On-line plastic crystallinity measuring method based on pressure sensor and temperature sensor

A temperature sensor and pressure sensor technology, which is applied in the field of plastic injection molding, can solve the problems of cumbersome steps, large limitations, and inability to obtain crystal form formation, evolution, and sizing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In this embodiment, the plastic material is polypropylene (PP), and the parameters of the injection molding process are as follows:

[0035] Process parameters

value

Process parameters

value

Injection temperature (°C)

240

Holding pressure (MPa)

100

Mold temperature (°C)

40

Holding time (s)

5

Injection time (s)

1

Cooling time (s)

50

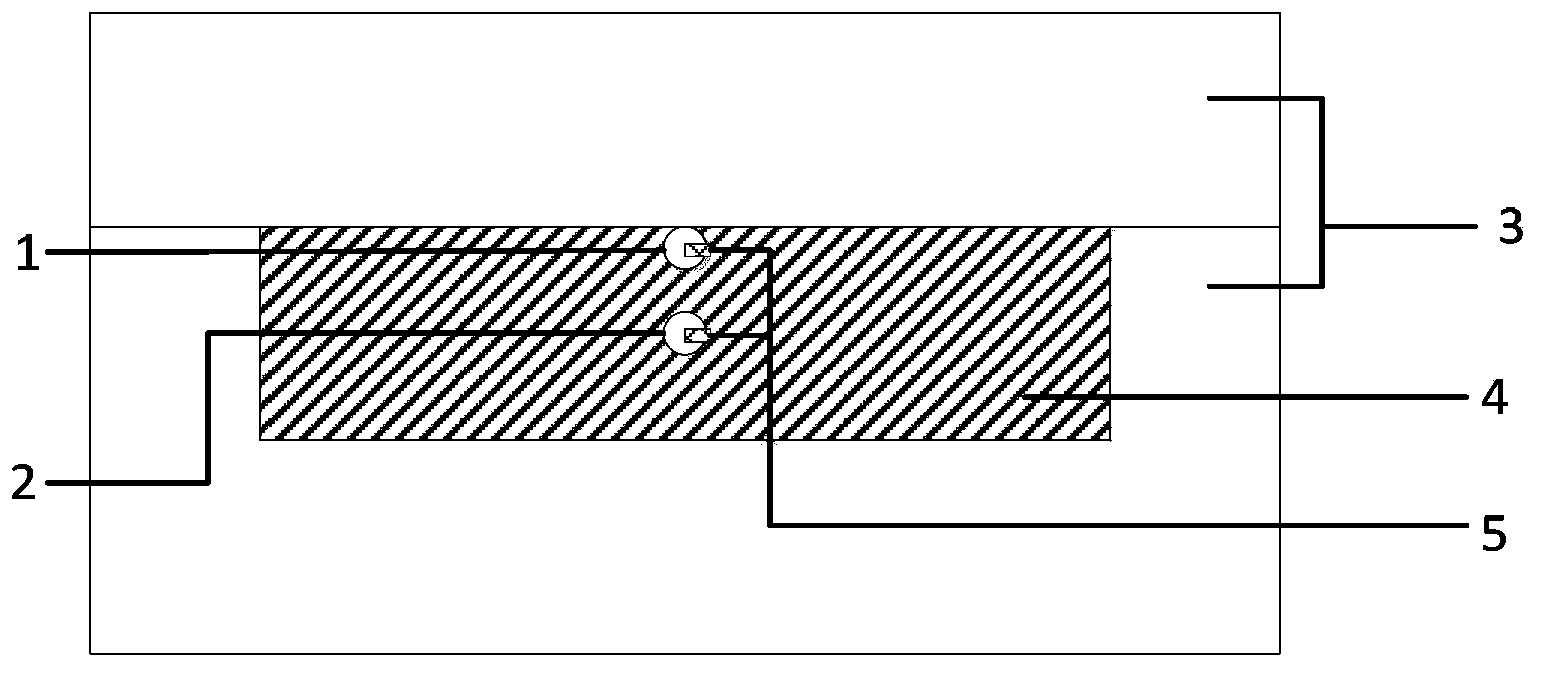

[0036] like figure 1 As shown, 1 is the surface detection point, 2 is the center detection point, 3 is the mold, 4 is the polymer, 5 is the temperature and pressure sensor.

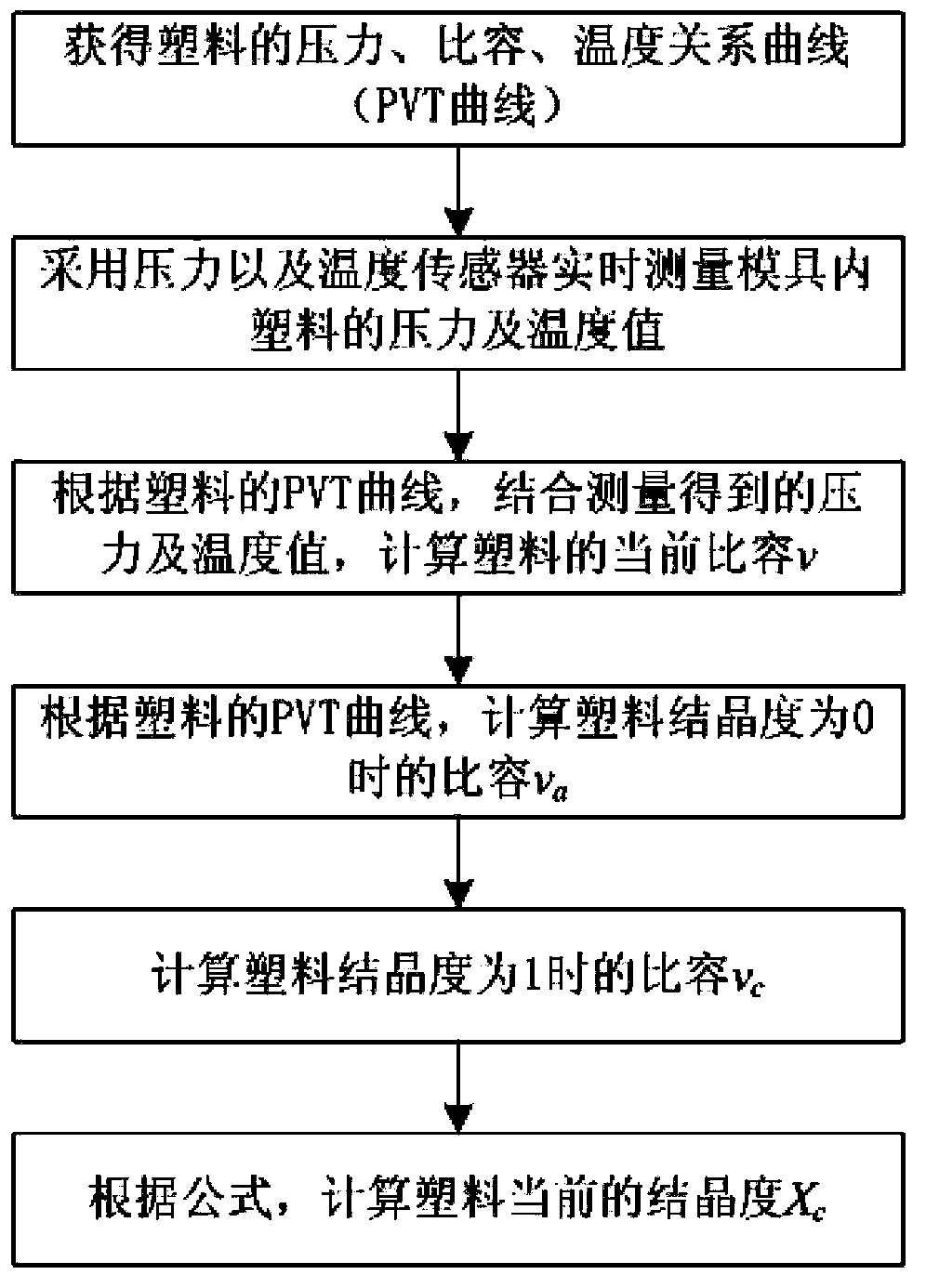

[0037] like figure 2 As shown, the implementation steps of the plastic crystallinity online measurement method used in the injection molding process in this embodiment are as follows:

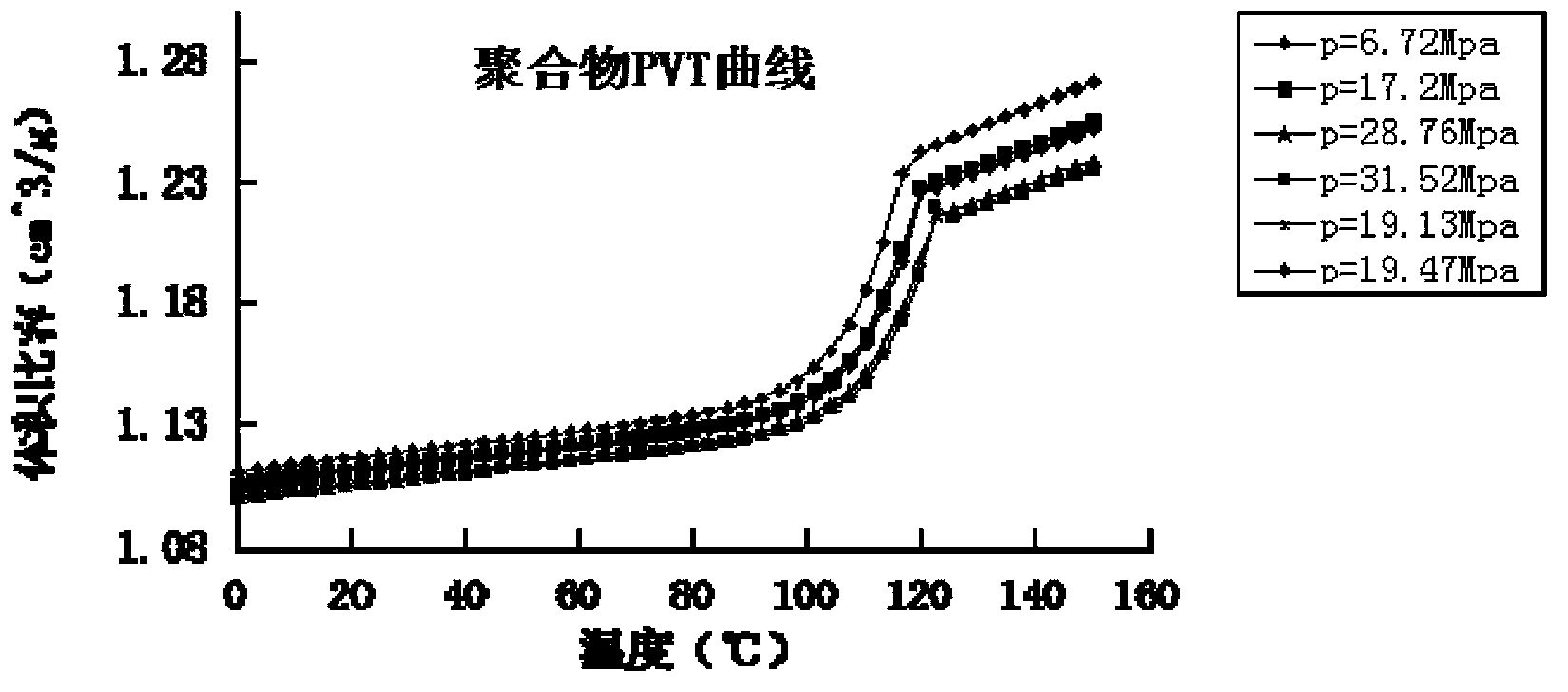

[0038] (1) Obtain the pressure, specific volume and temperature relationship curve (PVT curve) of the plastic;

[0039] The Tait equation of the two-phase model is used to describe the PVT curve. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com