Boron-containing plastic crystal polymer and preparation method and application thereof

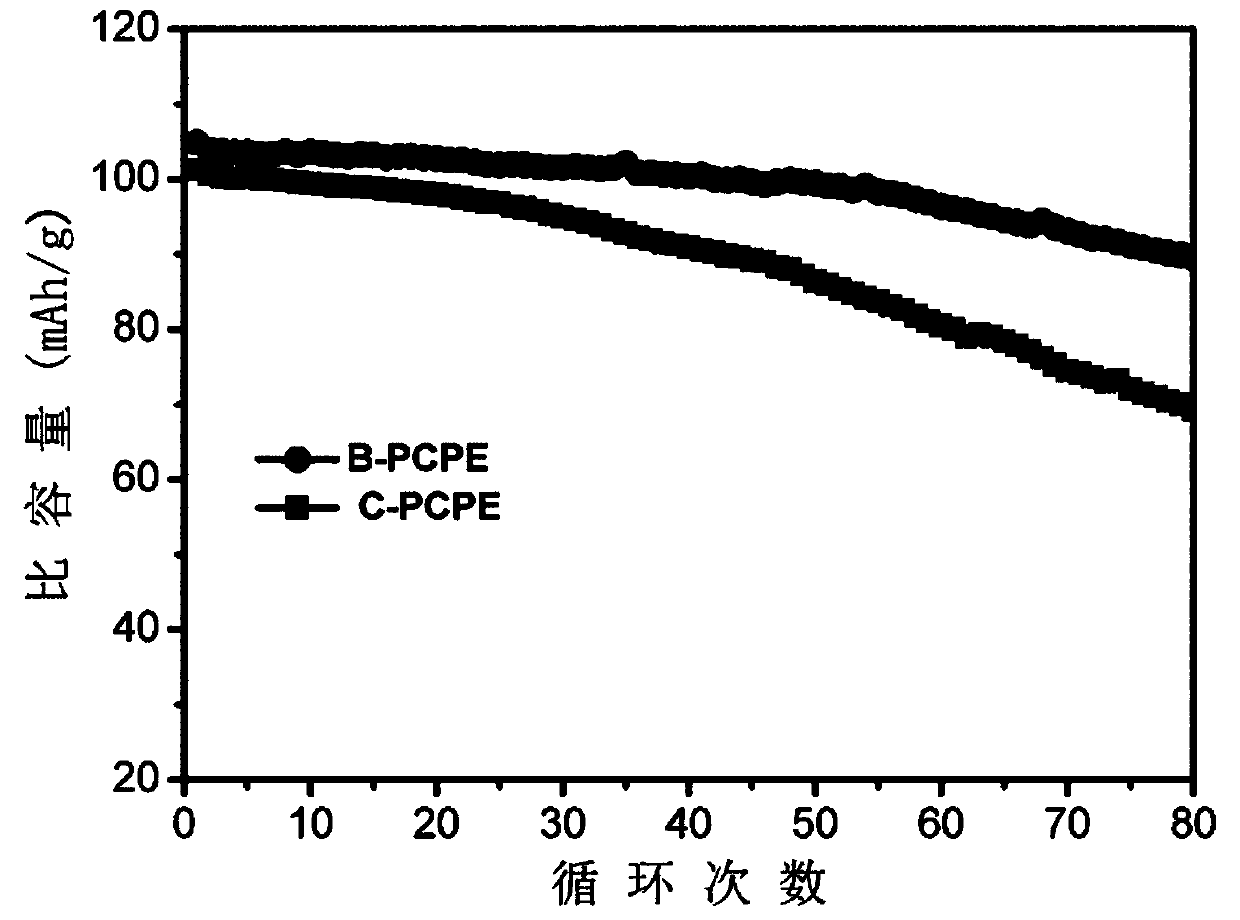

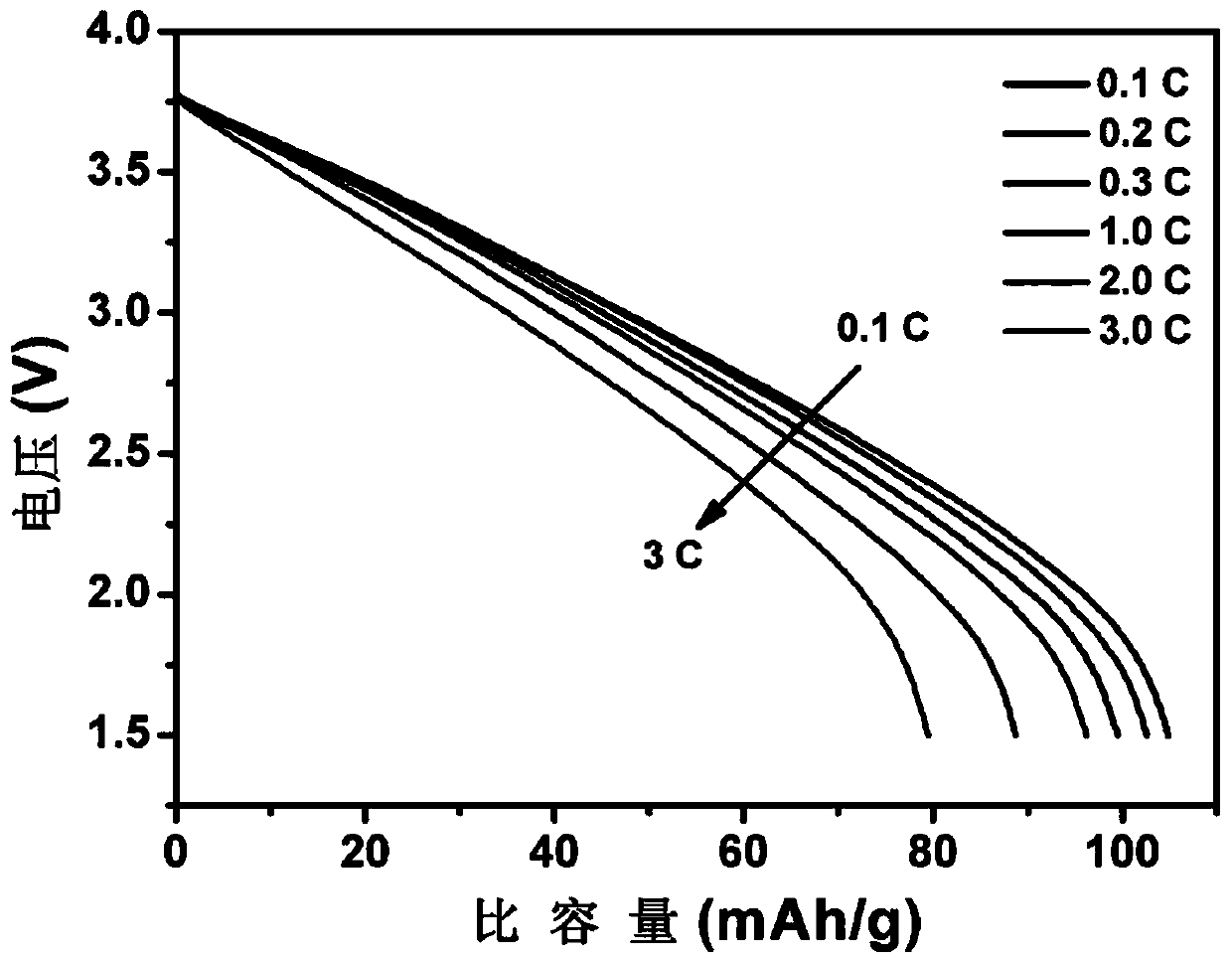

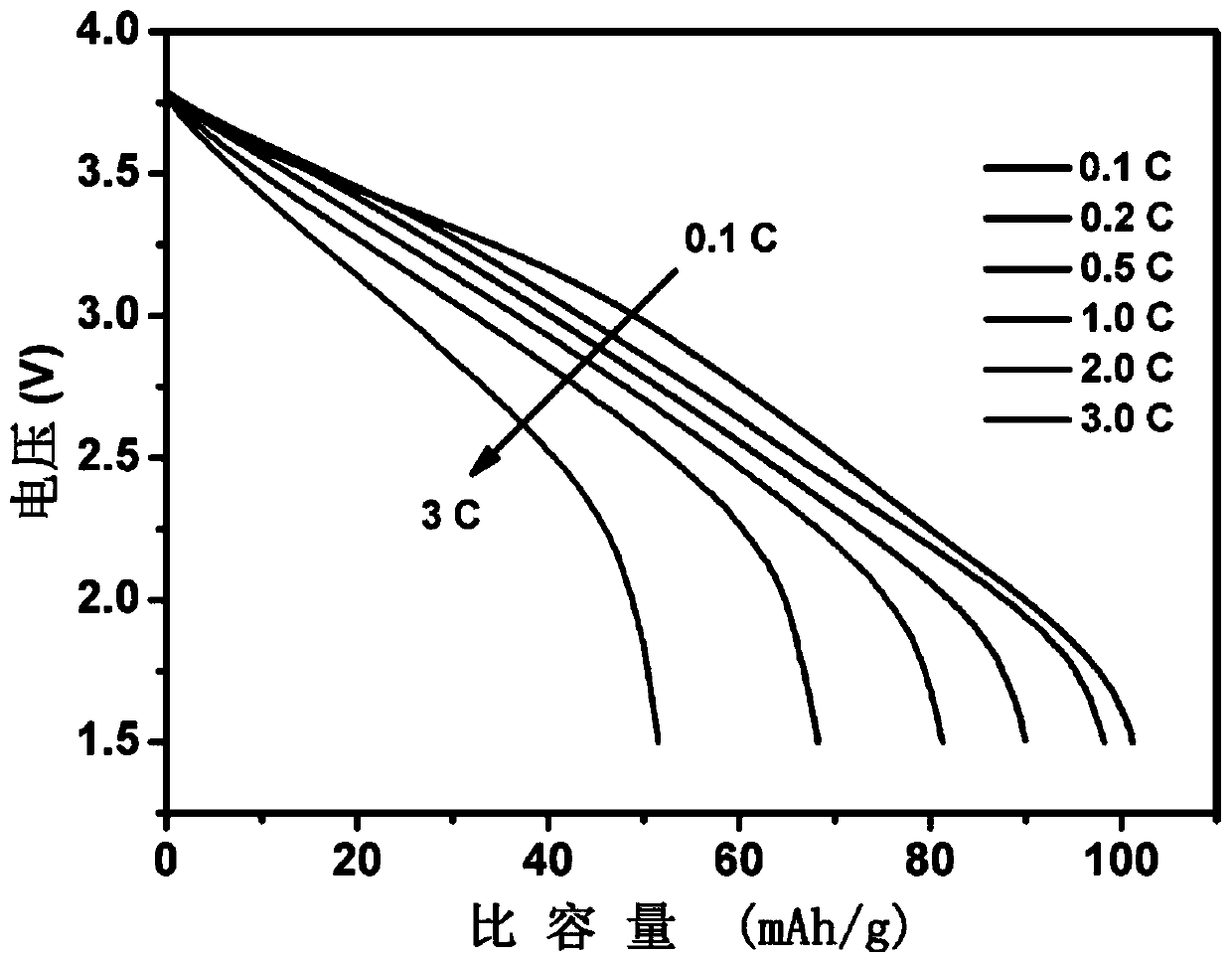

A technology of polymers and mixtures, applied in the field of boron-containing plastic crystal polymers and its preparation, can solve the problems of high electrode/electrolyte interface impedance, low room temperature ion conductivity, high working temperature, etc., and achieve good rate performance and cycle stability Sex, high sodium ion migration number, and the effect of reducing interfacial impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Preparation of boron-containing ternary crosslinker (B-crosslinker)

[0050] Measure 2.6mL of trimethyl borate and 8.5mL of hydroxyethyl methacrylate and dissolve in 25mL of anhydrous acetonitrile, and stir the mixture at 50°C for 3-4 hours under the protection of an inert atmosphere, and then raise the temperature to 70°C , continue to stir for 3 to 5 hours, and remove the methanol produced by the reaction to ensure that the reaction is carried out thoroughly. After the reaction, unreacted trimethyl borate and residual solvent were distilled off under reduced pressure, and vacuum-dried for 48 hours. The obtained light yellow liquid product (that is, B-crosslinker) is sealed and stored in a glove box to prevent its hydrolysis (for specific preparation methods, please refer to the literature: ACS Appl. Mater. Interfaces 2016, 8, 27740-27752).

[0051] The boron-containing ternary crosslinker (B-crosslinker) used in the following examples and comparative examples were...

Embodiment 2

[0063] 1. Preparation of all-solid plastic crystal polymer electrolyte membrane

[0064] Take a certain amount of sodium trifluoromethanesulfonate (NaOTf) and join in succinonitrile (SN), heated and stirred to form transparent and uniform NaOTf salt solution 1 of succinonitrile, NaOTf concentration in SN in solution 1 is 1.25mol / L. Then add a certain amount of B-crosslinker (n=6) crosslinking agent to solution 1, and add a certain mass fraction of 184 photoinitiator to the system at the same time, continue to stir to form a uniform solution 2, in solution 2, add The mass fraction of B-crosslinker (n=6) is 30wt.%, and the content of photoinitiator 184 is 5wt.% of the mass of active monomer B-crosslinker (n=6). Then, inject the mixed solution into the polyacrylonitrile non-woven fabric. After the solution is completely immersed, the non-woven fabric containing the mixed solution is sandwiched between two clean glass sheets, and the film is cured by ultraviolet curing technolo...

Embodiment 3

[0074] 1. Preparation of all-solid plastic crystal polymer electrolyte membrane

[0075] Weigh a certain amount of bis(trifluoromethylsulfonimide) sodium (NaTFSI) and add it to succinonitrile (SN), heat and stir until NaTFSI salt solution 1 of transparent and uniform succinonitrile is formed, NaTFSI in solution 1 The concentration in SN is 0.25mol / L. Then add a certain amount of B-crosslinker (n=20) crosslinking agent to solution 1, and add a certain mass fraction of 1173 photoinitiator to the system at the same time, continue to stir so that a uniform solution 2 is formed, in solution 2, add The mass fraction of B-crosslinker (n=20) is 8wt.%, and the content of photoinitiator 1173 is 0.5wt.% of the mass of active monomer B-crosslinker (n=20). Then, the mixed solution is injected into the cellulose membrane support material, and after the solution is completely immersed, the non-woven fabric containing the mixed solution is sandwiched between two clean glass sheets, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sub-conductivity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com