Inorganic nano particle filler for solid state electrolyte and preparation method of inorganic nano particle filler

An inorganic nanoparticle, solid electrolyte technology, applied in solid electrolyte, non-aqueous electrolyte, inorganic pigment treatment and other directions, can solve the problems of inability to meet large-scale industrial production, inability to uniformly disperse, harsh preparation process, etc., and achieve a simple and easy preparation process. performance, ensure conductivity, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

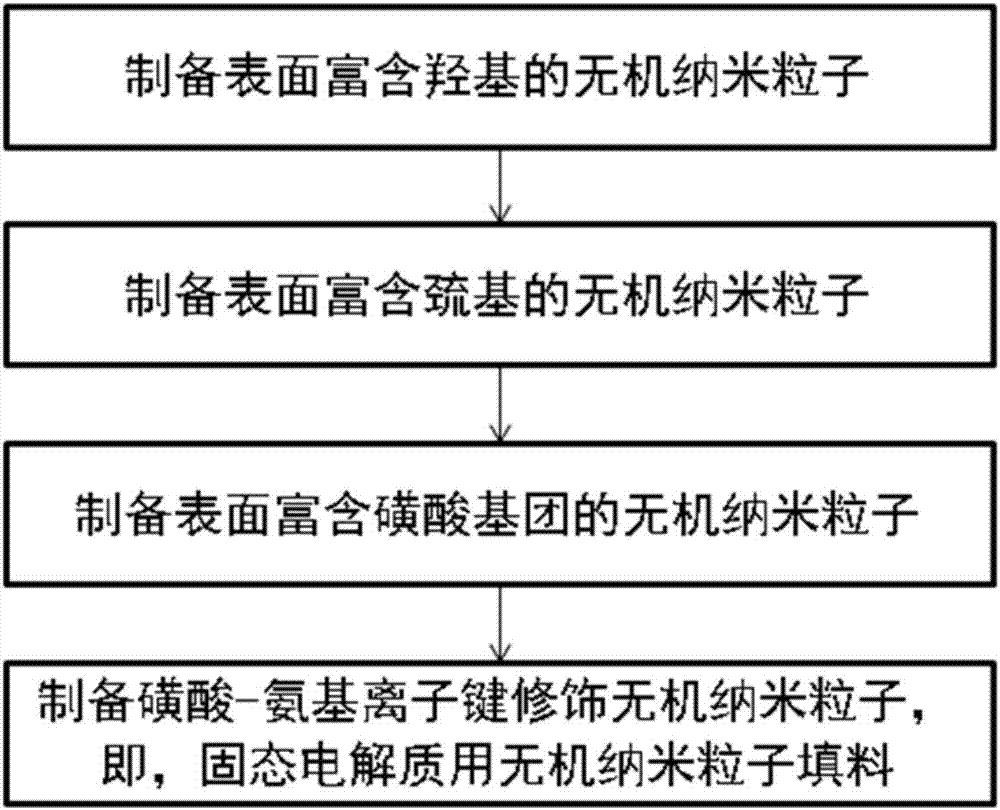

[0032] The preparation method may specifically include the following steps:

[0033] (1) Place the inorganic nanoparticles in an alkaline aqueous solution (such as sodium hydroxide aqueous solution) for activation treatment at 60-90°C for 2-24 hours, the ratio of the inorganic nanoparticles to the alkaline aqueous solution is 1g / 100mL-1g / 2mL, Then cool to room temperature, wash repeatedly with deionized water, and dry to obtain inorganic nanoparticles grafted with hydroxyl groups on the surface; the pH value of the alkaline aqueous solution can be 9-12;

[0034] (2) Disperse the surface hydroxyl-rich inorganic nanoparticles obtained in step (1) in deionized water at a ratio of 1g / 10mL to 1g / 2mL. After ultrasonic dispersion at room temperature for 10 to 40 minutes, add dissolved The organic solution of mercaptopropyltrimethoxysilane (that is, mercaptopropyltrimethoxysilane coupling agent), the mass ratio of inorganic nanoparticles to silane coupling agent is 10 / 1~1 / 10, and the ...

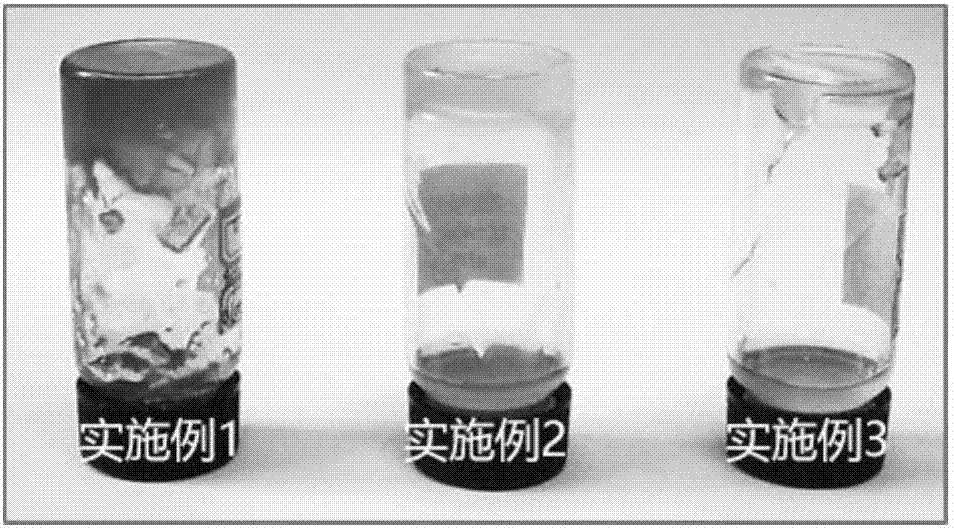

Embodiment 1

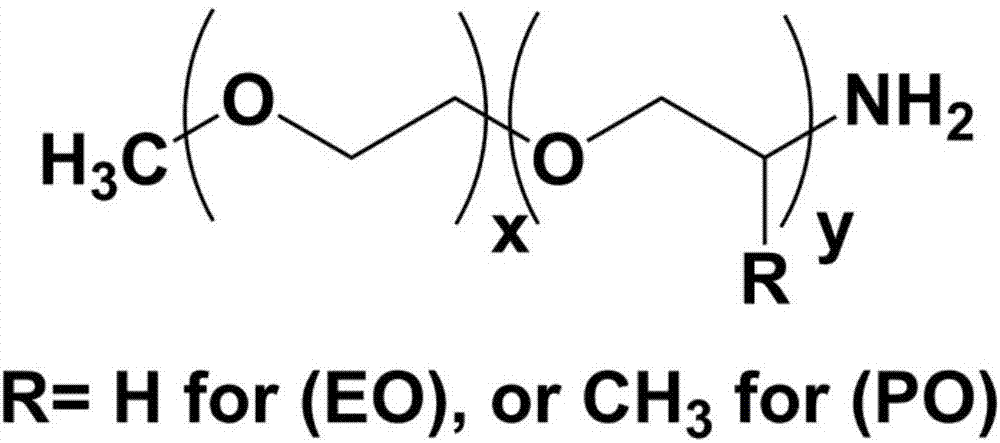

[0044] The ionic bond modified inorganic nano particle filler is specifically the amino-terminated polyether ( M-600) obtained through sulfonic acid-amino ionic bonds, and the mass ratio of the two is 10 / 1.

[0045] The specific preparation method is:

[0046] Disperse 1 g of silica particles with an average particle size of 10 nm in 100 mL of aqueous sodium hydroxide solution with a concentration of 0.1 mol / L, oscillate ultrasonically for 30 min, then heat and reflux at 60°C for 2 h, filter with suction, wash with deionized water several times, and dry to obtain Surface activation of silica nanoparticles with a large number of hydroxyl groups. Disperse 50 g of silica nanoparticles modified with hydroxyl groups in 100 mL of deionized water, vibrate ultrasonically for 10 min, and then add dropwise 5 mL of acetone solution in which 5 g of mercaptopropyltrimethoxysilane is dissolved. Heat to reflux at 60°C for 12 hours, wash with acetone several times after suction filtration,...

Embodiment 2

[0049] Ionic bond modified inorganic nanoparticle filler, specifically the amino-terminated polyether ( M-1000) obtained through sulfonic acid-amino ionic bonds, the mass ratio of the two is 5 / 1.

[0050] The specific preparation method is:

[0051] Disperse 20g of silica particles with an average particle size of 100nm in 100mL of 2mol / L sodium hydroxide aqueous solution, oscillate ultrasonically for 30min, then heat and reflux at 80°C for 12h, wash with deionized water several times after suction filtration, and dry to obtain the surface Activates silica nanoparticles with a large number of hydroxyl groups. Disperse 20 g of silica nanoparticles modified with hydroxyl groups in 100 mL of deionized water, vibrate ultrasonically for 20 min, and then add dropwise 4 mL of methanol solution in which 4 g of mercaptopropyltrimethoxysilane is dissolved. Heat to reflux at 80°C for 24 hours, wash with methanol several times after suction filtration, and dry to obtain silica nanopart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com