Composite solid electrolyte material, preparation method thereof, and all-solid-state battery

A solid electrolyte and solid electrolyte layer technology, applied in the field of lithium-ion batteries, can solve the problems of low room temperature ionic conductivity, poor electrochemical stability, narrow electrochemical window, etc., to achieve enhanced electrochemical stability, improved capacity fading, The effect of interfacial contact stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

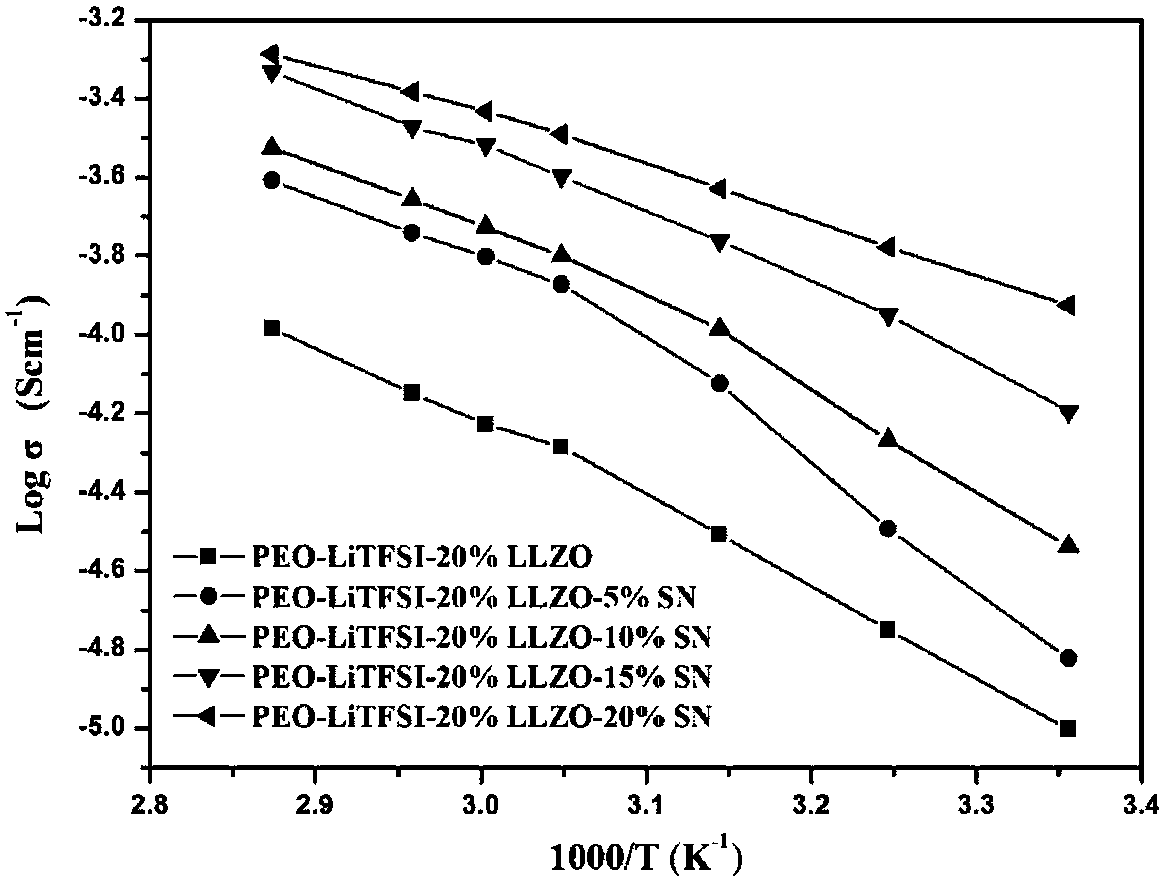

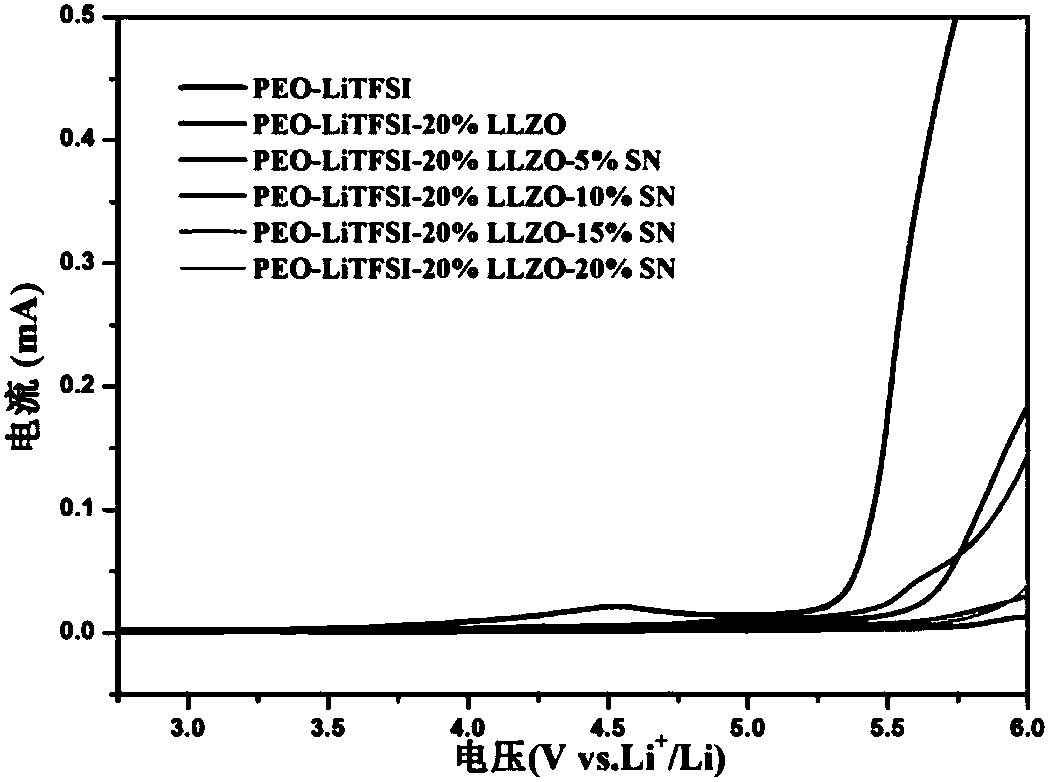

[0031] The invention relates to an organic / inorganic composite solid electrolyte material and a preparation method thereof. This method takes the viscosity average molecular weight Mv as 5×10 3 ~9×10 6 The polyethylene oxide (PEO) is the matrix of the solid electrolyte, and the molar ratio of the oxygen atom in the polyethylene oxide to the Li in the lithium salt is between 8:1 and 30:1; an inorganic electrolyte with high lithium ion conductivity is selected Li7La3Zr2O12(LLZO), Li 10 GeP 2 S 12 (LGPS) and Li 2 O-Al 2 O 3 -TiO 2 -P 2 O 5 (LATP) as an inorganic filler material, select malononitrile, succinonitrile, adiponitrile, N-methyl-N-ethylbis(trifluoromethylsulfonyl)imide tetrahydropyrrole (PY 12 TFSI) and nitrile group-containing quaternary ammonium salt and other plastic crystal compound materials or multiple in any ratio as solid plasticizing materials, select lithium hexafluorophosphate, lithium tetrafluoroborate, lithium hexafluoroarsenate, lithium perchlorate, One or m...

Embodiment 1

[0034] The ready-to-use polyethylene oxide, inorganic powder, plastic crystal compound and lithium salt are dried; weigh 0.2753g PEO (viscosity average molecular weight Mv is 5 million) and 0.0997g LiTFSI, dissolve them in 15ml acetonitrile solution, in 60 Magnetic stirring at 500r / min for 12h at ℃ to obtain homogeneous and transparent solution A. Weigh out 0.0857g Li 7 La 3 Zr 2 O 12 (LLZO) powder and 0.0429 g of succinonitrile (SN) were added to solution A, and magnetically stirred at a rotation speed of 500 r / min at 60° C. for 12 hours to obtain a white suspension B. The suspension B obtained above is poured into a mold for forming by a casting method. Place the mold in a dry and dust-free environment for 12 hours at room temperature, and then put it in a vacuum drying box for vacuum drying at 45° C. for 24 hours to obtain the desired composite solid electrolyte material. The prepared electrolyte material is processed into the required shape, superimposed with the positive ...

Embodiment 2

[0036] The polyoxyethylene, inorganic powder, plastic crystal compound and lithium salt to be used are dried; weigh 0.2753g PEO (viscosity average molecular weight Mv is 1.2 million) and 0.0997g LiTFSI, dissolve them in 15ml acetonitrile solution, and weigh them at 60 Magnetic stirring at 500r / min for 12h at ℃ to obtain homogeneous and transparent solution A. Weigh 0.7g Li 10 GeP 2 S 12 (LGPS) powder and 0.0331g of succinonitrile (SN) were added to solution A, and magnetically stirred at a speed of 500r / min at 60°C for 12h to obtain a white suspension B. The suspension B obtained above is poured into a mold for forming by a casting method. Place the mold in a dry and dust-free environment for 12 hours at room temperature, and then put it in a vacuum drying box for vacuum drying at 45° C. for 24 hours to obtain the desired composite solid electrolyte material. The prepared electrolyte material is processed into the required shape, superimposed with the positive electrode active...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com