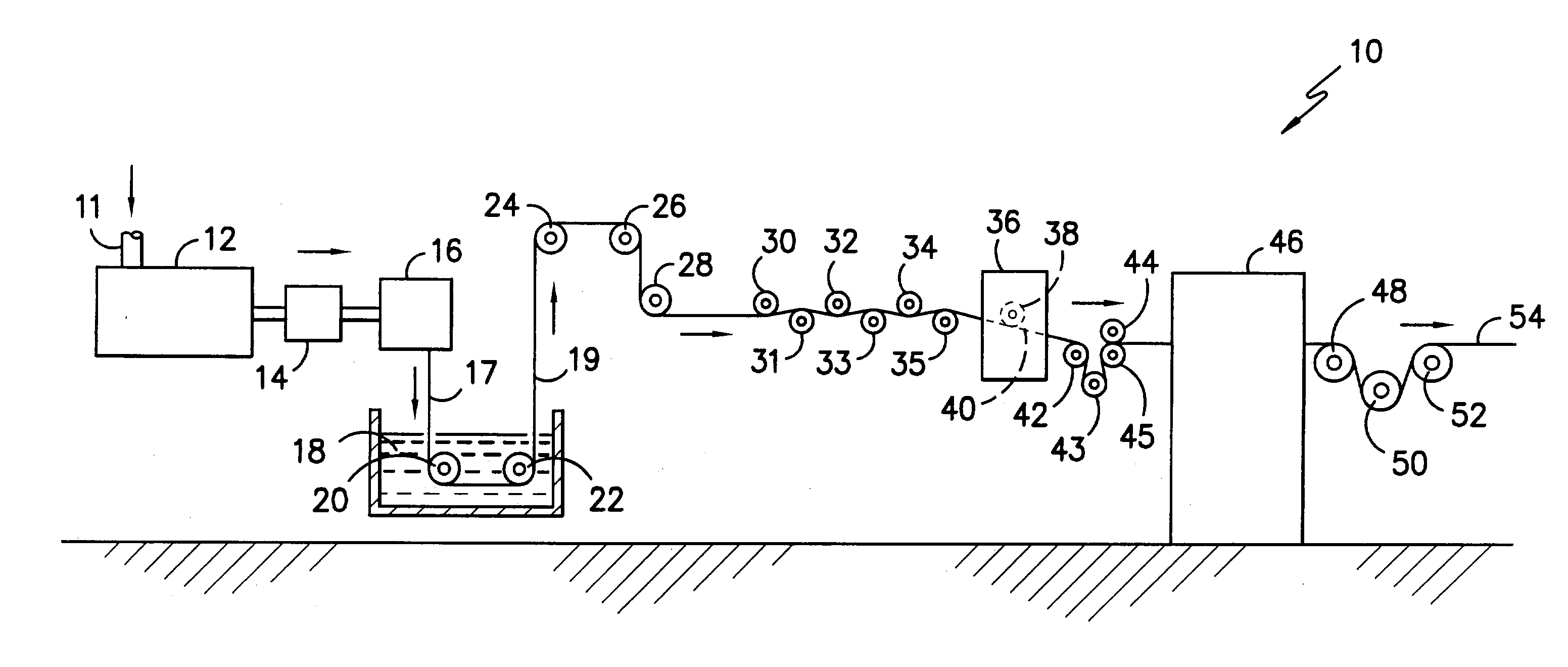

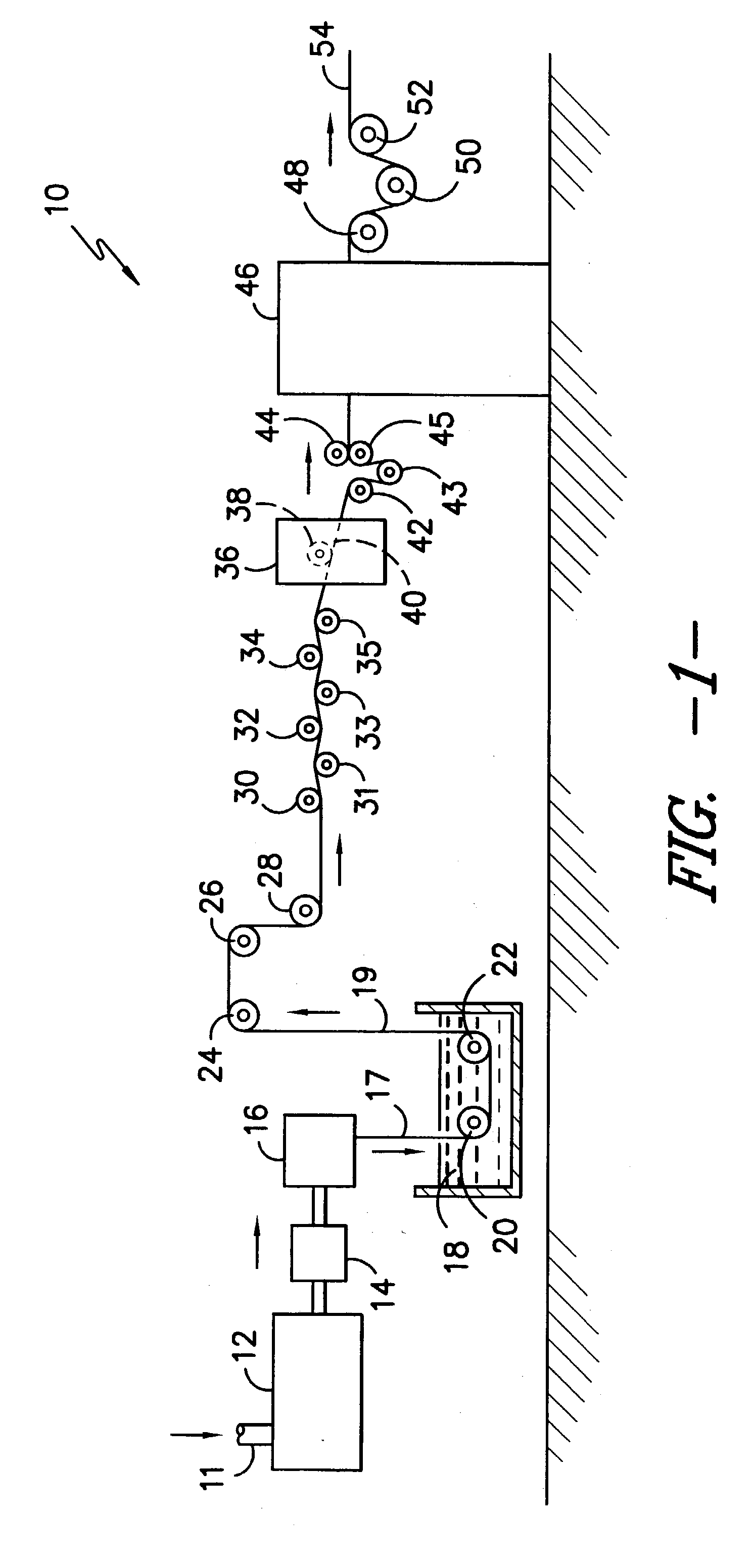

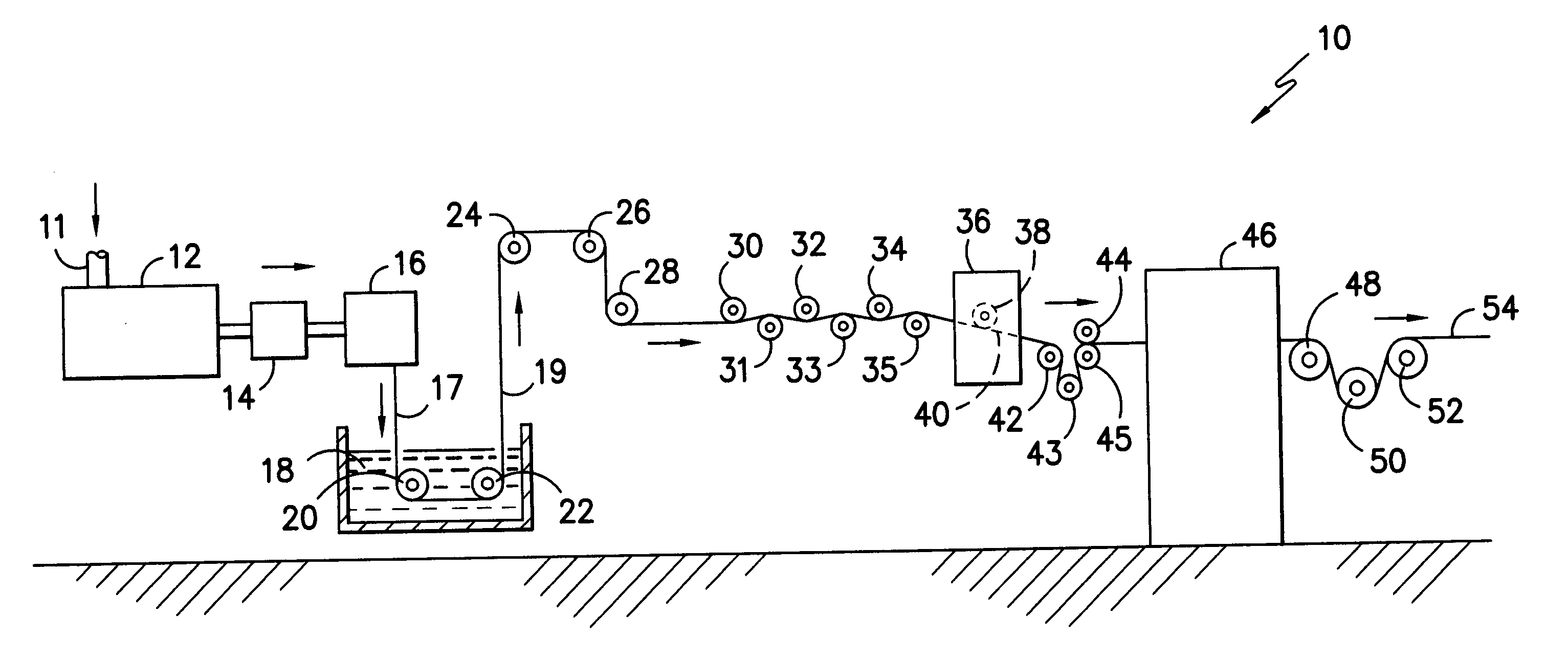

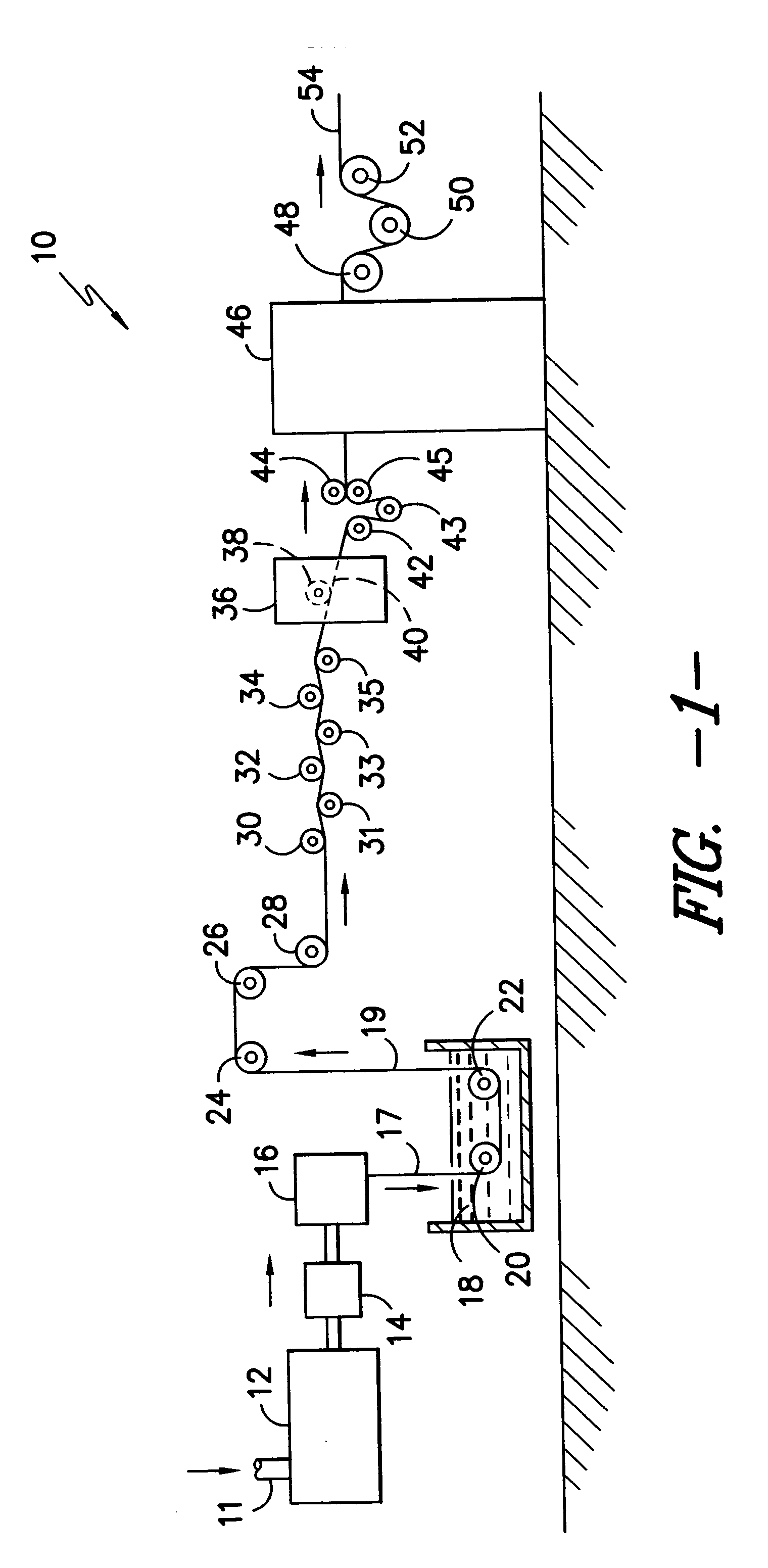

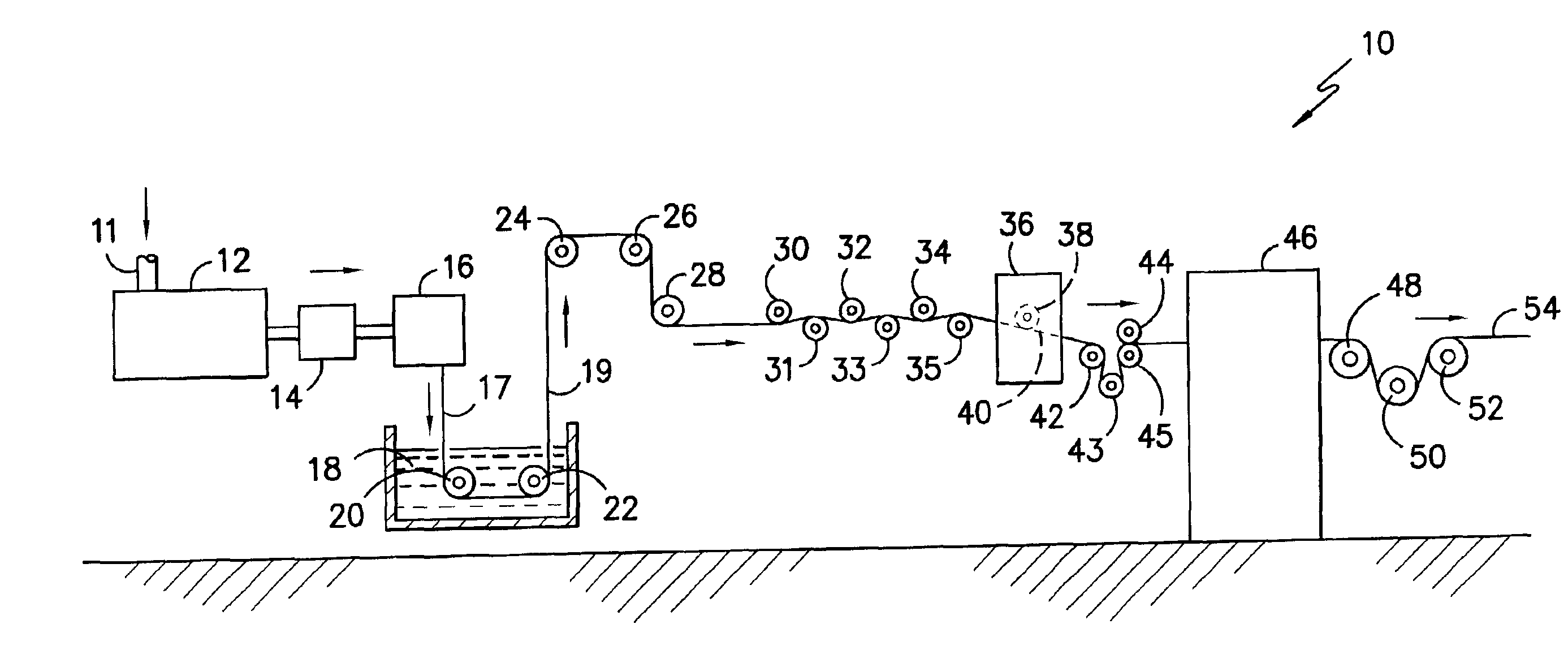

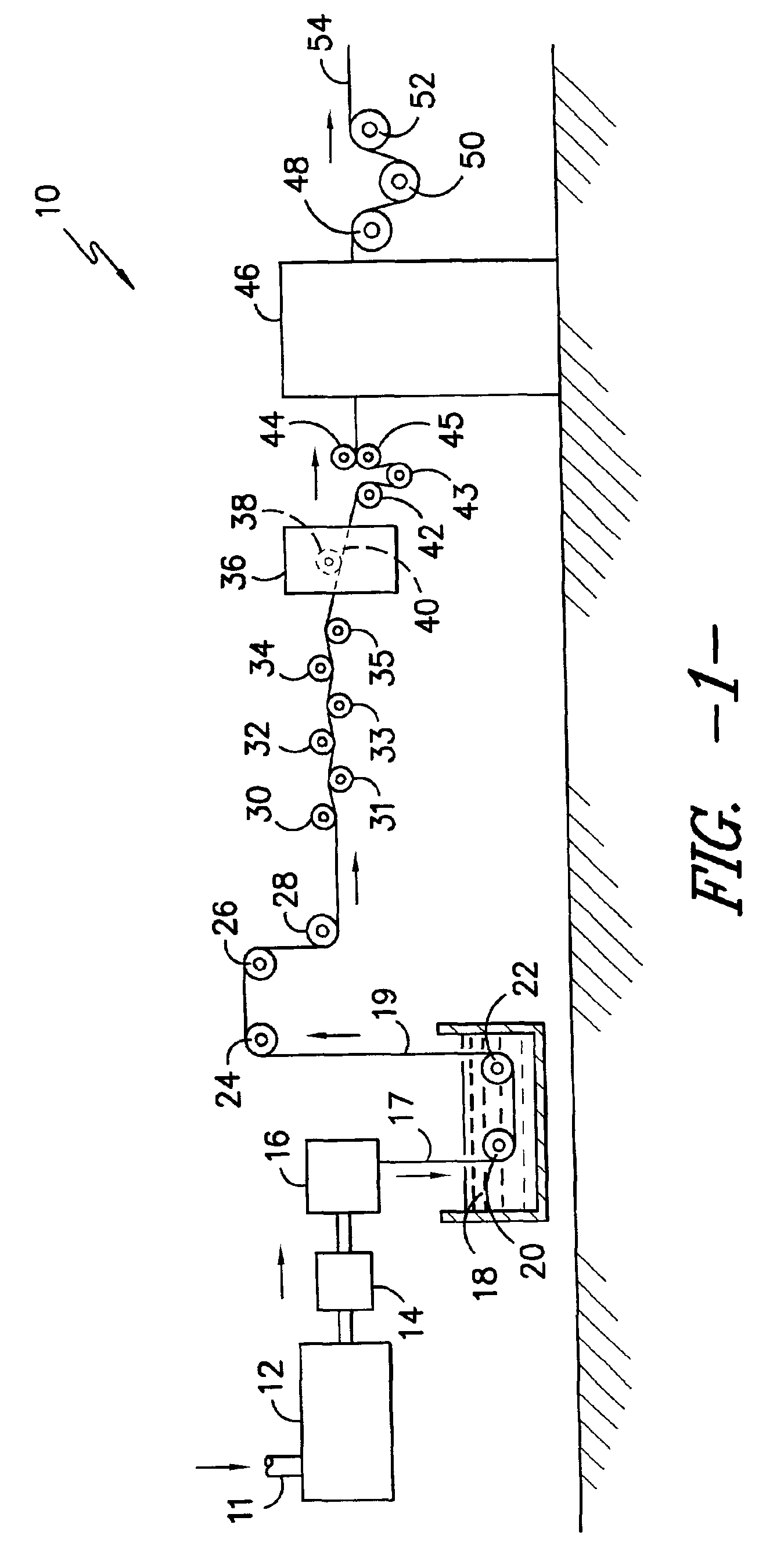

Method of producing low-shrink polypropylene tape fibers

InactiveUS6998081B2Low shrinkageLow heat shrinkageHollow filament manufactureLayered productsFiberPolymer science

Improvements in preventing heat- and moisture-shrink problems in specific polypropylene tape fibers are demonstrated herein. Such fibers are manufactured through the initial production of polypropylene films or tubes which are then slit into very thin, though flat tape fibers thereafter. Such fibers include rigidifying nucleating compounds that nucleate polymer crystals within the target polypropylene after exposure to sufficient heat to melt the initial pelletized polymer and upon allowing such a melt to cool. Specific methods of manufacture of such inventive tape fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

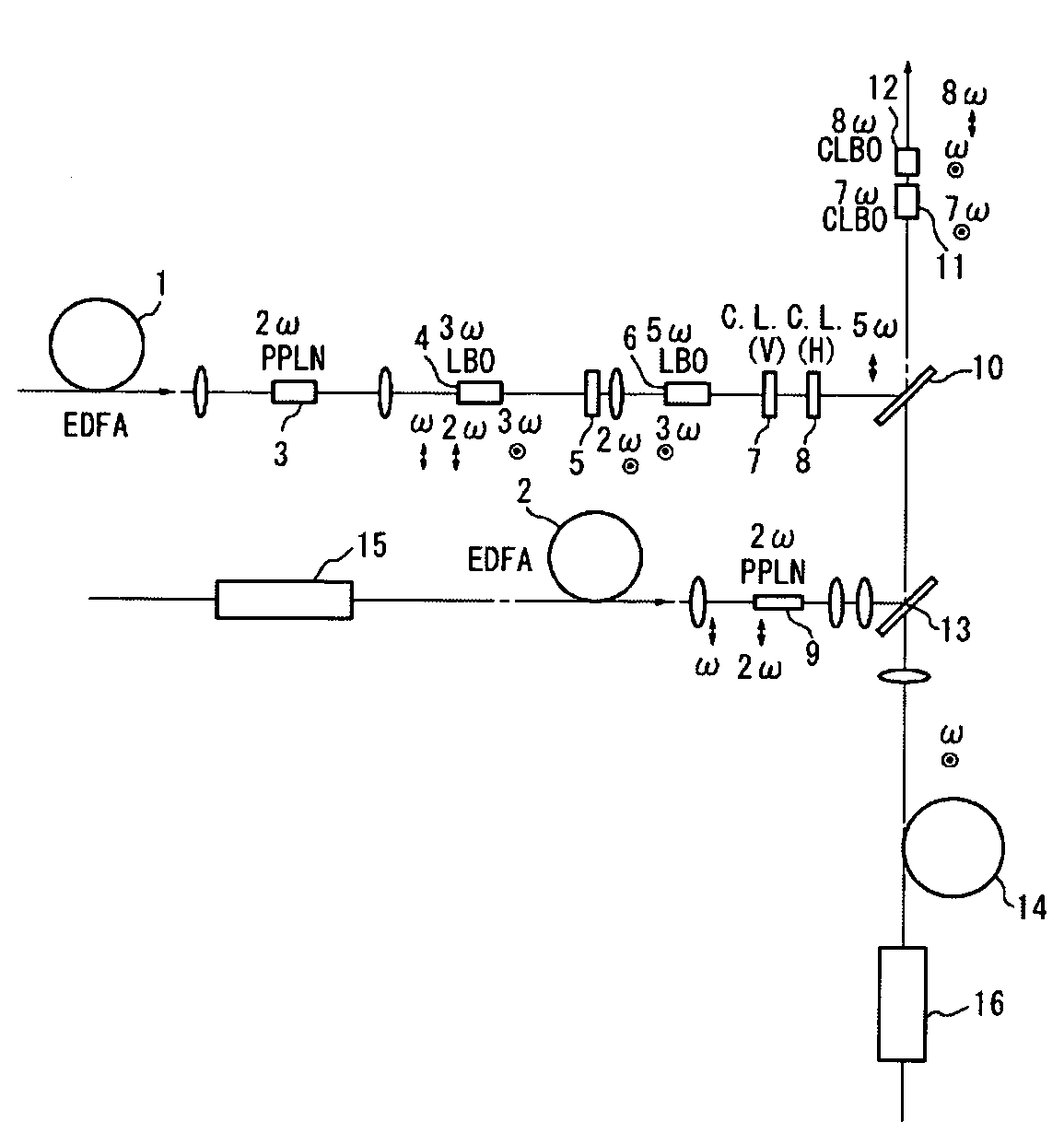

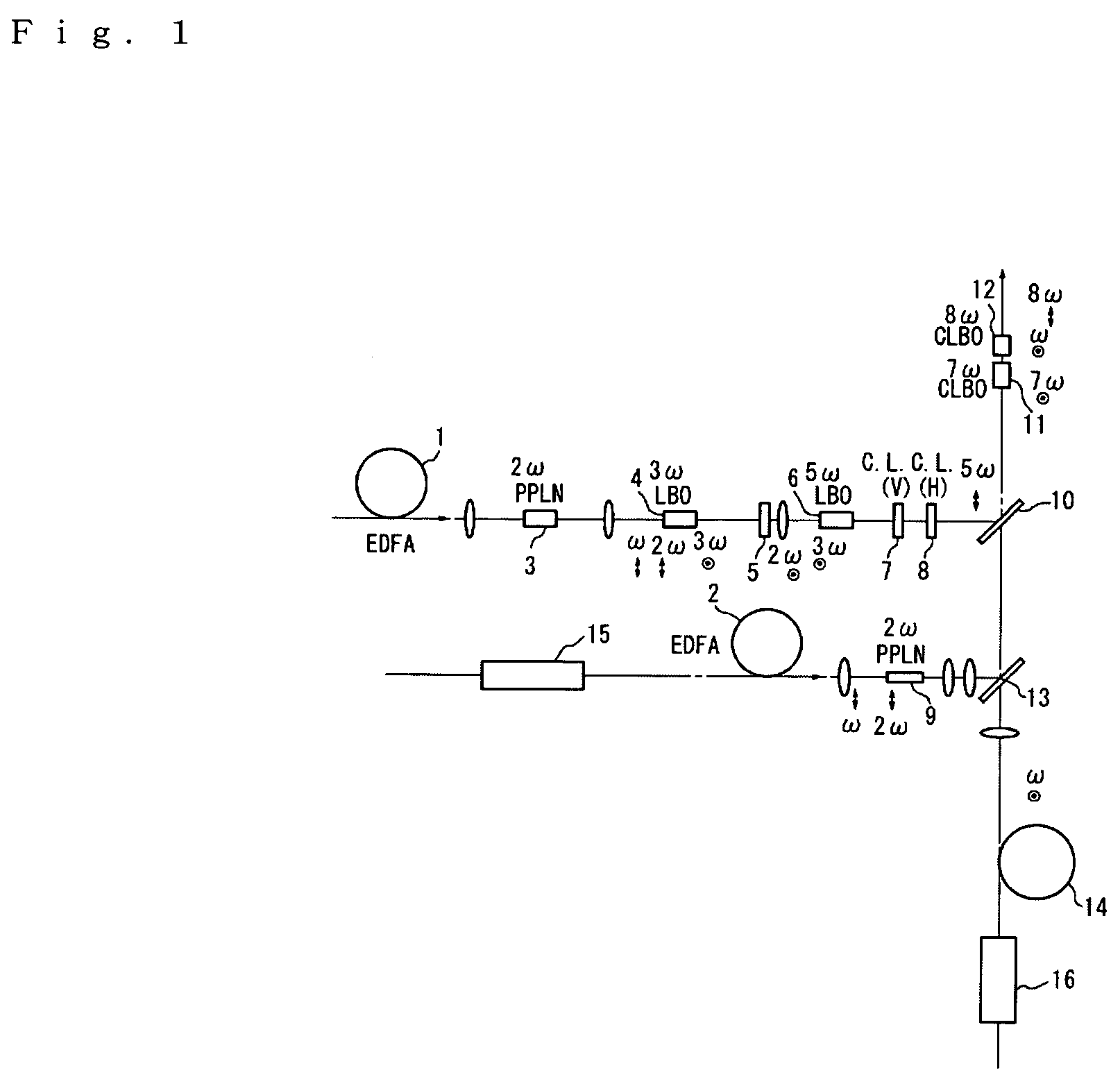

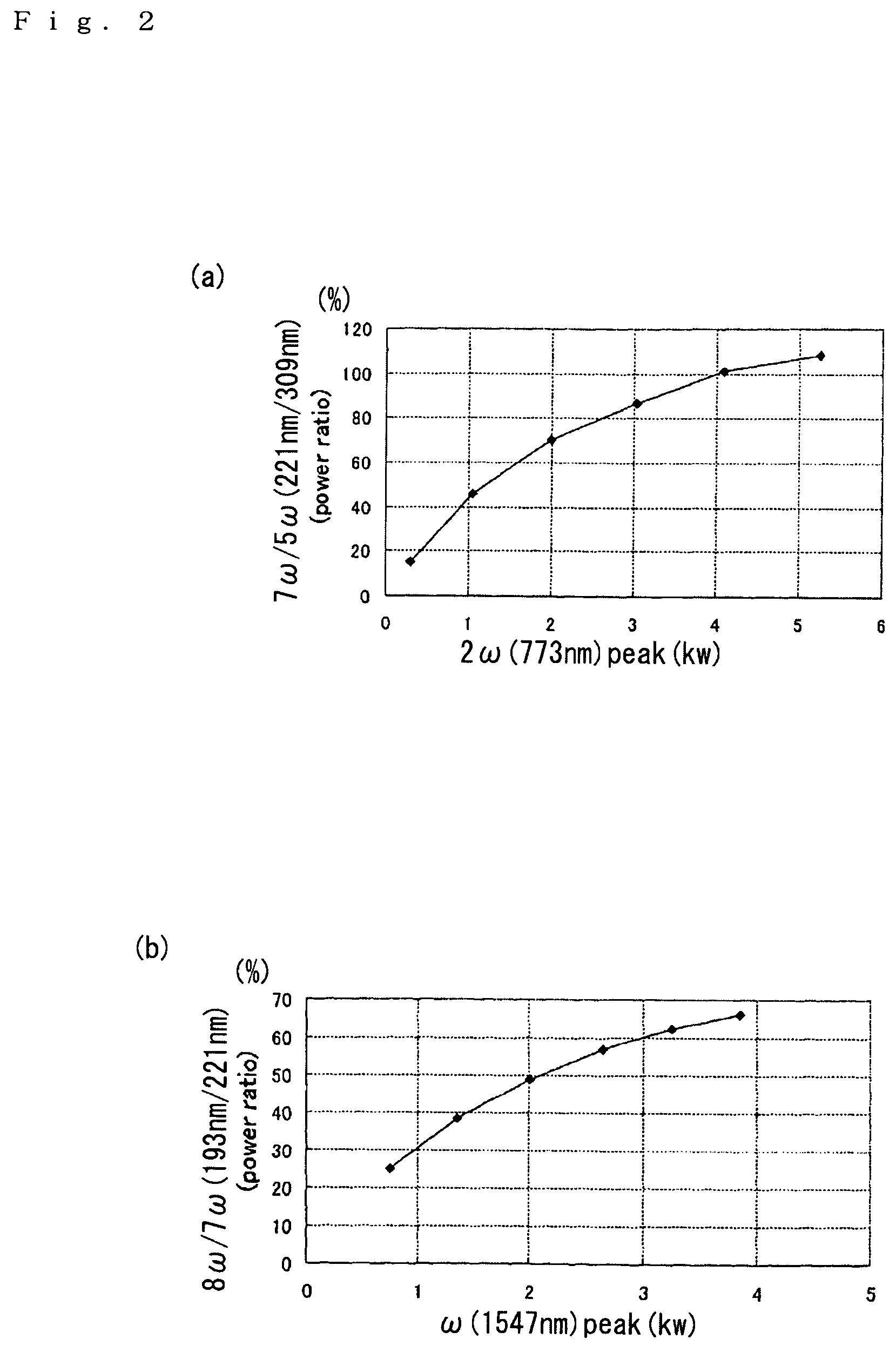

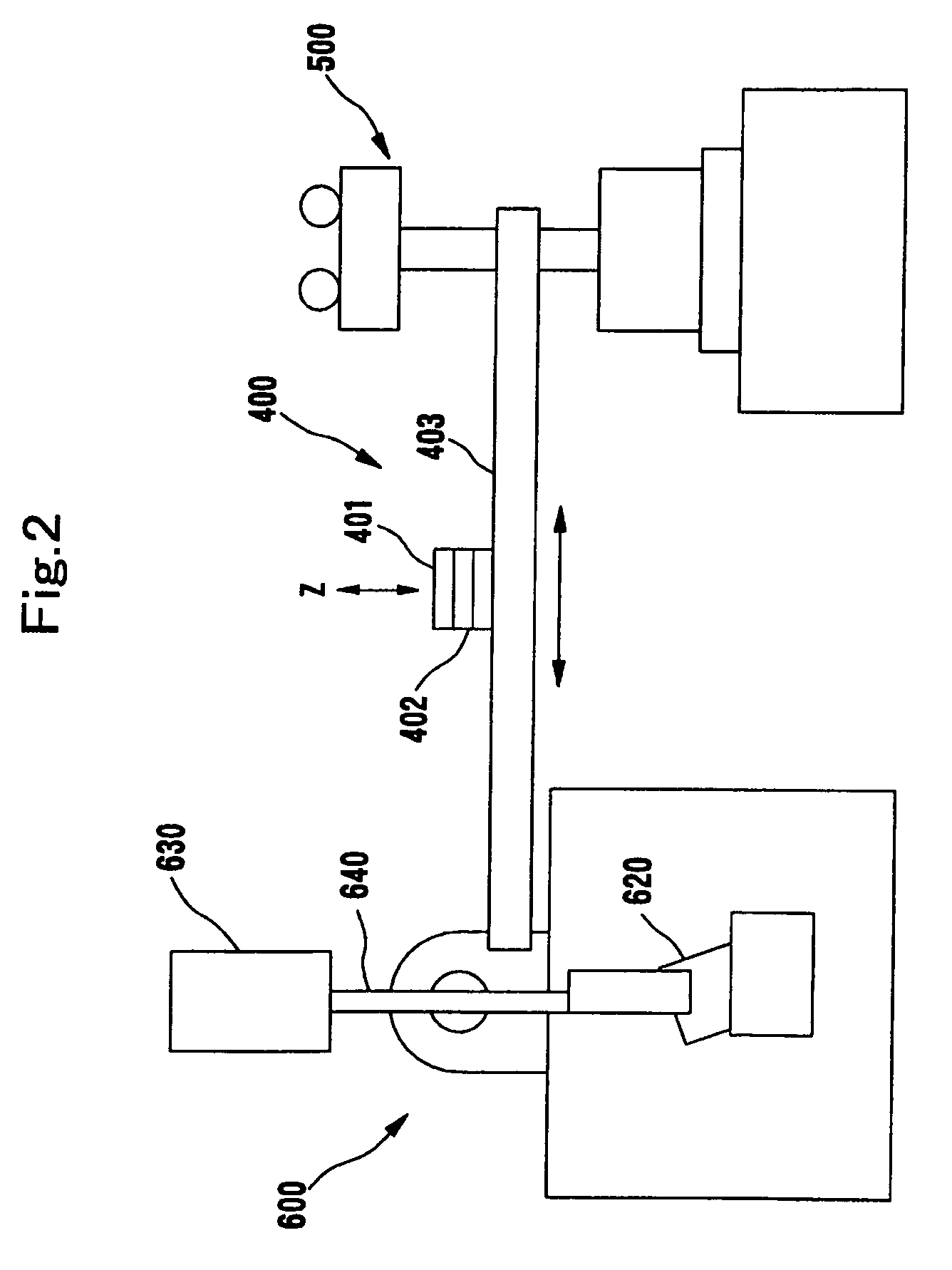

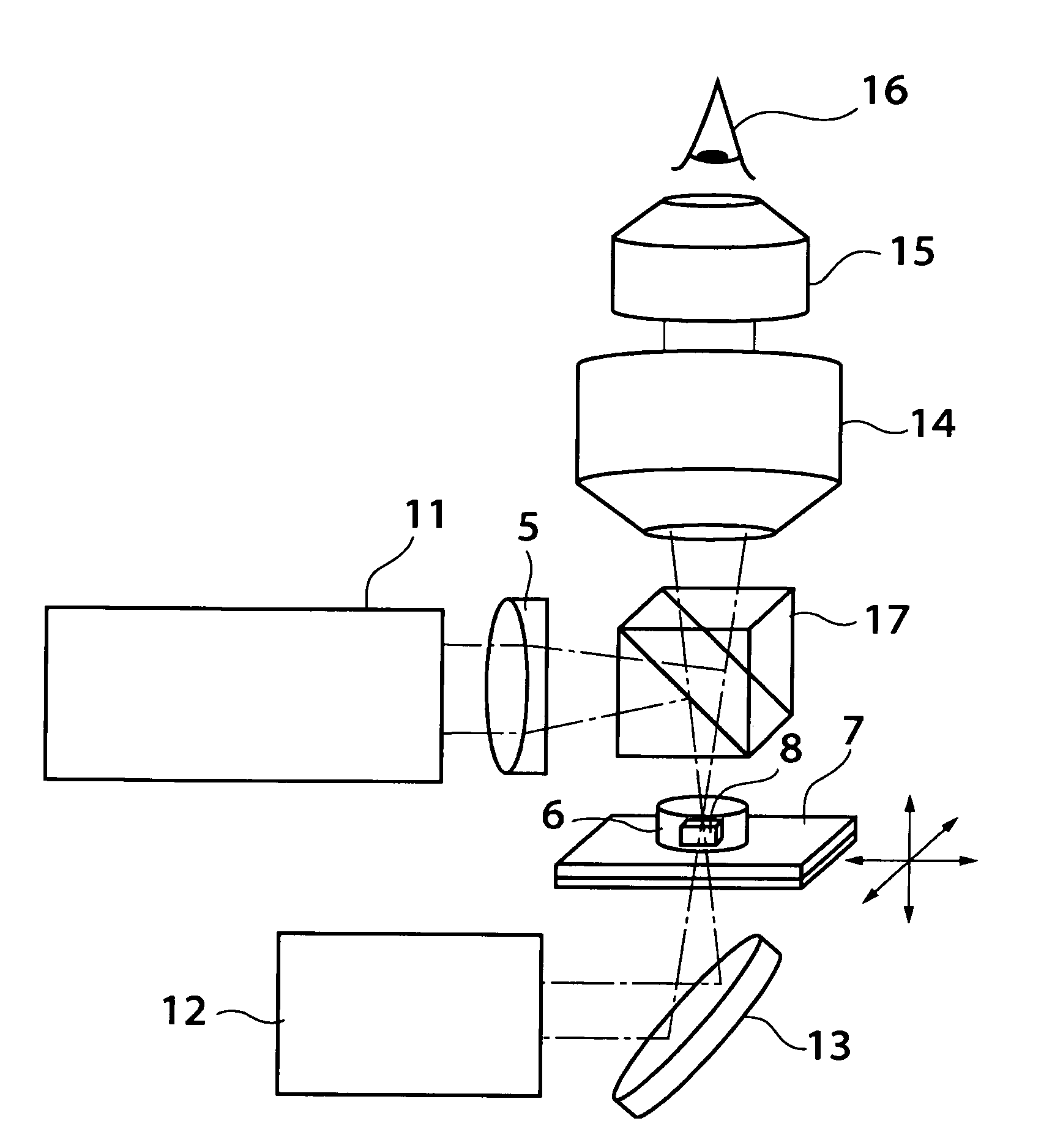

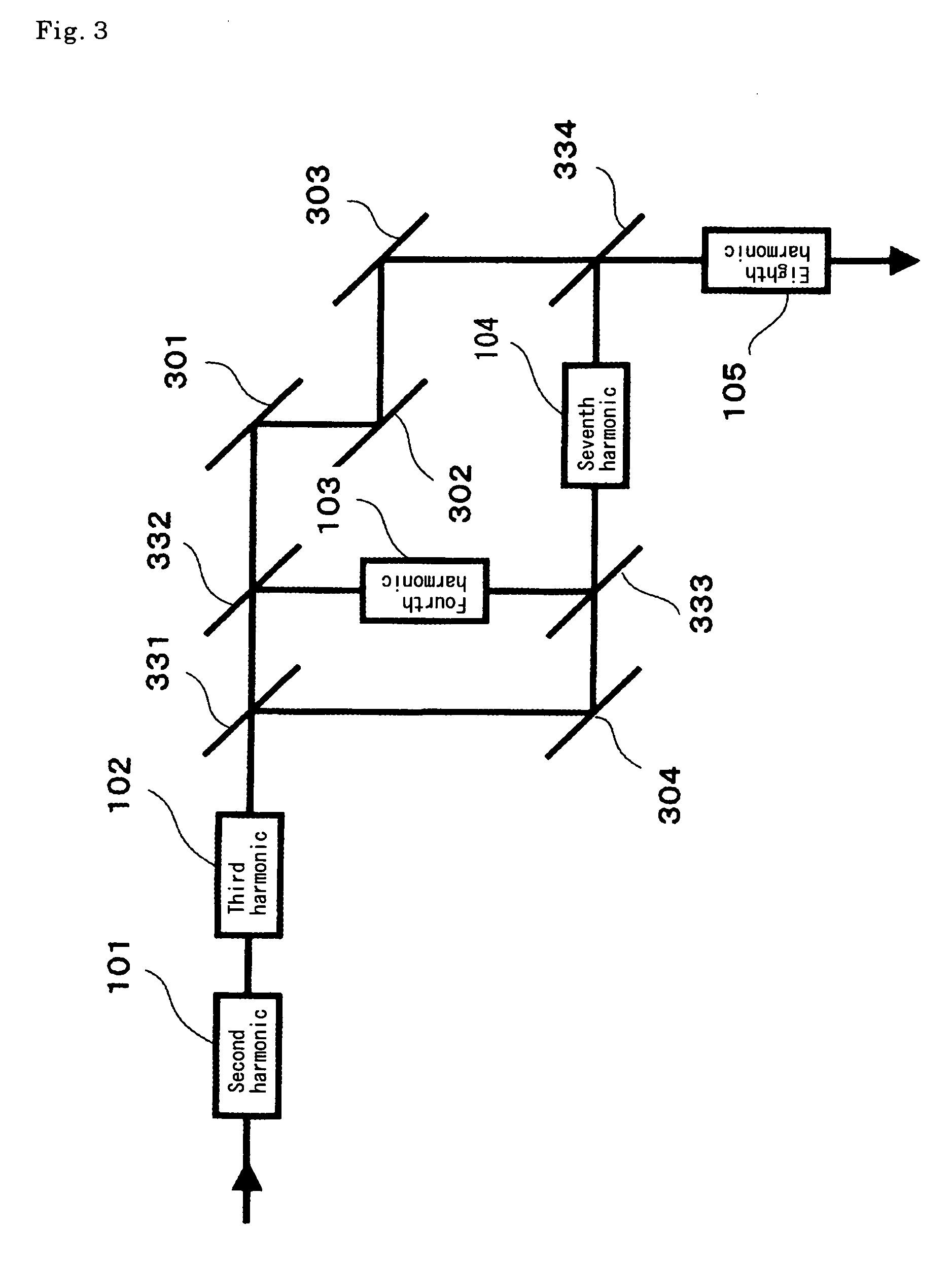

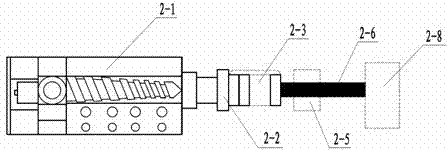

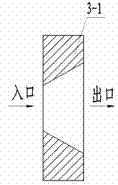

Processing method of polymer crystal, processing system of polymer crystal, and observation system of polymer crystal

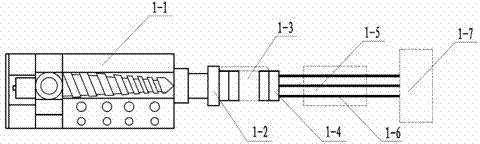

ActiveUS7356240B2Avoid damageQuick observationCoupling light guidesWelding/soldering/cutting articlesOrthogonal coordinatesOptical axis

The ultraviolet short-pulse laser light emitted from the ultraviolet short-pulse laser light source 1 is focused on and caused to irradiate a macromolecular crystal 8 contained in a sample container 6 via a shutter 2, intensity adjusting element 3, irradiation position control mechanism 4, and focusing optical system 5. The sample container 6 is carried on a stage 7, and can be moved in three dimensions along the directions of the x, y and z axes in an x-y-z orthogonal coordinate system with the direction of the optical axis being taken as the z axis; furthermore, the sample container 6 can be rotated about the z axis. Working of the macromolecular crystal is performed by means of ultraviolet short-pulse laser light that is focused on and caused to irradiate the surface of the macromolecular crystal 8. In this way, various types of working can be securely performed on macromolecular crystals with little damage and by means of a simple operation.

Owner:NIKON CORP +6

Thermoplastic monofilament fibers exhibiting low-shrink, high tenacity, and extrimely high modulus levels

Unique thermoplastic monofilament fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than any other previously produced thermoplastic fibers, particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

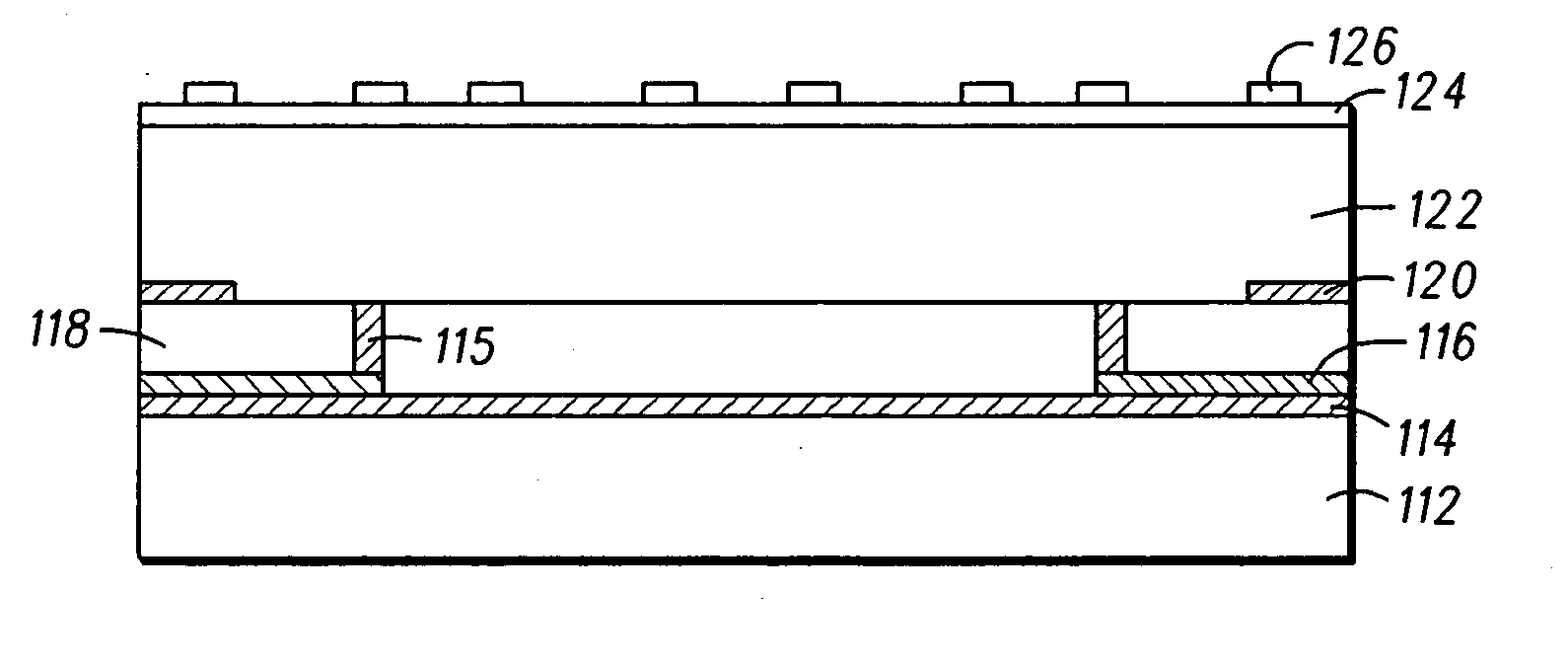

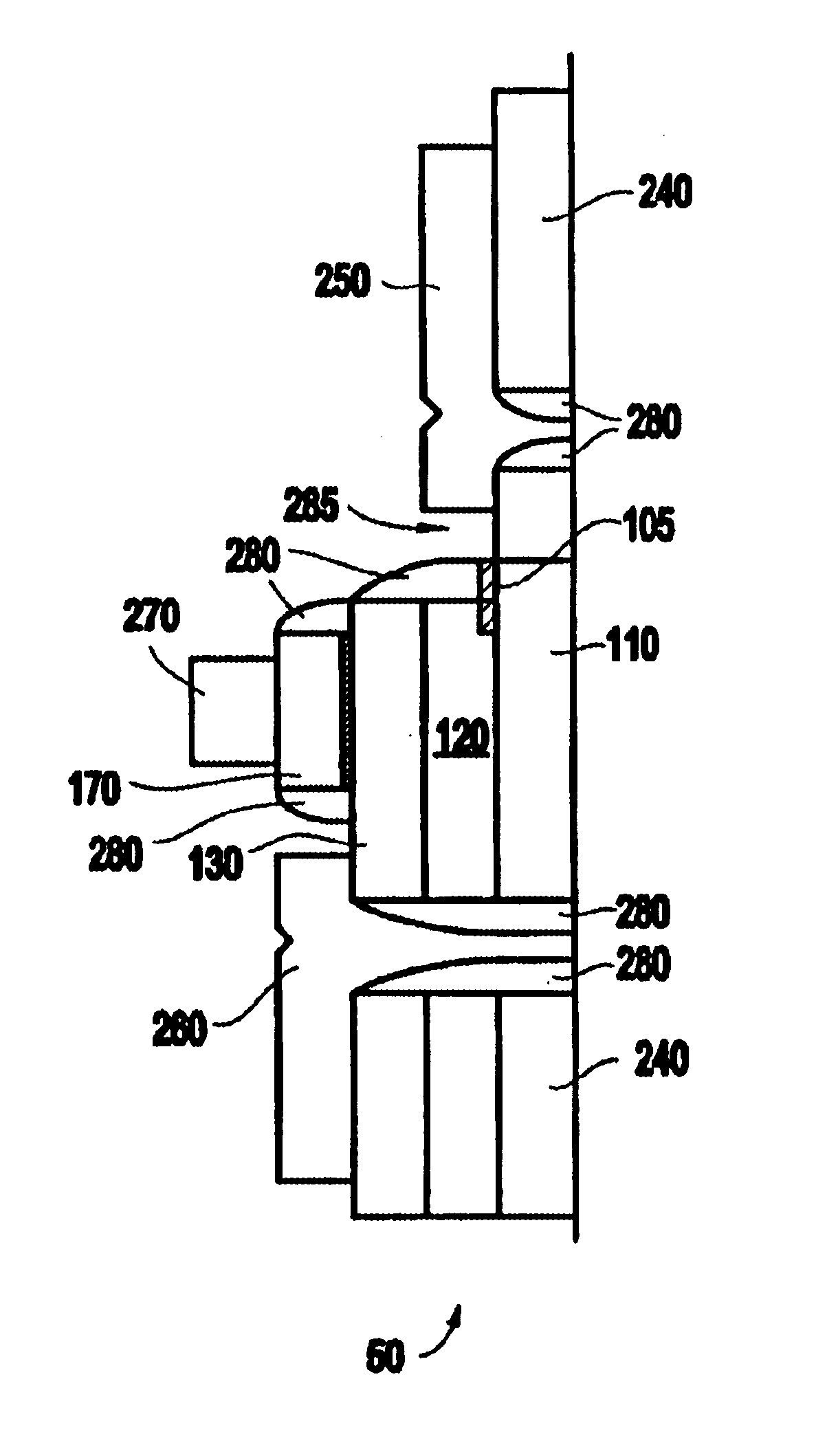

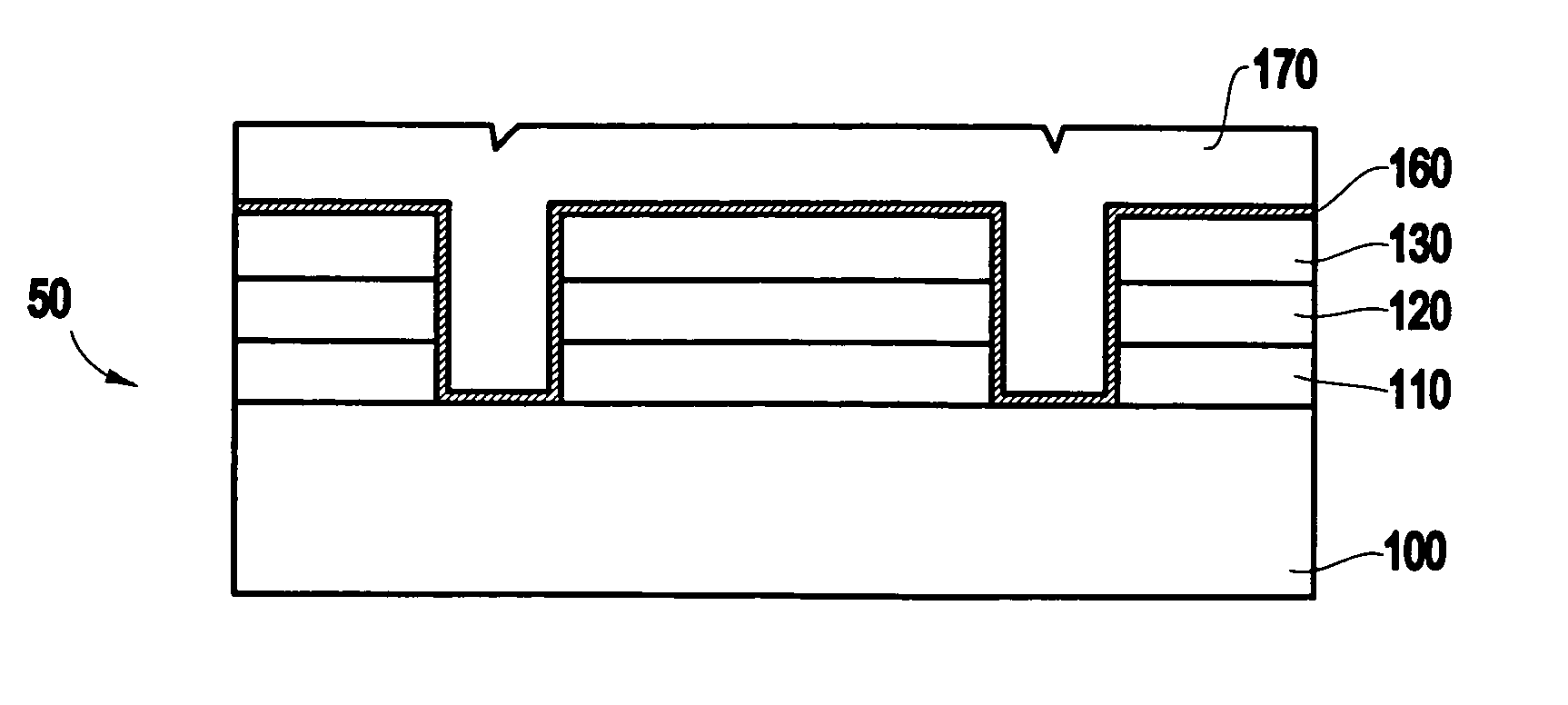

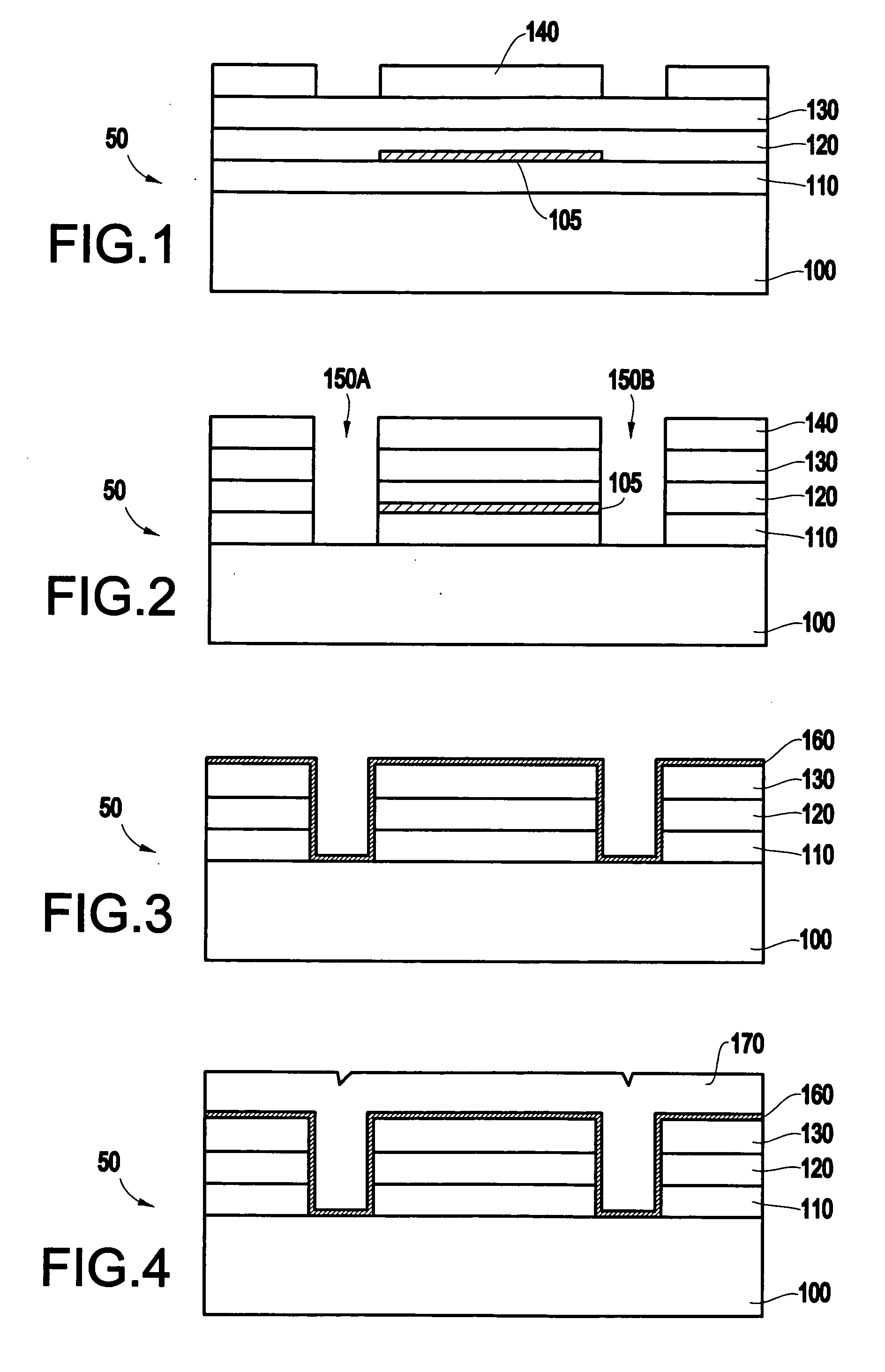

Polymer thin-film transistor with contact etch stops

A method and structure of forming a vertical polymer transistor structure is disclosed having a first conductive layer, filler structures co-planar with the first conductive layer, a semiconductor body layer above the first conductive layer, a second conductive layer above the semiconductor body layer, and an etch stop strip positioned between a portion of the first conductive layer and the semiconductor body layer.

Owner:GOOGLE LLC

Method of producing low-shrink polypropylene tape fibers comprising high amounts of nucleating agents

InactiveUS20040084802A1Low shrinkageImprove solubilityCeramic shaping apparatusMonocomponent polypropylene artificial filamentFiberPolymer science

Improvements in preventing heat- and moisture-shrink problems in specific polypropylene tape fibers are provided. Such tape fibers are basically manufactured through the initial production of polypropylene films or tubes which are then slit into very thin, though flat (and having very high cross sectional aspect ratios) tape fibers thereafter. These inventive tape fibers (and thus the initial films and / or tubes) require the presence of relatively high amounts of certain compounds that quickly and effectively provide rigidity to the target polypropylene tape fiber. Generally, these compounds include any structure that nucleates polymer crystals within the target polypropylene after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target polypropylene without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for polypropylene crystal growth. Subsequent to slitting the initial film and / or tube, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1 ]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive tape fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

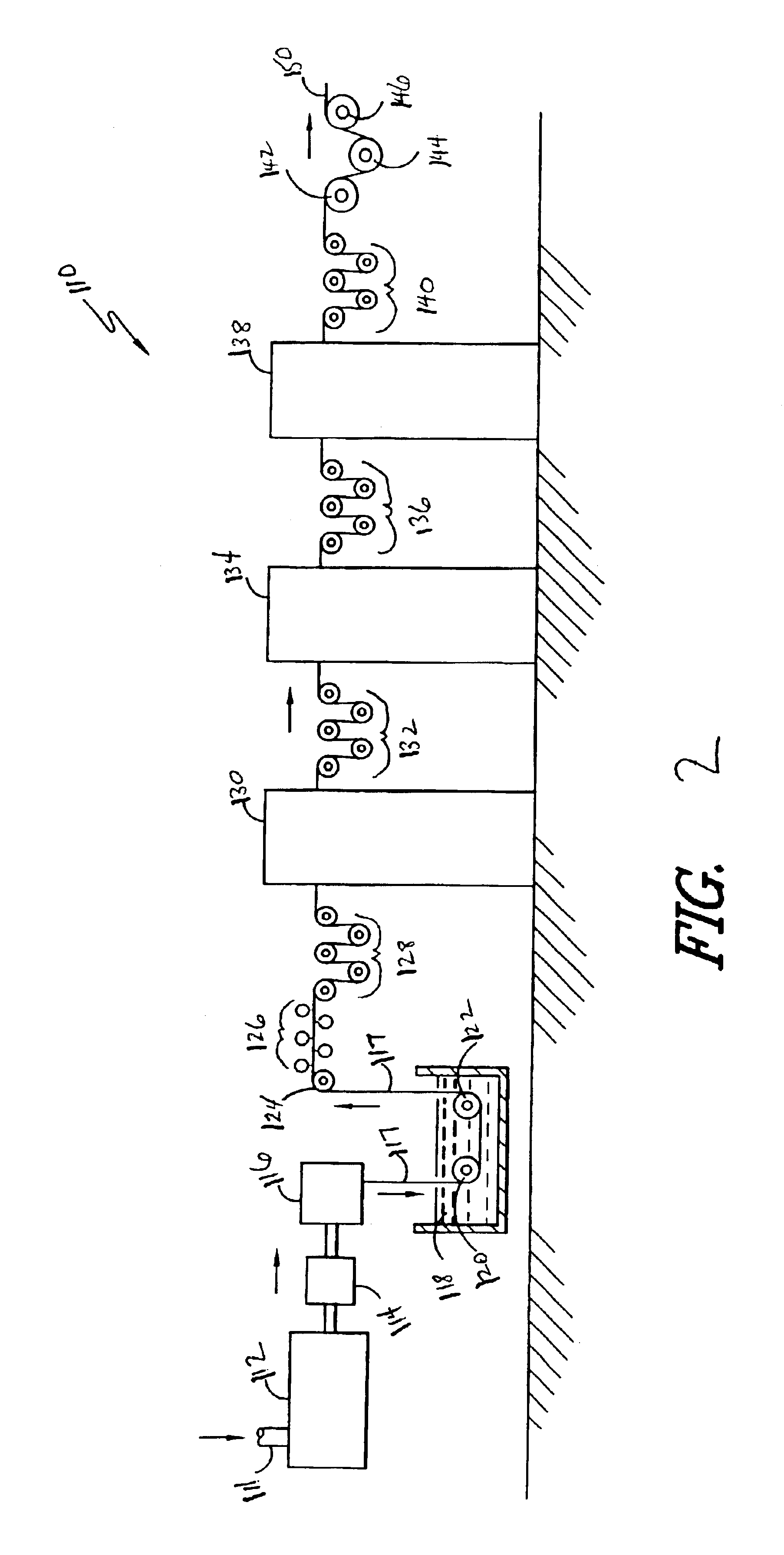

Method for preparing heat-conductive composite material

The invention discloses a method for preparing a heat-conductive composite material, wherein a crystalline polymer and a heat-conductive filling material are used as the raw materials; the crystalline polymer and the heat-conductive filling material are mixed according to the weight ratio of (50-80):(50-20); in the event of processing, polymer melt flows through a strong-shearing flow field; the dispersed state of the filling material in a polymer matrix is improved; more mutual contact heat-conductive network structures including the heat-conductive filling material, polymer crystal and the heat-conductive filling material are formed, and therefore, the heat-conductive coefficient of the composite material can also be greatly increased. On the basis of the existing traditional extrusion equipment, a bidirectional tensile mixer is additionally arranged; and the method for preparing the heat-conductive composite material prepared by the invention has the advantages of being simple to operate, continuous for production, convenient for operation control, steady in quality and high in production efficiency and has wide industrialization and market prospects.

Owner:SICHUAN UNIV

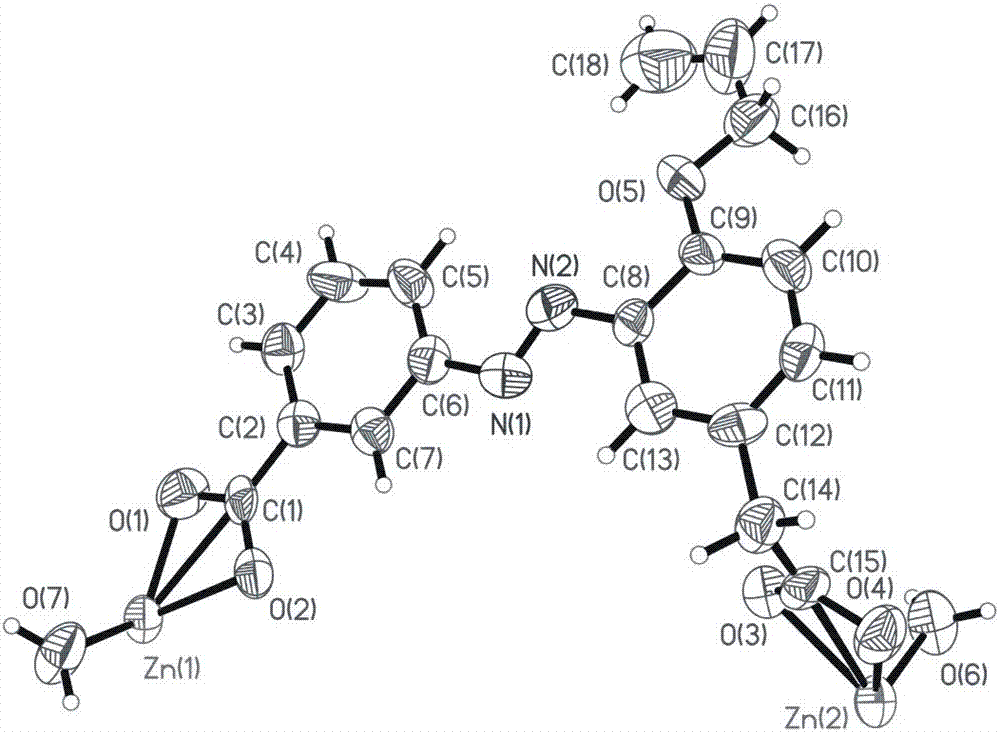

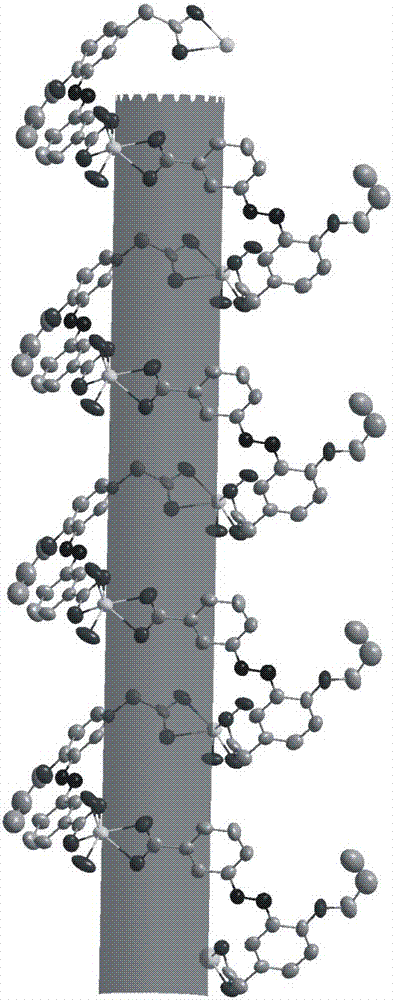

Chiral coordination polymer crystal and preparation method thereof

The present invention discloses a chiral coordination polymer crystal and a preparation method thereof, (1) the chiral coordination polymer crystal has the characteristics of simple preparation, and single chiral structure; (2) ligand 3-(3-carboxylic)-4-allyloxy-azo phenylacetic acid exists in general in a trans stable configuration, and has a special structure, a specific spiral mode is used for coordination reaction in the coordination reaction, a coordination polymer can be obtained by the specific spiral mode under normal temperature liquid phase conditions from the ligand and a metal ion, and preferably, when the metal ion is Zn<2+>, a single chiral crystal structure can be obtained; (3) chiral auxiliaries and chiral ligands are not needed in the preparation method of the chiral coordination polymer crystal, a single chiral spiral can be realized by lattice orientation special selectivity, and the single chiral crystal can be formed, and has potential application in efficient chiral separation and chiral recognition and other aspects.

Owner:SHANDONG UNIV OF SCI & TECH

Automatic self cleaning bladder relief and hydration system

InactiveUS20050154360A1Maximum comfortMinimizing bulkNon-surgical orthopedic devicesSuction devicesSemi automaticEngineering

This invention relates to an automatic or semi-automatic bladder relief and hydration system, specifically designed to increase the overall sanitation and comfort for users that may require a means to dispose of their urine and hydrate in the absence of other sanitary facilities or sources of potable fluids due to situations such as aircraft pilots, hazmat / biohazard workers and incontinent individuals. For user comfort this invention incorporates an inflatable urine collection means that may be deflated after use. In one embodiment a dual chambered back pack serves to store a user's urine and in a separate sanitary chamber provide the user with a potable fluid and / or liquid food source. To prevent user error and failure to recharge the power unit this invention incorporates a disposable battery that is integrated into a disposable urine storage bag. This invention also utilizes a disposable urine storage bag with an isolated cleaning fluid chamber with a directional valve system and directional pump system that automatically rinses and sanitizes the pump, hoses, collection means and the user with a cleaning fluid stored in the cleaning fluid chamber of the disposable urine storage bag. The disposable urine storage bag also contains absorbent polymer crystals capable of absorbing the urine as it is deposited in the bag during use.

Owner:HARVIE MARK R

Polymer thin-film transistor with contact etch stops

A method and structure of forming a vertical polymer transistor structure is disclosed having a first conductive layer, filler structures co-planar with the first conductive layer, a semiconductor body layer above the first conductive layer, a second conductive layer above the semiconductor body layer, and an etch stop strip positioned between a portion of the first conductive layer and the semiconductor body layer.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com