Light-color multi-carboxyl oxidized polysaccharide tanning agent as well as preparation method and application thereof

An oxidized polysaccharide tanning agent and a technology for oxidized polysaccharide, applied in the field of leather and fur tanning agents, can solve the problems of affecting the color and appearance of leather or fur, dark product color, restricting the application of chrome-free leather, etc. The effect of chromaticity, excellent coordination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of light-colored polycarboxylated starch tanning agent:

[0038]In parts by weight, put 40 parts of starch, 100 parts of water, 0.04 parts of ferrous sulfate and 3.2 parts of tetrahydrofuran in a reactor, add 20 parts of hydrogen peroxide dropwise, and oxidize at a temperature of 70 ° C for 4 h to obtain oxidized starch solution; add 6 parts of sodium chloride to the above solution, stir evenly and let it stand for 30 min, fully separate the aqueous phase from the organic phase, discard the organic phase containing colored substances, and finally obtain the aqueous phase, that is, light-colored polycarboxylated starch Tanning agent.

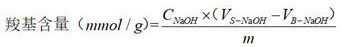

[0039] In this step, the carboxyl content, weight-average molecular weight and chromaticity of the oxidized starch tanning agent were measured, and the results are shown in Table 1.

[0040] Application of light-colored polycarboxylated starch oxidized starch tanning agent in leather tanning:

[0041] The pickled hides obtain...

Embodiment 2

[0055] Preparation of light-colored polycarboxylated dextrin tanning agent:

[0056] In parts by weight, 20 parts of dextrin, 100 parts of water, 0.02 parts of ferric sulfate and 1.6 parts of ethyl acetate were placed in a reactor, 16 parts of hydrogen peroxide were added dropwise, and oxidized at a temperature of 70°C for 0.5 h to obtain Oxidized dextrin solution: Stir the oxidized dextrin solution evenly and let it stand for 30 minutes. After the aqueous phase and the organic phase are fully separated, discard the organic phase containing colored substances, and finally obtain the aqueous phase, that is, light-colored polycarboxy oxidized dextrin tanned agent.

[0057] The carboxyl content of the oxidized dextrin tanning agent in this example is 5.7 mmol / g; the weight-average relative molecular mass is 1495 g / mol; the chroma is 45.

[0058] Application of light-colored polycarboxy oxidized dextrin tanning agent in leather tanning:

[0059] Put the pickled hides obtained by...

Embodiment 3

[0061] Preparation of light-colored polycarboxylated cellulose oxidized tanning agent:

[0062] In parts by weight, put 60 parts of cellulose, 100 parts of water, 0.06 parts of copper sulfate and 4.8 parts of tetrahydrofuran in a reactor, drop 18 parts of hydrogen peroxide, and oxidize at a temperature of 70 ° C for 2 h to obtain oxidized fibers plain solution; add 18 parts of potassium chloride to the above solution, stir evenly and let it stand for 30 min, fully separate the aqueous phase from the organic phase, discard the organic phase containing colored substances, and finally obtain the aqueous phase, that is, the light-colored polycarboxylated Cellulose tanning agent.

[0063] The carboxyl content of the oxidized cellulose tanning agent in this example is 11.8 mmol / g; the weight-average molecular weight is 1115 g / mol; the chroma is 10.

[0064] Application of light-colored polycarboxylated oxidized cellulose tanning agent in leather tanning:

[0065] The pickled hides...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com