Silicon oxide coated nano zero-valent iron particles and preparation method and application thereof

A nano-zero-valent iron, silicon oxide technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. The problem of uneven particle distribution, etc., to achieve the effects of excellent physical and chemical properties, excellent anti-oxidation performance, and excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

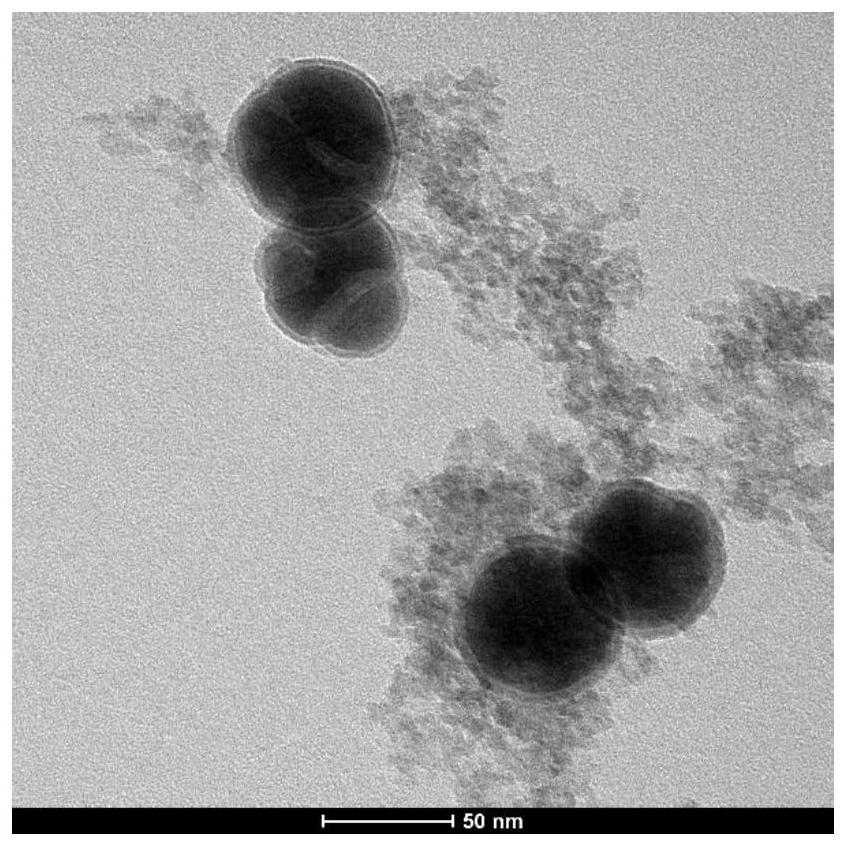

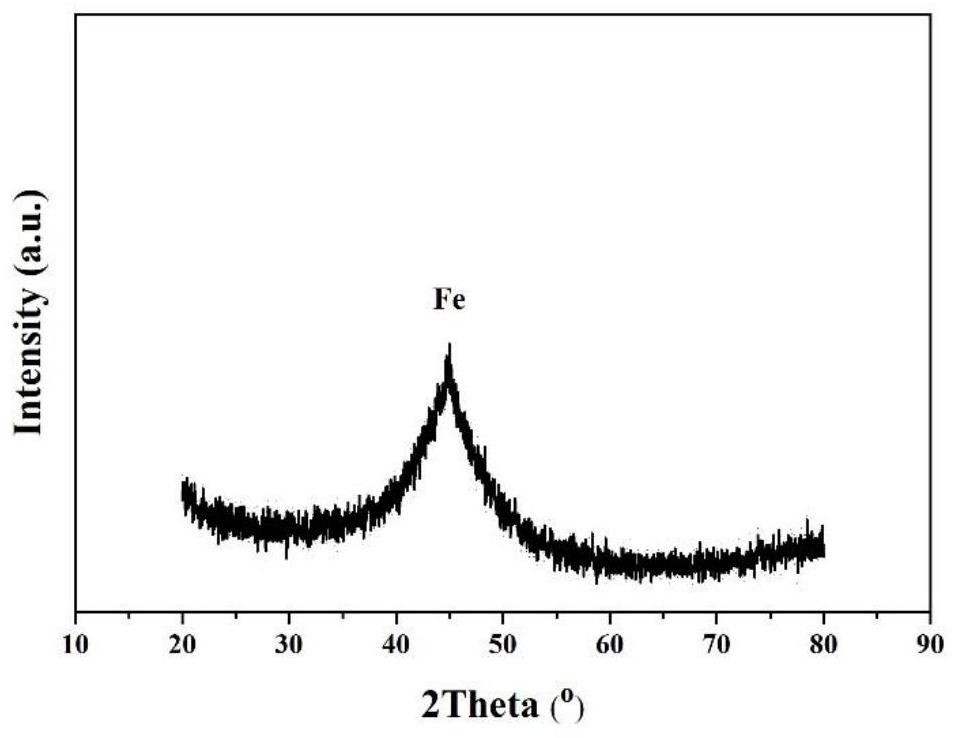

[0032] A method for preparing silicon oxide-coated nanometer zero-valent iron particles (Si-nZVI) is provided, which specifically includes the following steps:

[0033] 1) Add 200 mL of Na with a concentration of 5 mmol / L in a 500 mL four-neck flask 2 Si 2 o 5 Solution, weigh 1.42gFeCl 3 ·6H 2 O powder was added to the above solution to dissolve, and the reaction solution was mechanically stirred for 1 h under the protection of nitrogen, and the stirring speed was controlled at 50 rpm.

[0034] 2) Weigh 0.5g NaBH 4 Dissolve in 50mL deoxygenation and deionization to get NaBH 4 solution, and NaBH under the action of a peristaltic pump 4 The solution was added dropwise into the four-necked flask at a flow rate of 5mL / min. The entire dropping process was required to be slow, and the control time was 10min. The nitrogen protection was continued, and stirring was continued at a stirring speed of 50rpm for 2h.

[0035] 3) After the reaction, through magnetic separation and sorti...

Embodiment 2

[0039] Provided is a method for preparing silicon oxide-coated nanometer zero-valent iron particles, which specifically includes the following steps:

[0040] 1) At room temperature, add 200mL of Na with a concentration of 10mmol / L to a 500mL four-neck flask 2 Si 2 o 5 solution, weigh 2.5g Fe(NO 3 ) 3 9H 2 The O powder was added into the solution for dissolution, and the reaction solution was mechanically stirred for 2 hours under the protection of nitrogen, and the stirring speed was controlled at 80 rpm.

[0041] 2) Weigh 1.0g NaBH 4 Dissolve in 50mL anaerobic water to get NaBH 4 solution, and NaBH under the action of a peristaltic pump 4 The solution was added dropwise into the four-necked flask at a flow rate of 10mL / min. The entire dropping process was required to be slow, and the control time was 5 minutes. The nitrogen protection was continued, and the stirring speed was continued at 80rpm for 2h.

[0042] 3) After the reaction, through magnetic separation and s...

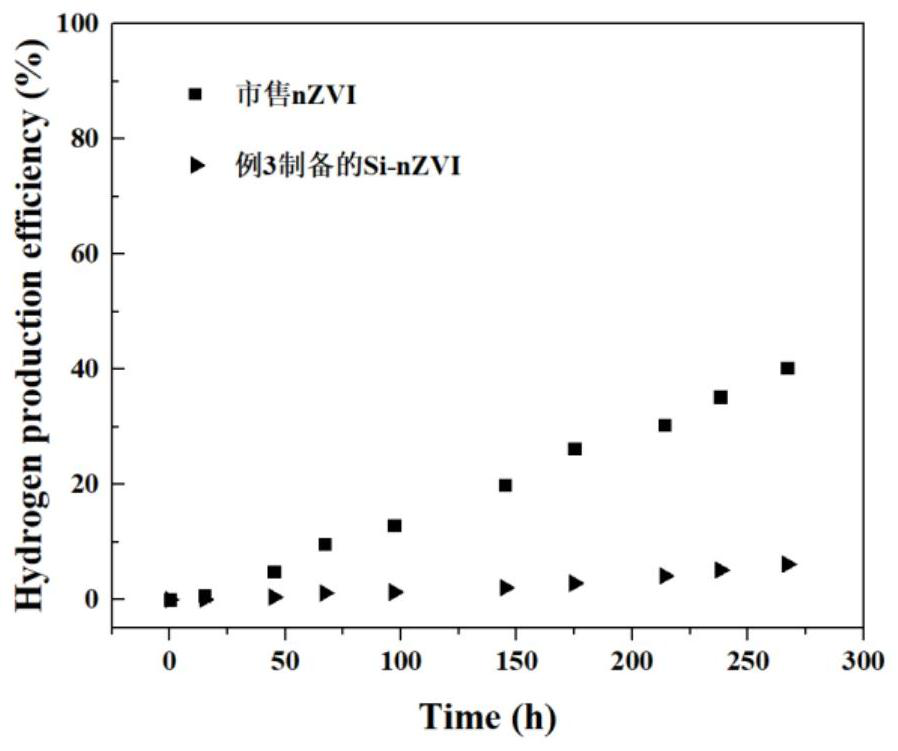

Embodiment 3

[0044] Provided is a method for preparing silicon oxide-coated nanometer zero-valent iron particles, which specifically includes the following steps:

[0045] 1) At room temperature, add 200 mL of Na with a concentration of 15 mmol / L into a 500 mL four-neck flask 2 SiO 3 solution, weigh 2g FeSO 4 ·7H 2 The O powder was added into the solution for dissolution, and the reaction solution was mechanically stirred for 2 hours under the protection of nitrogen, and the stirring speed was controlled at 80 rpm.

[0046] 2) Weigh 1.0g KBH 4 Dissolved in 50mL anaerobic water to obtain KBH 4 solution, and KBH under the action of a peristaltic pump 4 The solution was added dropwise into the four-necked flask at a flow rate of 15mL / min. The whole dropping process was required to be slow, nitrogen protection continued, and stirring continued at a stirring speed of 80rpm for 2h.

[0047] 3) After the reaction, the precipitate was washed with deoxygenated deionized water and absolute eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com