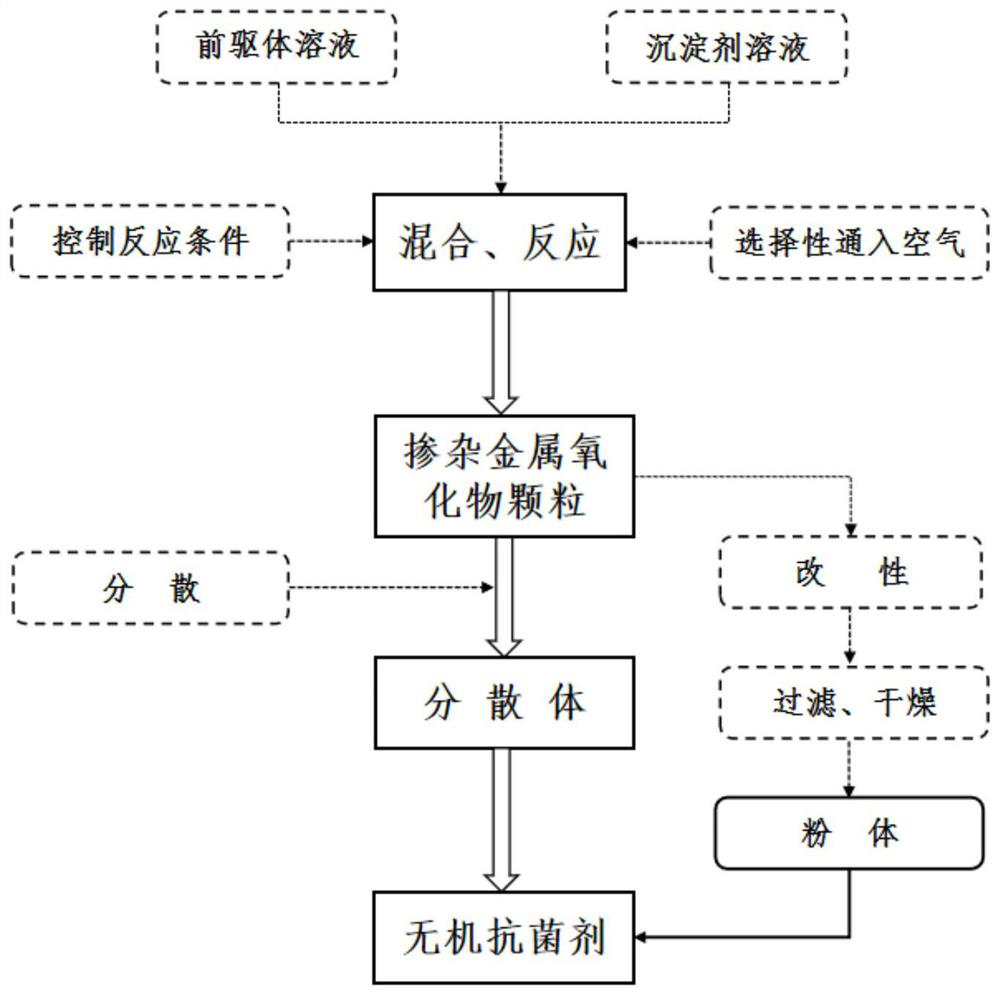

Preparation method of metal oxide doped nanoparticle, dispersoid or powder for resisting bacteria and preventing mildew

A technology of oxide particles and nanoparticles, which is applied in the field of antibacterial materials, can solve the problems that it cannot be used as an antibacterial agent, it is difficult to achieve antibacterial effect, and the antibacterial effect is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0066] Examples 1-4: Copper-doped nano-zinc oxide particles, dispersions, and powder preparation examples

Embodiment 1

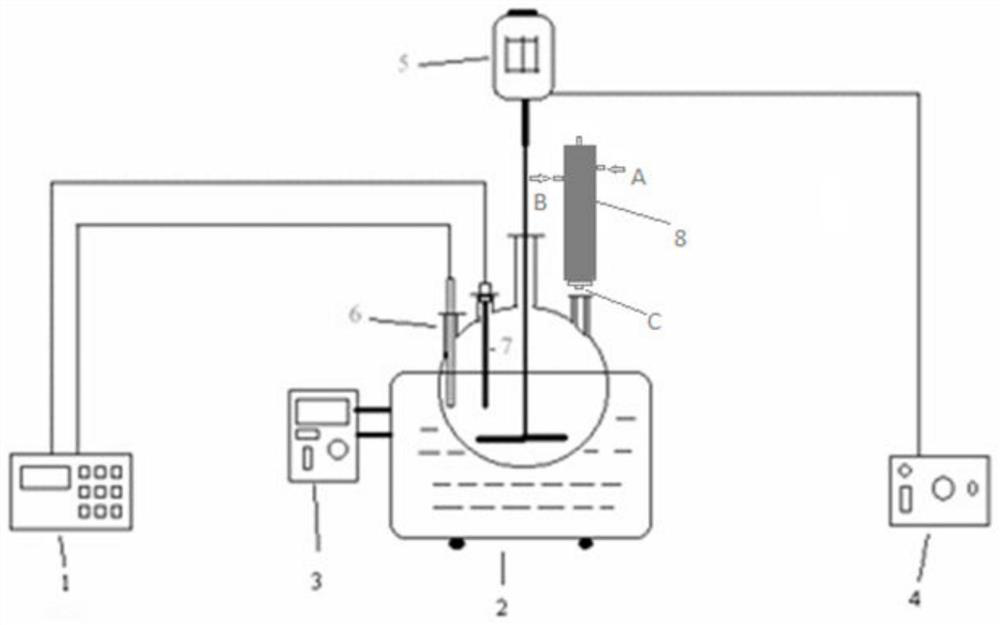

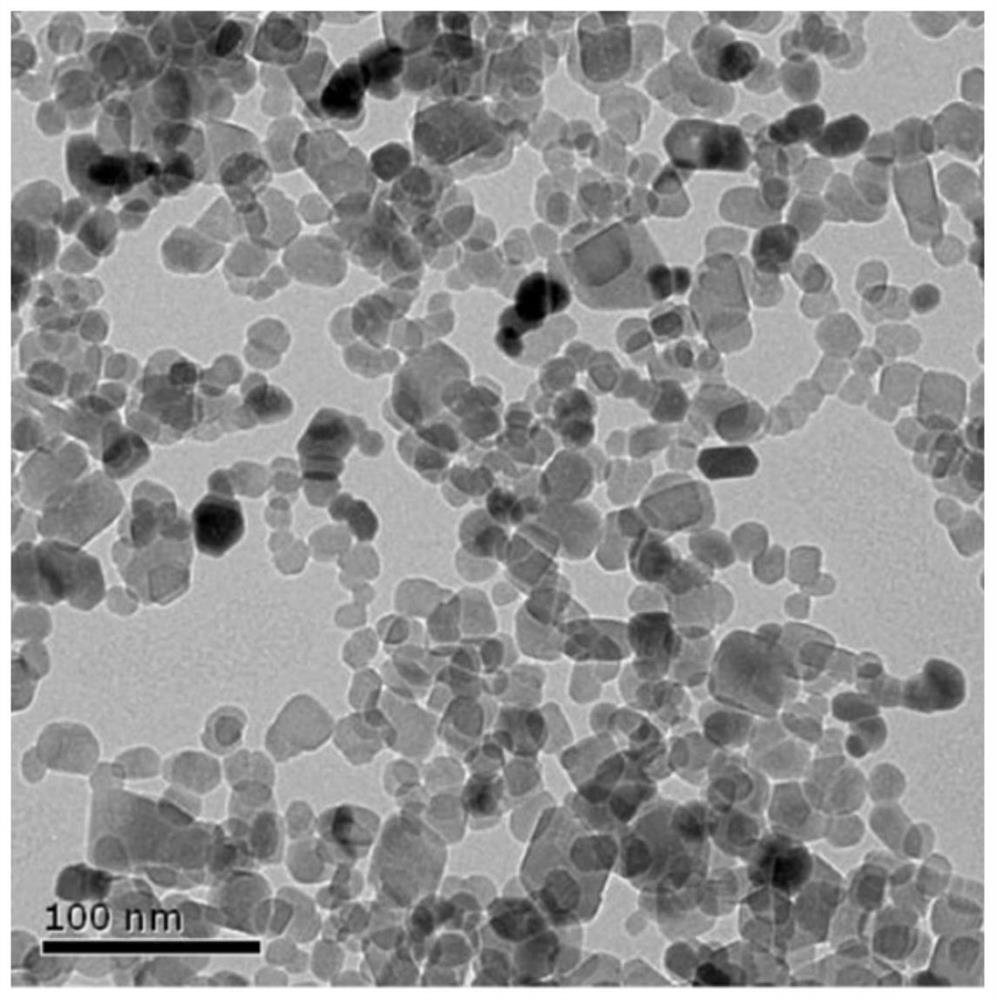

[0068] Take an appropriate amount of copper chloride ethanol solution and add it to the zinc chloride solution, so that the ratio of the amount of copper chloride to zinc chloride is 1:19. The mixed solution is the doped metal oxide precursor solution, and the sodium hydroxide solution is used as the precipitant solution. The microchannel tubular device described in the publication specification of the international patent application PCT / CN2010 / 071651 and the common four-neck round bottom flask with mechanical stirring together constitute a strong mixing zone. The precipitant solution that will contain the precipitant solution that the precursor solution that contains zinc chloride and cupric chloride solution (both total concentration is 0.15mol / L) and concentration about 0.3mol / L sodium hydroxide solution is passed through rapidly such as figure 2 The A and B inlets of the microchannel tubular device, the precursor solution and the precipitant solution are quickly and stro...

Embodiment 2~4

[0070] Doped zinc oxide particles and dispersions were prepared using the method and steps described in Example 1. The difference is that in Example 2, an aqueous solution of zinc nitrate was used to replace the aqueous solution of zinc chloride; in Example 3, an aqueous solution of zinc acetate was used to replace the aqueous solution of zinc chloride; in Example 4, an aqueous solution of zinc sulfate was used to replace the aqueous solution of zinc chloride. Compared with the copper-doped zinc oxide nanoparticles and dispersions prepared in Examples 2 to 4 and Example 1, except that the particle size and morphology of the finally prepared copper-doped zinc oxide nanoparticles are slightly different, other The detection and characterization results are similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com