Transition metal carbon/nitride-based current collector for negative electrode of metal secondary battery as well as preparation method and application of transition metal carbon/nitride-based current collector

A transition metal, secondary battery technology, applied in the field of electrochemical power supply, can solve the problems of large volume change, dendrite growth, low Coulombic efficiency, etc., and achieve the effects of simple preparation method, improved battery life, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0057] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0059] (1) Preparation of two-dimensional transition metal carbon / nitride current collector thin films

[0060] (1) 5g MAX(Ti 3 AlC 2 ) into 100 mL of HCl containing 5 g LiF and 2 M, stirred at 35° C. for 24 hours, etch and stripped to obtain a dark green solution.

[0061] (2) Centrifuge the dark green solution obtained in step (1) until neutral with absolute ethanol, centrifuge at 8,000 rpm for 5 minutes, then add 100 mL of ultrapure water for ultrasonication for 1 hour, and finally centrifuge at 3,500 rpm for 60 minutes , take the upper dark green solution, which is the dispersion containing two-dimensional transition metal carbon / nitride nanosheets, and the chemical formula of the prepared two-dimensional transition metal carbon / nitride nanosheets is Ti 3 C 2 T y .

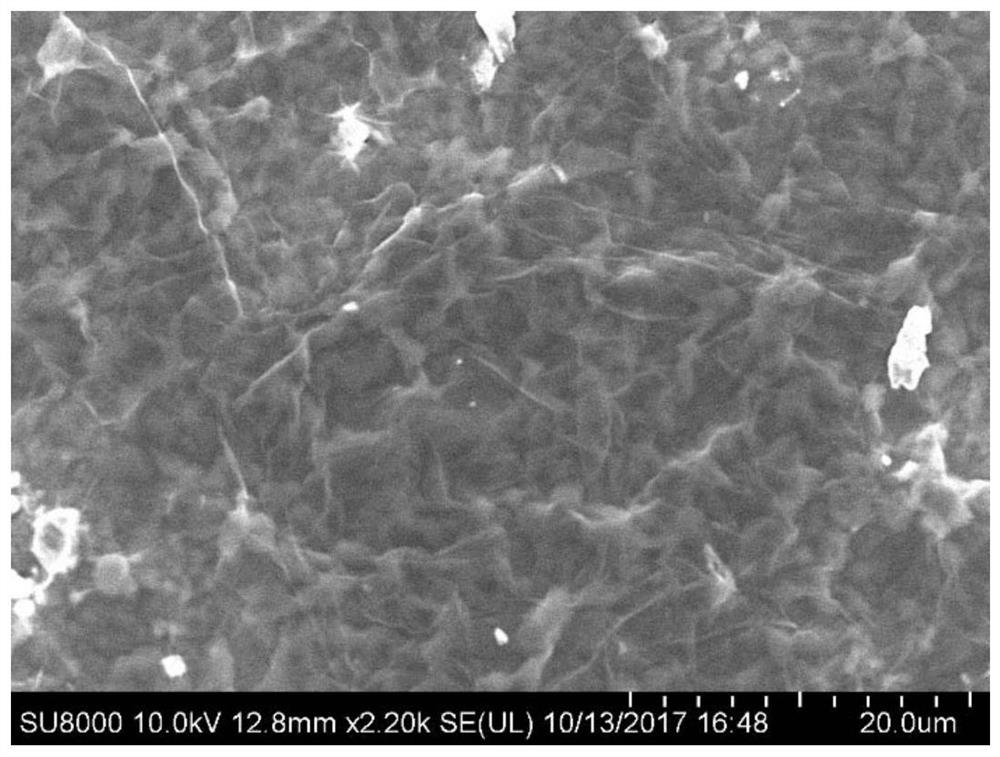

[0062] (3) Continue to sonicate the dark green solution obtained in step (2) for 15 minutes, use a vacuum filtration device, and use a Celgard3501 diaphragm to perform suction filtration, wash the salt an...

Embodiment 2

[0073] The only difference from Example 1 is that the etching conditions in step (1) are different. The specific etching conditions are: add 5gMAX to 100mL HCl containing 2g LiF and 2M, and first stir at 35°C for 24 hours to etch and peel off.

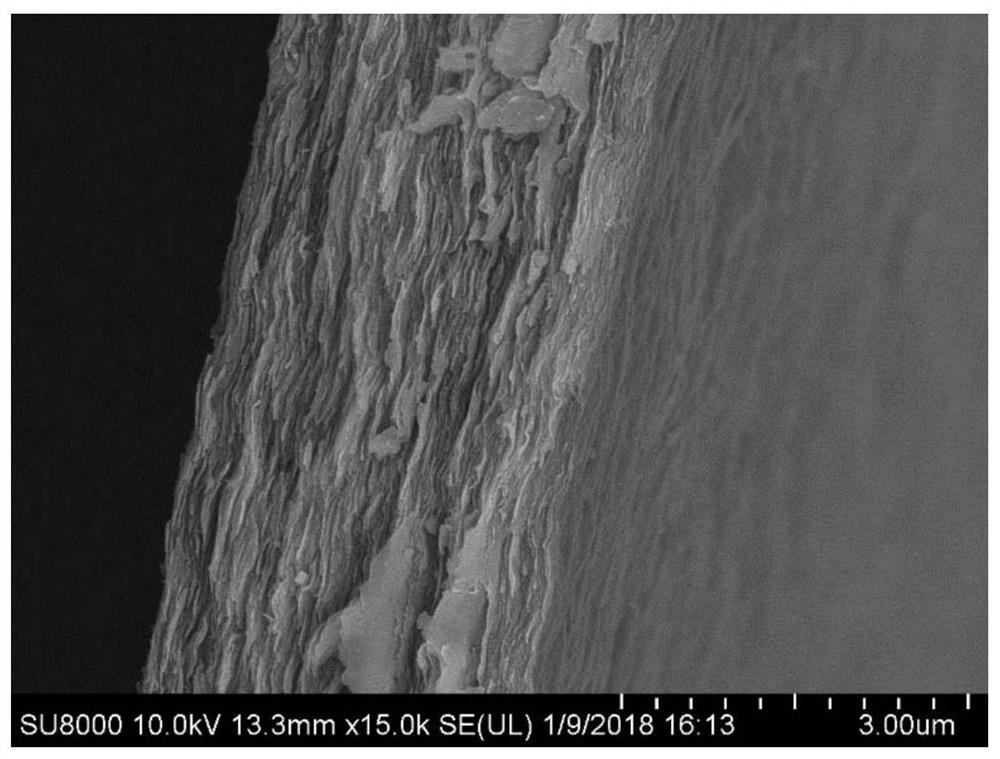

[0074] Characterized by XPS, the polar functional group atomic percentage content on the surface and interlayer of the current collector film prepared in Example 2 was 43%, which was 6% lower than that in Example 1. Moreover, the surface of the current collector film has almost no defects, and the pore size distribution shows that the size of the defects is about 5nm. The thickness of the monolithic two-dimensional transition metal carbon / nitride nano sheet is within 10nm, and the diameter is about 200nm. Characterized by a scanning electron microscope, the prepared current collector film is stacked in a sandwich-shaped layer. The thickness of the current collector film is about 5 μm, and the interlayer distance is between 50 and 100 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com