Lithium battery modified diaphragm, preparation method thereof and lithium battery

A lithium battery separator, lithium battery technology, applied in lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve problems such as piercing the separator and lithium dendrite growth, achieve strong coordination ability, reduce deposition Potential, the effect of inhibiting the growth of lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0059] Example 1

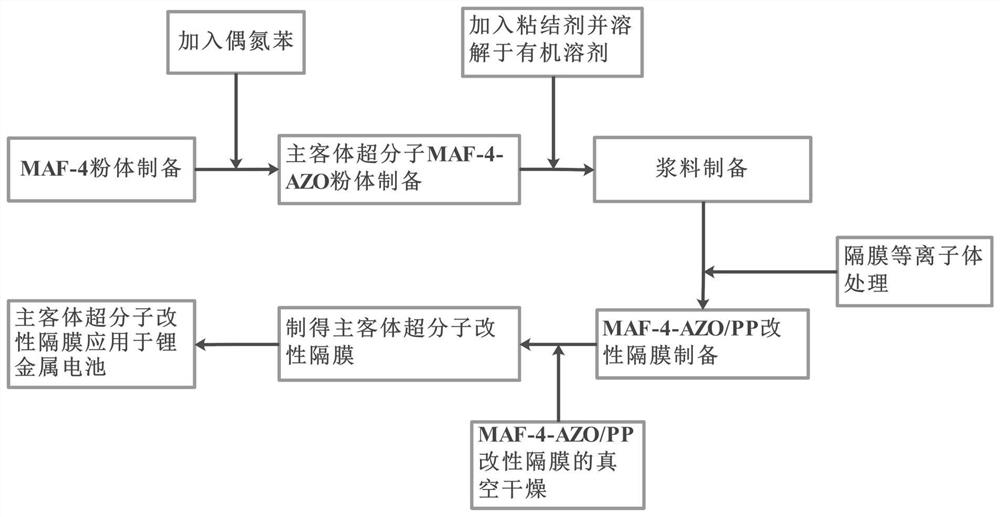

[0060] The present embodiment 1 provides a preparation method of a lithium battery modified diaphragm, and the preparation method includes the following steps:

[0061] Step 1. Prepare MAF-4 powder:

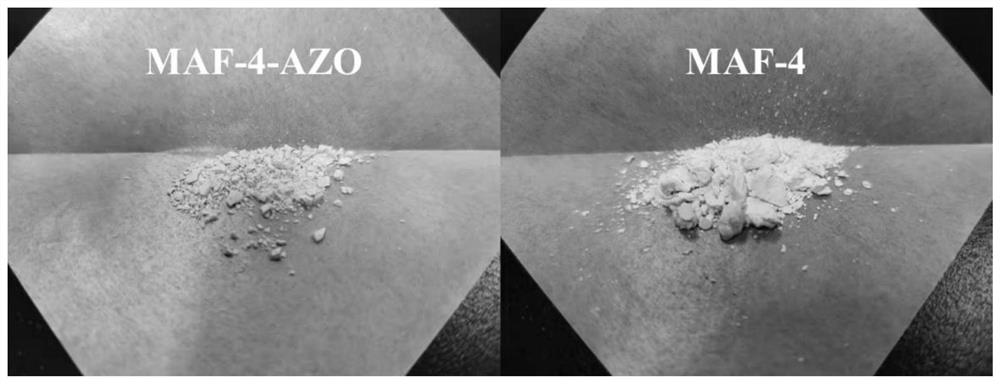

[0062] Step 1.1, take 10mmol of zinc nitrate hexahydrate and disperse it in 100mL of 25% ammonia solution to obtain A solution, take 20mmol of 2-methylimidazole and disperse it in 100mL of anhydrous methanol to obtain B solution, A and B solutions are respectively in a water bath at 25°C Magnetic stirring for 40min, after uniform dispersion, B solution was added dropwise to A solution at a drop rate of 60 drops / min, and the reaction was continued to stir for 5h to obtain a milky white MAF-4 precursor suspension;

[0063] Step 1.2. Centrifugal separation of the milky white MAF-4 precursor suspension, washing and centrifugation. After drying for 12h and vacuum activation at 150℃ for 3h, the obtained white powder is MAF-4;

[0064] Step 2. Preparation of host-g...

Example Embodiment

[0070] Example 2

[0071] The present embodiment 2 provides a preparation method of a lithium battery modified diaphragm, and the preparation method includes the following steps:

[0072] Step 1. Prepare MAF-4 powder:

[0073] Step 1.1, take 20mmol of zinc nitrate hexahydrate and disperse it in 200mL of 25% ammonia solution to obtain A solution, take 40mmol of 2-methylimidazole and disperse it in 200mL of anhydrous methanol to obtain B solution, A and B solutions are respectively water bathed at 25°C Magnetic stirring for 60min, after uniform dispersion, B solution was added dropwise to A solution at a drop acceleration rate of 120 drops / min, and the reaction was continued to stir for 7h to obtain a milky white MAF-4 precursor suspension;

[0074] Step 1.2. Centrifuge the milky white MAF-4 precursor suspension and wash the centrifuged product. The washing method is to use anhydrous methanol for three times, and the speed of the centrifuge is 8000 rpm; After vacuum activation...

Example Embodiment

[0091] Example 3

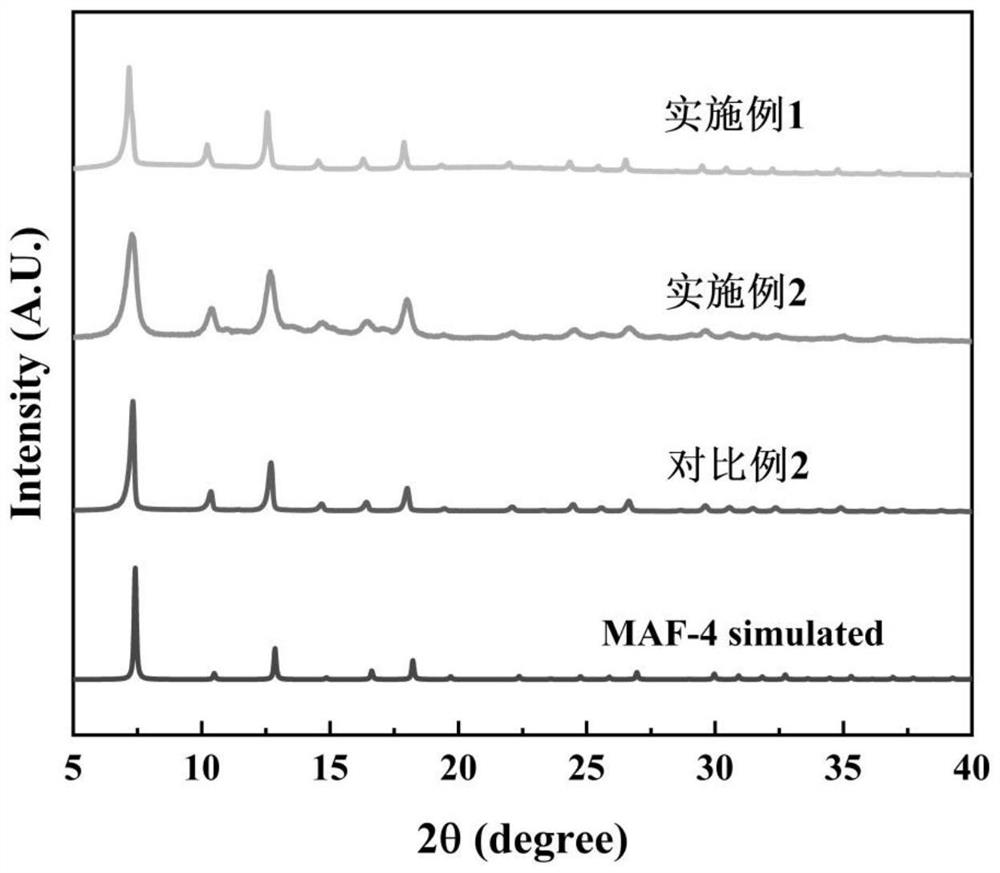

[0092] In Example 3, performance tests were performed for lithium batteries including the modified separator for lithium batteries provided in Example 1 of the present application, the lithium battery separator provided in Comparative Example 1, and the MAF-4 / PP separator provided in Comparative Example 2.

[0093] The assembly process of the lithium battery including the lithium ion battery modified separator provided in Example 1 of the present application includes: first assembling the separator into a Li|Cu half-cell and a Li|Li symmetrical battery in a glove box filled with high-purity argon, and the negative electrode All use lithium metal, the electrolyte is 1M LiTFSI DOL / DME (V:V=1:1) + 1wt% anhydrous lithium nitrate, the volume of the added electrolyte is 30μL, and the assembled battery is a CR2032 type button battery. The button cell was left standing at room temperature of 25°C for 6 hours.

[0094] The assembling process of the lithium battery i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com