Organic/inorganic composite solid electrolyte with bicontinuous structure and preparation method thereof

A solid electrolyte, inorganic composite technology, applied in composite electrolyte, electrolyte battery manufacturing, electrolyte and other directions, can solve the problems of complex preparation process, electrochemical performance to be optimized, etc., to achieve simple preparation method, precise control of electrochemical performance, easy effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

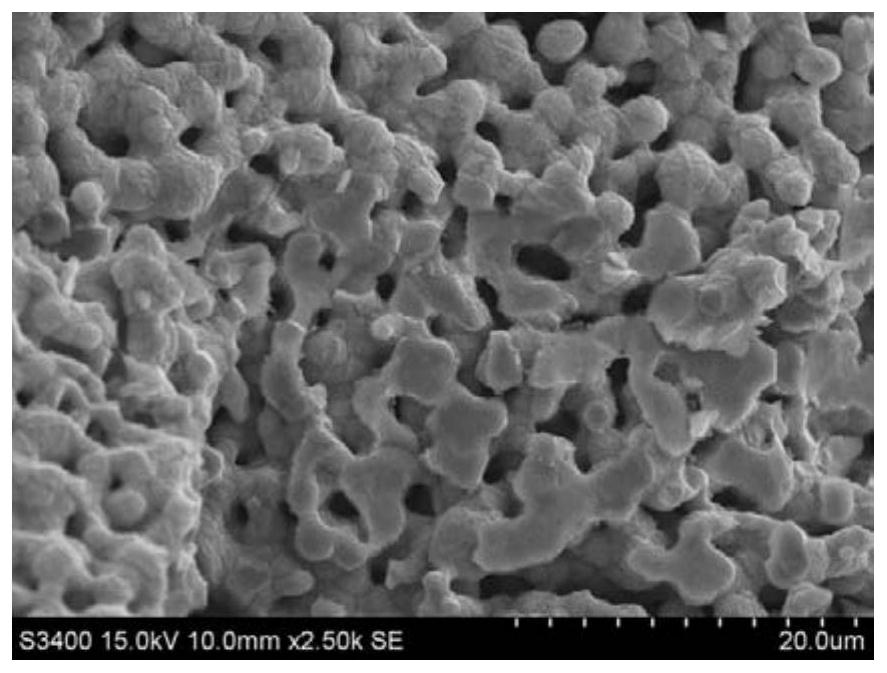

[0036] An organic / inorganic composite solid electrolyte with a bicontinuous structure, the preparation method of which is as follows:

[0037] 1) According to the chemical formula Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 In the molar ratio of elements, weigh 5.7864g lithium carbonate, 10.8728g lanthanum oxide, 2.9494g tantalum oxide and 3.8379g zirconia to form LLZO precursor powder, add PMMA and MgO to the precursor powder, PMMA accounts for LLZO precursor powder, PMMA and 25wt% of the total mass of MgO, MgO accounts for 0.5wt% of the LLZO precursor powder, then adds PVA aqueous solution (mass concentration is 10%) to the mixed powder, the PVA aqueous solution accounts for 10wt% of the mixed powder gross mass, and the resulting mixture is ground for 100min Finally, 0.6 g of the ground mixture was taken for tableting (tablet diameter 10 mm), placed in a zirconia crucible, placed in a Nabertherm muffle furnace, and heated to 1000 °C at a heating rate of 1 °C / min at room temperature. ...

Embodiment 2

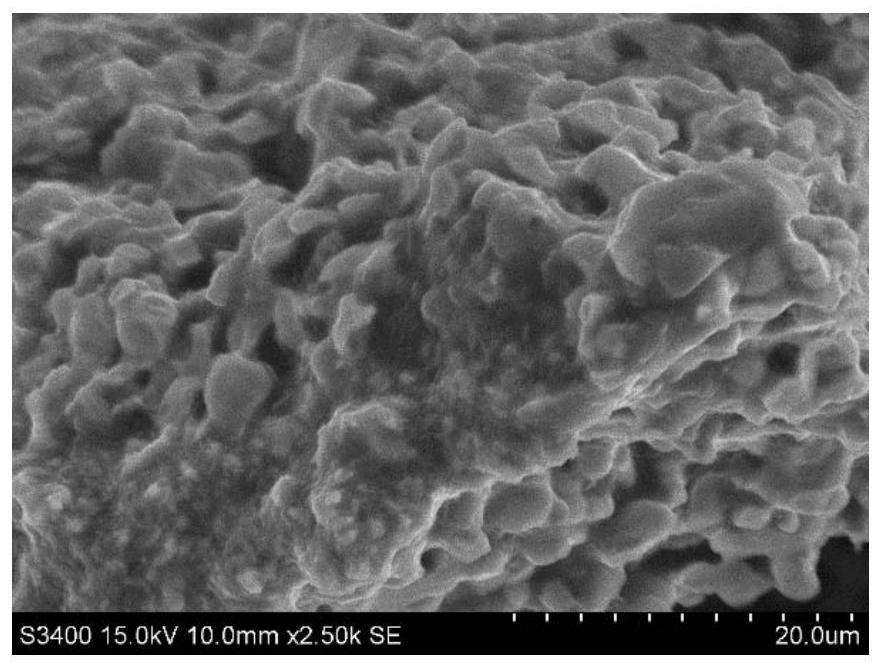

[0040] An organic / inorganic composite solid electrolyte with a bicontinuous structure, the preparation method of which is as follows:

[0041] 1) According to the chemical formula Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Medium element molar ratio Weigh 2.34g lithium oxide, 10.8728g lanthanum oxide, 2.9494g tantalum oxide and 3.8379g zirconia to form LLZO precursor powder, add PMMA and MgO to the precursor powder, PMMA accounts for LLZO precursor powder, PMMA and 15wt% of the total mass of MgO, MgO accounts for 0.5wt% of the LLZO precursor powder, then adds PVA aqueous solution (mass concentration is 10%) in the mixed powder, the PVA aqueous solution accounts for 10wt% of the total mass of the mixed powder, and the resulting mixture is ground for 10min Finally, 0.6 g of the ground mixture was taken for tableting (10 mm in diameter), placed in a zirconia crucible, placed in a Nabertherm muffle furnace, and heated to 1100 °C at a heating rate of 3 °C / min at room temperature Carry out...

Embodiment 3

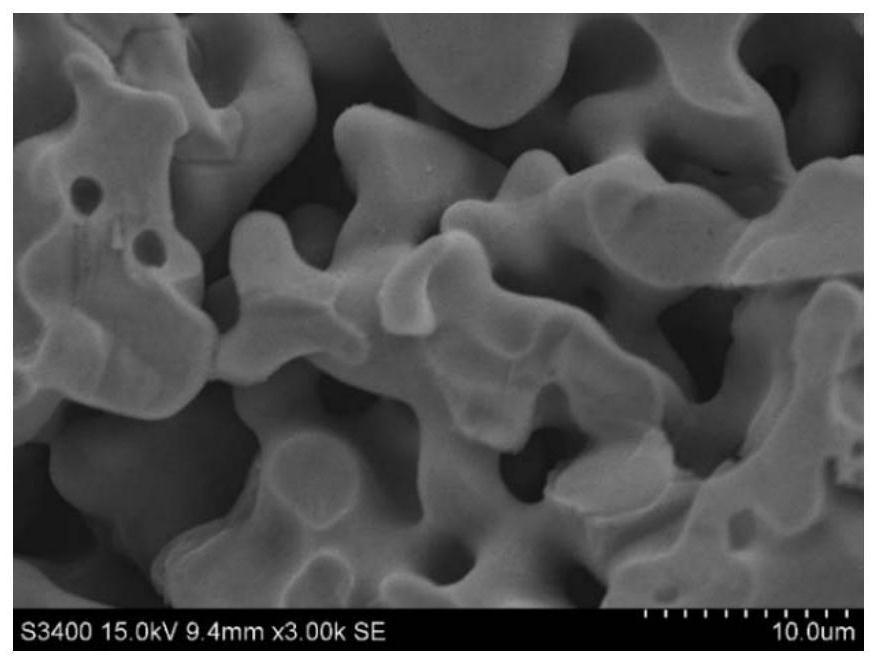

[0047] An organic / inorganic composite solid electrolyte with a bicontinuous structure, the preparation method of which is as follows:

[0048] 1) According to the chemical formula Li 6.4 Ga 0.2 La 3 Zr 2 o 12 Medium element molar ratio Weigh 1.8365g lithium oxide, 8.5333g lanthanum oxide, 0.3273g gallium oxide and 4.303g zirconia to form LLZO precursor powder, add PMMA and MgO to the precursor powder, PMMA accounts for LLZO precursor powder, PMMA and 5wt% of the total mass of MgO, MgO accounts for 1wt% of the LLZO precursor powder, then adds PVA aqueous solution (mass concentration is 10%) in the mixed powder, the PVA aqueous solution accounts for 10wt% of the mixed powder gross mass, after the gained mixture is ground for 45min , take 0.6g of the ground mixture and press it into tablets (10mm in diameter), put it in a zirconia crucible, put it in a Nabertherm muffle furnace, and heat it up to 800°C at a heating rate of 3°C / min at room temperature. Sintering, the sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com