Bismuth phosphate-based heterojunction photocatalyst and preparation method thereof

A photocatalyst, bismuth phosphate-based technology, applied in the field of photocatalysis, can solve the problems of high power consumption, long time, etc., and achieve the effects of improving life, improving efficiency, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The steps of the bismuth phosphate-based heterojunction photocatalyst prepared in this example are as follows:

[0035] Step 1. BiPO 4 Preparation: Weigh 0.485g Bi(NO 3 ) 3 ·5H 2 O was added to ultrapure water and sonicated until completely dissolved, then 0.156g NaH was added 2 PO 4 2H 2 O was added to the solution and mixed and stirred to obtain a mixed solution. Then, the mixed solution was placed in a microwave device and stirred for 15 minutes. The power was set to 800W. The resulting precipitate was centrifuged at a high speed and dried in an oven at 60°C for 12 hours to obtain BiPO. 4 solid powder.

[0036] Step 2, g-C 3 N 4 Preparation: Weigh 5g of melamine into a crucible, cover and calcinate in a muffle furnace at 550°C for 4h, and set the heating rate at 5°C / min. After taking it out, the light yellow solid obtained after naturally cooling to room temperature was ground into powder with an agate mortar and set aside.

[0037] Step 3, g-C 3 N 4 / BiP...

Embodiment 2

[0039] Other conditions are the same as in Example 1, except that 0.1g, 0.3g, 1g g-C are added respectively 3 N 4 , to test the addition of different amounts of g-C 3 N 4 , for g-C 3 N 4 / BiPO 4 performance impact.

Embodiment 3

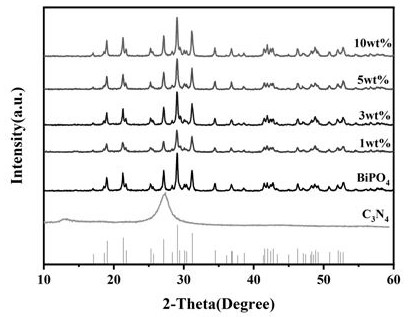

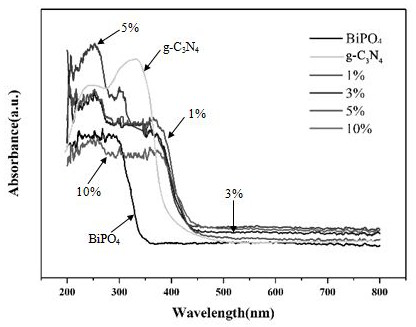

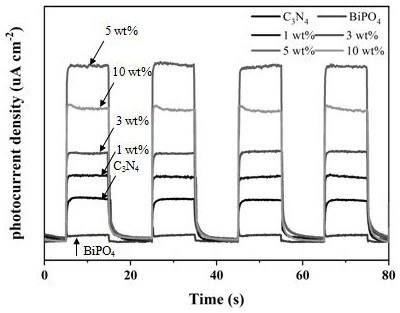

[0041] The samples of Example 1 and Example 2 were characterized by XRD, ultraviolet-visible diffuse reflectance, and photocurrent, and the characterization results are shown in figure 1 , figure 2 , image 3 , the percentage content in the figure is g-C 3 N 4 Addition amount and BiPO 4 The mass percentage of the amount added.

[0042] XRD is used to determine the crystal phase structure of the prepared samples. The XRD patterns of photocatalytic materials with different proportions prepared in this experiment are as follows: figure 1 shown. In the figure, for BiPO prepared by microwave method 4 , 19.0°, 21.3°, 25.3°, 27.2°, 29.1°, 31.2°, 34.5° and 36.9° correspond to BiPO 4 (011), (-111), (111), (200), (120), (012), (-202) and (-212) crystal planes, which are also consistent with the standard spectrum library (JCPDS15-0767) The results were consistent. The sharp and intense diffraction peaks of the samples indicate pure BiPO 4 It is highly crystalline. The pure g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com