Alumina-coated granules, as well as preparation method and application thereof

An alumina, coating type technology, applied in the field of chemistry, can solve the problems of uniformity and universality to be improved, and achieve the effect of high practical application prospect, simple coating method and strong universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. Preparation of alumina-coated manganese trioxide

[0055] Mix 0.2g of manganese trioxide nanoparticles (average particle size is 100nm), 0.1g of aluminum salt aluminum nitrate (5.3*10 -3 mol / L), precipitant ammonium bicarbonate 1g (0.25mol / L) mixed in solvent water 50ml, reflux at 90°C under stirring for 2h for hydrolysis reaction, centrifuged, washed and dried to obtain aluminum hydroxide-coated trioxide Dimanganese particles were then calcined at 500° C. for 2 hours to obtain alumina-coated manganese trioxide particles.

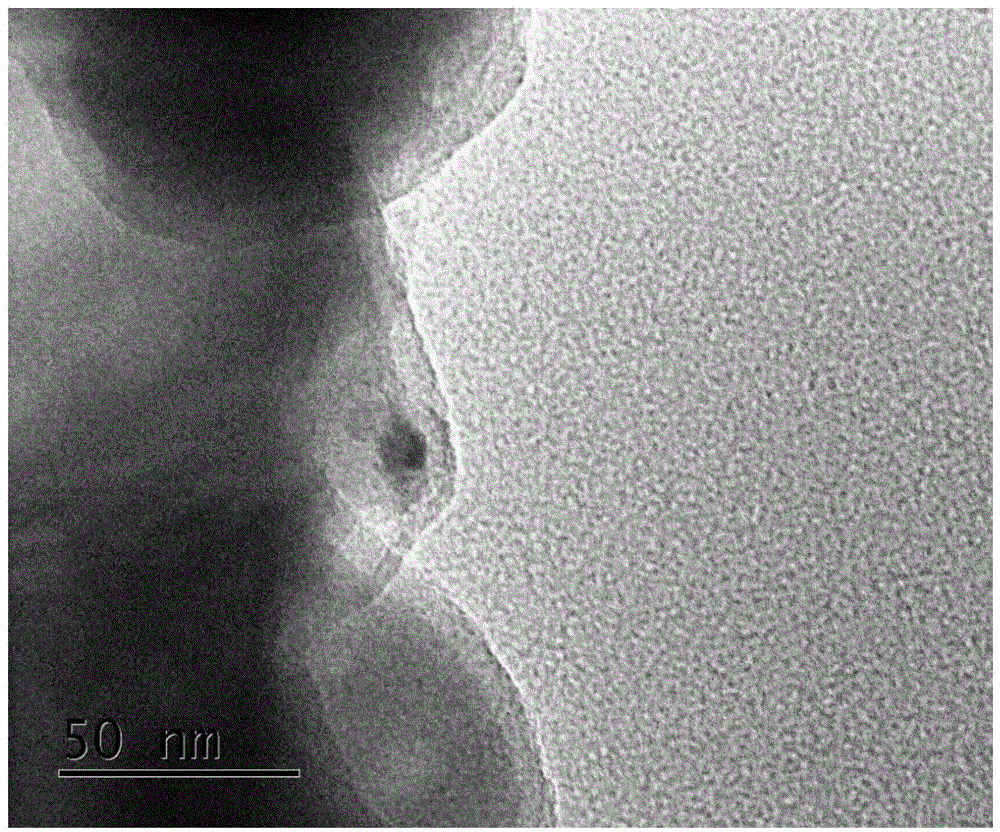

[0056] The aluminum oxide-coated manganese trioxide particles have a core-shell structure, and its electron micrograph is shown in figure 1 shown. The material constituting the core is manganese trioxide with a particle size of 100nm, the material constituting the shell is aluminum oxide with a thickness of 8nm; and the aluminum oxide uniformly covers the surface of the manganese trioxide.

[0057] 2. The manganese trioxide particles coated wit...

Embodiment 2

[0068] 1. Preparation of alumina-coated nickel-cobalt lithium manganese oxide

[0069] 0.5 g of nickel-cobalt lithium manganese oxide LiNi with an average particle size of 10 μm 0.5 co 0.2 mn 0.3 o 2 , 0.1g of aluminum nitrate, 2g of precipitating agent ammonium bicarbonate mixed in 100ml of water and refluxed at 90°C under stirring for 2h of hydrolysis reaction, centrifuged, washed, dried, and then calcined at 500°C for 2h to obtain alumina-coated nickel-cobalt-manganese Lithium oxide particles.

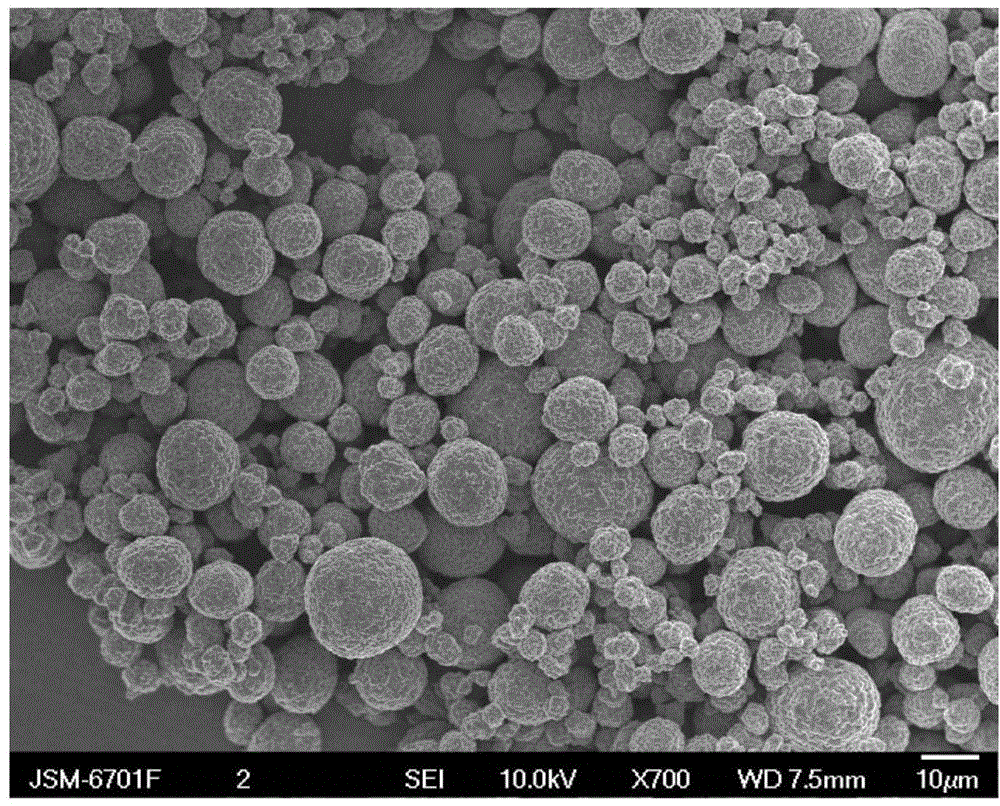

[0070] The alumina-coated nickel-cobalt-lithium-manganese oxide particles have a core-shell structure. The material constituting the core is lithium nickel cobalt manganese oxide with an average particle size of 10 μm, such as image 3 Shown; the material constituting the shell is alumina with a thickness of 8nm, such as Figure 4 shown; and aluminum oxide evenly covers the surface of nickel cobalt lithium manganese oxide.

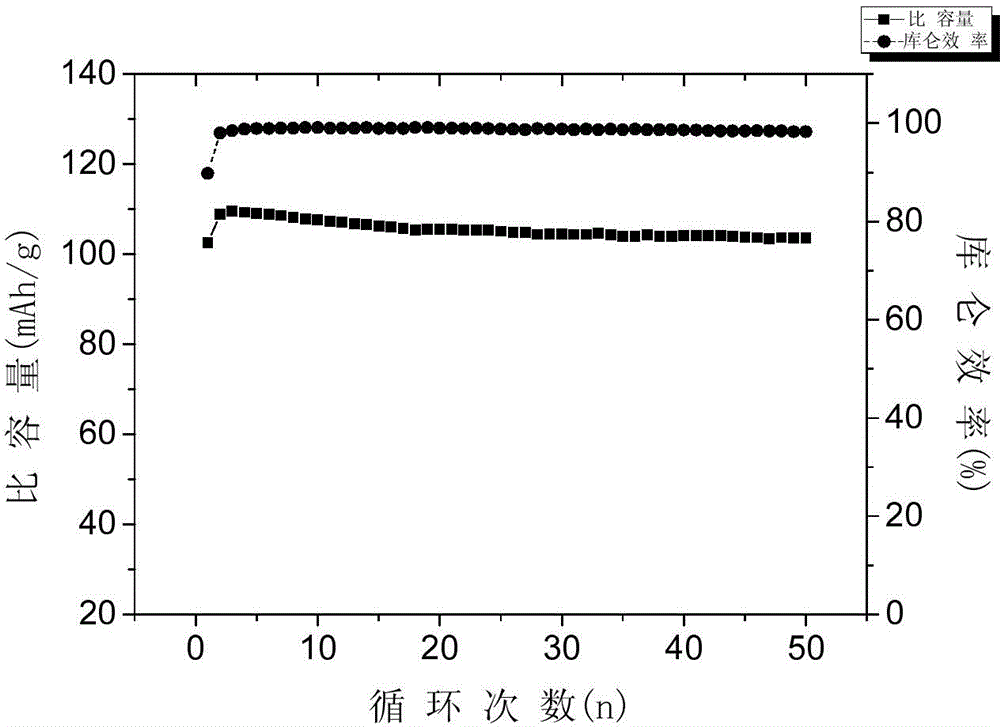

[0071] 2. Preparation of alumina-coated nickel-coba...

Embodiment 3

[0079] 1. Preparation of alumina-coated silver nanoparticles

[0080] Dissolve 0.2g of silver nanoparticles with an average particle size of 55nm (purchased from Beijing Deke Daojin Technology Co., Ltd.), 0.07g of aluminum nitrate, 2g of precipitant ammonium carbonate and 0.1g of PVP (0.018mol / L) in 50ml of water and mix , refluxed at 100°C for 2h under stirring, centrifuged, washed, dried, and calcined at 500°C for 2h to obtain alumina-coated silver nanoparticles.

[0081] The aluminum oxide-coated silver nanoparticles have a core-shell structure, and its transmission electron microscope pictures are as follows: Figure 6 shown. The material constituting the core is silver nanoparticles with an average particle diameter of 55nm, and the material constituting the shell is aluminum oxide with a thickness of 3nm; and the aluminum oxide uniformly covers the surface of the silver nanoparticles.

[0082] 2. Surface enhanced Raman test

[0083] Disperse aluminum oxide-coated silver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com