Three-dimensional self-supported lithium-loving carrier-packaged metal lithium composite negative electrode and preparation method thereof

A lithium metal, self-supporting technology, applied in the direction of battery electrodes, lithium batteries, nanotechnology for materials and surface science, etc., can solve the problems of lithium metal volume change, deposition of dendrites, lack of protection methods, etc., to achieve life expectancy The effect of long life, high safety and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

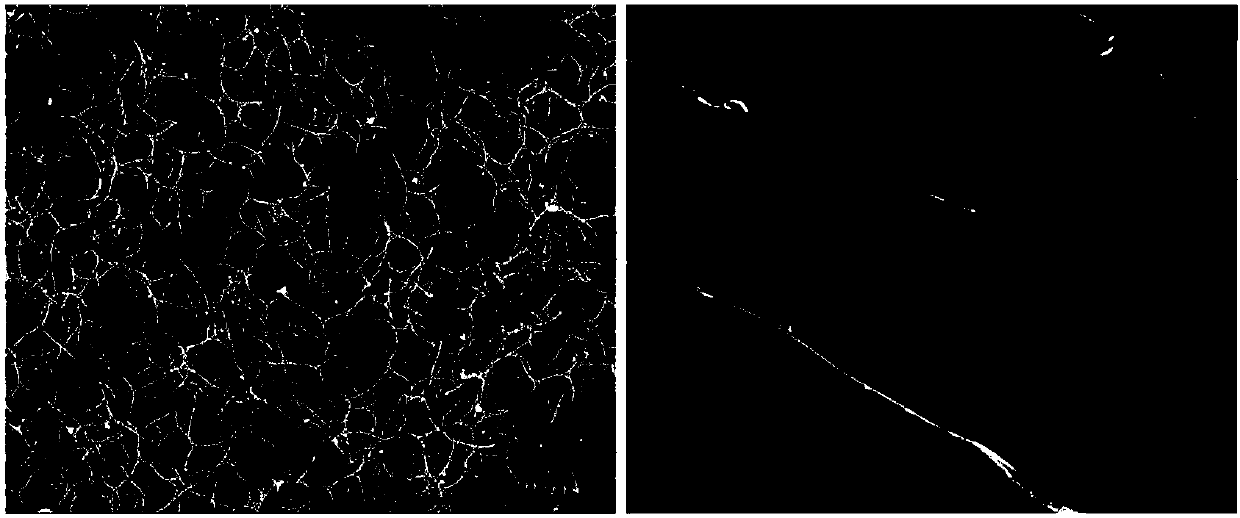

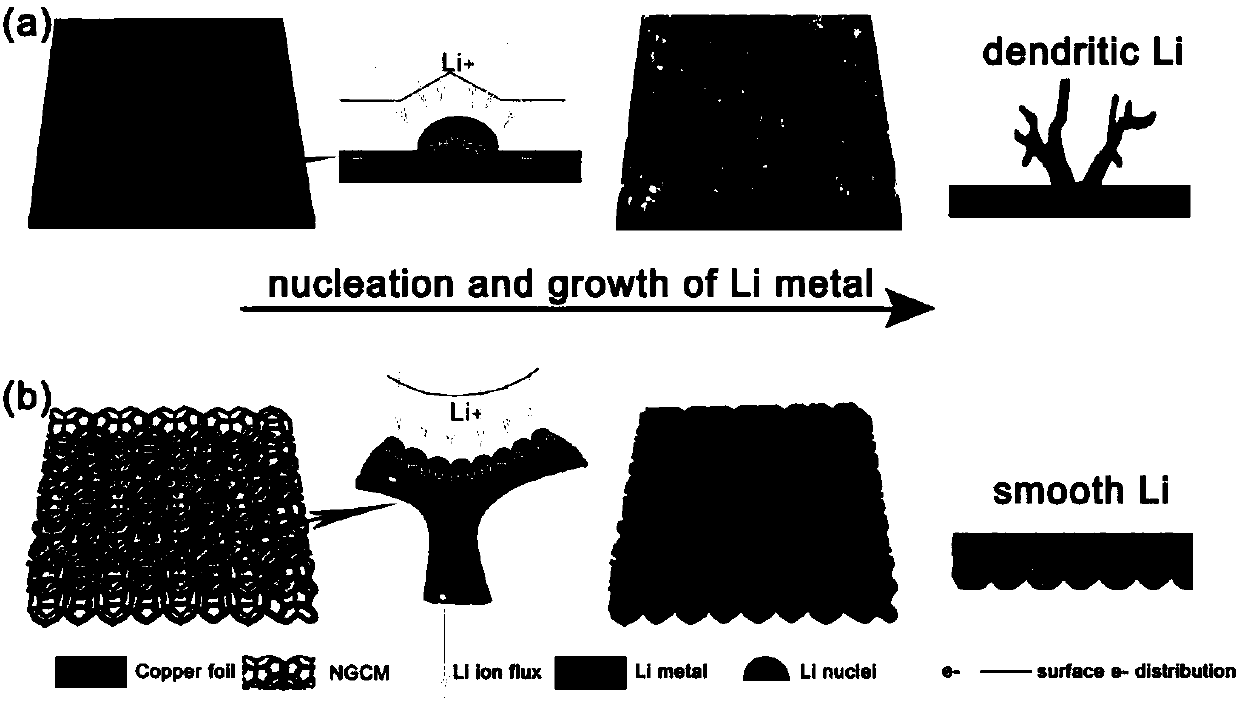

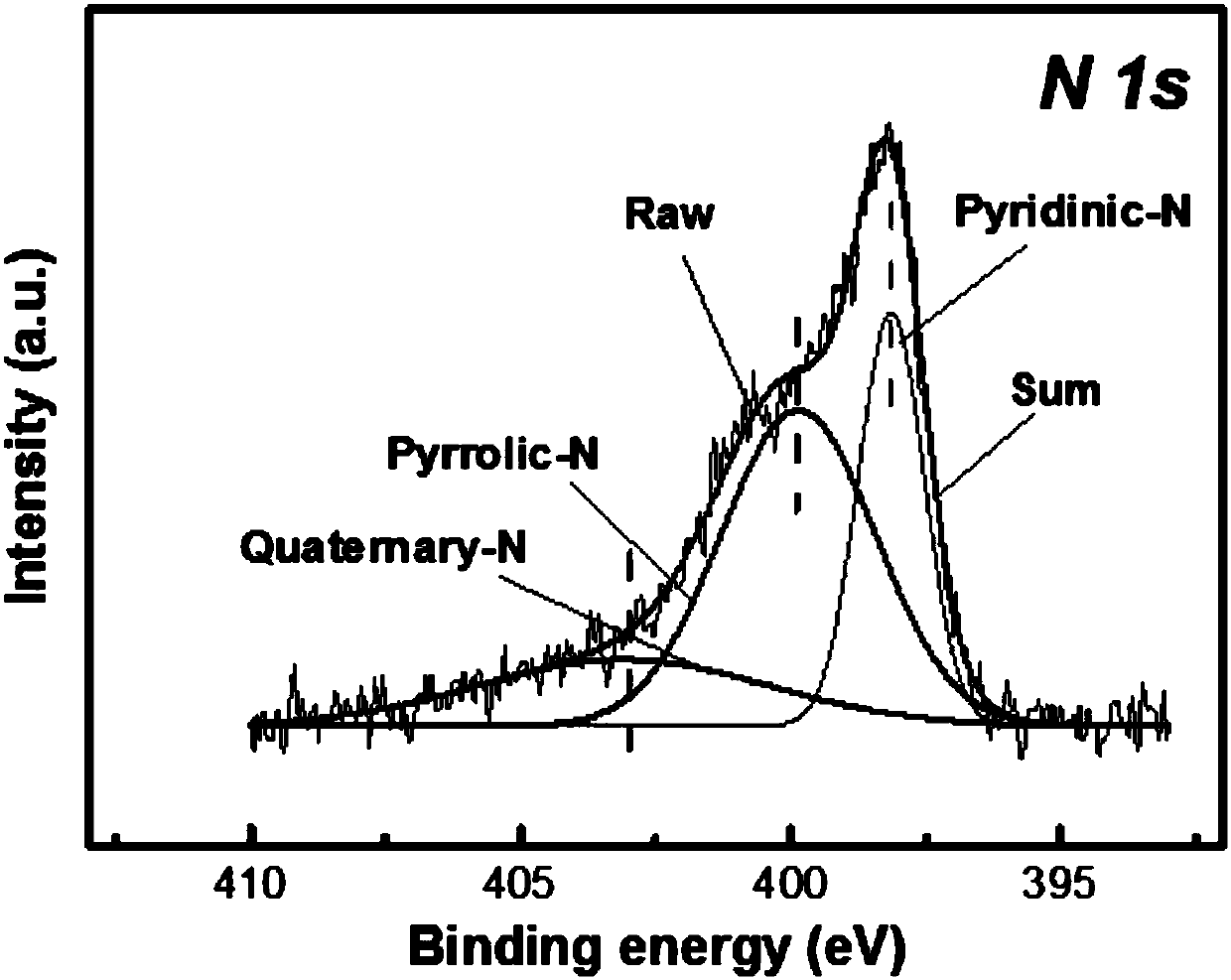

[0048] (1) Preparation of a three-dimensional self-supporting lithiophilic carrier

[0049] The commercial melamine foam was ultrasonically cleaned in acetone, deionized water and ethanol in sequence, and then cleaned at 3 °C min in a high-purity nitrogen atmosphere. -1 The heating rate was raised to 900°C for carbonization of lithium, and the temperature was kept for 1 hour to obtain a three-dimensional self-supporting nitrogen-rich carbon sponge. Most of the high nitrogen content in the carrier exists in the form of pyrrole nitrogen and pyridine nitrogen. These nitrogen-containing functional groups have a relatively strong relationship with lithium High binding energy, with lithium-philic properties.

[0050] (2) Preparation of metal lithium anode encapsulated by three-dimensional self-supporting lithium-philic carrier

[0051] The above-mentioned three-dimensional self-supporting nitrogen-rich carbon sponge carrier was cut into the desired shape as the working electrode, a...

Embodiment 2

[0060] (1) Preparation of a three-dimensional self-supporting carrier

[0061] The commercial melamine foam was ultrasonically cleaned in acetone, deionized water and ethanol in sequence, and then heated at 5 °C for min in a high-purity nitrogen atmosphere. -1 The heating rate was increased to 950°C for carbonization of lithium, and the temperature was maintained for 1 hour to obtain a three-dimensional self-supporting nitrogen-rich carbon sponge. Most of the high nitrogen content in the carrier exists in the form of pyrrole nitrogen and pyridine nitrogen. These nitrogen-containing functional groups have a relatively strong relationship with lithium High binding energy, with lithium-philic properties.

[0062] (2) Preparation of metal lithium anode encapsulated by three-dimensional self-supporting lithium-philic carrier

[0063] The above-mentioned three-dimensional self-supporting nitrogen-rich carbon sponge carrier was cut into the desired shape as the working electrode, an...

Embodiment 3

[0066] (1) Preparation of a three-dimensional self-supporting carrier

[0067] The commercial melamine foam was ultrasonically cleaned in acetone, deionized water and ethanol in sequence, and then cleaned at 3 °C min in a high-purity nitrogen atmosphere. -1 The heating rate was raised to 900°C for carbonization of lithium, and the temperature was kept for 1 hour to obtain a three-dimensional self-supporting nitrogen-rich carbon sponge. Most of the high nitrogen content in the carrier exists in the form of pyrrole nitrogen and pyridine nitrogen. These nitrogen-containing functional groups have a relatively strong relationship with lithium High binding energy, with lithium-philic properties.

[0068] (2) Preparation of metal lithium anode encapsulated by three-dimensional self-supporting lithium-philic carrier

[0069] The above-mentioned three-dimensional self-supporting nitrogen-rich carbon sponge carrier was cut into the required shape as the working electrode, and the metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com