Electrode with biopolymer coating and preparation method thereof

A biopolymer and electrode technology, which is applied in the direction of electrode manufacturing, battery electrodes, electrode collector coating, etc., can solve the problems of complex preparation process and unsuitability for large-scale production, and achieve convenient preparation and inhibit the growth of dendrites , to reduce the effect of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

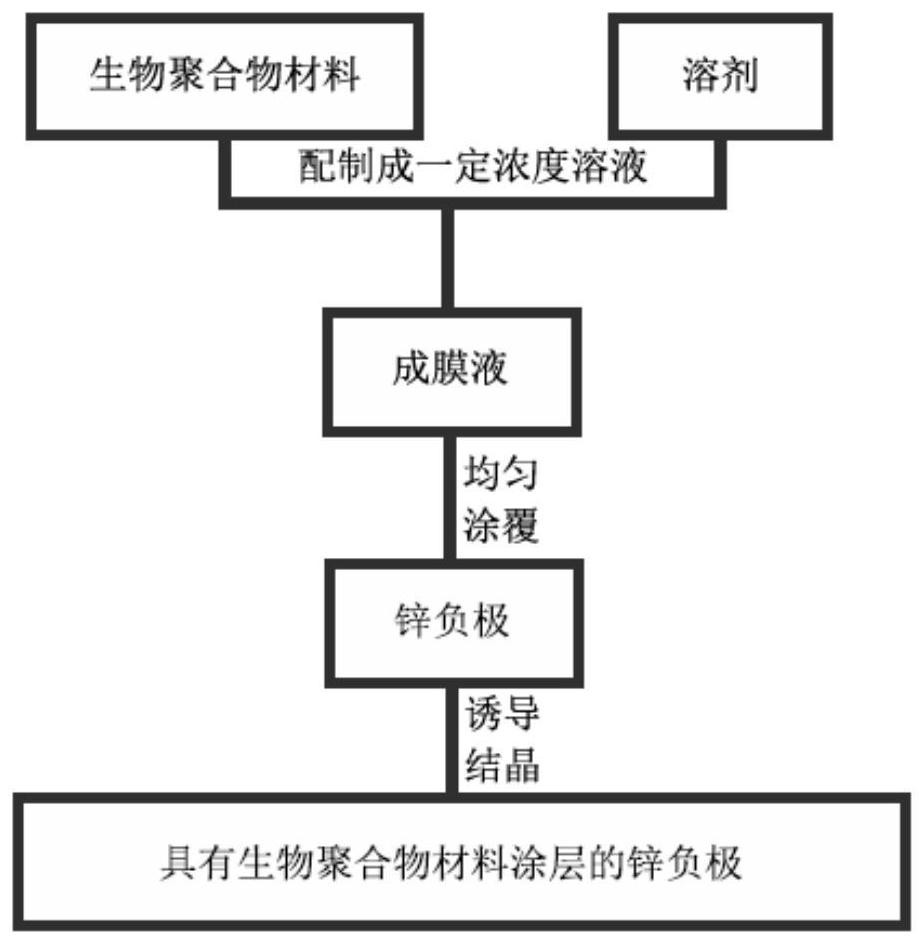

[0043] The flow chart of the preparation method of the electrode with biopolymer coating of the present invention is as follows figure 1 As shown, it mainly includes three steps of configuring the film-forming solution, uniformly coating the film-forming solution and inducing crystallization.

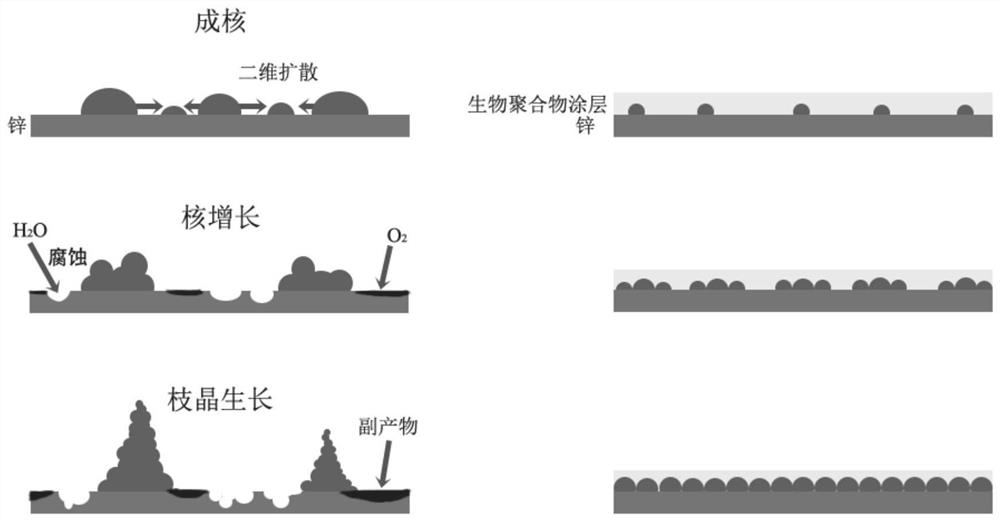

[0044] The biopolymer coating can effectively reduce the corrosion and passivation of the electrode by the electrolyte and inhibit the growth of dendrites, such as figure 2 As shown, the formation of Zn dendrites in aqueous electrolytes for uncoated Zn electrodes is difficult to avoid, because the newly deposited Zn ions prefer to adsorb at the initial nucleation sites to minimize the surface energy. Moreover, the dissolved O in the aqueous electrolyte 2 And free water can also cause corrosion and side reactions. The biopolymer material coating can form a diffusion layer on the surface of the zinc electrode, and the functional groups on the polymer that coordinate with the zinc ions ...

Embodiment 1

[0046] (1) Disperse 2 g of polyvinyl alcohol (PVA) in 20 ml of deionized water, stir vigorously at 85° C. for 1 h, and cool naturally to room temperature to obtain a PVA gel.

[0047] (2) Silk fibroin, PVA gel and ZnSO 4 According to the mass ratio of 8:1:1, it is mixed in the ethanol aqueous solution, and the mass ratio of solute and solvent is 5%, to obtain the film-forming liquid.

[0048] (3) Evenly drop the film-forming solution on the Zn sheet and let it dry naturally.

[0049] (4) Soak the above coating in 75% ethanol aqueous solution to induce the secondary structure transformation of silk fibroin to obtain a zinc negative electrode with a polymer coating.

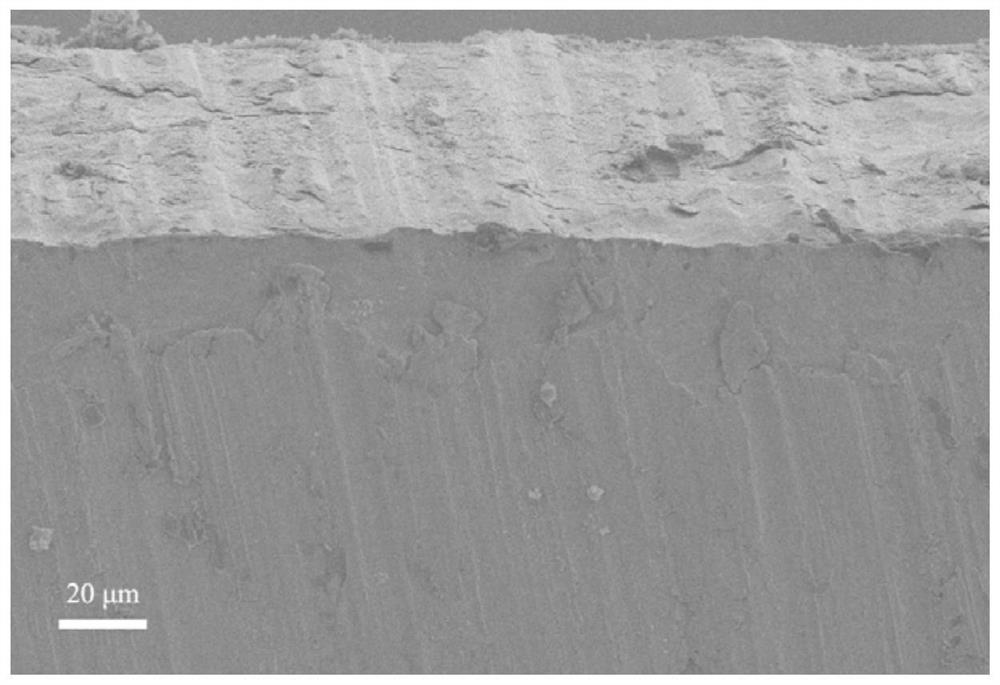

[0050] The resulting zinc anode with silk fibroin coating image 3 , that is, the direct topography of the product, and the clear coating structure on the electrode can be directly observed.

Embodiment 2

[0052] (1) Gelatin powder was dissolved in deionized water at a concentration of 15 wt%, and then stirred at 50° C. for 30 minutes. After removing air bubbles by sonication, the gelatin solution was poured into the mold and left to stand at 4 °C for 1 h to obtain a gelatin gel.

[0053] (2) Hemoglobin, gelatin gel and ZnCl 2 Mix in deionized water according to the mass ratio of 7:2:1, and the mass ratio of solute and solvent is 50%, to obtain a film-forming liquid.

[0054] (3) Use a brush to evenly brush the film-forming solution on the Zn sheet, and let it dry naturally.

[0055] (4) Use a temperature control box to rapidly cool the sample from 293K to 283K to induce protein crystallization. Finally, a zinc anode with polymer coating was obtained.

[0056] Use the above products as the positive and negative electrodes of the battery, glass fiber as the separator, 2M ZnCl 2 The solution is used as the electrolyte, and the model of the battery case is CR2032, which is asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com