Method for preparing lithium manganese phosphate positive material of lithium battery by spray pyrolysis

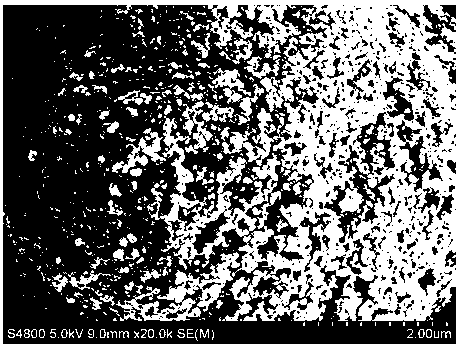

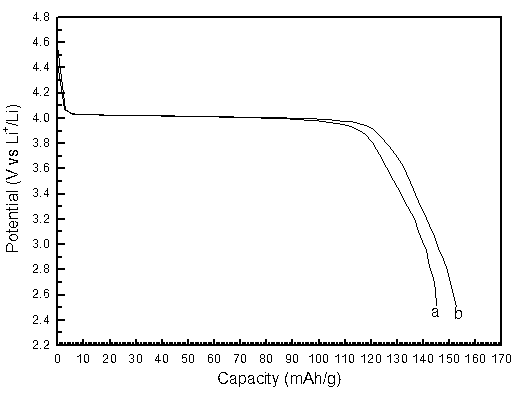

A technology of lithium manganese phosphate and cathode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of inability to effectively control the particle size and phase composition of lithium manganese phosphate, and achieve good electrochemical performance, fine and uniform particles, and purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing lithium manganese phosphate lithium cathode material by spray pyrolysis, comprising the following process steps:

[0025] A. Weigh the lithium source compound, the manganese source compound, the phosphorus source compound and the carbon source compound in a molar ratio of 1:1:1:0.01, dissolve them in deionized water, alcohol, amyl alcohol or acetone to make their solid content be 10%, stir evenly to obtain mixed slurry;

[0026] B. Perform high-temperature spray pyrolysis of the mixed slurry obtained in step A in an inert atmosphere in a spray pyrolysis furnace at 350° C. to obtain lithium manganese phosphate precursor powder;

[0027] C. Put the lithium manganese phosphate precursor powder obtained in step B in an inert atmosphere protection furnace, bake at 500° C. for 2 hours, and cool naturally to obtain a lithium manganese phosphate lithium cathode material.

Embodiment 2

[0029] A method for preparing lithium manganese phosphate lithium cathode material by spray pyrolysis, comprising the following process steps:

[0030] A. Weigh the lithium source compound, the manganese source compound, the phosphorus source compound and the carbon source compound in a molar ratio of 1.05:1:1:0.5, dissolve them in deionized water, alcohol, pentanol or acetone to make their solid content be 60%, stir evenly to obtain mixed slurry;

[0031] B. Perform high-temperature spray pyrolysis of the mixed slurry obtained in step A in an inert atmosphere in a spray pyrolysis furnace at 650° C. to obtain lithium manganese phosphate precursor powder;

[0032] C. Place the lithium manganese phosphate precursor powder obtained in step B in an inert atmosphere protection furnace, bake at 850° C. for 6 hours, and cool naturally to obtain a lithium manganese phosphate lithium cathode material.

Embodiment 3

[0034] A method for preparing lithium manganese phosphate lithium cathode material by spray pyrolysis, comprising the following process steps:

[0035] A. Weigh the lithium source compound, the manganese source compound, the phosphorus source compound and the carbon source compound in a molar ratio of 1.03:1:1:0.26, dissolve them in deionized water, alcohol, amyl alcohol or acetone to make their solid content be 35%, stir evenly to obtain mixed slurry;

[0036] B. Perform high-temperature spray pyrolysis of the mixed slurry obtained in step A in an inert atmosphere in a spray pyrolysis furnace at 500° C. to obtain lithium manganese phosphate precursor powder;

[0037] C. Place the lithium manganese phosphate precursor powder obtained in step B in an inert atmosphere protection furnace, bake at 675° C. for 4 hours, and cool naturally to obtain a lithium manganese phosphate lithium cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com