Lithium battery separator, fabrication method thereof and lithium battery employing separator

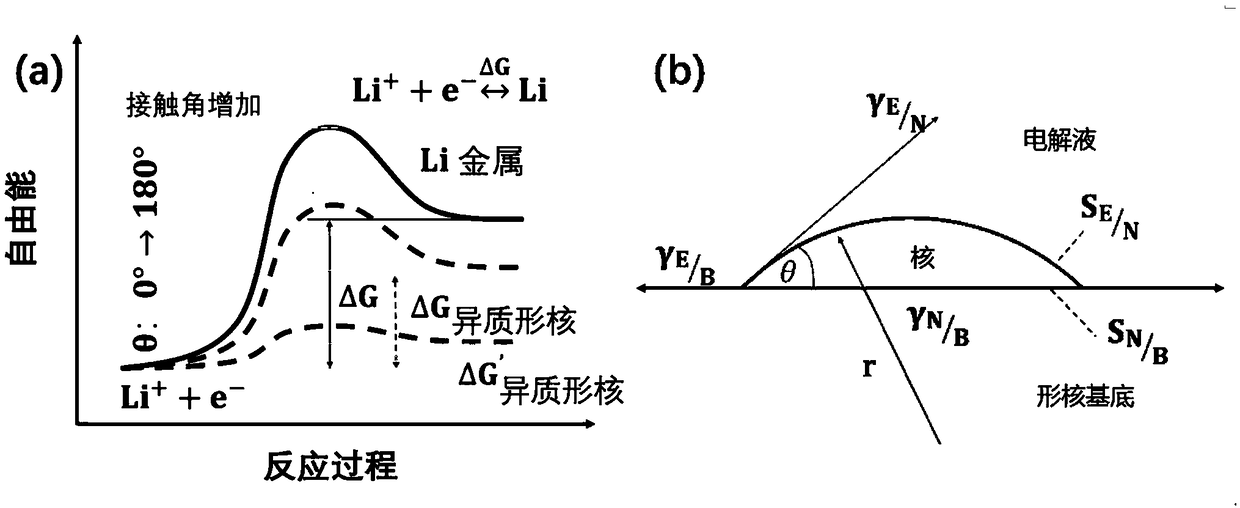

A technology of lithium battery separator and lithium battery, which is applied in the direction of secondary batteries, battery components, nanotechnology for materials and surface science, etc., can solve the loss of electrolyte solution and active lithium, hinder the wide application of lithium metal negative electrodes, Reduced Coulombic efficiency and other issues, to achieve the effect of facilitating uniform nucleation, strong capacity retention, and eliminating short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The specific preparation method of the above diaphragm and lithium battery comprises the following steps:

[0039] Step 1, uniformly deposit elements with good wettability with lithium on the separator of lithium battery by DC magnetron sputtering process;

[0040] Install the pre-purchased battery diaphragm as the diaphragm substrate in the sputtering chamber and cover it with a baffle, select the corresponding target according to the deposition elements, clean the target with acetone and dry it, and pre-sputter for 5 minutes to remove surface oxides and impurities , to ensure that there is no impurity deposited on the surface of the subsequent separator substrate, and the purity of the target is ≥99.99%; start sputtering to deposit elements with good wettability with lithium on the battery separator substrate, and the process parameters of DC magnetron sputtering are: background Vacuum degree (0.1~9.9)×10 -5Pa, the working pressure is 0.25-0.35Pa, the target distance...

Embodiment 1

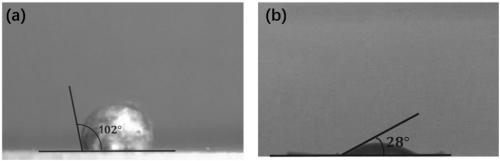

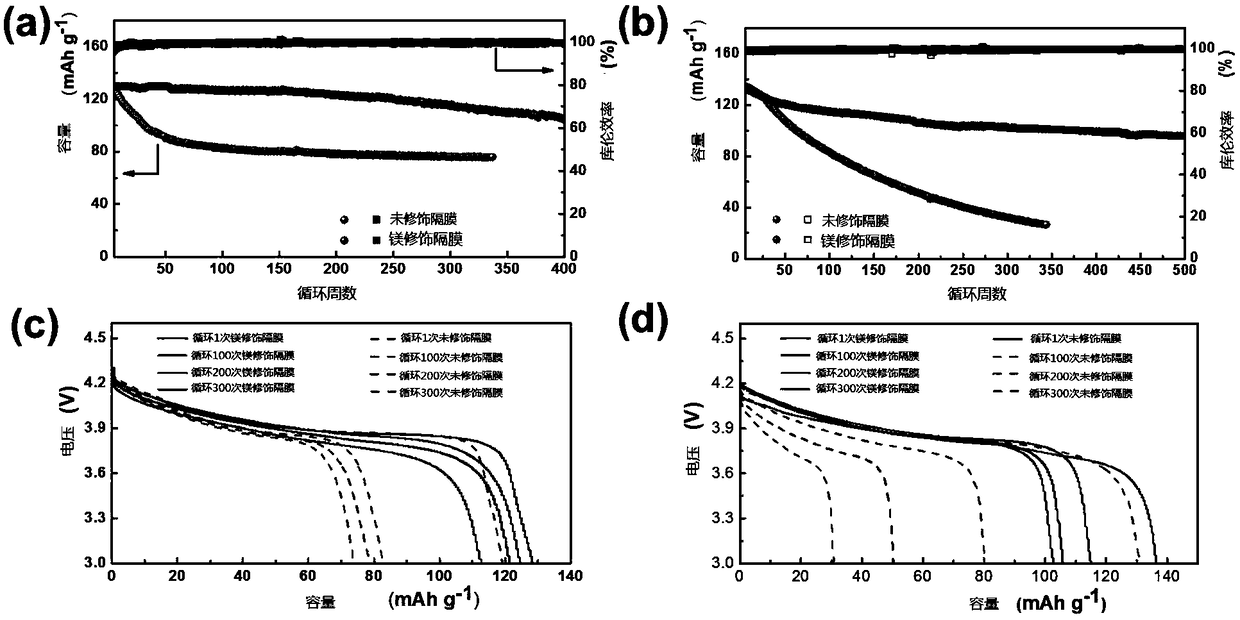

[0057] Preparation of Mg-modified separator and its application on Li-LiCoO 2 full battery;

[0058] Install the pre-purchased battery separator in the sputtering chamber and cover it with a baffle. The Mg target with a purity of 99.99% is cleaned and dried with acetone, and then pre-sputtered for 5 minutes to remove surface oxides and impurities to ensure the smoothness of subsequent separator surface deposition. It is pure Mg, and the process parameters of DC magnetron sputtering are: the background vacuum degree is 5.0×10 -4 Argon gas with a purity of 99.99% was introduced at Pa, the working pressure was 0.30 Pa, the target distance was 10 cm, the sputtering power was 70 W, the sputtering temperature was 25° C., and the sputtering was 1 min.

[0059] LiCoO with a weight ratio of 8:1:1 2 , Super-P and PVDF were dispersed in NMP, and the mixture was ball-milled for 1.5 h to achieve thorough mixing to form LiCoO 2 slurry, the LiCoO 2 The slurry was dropped on the Al foil, ...

Embodiment 2

[0063] Fabrication of Ti-modified separators and their application on Li-LiCoO 2 full battery.

[0064] Install the pre-purchased battery diaphragm in the sputtering chamber and cover it with a baffle. The Ti target with a purity of 99.99% is cleaned and dried with acetone, and then pre-sputtered for 5 minutes to remove surface oxides and impurities to ensure the smoothness of subsequent deposition on the diaphragm surface. It is pure Ti, and the process parameters of DC magnetron sputtering are: the background vacuum degree is 5.0×10 -4 Argon gas with a purity of 99.99% was introduced at Pa, the working pressure was 0.30 Pa, the target distance was 10 cm, the sputtering power was 80 W, the sputtering temperature was 25° C., and the sputtering was 3 min.

[0065] LiCoO with a weight ratio of 8:1:1 2 , Super-P and PVDF were dispersed in NMP, and the mixture was ball milled for 2h to achieve thorough mixing to form LiCoO 2 slurry, the LiCoO 2 The slurry was dropped on the Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com